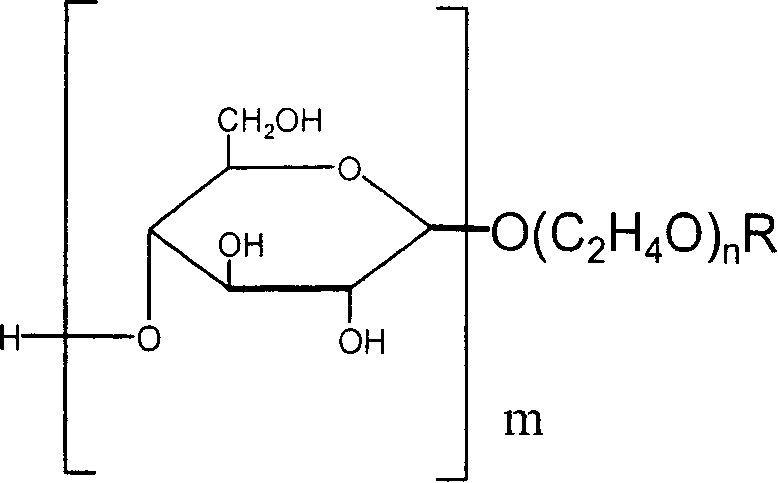

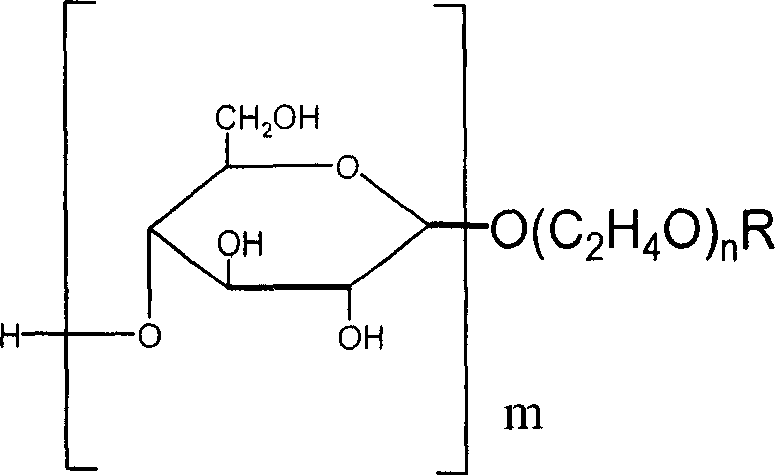

Surface active agent alcohol ether glucoside and its preparation method

A technology of surfactant and alcohol ether glycoside, applied in the field of nonionic surfactant and its preparation, can solve the problem of poor water solubility, limited application field of alkyl polyglycosides, water solubility and hard water resistance of long carbon chain alkyl polyglycosides Not ideal and other problems, to achieve the effect of good surface activity, outstanding easy biodegradability, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

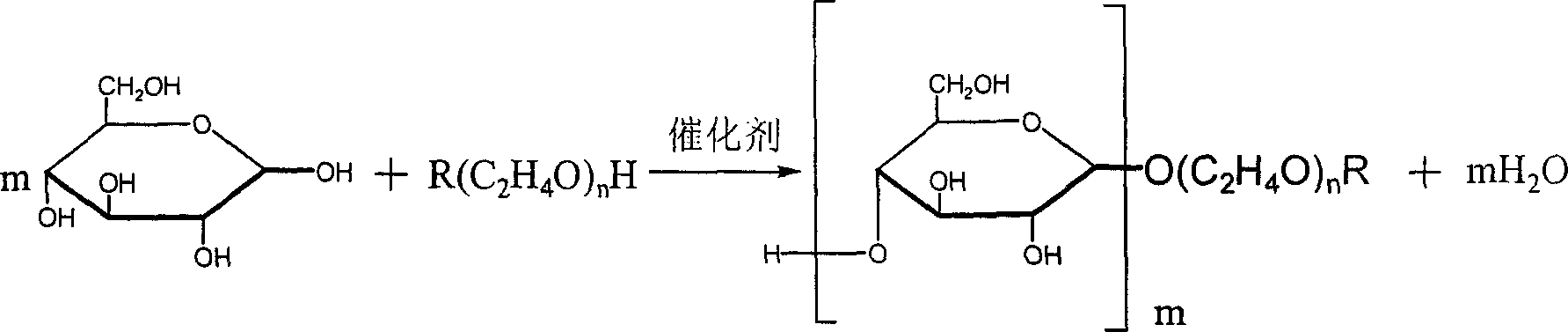

Method used

Image

Examples

Embodiment 1

[0019] 0.8 mol C 12-14 Add fatty alcohol polyoxyethylene ether (EO number is 0.5), 0.2 mole of anhydrous glucose and 1.5 g of dodecylbenzenesulfonic acid into the reactor, stir and heat to 100°C. React at a system pressure of 25mmHg and 100°C for 4hrs, cool down to 80°C, add 0.7g of a mixture of MgO and NaOH, and adjust the pH to 8. The material is sent to the molecular distillation evaporator, under the temperature condition of 140°C, the system pressure is 0.5mmHg, 0.66 mole of unreacted free alcohol ether is released, and the recovery rate is 98.5%; 0.129 mole of alcohol ether glycoside product is obtained, and the product yield is 99.8%. The average degree of polymerization was 1.55.

Embodiment 2

[0021] 2M 3 Add C to the reactor 12-16 3000 moles of fatty alcohol ether (EO number is 1), blow nitrogen, turn on the stirring and external circulation pump, add ~1000 moles of water glucose and 1.8 kg of p-toluenesulfonic acid catalyst at one time. React at a system pressure of 15mmHg and 110°C for 3.5hrs, cool down to 90°C, add 210g of a mixture of MgO and NaOH, and adjust the pH to 8.5. The material is sent into the thin film scraper evaporator, under the temperature condition of 160~180°C, the system pressure is 1.8mmHg, 2383.3 moles of unreacted free alcohol ethers are released, and the recovery rate is 97.5%; 552.5 moles of alcohol ether glycoside products are obtained, and the product yield is 99.5% , the average degree of polymerization of sugar rings is 1.8.

Embodiment 3

[0023] 2M 3 Add C to the reactor 8-18 3000 moles of fatty alcohol ether (EO number is 1.5), nitrogen gas flow, stirring and material external circulation pump are turned on, 600 moles of anhydrous glucose and 1.2 kg of p-toluenesulfonic acid / phosphoric acid / ethylenediaminetetraacetic acid mixed catalyst are added. React at a system pressure of 10mmHg and 120°C for 4hrs, cool down to 80°C, add 270g of MgO, and adjust the pH to 7. The material is sent into the thin-film scraper evaporator, under the temperature condition of 175-180°C, the system pressure is 0.7mmHg, 2481.8 moles of unreacted free alcohol ethers are released, and the recovery rate is 97.5%; 452.3 moles of alcohol ether glycoside products are obtained, and the product yield is 99.5% , the average degree of polymerization of sugar rings is 1.32.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com