Glass fiber, preparation method thereof and glass fiber composite material

A glass fiber and content technology, applied in the field of its preparation and glass fiber, can solve the problems of restricting the conversion of wind energy and electric energy, low output, restricting the cost of wind power generation, etc., and achieve the effect of reducing carbon emissions and low viscosity temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

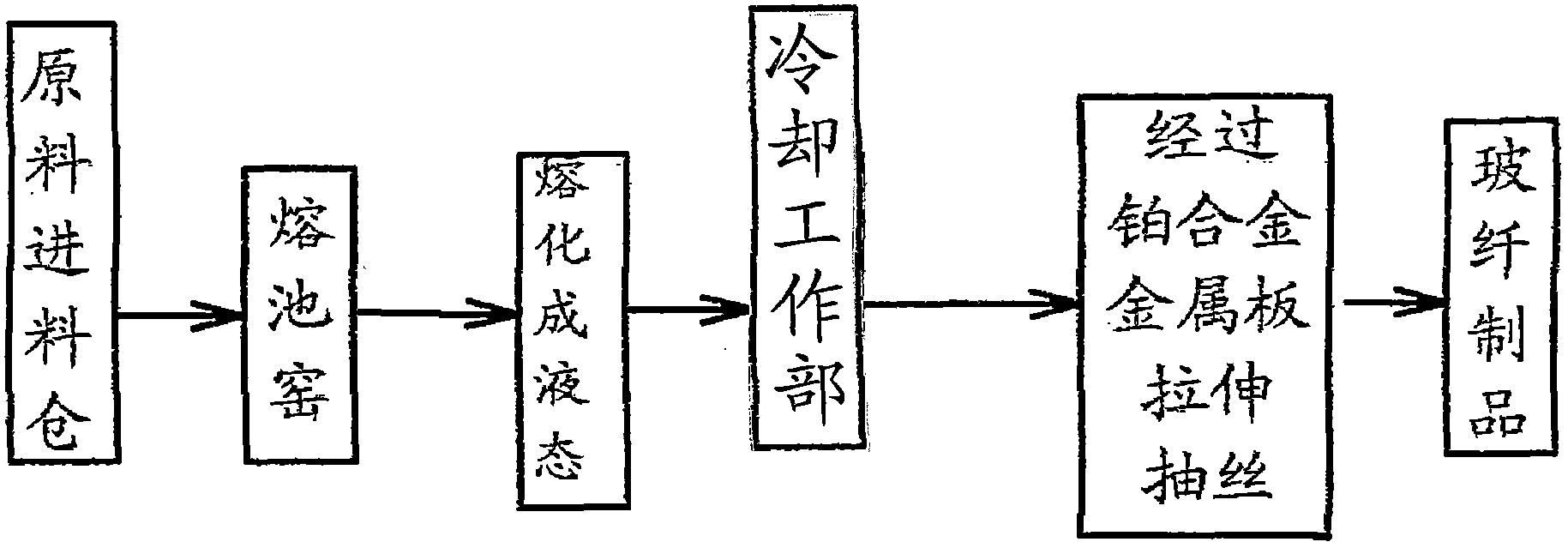

[0053] Now the preparation technology of glass fiber of the present invention is made its goods with stretching spinning process and is described further, and its manufacturing process comprises the following steps:

[0054] (1) First, the raw materials are prepared, and the ratio of the raw materials is calculated according to the glass fiber composition of the above-mentioned first embodiment and various modification examples thereof.

[0055] (2) Prepare the production line equipment required for the drawing and drawing process including the raw material warehouse, melting pool kiln, and platinum alloy drawing plate with drawing holes.

[0056] (3), press figure 2 In the production flow of the process shown, the predetermined raw materials prepared in step (1) are put into the feed bin, and then the raw materials are transported from the feed bin to the molten pool kiln, and then melted at the predetermined temperature after entering the molten pool and Air bubbles are re...

Embodiment 1

[0063] In terms of weight percentage, the content of silicon oxide in the glass is 54.8%, the content of calcium oxide is 12.2%, the content of magnesium oxide is 8%, the content of aluminum oxide is 25%, and the content of silicon oxide is 4.5 times that of calcium oxide. The content of calcium oxide is 1.52 times that of magnesium oxide.

[0064] Its actual melting viscosity temperature is 10 1.5 (Pa·s) when the temperature is 1690°C viscosity temperature, the actual homogenized air bubble viscosity temperature is 10 2 (Pa·s) at 1495°C; molding viscosity temperature 10 3 (Pa·s) is 1295°C; the upper line of crystal folding temperature is 1265°C.

[0065] The nominal diameter of the glass fiber is within 3 microns to 15 microns, the deviation of the glass fiber diameter is within ±15% of the nominal diameter, and the breaking strength (N / tex) is 0.88 when the diameter is less than or equal to 9 microns.

Embodiment 2

[0067] In terms of weight percentage, the content of silicon oxide in the glass is 56.3%, the content of calcium oxide is 13%, the content of magnesium oxide is 8.7%, the content of aluminum oxide is 22%, and the content of silicon oxide is 4.3 times that of calcium oxide. The content of calcium is 1.5 times that of magnesium oxide.

[0068] The actual melting viscosity temperature is 10 1.5 (Pa·s) when the temperature is 1660°C viscosity temperature, the actual homogenized bubble discharge viscosity temperature is 10 2 (Pa·s) at 1465°C; molding viscosity temperature 10 3 (Pa·s) is 1275°C; the upper line of crystal folding temperature is 1245°C.

[0069] The nominal diameter of the glass fiber is within 3 microns to 15 microns, the deviation of the glass fiber diameter is within ±15% of the nominal diameter, and the breaking strength (N / tex) is 0.75 when the diameter is less than or equal to 9 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com