Auxiliary-heat bamboo bending device

An auxiliary heat and bamboo technology, applied in the direction of wood bending, wood heating, reed/straw treatment, etc., can solve the problems of bamboo is not easy to fix, the production efficiency is not on the same plane, and the bending point of the bamboo is offset from the curvature of the bamboo branch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

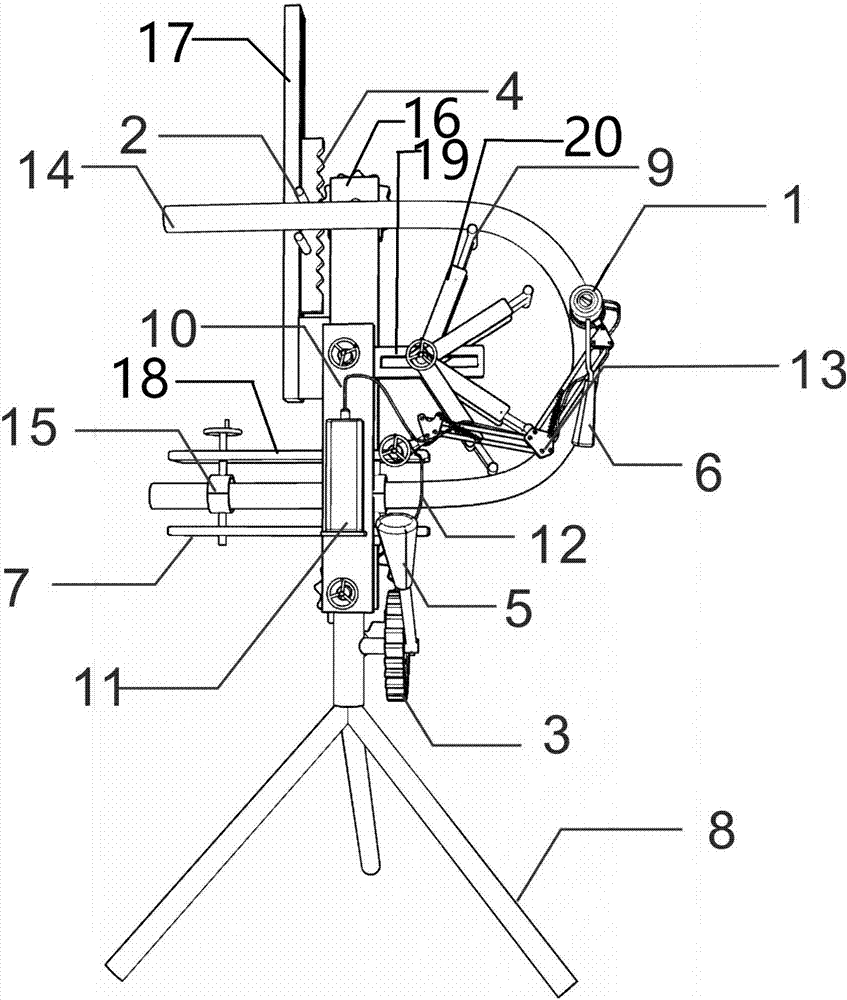

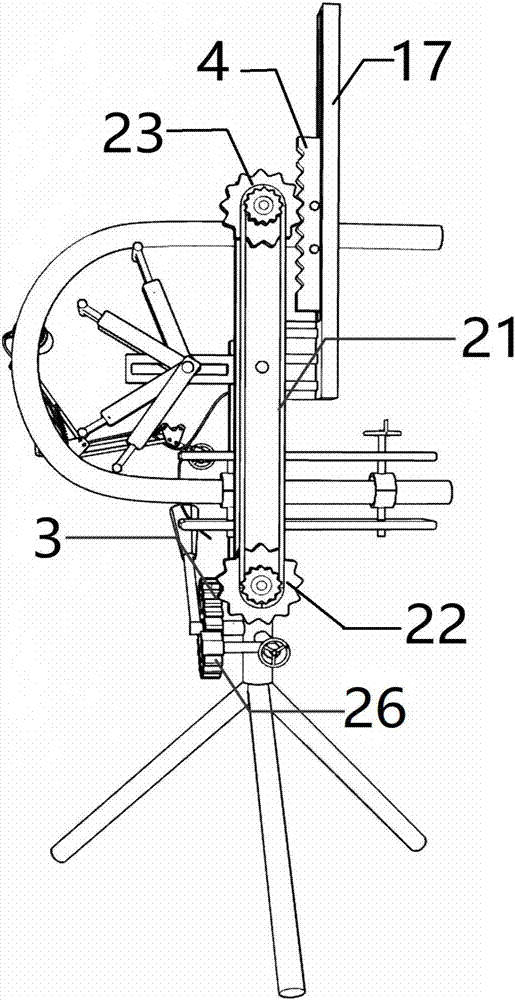

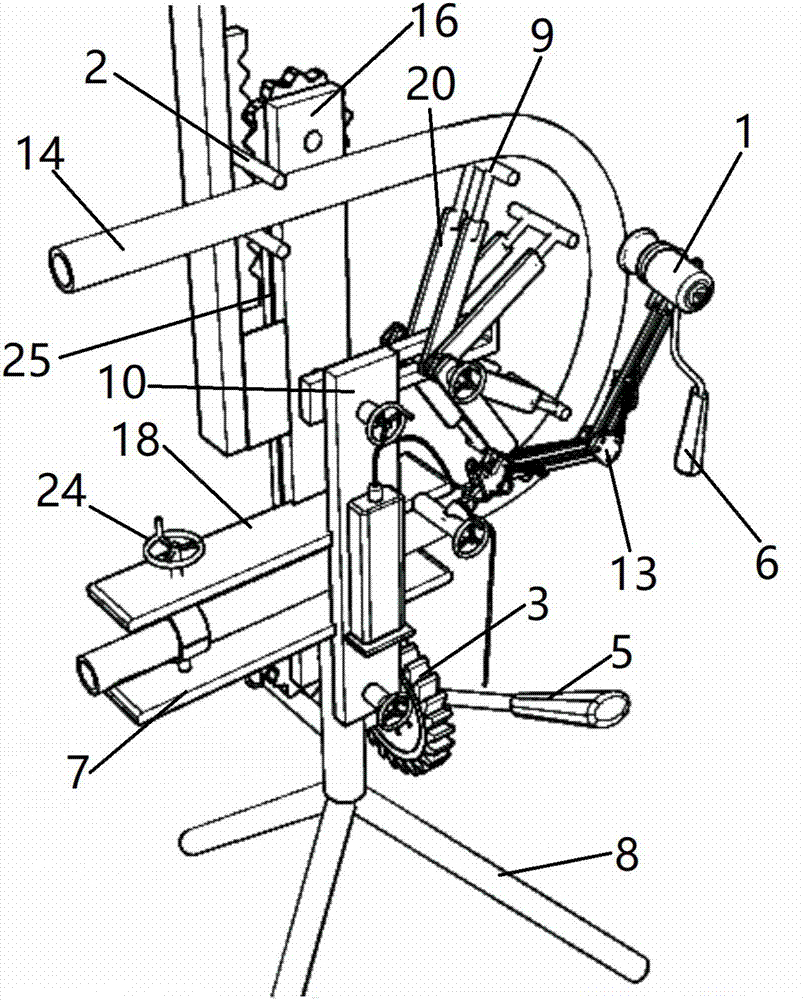

[0066] The embodiment of the present invention discloses a device for assisting heat-bending bamboo 14. One end of the pre-bent bamboo 14 is fixed by a first fixing component, and the other end of the pre-bending bamboo 14 is fixed by a second fixing component, wherein The second fixed assembly is positioned on the same vertical direction as the first fixed assembly, and then the bamboo 14 fixed between the first fixed assembly and the second fixed assembly is heated and at the same time the second fixed assembly is controlled by the control assembly on the first guide rail 25 and move downwards to apply force to the bamboo 14 so that the bamboo 14 bends in the vertical plane, which makes up for the poor style of the existing fire column, the material of the bamboo 14 is easy to decay, and is not conducive to preservation; Requirements, bamboo itself is not easy to fix, and affects the overall aesthetics. It solves the existing method of bending bamboo 14 manually, which is dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com