Growth method of silicon carbide crystal grown by pvt method

A growth method, a technology of silicon carbide, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of crystal defects and low quality of silicon carbide crystal growth, so as to improve quality and reduce carbon inclusion defects , the effect of avoiding crystal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] As mentioned in the background technology, in the initial stage of silicon carbide crystal growth, the growth atmosphere is rich in gaseous silicon, and under the action of axial temperature gradient, the steam is transported to the low-temperature silicon carbide seed crystal region, and the saturated vapor pressure of the silicon-rich gas phase decreases, condensing into Liquid-phase silicon causes crystallization defects. In order to overcome this defect, gas that can react with silicon vapor at high temperature is usually introduced into the silicon carbide raw material to form silicide, thereby removing gas-phase silicon in the growth atmosphere. However, silicon carbide crystals produced by this method still have crystal defects.

[0057] Based on the above-mentioned problems and detailed analysis of various factors, the inventor determined that the main reason for the crystallization defects in silicon carbide crystals is that the uniformity of chlorine-containing...

Embodiment 2

[0071] This embodiment provides a method for growing silicon carbide crystals, which is realized based on the crucible for growing silicon carbide crystals by the PVT method described in Embodiment 1. For the beneficial effects that the crucible can achieve, please refer to Embodiment 1, as follows No longer.

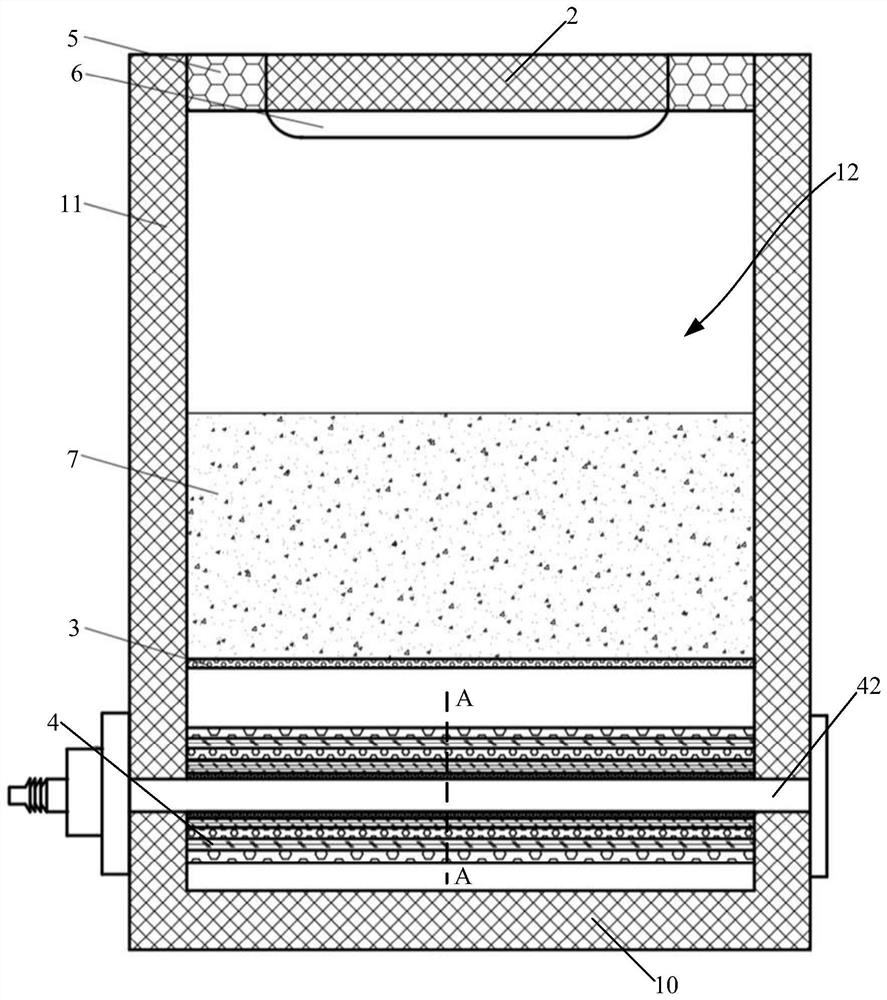

[0072] Such as Figure 2 to Figure 4 As shown, the growth method comprises the steps of:

