Hard water-resistant semi-synthetic metal cutting fluid and preparation method thereof

A metal cutting fluid, semi-synthetic technology, applied in lubricating compositions, petroleum industry, etc., to achieve good emulsification stability and superior defoaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

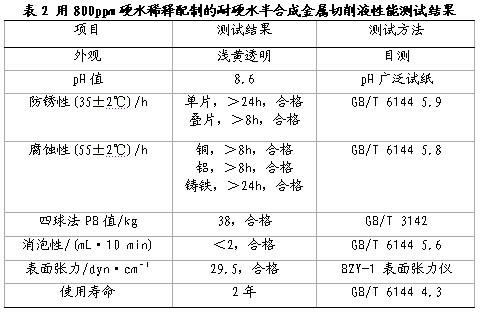

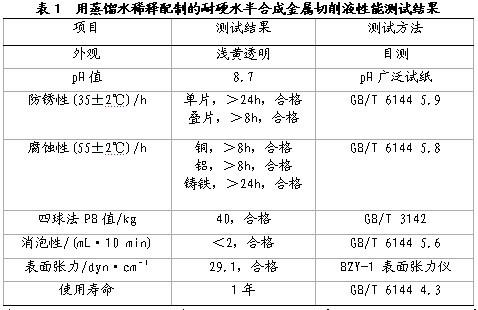

Examples

Embodiment 1

[0035] A semi-synthetic metal cutting fluid resistant to hard water, wherein each raw material component is calculated by weight percentage, and its composition and content are as follows:

[0036] Base oil 20%

[0037] Non-ionic surfactant 50%

[0038] Anionic surfactant 5%

[0039] Rust inhibitor 5%

[0040] Couplant 3%

[0041] Corrosion and scale inhibitor 1%

[0042] Extreme pressure agent 5%

[0043] Defoamer 0.5%

[0044] Fungicide 0.5%

[0045] water 10%;

[0046] Described base oil is mineral oil;

[0047] Described nonionic surfactant is straight-chain fatty alcohol polyoxyethylene ether;

[0048] Described anionic surfactant is sodium petroleum sulfonate;

[0049] Described antirust agent is boric acid monoethanolamine;

[0050] Described coupling agent is ethylene glycol butyl ether;

[0051] The corrosion and scale inhibitor is monoethanolam...

Embodiment 2

[0061] A semi-synthetic metal cutting fluid resistant to hard water, wherein each raw material component is calculated by weight percentage, and its composition and content are as follows:

[0062] Base oil 25%

[0063] Non-ionic surfactant 34.5%

[0064] Anionic surfactant 10%

[0065] Rust inhibitor 8%

[0066] Couplant 3.5%

[0067] Corrosion and scale inhibitor 0.5%

[0068] Extreme pressure agent 6%

[0069] Defoamer 0.3%

[0070] Fungicide 0.2%

[0071] Water 12%.

[0072] Wherein, the base oil is a synthetic ester;

[0073] Described nonionic surfactant is branched chain fatty alcohol polyoxyethylene ether;

[0074] Described anionic surfactant is Turkish red oil;

[0075] Described antirust agent is amide caproic acid triethanolamine salt;

[0076] Described coupling agent is diethylene glycol monobutyl ether;

[0077] The corrosion and scale inhibitor is monoethanolamine borate;

[00...

Embodiment 3

[0087] A semi-synthetic metal cutting fluid resistant to hard water, wherein each raw material component is calculated by weight percentage, and its composition and content are as follows:

[0088] Base oil 29.5%

[0089] Non-ionic surfactant 30%

[0090] Anionic surfactant 8.5%

[0091] Rust inhibitor 7.5%

[0092] Couplant 2.9%

[0093] Corrosion and scale inhibitor 0.6%

[0094] Extreme pressure agent 6.9%

[0095] Defoamer 0.4%

[0096] Fungicide 0.4 %

[0097] Water 13.3%;

[0098] Wherein, described base oil is peanut oil;

[0099] Described nonionic surfactant is aromatic fatty alcohol polyoxyethylene ether;

[0100] Described anionic surfactant is sodium petroleum sulfonate;

[0101] The rust inhibitor is a mixture of ammonium sulfonate and borate in a mass ratio of 1:2, i.e. ammonium sulfonate: borate;

[0102] Described coupling agent is triethylene glycol monobutyl ether;

[0103] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com