Laser projection display device and laser drive control method

A technology of display device and laser projection, which is applied in the direction of using projection device image reproducer, static indicator, picture duplicator, etc., which can solve problems such as change and white balance change of the display screen, so as to reduce change, prevent blackening, High-quality images show the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

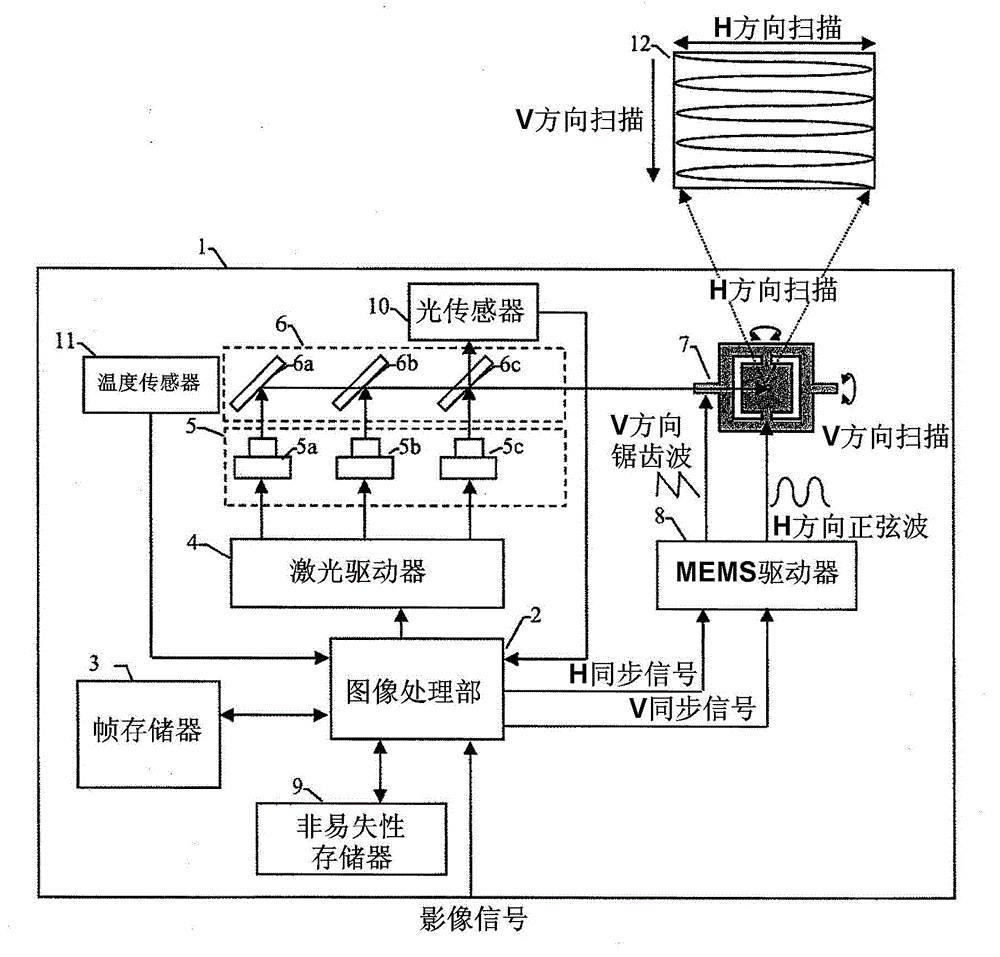

[0063] pass Figure 5 to Figure 13 Example 1 of the present invention will be described.

[0064] Figure 5 yes means figure 1 A diagram of the details of the internal structure of the image processing section 2 and the laser driver 4 . An image signal input from the outside of the image processing unit 2 is input to the image correcting unit 50 . The image correction unit 50 performs general image quality correction processing such as correction of image distortion due to scanning by the MEMS scanning mirror 7 and gamma adjustment of the image, and sends an image signal to the feature detection unit 51 .

