Method for preparing electrolyte for vanadium cell

A vanadium battery and electrolyte technology, applied in the field of fuel cells, can solve the problems of many processes, many steps, and difficult to purify, and achieve the effects of inhibiting crystallization, improving stability and electrochemical activity, and accelerating dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

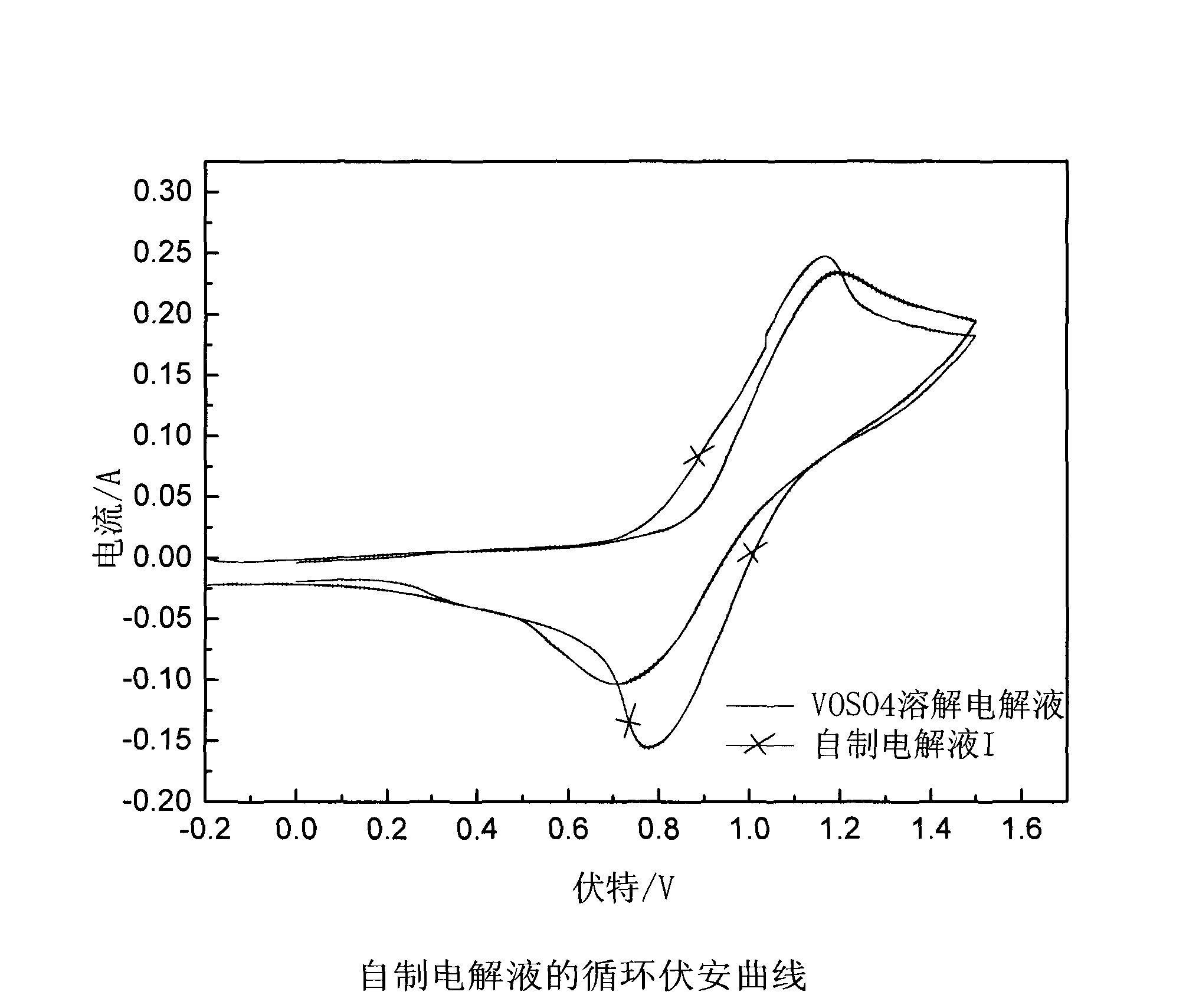

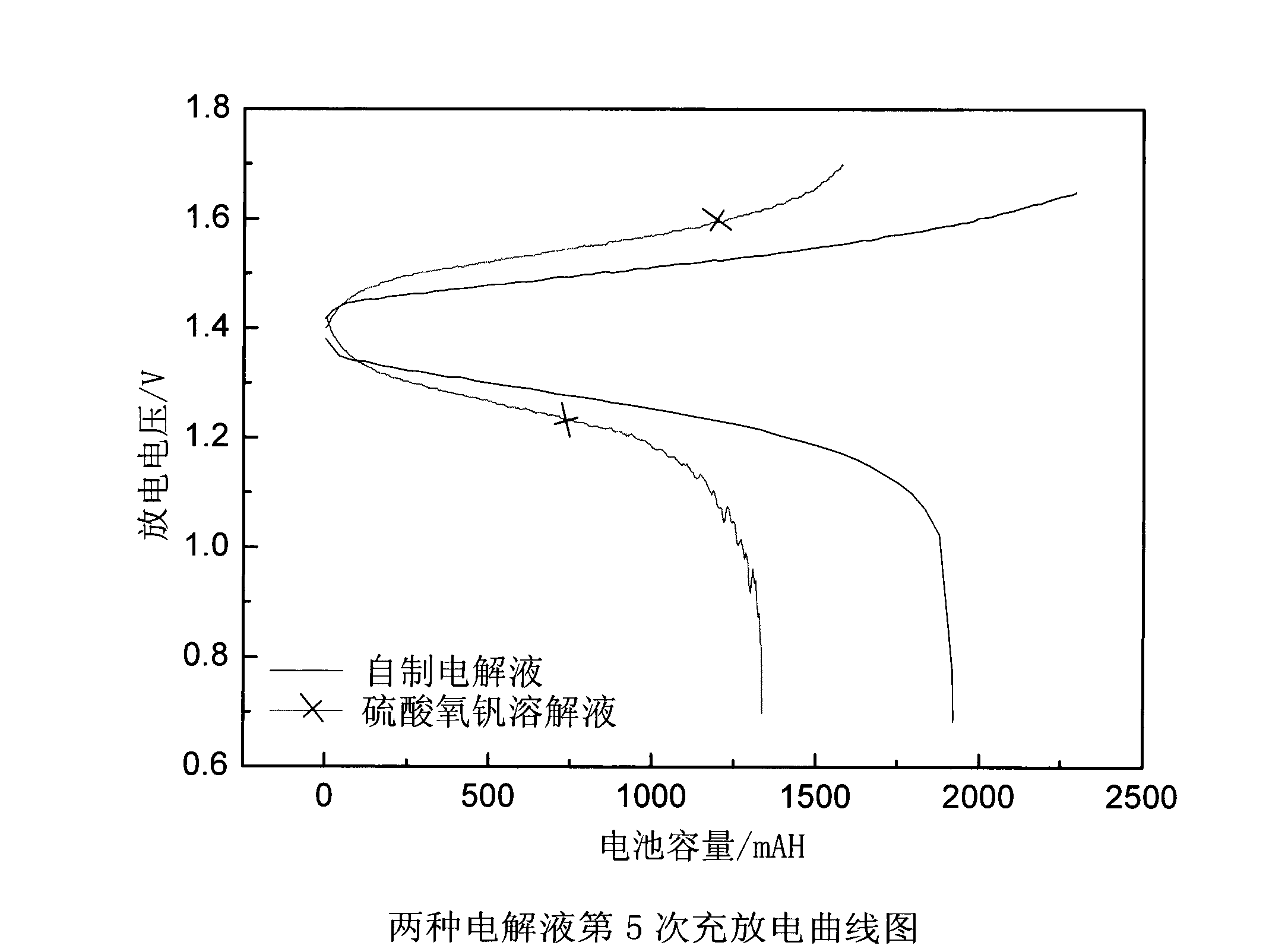

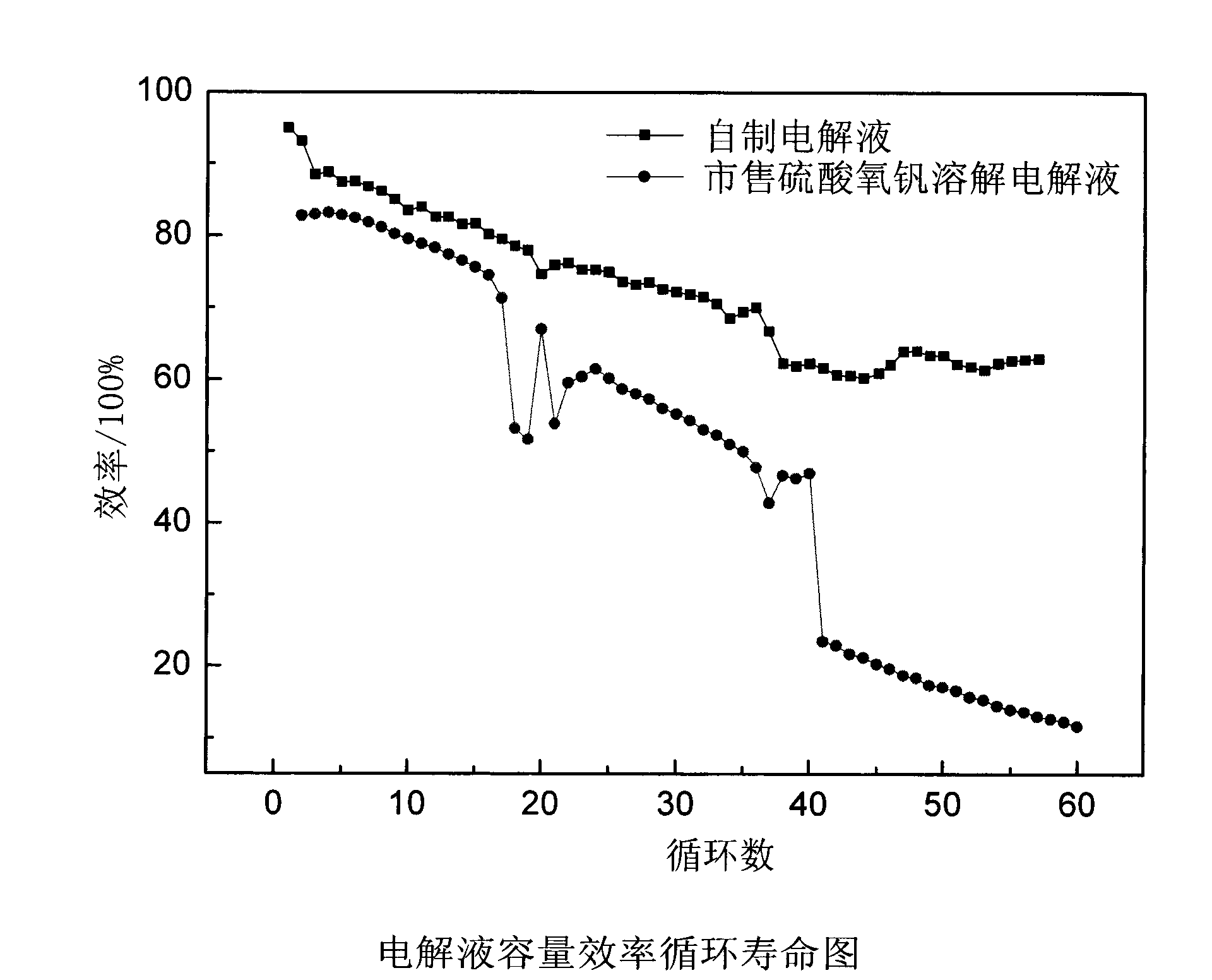

Image

Examples

Embodiment 1

[0038] Weigh 73g V 2 o 5 The concentration in 300mL is 4mol·L -1 In the sulfuric acid aqueous solution, under normal temperature, add catechol 3-10g, and keep stirring until V 2 o 5 Dissolve completely, add 5 mL of mercaptophenol, dilute the solution to 400 mL, and obtain a total vanadium content ≥ 1.8 mol L -1 Solution I.

