Method for preparing ultralow-metallic-element ultrahigh-purity quartz through mixed acid hot-pressing leaching reaction

A hot-pressing leaching, metal element technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of limited reserves and uneven distribution of high-quality quartz resources, and achieve the effect of increasing the contact surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

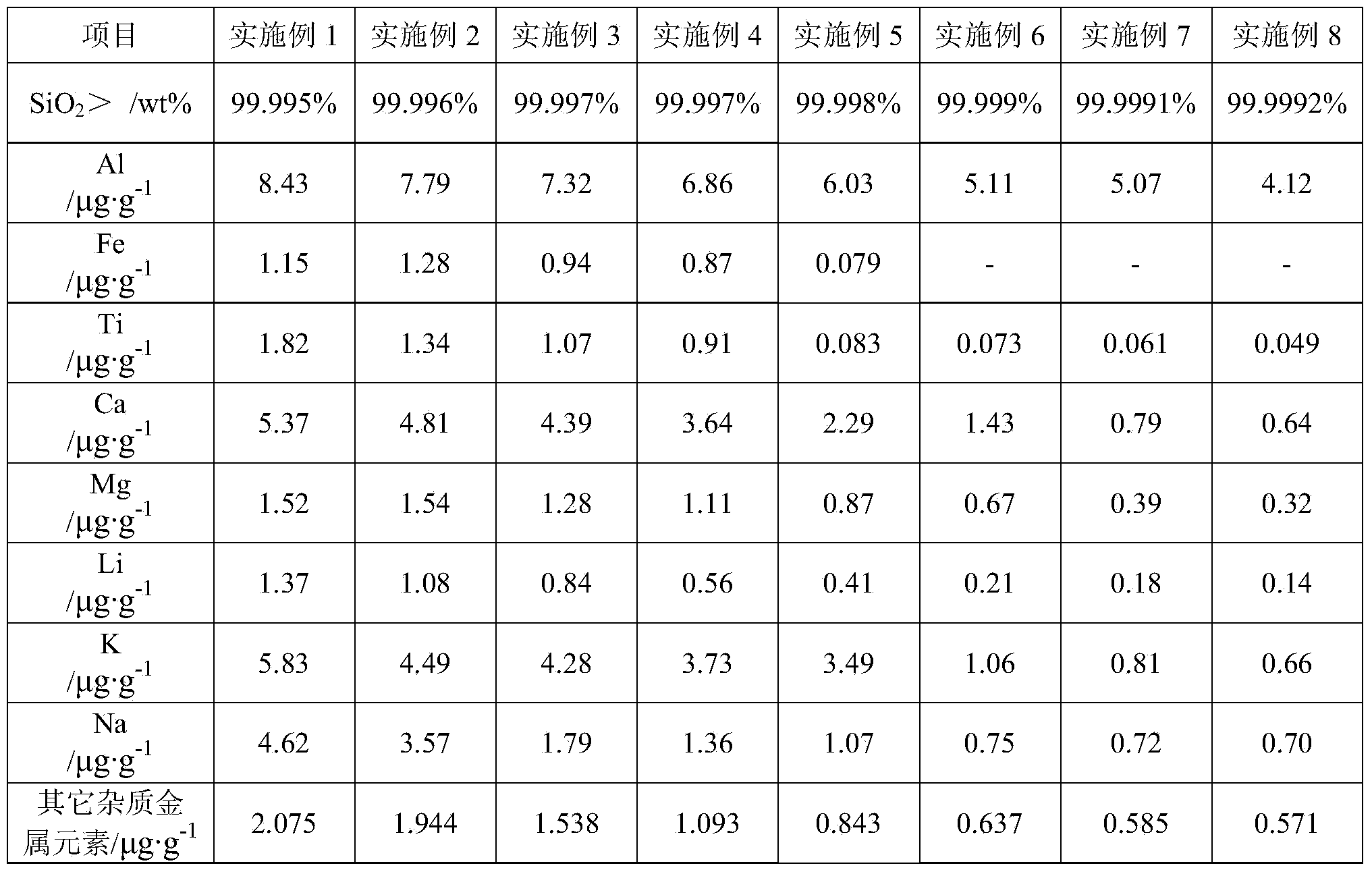

Examples

Embodiment 1

[0058] (1) Crushing and grading

[0059] The vein quartz raw ore is crushed and graded to prepare vein quartz sand with a particle size of 96-212 μm, and the vein quartz sand SiO 2 The purity is 99.8-99.9%, and the content of impurity metal elements: Al20-160μg·g -1 , Fe10~210μg·g -1 , Ti6~35μg·g -1 , Ca5~70μg·g -1 , Mg0.5~20μg·g -1 , Li2~15μg·g -1 , Na15~75μg·g -1 , K15~75μg·g -1 ;

[0060] (2) Magnetic separation

[0061] The sample obtained in step (1) is subjected to high-gradient pulsating strong magnetic separation under the conditions of pulp concentration of 35wt%, magnetic field strength of 0.8T, and pulsation intensity of 200r / min, and non-magnetic products are dried for use;

[0062] (3) Three-stage priority reverse flotation

[0063] Reverse flotation of the non-magnetic product obtained in step (2), the three-stage preferential reverse flotation refers to: one-stage reverse flotation to separate iron minerals, after drug removal, second-stage reverse flo...

Embodiment 2

[0073] (1) Crushing and grading

[0074] The vein quartz raw ore is crushed and graded to prepare vein quartz sand with a particle size of 96-212 μm, and the vein quartz sand SiO 2 The purity is 99.8-99.9%, and the content of impurity metal elements: Al20-160μg·g -1 , Fe10~210μg·g -1 , Ti6~35μg·g -1 , Ca5~70μg·g -1 , Mg0.5~20μg·g -1 , Li2~15μg·g -1 , Na15~75μg·g -1 , K15~75μg·g -1 ;

[0075] (2) Magnetic separation

[0076] The sample obtained in step (1) is subjected to high-gradient pulsating strong magnetic separation under the conditions of pulp concentration of 35wt%, magnetic field strength of 1.2T, and pulsation intensity of 300r / min, and non-magnetic products are dried for use;

[0077] (3) Three-stage priority reverse flotation

[0078] Reverse flotation of the non-magnetic product obtained in step (2), the three-stage preferential reverse flotation process is: one stage of reverse flotation to separate iron minerals, after drug removal, the second stage of re...

Embodiment 3

[0088] (1) Crushing and grading

[0089] The vein quartz raw ore is crushed and graded to prepare vein quartz sand with a particle size of 96-212 μm, and the vein quartz sand SiO 2 The purity is 99.8-99.9%, and the content of impurity metal elements: Al20-160μg·g -1 , Fe10~210μg·g -1 , Ti6~35μg·g -1 , Ca5~70μg·g -1 , Mg0.5~20μg·g -1 , Li2~15μg·g -1 , Na15~75μg·g -1 , K15~75μg·g -1 ;

[0090] (2) Magnetic separation

[0091] The sample obtained in step (1) is subjected to high-gradient pulsating strong magnetic separation under the conditions of pulp concentration of 35wt%, magnetic field strength of 1.2T, and pulsation intensity of 300r / min, and non-magnetic products are dried for use;

[0092] (3) Three-stage priority reverse flotation

[0093] Reverse flotation of the non-magnetic product obtained in step (2), the three-stage preferential reverse flotation process is: one stage of reverse flotation to separate iron minerals, after drug removal, the second stage of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com