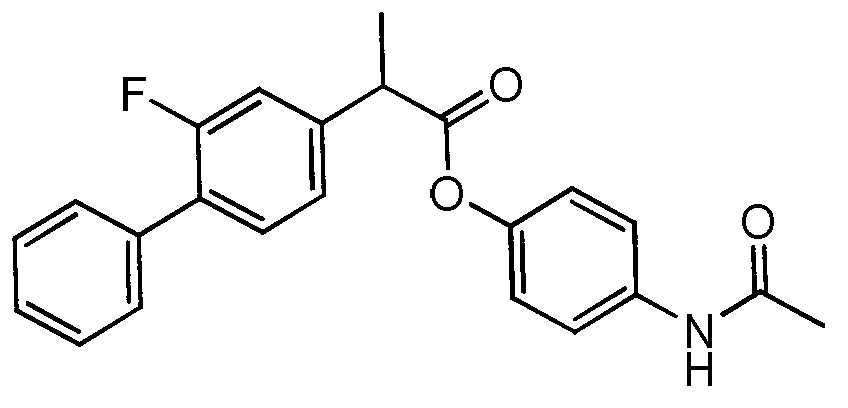

Flurbiprofen acetaminophen resin lipid microsphere injection, freeze-drying lipid microsphere injection and preparation methods

A technology of acetaminophen ester lipid and acetaminophen ester, applied in flurbiprofen acetaminophen ester lipid microsphere injection, non-steroidal anti-inflammatory analgesic drug injection, freeze-dried lipid microsphere In the field of injections and preparations, it can solve the problems of small dosage, long-term stability, venous irritation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Prepare flurbiprofen acetaminophen lipid microsphere injection according to the following method:

[0096] (1) Preparation of medicated oil phase: Mix 1 g of flurbiprofen acetaminophen, 10 g of soybean oil for injection, 2.6 g of soybean lecithin and 0.5 g of oleic acid, heat to 65°C, and stir evenly to obtain a clear Medicinal oil phase;

[0097] (2) Prepare the water phase: mix 1.4g of soybean lecithin with 7ml of water for injection, heat to 65°C, stir evenly to obtain a clear water phase;

[0098] (3) Preparation of colostrum: under 10000rpm high-speed stirring, add the water phase obtained in step (2) to the oil phase obtained in step (1), stir evenly and adjust the pH value to 6 to obtain colostrum;

[0099] (4) Dilution: dilute the colostrum obtained in step (3) with 78ml of water for injection, the concentration of flurbiprofen acetaminophen in the diluted colostrum is 11.8mg / ml;