[0039] The above solution is placed in the positive and negative electrolyte liquid storage tanks of the vanadium battery respectively according to the ratio of volume ratio 2: 1, with graphite felt as the electrode, with ion exchange membrane (can be a cation exchange membrane such as: perfluorosulfonic acid membrane , can also use anion exchange membrane) as a battery separator, at a current density of 30 to 80mA·cm -2 Under the current density of charge and discharge activation, the concentration of vanadium ions is ≥1.8mol L respectively. -1 Positive and negative electrolytes for all-vanadium redox flow batteries. The charging current density is...

Embodiment 2

[0041] Weigh 181.0g V 2 o 5 The concentration in 250.0mL is 3.0~4.0mol·L -1 In the sulfuric acid aqueous solution, add ascorbic acid 30g, stir to V 2 o 5 Dissolve completely, add 5 mL each of mercaptophenol and mercaptonicotinic acid, and 8 mL of triethanolamine to obtain solution II with a total vanadium content ≥ 3.0 mol·L-1.

[0042] With the above solution as the negative electrode electrolyte, an equal volume of Na with the same ion concentration 2 SO 4 +H 2 SO 4 The solution is a catholyte, which is respectively placed in electrolytic cells separated by ion-exchange membranes (such as cation-exchange membranes such as perfluorosulfonic acid membranes, or anion-exchange membranes). With the lead plate as the electrode, the current density is 80mA·cm -2 Electrolyze at a current density of 3.0 mol L-1, and control the end point of electrolysis by detecting the potential of the electrolyte. The end point potential is 150-250Mv, and the V 3+ / V 4+ electrolyte.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com