PVD coating with strong (111) texture and preparation method thereof

A coating and texture technology, applied in the fields of cutting tools and powder metallurgy composite materials, to achieve the effect of improving crystal integrity, reducing crystal defects and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

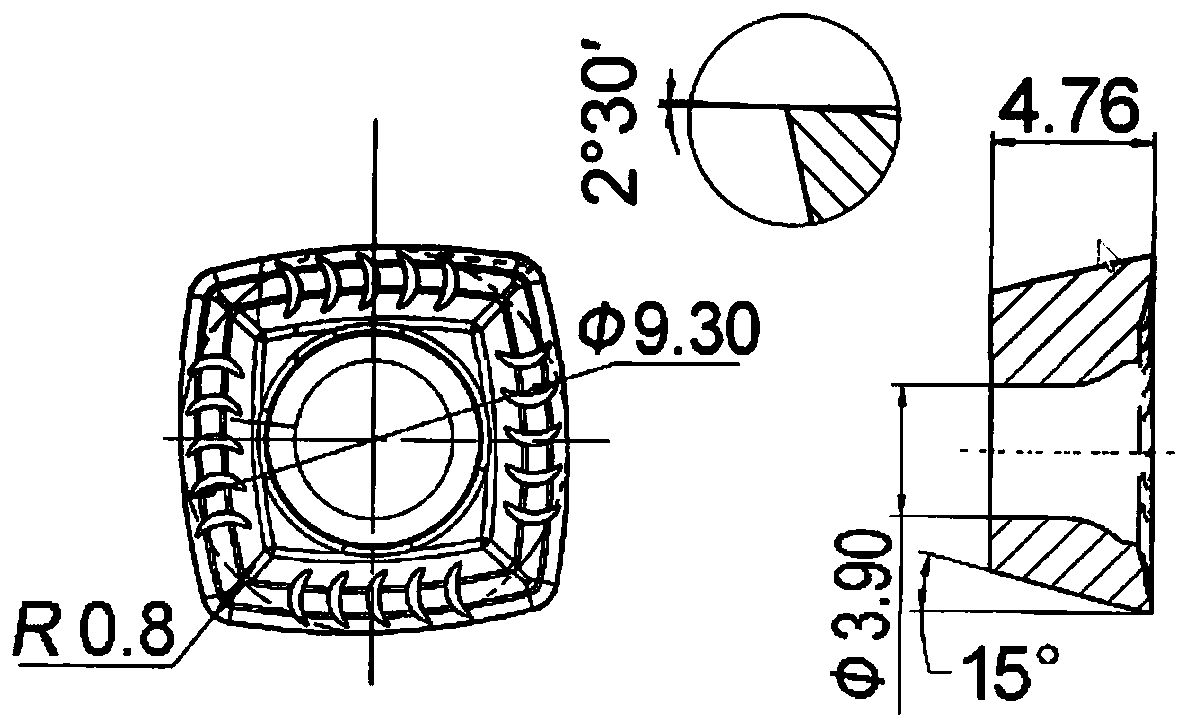

[0036] WC–0.7Cr prepared by pressure sintering process 3 C 2 –0.4VC–10Co (where the value is the mass fraction, %, the same below) and WC–0.4Cr 3 C 2 –0.3VC–6Co carbide inserts, and TiC 0.7 N 0.3 –25WC–10TaC–2Mo 2 C–6Co–6Ni cermet inserts as figure 1 Substrate for coated inserts for milling operations shown. At the same time, alloy samples for testing with the corresponding material of 10×10×5mm were also prepared. The scanning electron microscope observation and analysis results show that the grain size of the two cemented carbides is ~0.4 μm, and the (Ti,M)C with a typical core ring structure in the cermet 0.7 N 0.3 (M=W, Ta, Mo) The grain size of the hard phase is ~1.2μm; the above three alloys all have a normal two-phase structure of hard phase + binder phase. The results of differential scanning calorimetry showed that the eutectic temperatures of the above three alloys were 1310°C, 1325°C and 1340°C, respectively.

[0037] Put the above-mentioned alloy blades a...

Embodiment 2

[0048] Three kinds of 10×10×5mm square cemented carbide samples, WC–10Co, WC–10Ni and WC–5Co–5Ni prepared by pressure sintering process, were used as coating substrates. Scanning electron microscope observation and analysis results show that the grain size of the three cemented carbides is ~1.2 μm, and they are all normal hard phase + binder phase two-phase structure. The results of differential scanning calorimetry showed that the eutectic temperatures of the above three alloys were 1370°C, 1400°C and 1385°C, respectively.

[0049] The above-mentioned square alloy samples treated by sandblasting and grinding were divided into 4 groups, and each group contained 3 kinds of alloys. 2 o 3 And 3% (mass fraction, the same below) graphite powder, CeO 2 and 4% graphite powder, Pr 6 o 11 and 5% graphite powder, Nd 2 o 3 In the mixed powder filler composed of 6% graphite powder; the purity of the above-mentioned rare earth oxide and graphite powder is 99.9%; the sieve aperture co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com