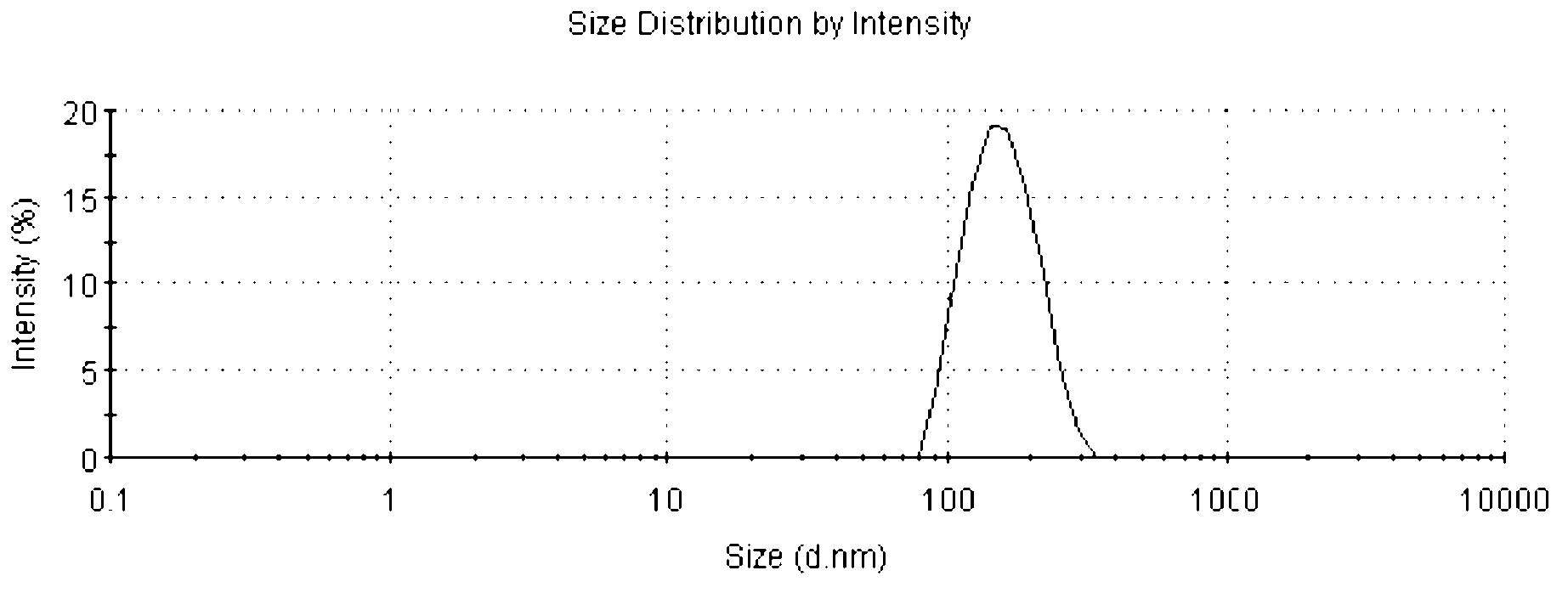

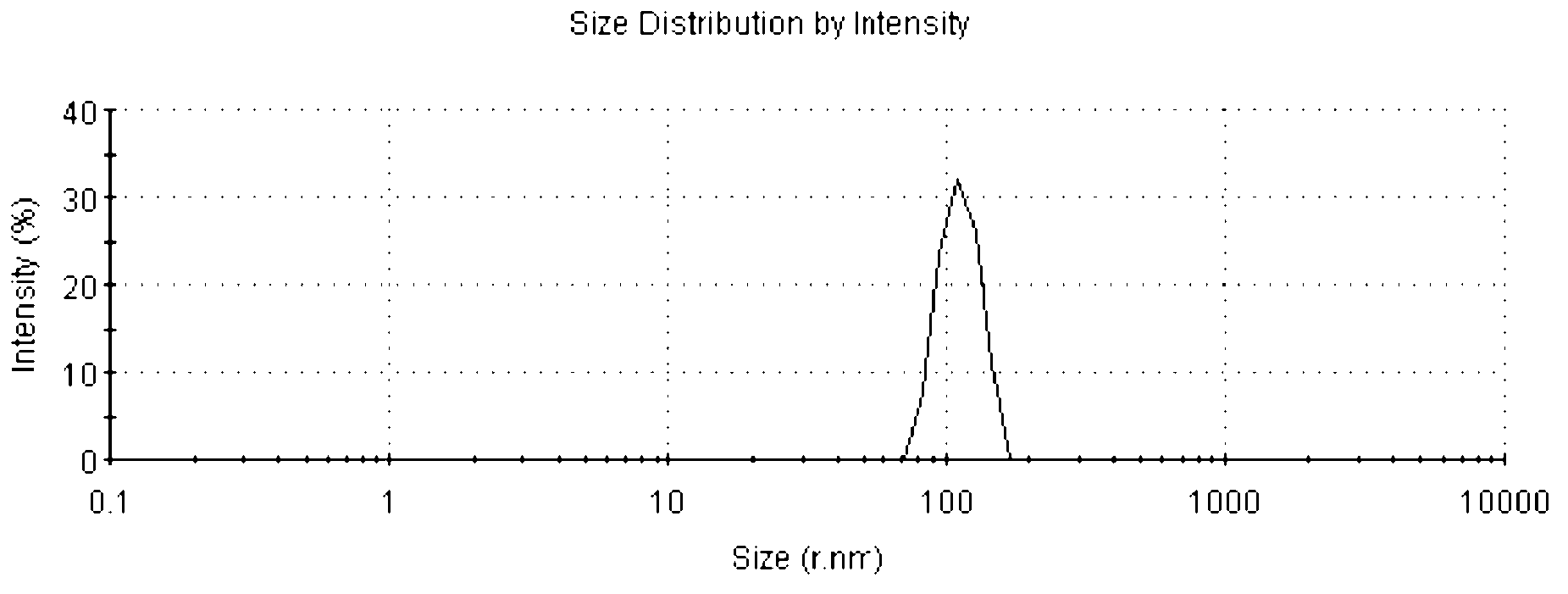

[0100] (5) Preparation of lipid microsphere injection: transfer the diluted col...

Embodiment 2

[0102] Prepare flurbiprofen acetaminophen lipid microsphere injection according to the following method:

[0103] (1) Preparation of medicated oil phase: Mix 2g of flurbiprofen acetaminophen, 15g of medium-chain fatty acid glycerides, 4.5g of egg yolk lecithin and 1.5g of sodium oleate, heat to 75°C, stir evenly to obtain clarified medicated oil phase;

[0104] (2) Prepare the water phase: mix 1.5g of egg yolk lecithin with 9ml of water for injection, heat to 75°C, stir evenly to obtain a clear water phase;

[0105] (3) Preparation of colostrum: under high-speed stirring at 10000rpm, add the water phase obtained in step (2) to the oil phase obtained in step (1), stir evenly and adjust the pH value to 7 to obtain colostrum;

[0106] (4) Dilution: dilute the colostrum obtained in step (3) with 67ml of water for injection, the concentration of flurbiprofen acetaminophen in the diluted colostrum is 26.3mg / ml;

[0107] (5) Preparation of lipid microsphere injection: transfer the ...

Embodiment 3

[0109] Prepare flurbiprofen acetaminophen lipid microsphere injection according to the following method:

[0110] (1) Preparation of medicated oil phase: Mix 0.1g of flurbiprofen acetaminophen, 1g of peanut oil and 0.9g of cholesterol in the total weight of the emulsifier, heat to 30°C, and stir well to obtain a clear medicated oil phase ;

[0111] (2) Preparation of water phase: Mix 0.1g of cholesterol with 1ml of water for injection, heat to 30°C, stir well to obtain a clear water phase;

[0112] (3) Preparation of colostrum: under 8000rpm high-speed stirring, add the water phase obtained in step (2) to the oil phase obtained in step (1), stir evenly and adjust the pH value to 5 to obtain colostrum;

[0113](4) Dilution: dilute the colostrum obtained in step (3) with 97ml of water for injection, and the concentration of flurbiprofen acetaminophen in the diluted colostrum is 1mg / ml;

[0114] (5) Preparation of lipid microsphere injection: transfer the diluted colostrum in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com