Heating device of drainage plate in muffle furnace and control method of heating device

A technology of a heating device and a control method, which is applied in the direction of manufacturing tools, glass molding, glass molding, etc., and can solve problems such as the limited effect of increasing the temperature of the drainage plate, the difficulty of further increasing the temperature of the drainage plate, and the limited means of raising the temperature of the drainage plate. , to achieve the effects of reducing heat loss, simple structure, stability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

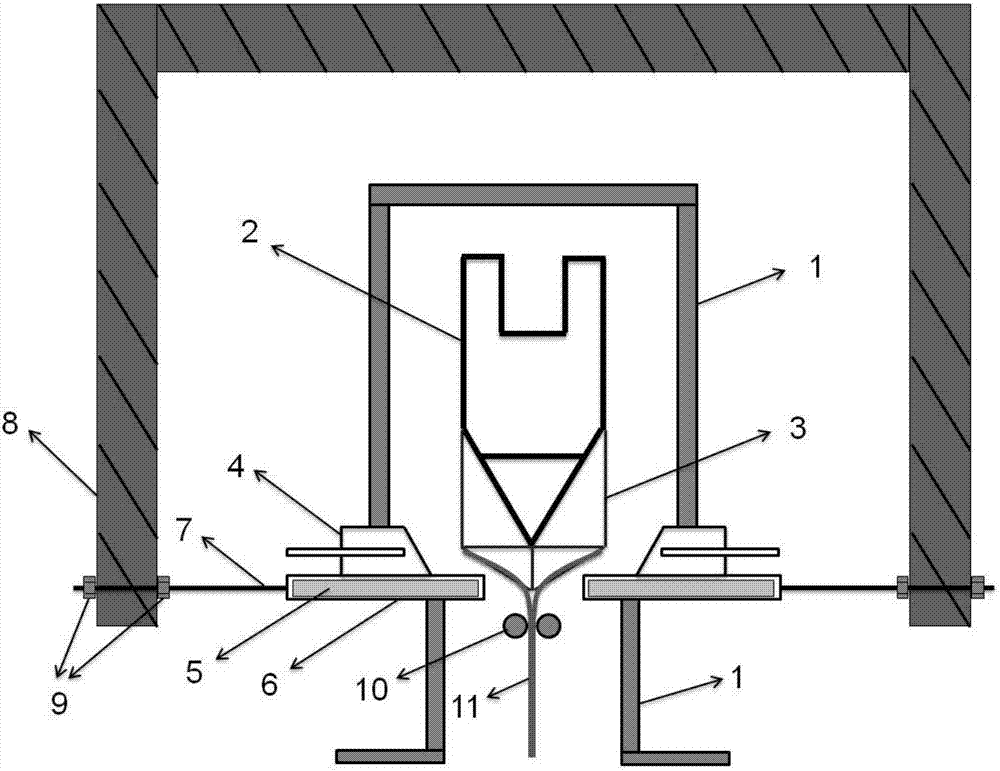

[0040] Such as figure 1As shown, under the soaking effect of the soaking hood 1, the molten glass has a certain viscosity, and is filled and evenly overflowed at the overflow tank 2, passes through the drainage plate 3, and is finally pulled down by the traction mechanism 10. A monolithic glass ribbon 11 is formed. Considering the decreasing distribution of the temperature field in the muffle furnace, and the use of the blower box 4 to adjust the thickness, the heat will be dissipated, resulting in a lower temperature at the diversion plate 3, and the molten glass may crystallize on the diversion plate 3 . In order to suppress crystallization of the molten glass on the diversion plate 3 , it is necessary to increase the temperature of the diversion plate 3 , which can be achieved by setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com