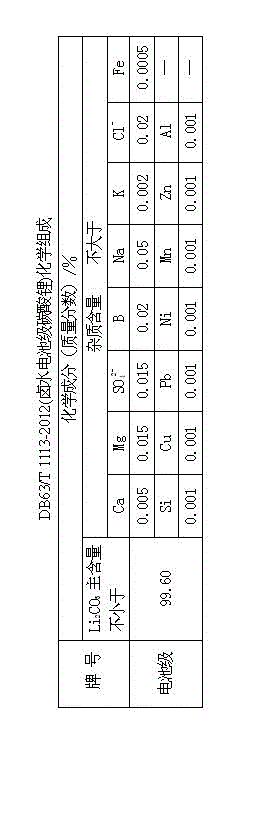

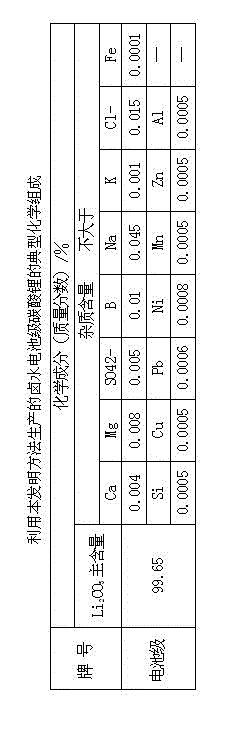

Method for preparing battery-level lithium carbonate by using salt lake brine

A technology of salt lake brine and lithium carbonate, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problem of not being suitable for the production of lithium carbonate in brine, and improve the comprehensive utilization rate of resources, low impurity index, and product quality. Stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Brine pretreatment: Brine pretreatment: the raw brine contains sediment impurities after being concentrated by the natural beach of Yantian, and the sediment can be removed by using a multi-media filter. At the same time, the iron that affects the separation of magnesium and lithium in the brine is removed Impurities, the filter material of the multimedia filter is composed of manganese sand, quartz sand, and activated carbon in a mass ratio of 1:1:1. The turbidity of the filtered brine is ≤0.5NTU, Fe 2+ Content ≤ 0.1mg / L, adjust its pH value between 3 and 3.5.

[0030] (2) Separation of magnesium and lithium: the selective two-stage magnesium and lithium separation of the raw material brine processed in the step (1) under the action of electric field force, the voltage of the first-level separation is DC120V, the current DA100A, and the voltage of the second-level separation is DC120V, current DA260A, the main composition (g / L) of lithium-rich brine is Mg 1.5, Li 1...

Embodiment 2

[0039] (1) Brine pretreatment: Brine pretreatment: the raw brine contains sediment impurities after being concentrated by the natural beach of Yantian, and the sediment can be removed by using a multi-media filter. At the same time, the iron that affects the separation of magnesium and lithium in the brine is removed Impurities, the filter material of the multimedia filter is composed of manganese sand, quartz sand, and activated carbon in a mass ratio of 1:1:1. The turbidity of the filtered brine is ≤0.5NTU, Fe 2+ Content ≤ 0.1mg / L, adjust its pH value between 3 and 3.5.

[0040] (2) Separation of magnesium and lithium: the selective two-stage magnesium and lithium separation of the raw material brine treated in step (1) under the action of electric field force, the voltage of the first-level separation is DC150V, the current DA150A, and the voltage of the second-level separation is DC135V, current DA290A, the main composition (g / L) of lithium-rich brine is Mg 4.5, Li 11.0, S...

Embodiment 3

[0049] (1) Brine pretreatment: Brine pretreatment: the raw brine contains sediment impurities after being concentrated by the natural beach of Yantian, and the sediment can be removed by using a multi-media filter. At the same time, the iron that affects the separation of magnesium and lithium in the brine is removed Impurities, the filter material of the multimedia filter is composed of manganese sand, quartz sand, and activated carbon in a mass ratio of 1:1:1. The turbidity of the filtered brine is ≤0.5NTU, Fe 2+ Content ≤ 0.1mg / L, adjust its pH value between 3 and 3.5.

[0050] (2) Separation of magnesium and lithium: the selective two-stage magnesium and lithium separation of the raw material brine treated in step (1) under the action of electric field force, the voltage of the first-level separation is DC180V, the current DA200A, and the voltage of the second-level separation is DC150V, current DA320A, the main composition (g / L) of lithium-rich brine is Mg10.0, Li 12.0, S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com