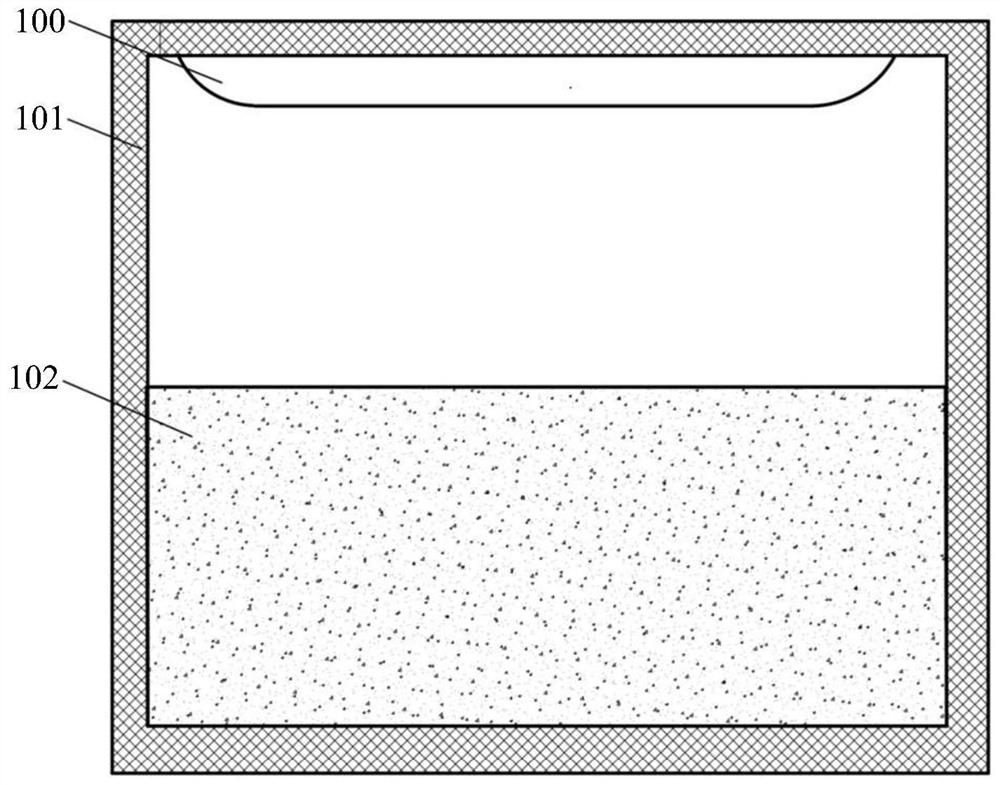

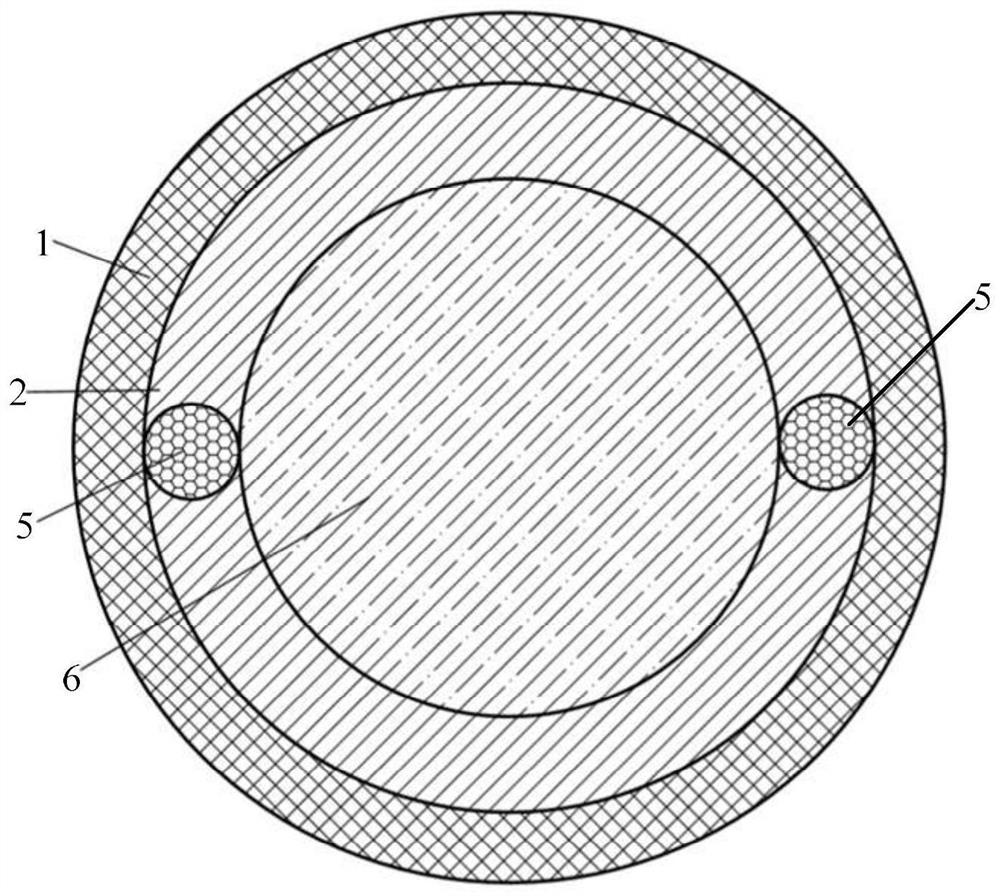

[0073] 1) Provide a crucible for growing silicon carbide crystals by PVT method as described in Embodiment 1, and place a silicon carbide raw material 7 on a porous graphite plate 3 in the crucible and place a silicon carbide seed above the accommodating chamber 12 of the crucible Crystal 6;

[0074] 2) Put the crucible into the silicon carbide single crystal growth chamber. The silicon carbide single crystal growth chamber is mainly used for heating. Generally, the silicon carbide single crystal growth temperature is above 2000°C, and eddy current heating is adopted, that is, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com