Method for raising iron content and reducing silicon in concentrate by means of low-intensity magnetic separation process

A weak magnetic separation and process technology, applied in chemical instruments and methods, wet separation, solid separation, etc., to achieve the effects of advanced equipment, simple process and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

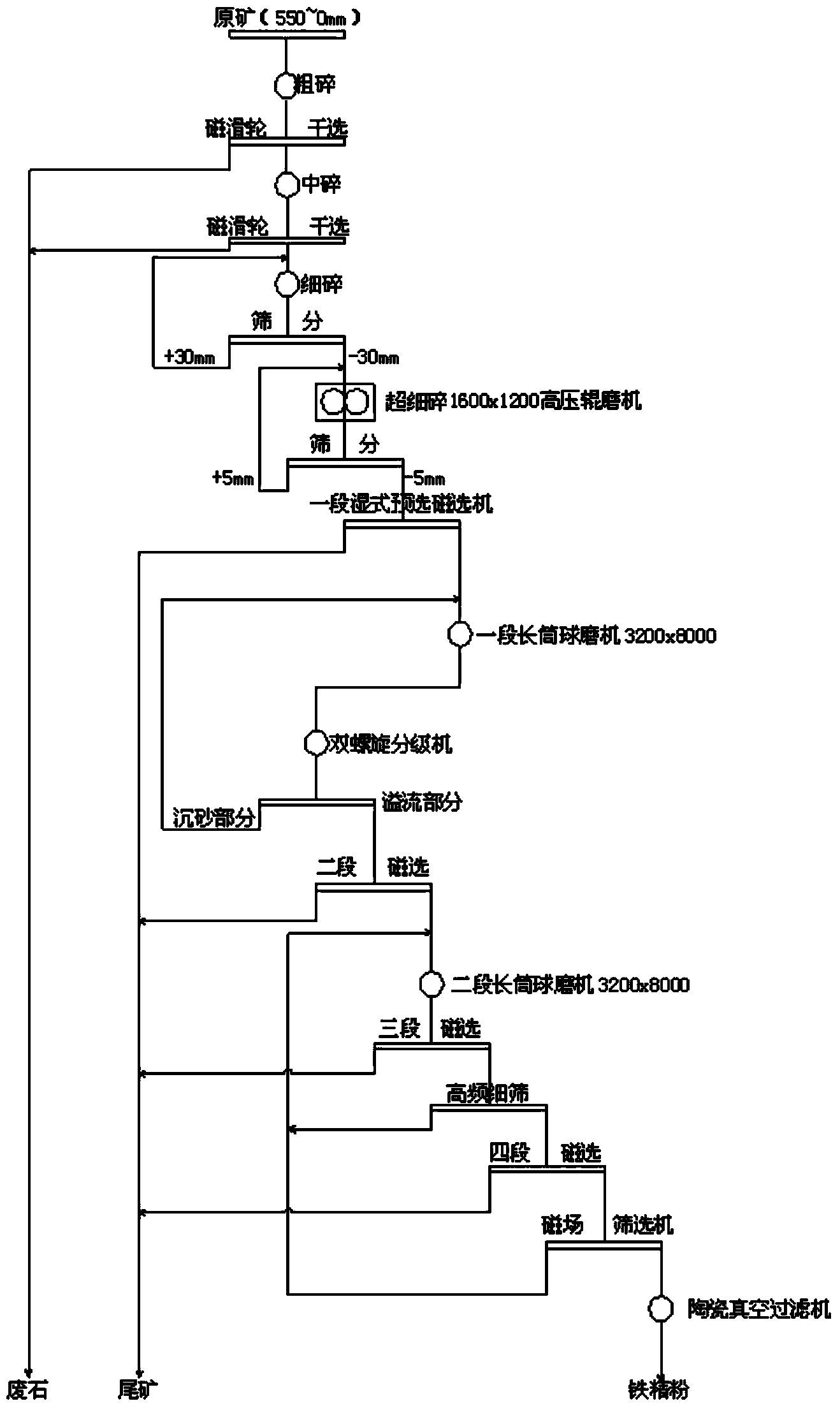

[0017] Such as figure 1 shown. A method for raising iron and reducing silicon by a weak magnetic separation process, comprising the following steps:

[0018] (1) The 550-0mm raw magnetite is conventionally crushed in three stages of coarse, medium and fine in the crusher, and two magnetic pulleys are added in the coarse crushing and medium crushing circuits, and one magnetic pulley is added in the fine crushing circuit. The magnetic pulley in the coarse crushing circuit is used to throw away the waste rock mixed in the raw ore, and the magnetic pulley in the medium and fine crushing circuits is used to throw away the large gangue that has been dissociated after crushing. The raw ore enters the cylindrical ore storage silo, and the raw ore from the cylindrical ore storage silo is screened by double-layer vibrating. The products on the screen with a particle size of >30mm are returned to fine crushing, and the products under the screen with a particle size of ≦30mm enter the hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com