Method for extracting platinum-palladium out of copper anode mud

A copper anode slime, platinum and palladium technology, applied in the direction of improving process efficiency and other directions, can solve the problems of waste of precious metal resources, affecting gold recovery rate, low platinum and palladium reduction rate, etc., to ensure metal recovery rate, easy control, and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

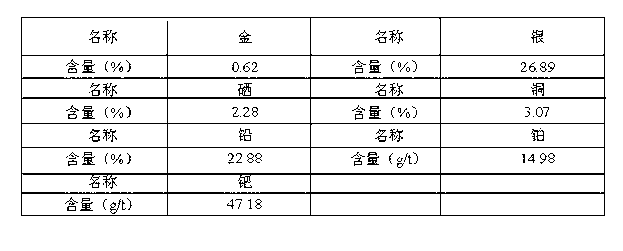

[0027] Implementation case: Copper anode slime contains the following elements as an example, and its element content is shown in Table 1

[0028] Table 1 Element content of copper anode slime

[0029]

[0030] Take the following process steps:

[0031] aRotary kiln roasting: first add 1t of 93.3% concentrated sulfuric acid to the pulping tank, then add 1t of copper anode slime, make slurry at room temperature for 6 hours, enter the rotary kiln for 5 hours through the automatic feeder, and control the temperature in the first zone of the rotary kiln at 350 °C , the temperature in the second zone is controlled at 480°C, the temperature in the third zone is controlled at 550°C, and the output of calcined sand is 1t; the calcined sand is put into reaction kettle 1, and 7m of clean water is added 3 , 700L of 93.3% sulfuric acid, constant temperature 85°C, react for 2h, put the tank and filter to obtain 700kg of copper and silver leaching residue, and the filtrate enters the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com