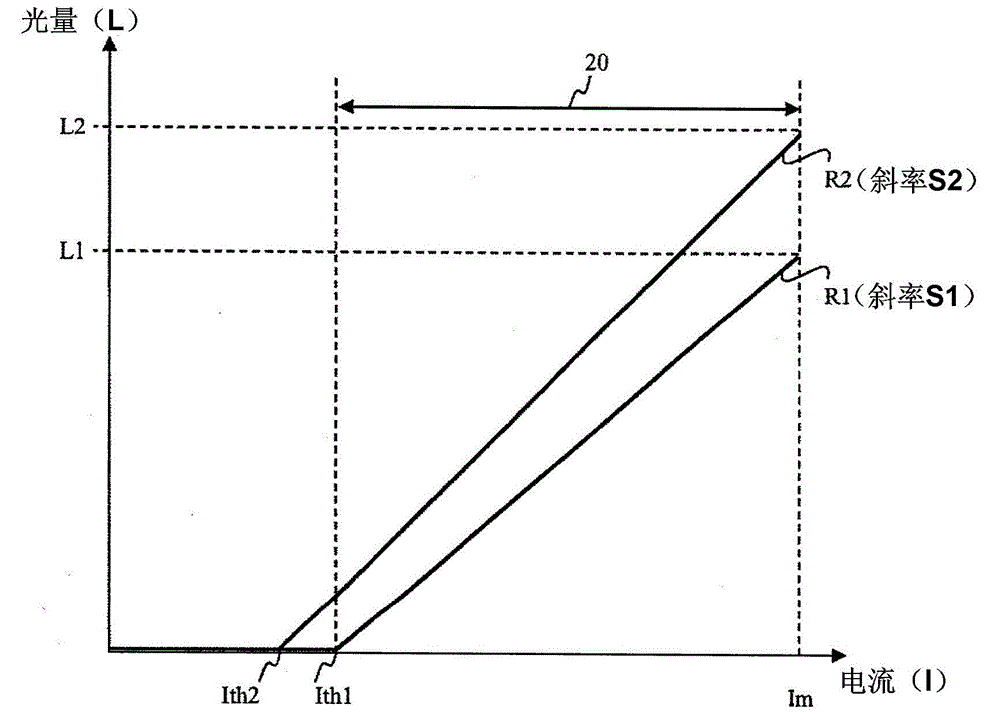

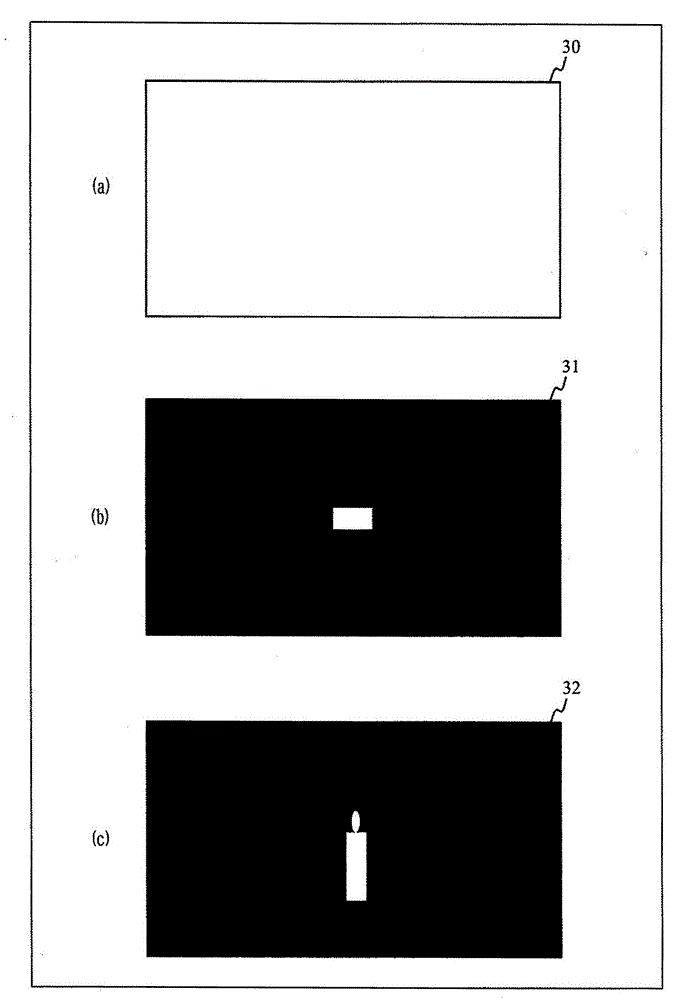

[0065] The feature detection unit 51 detects image feature quantities such as APL (Average Picture Level), histogram, hue, histogram and hue of each region when the image is divided into a plurality of regions. In particular, this embodiment is useful because the APL representing the average image luminance of each color frame corresponds to the above-mentioned load on ...

Embodiment 2

[0129] In the first embodiment described above, an example in which current gain is performed based on the temperature information of the temperature sensor 11 and the ACL value of the frame has been described. In addition to this control method, it is also possible to control the current gain by increasing the light emission for current gain control with a different light emission intensity from the processing for threshold current control. In this case, the threshold current and the slope of the light intensity with respect to the image signal can be kept constant even against sudden changes in temperature and load, and the same effect as that of the first embodiment can be obtained. Furthermore, in this control method, since the temperature sensor 11 is unnecessary, cost can be reduced.

[0130]Hereinafter, the structure in which light emission for current gain control is increased is referred to as Embodiment 2 of the present invention, referring to Figure 14 ~ Figure 18...

Embodiment 3

[0174] The following describes an embodiment in which the light sensor and the temperature sensor are canceled, and the threshold current adjustment amount and the current gain value are controlled according to the feature value of the image.

[0175] In Embodiments 1 and 2 above, an example in which the state of the laser light source 5 is detected by the optical sensor 10 and the temperature sensor 11 and the threshold current and current gain are controlled is described. And it discloses a method for adjusting the threshold current and the current gain when the scene of the displayed image changes.

[0176] As described above, the main reason for the necessity of these threshold current and current gain adjustments is that the temperature rise due to the accumulation of optical conversion loss of the semiconductor laser is to such an extent that the temperature characteristics of the semiconductor laser output are affected. In the third embodiment, the estimation of the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com