High-gradient visual tubular single crystal growth furnace

A growth furnace and tube-type technology, which is applied in the field of large-gradient visualized tube-type single crystal growth furnace, can solve the problems that the growth interface cannot be observed, and it is difficult to realize a large gradient, so as to facilitate the promotion of industrialization and avoid the radial temperature field Effects of asymmetric, low-cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

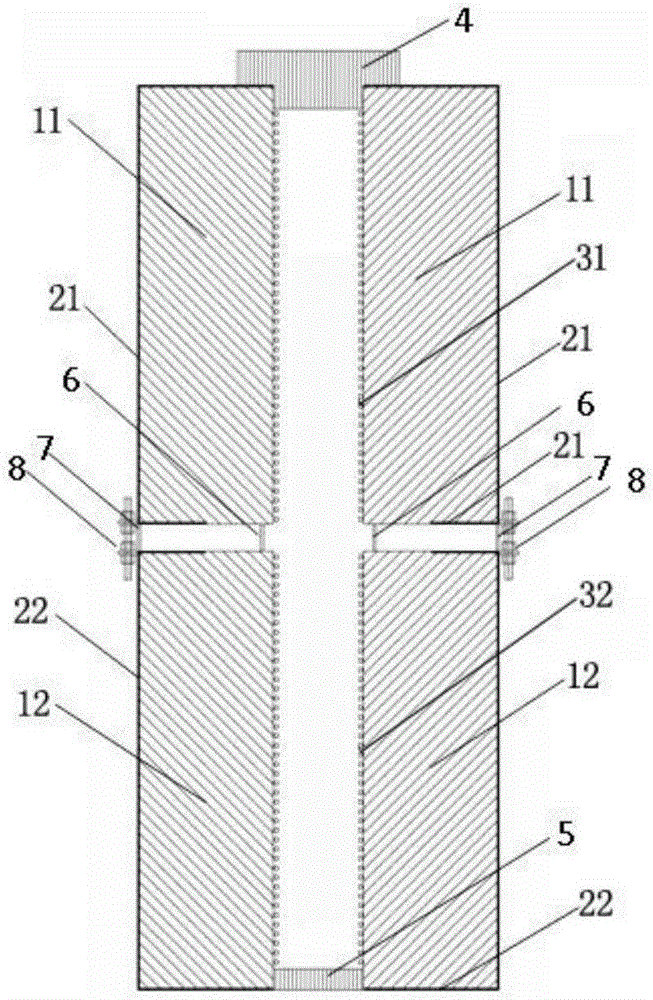

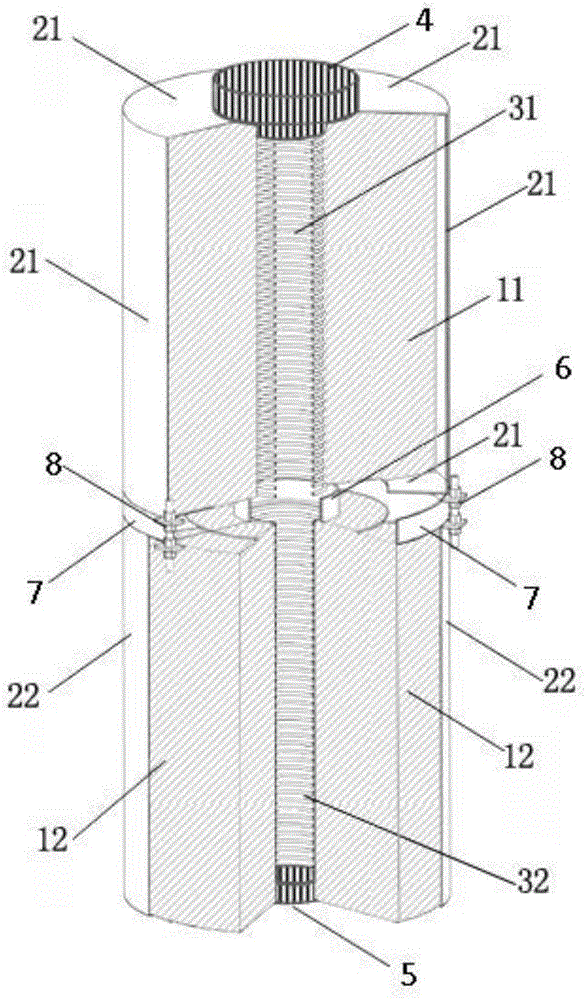

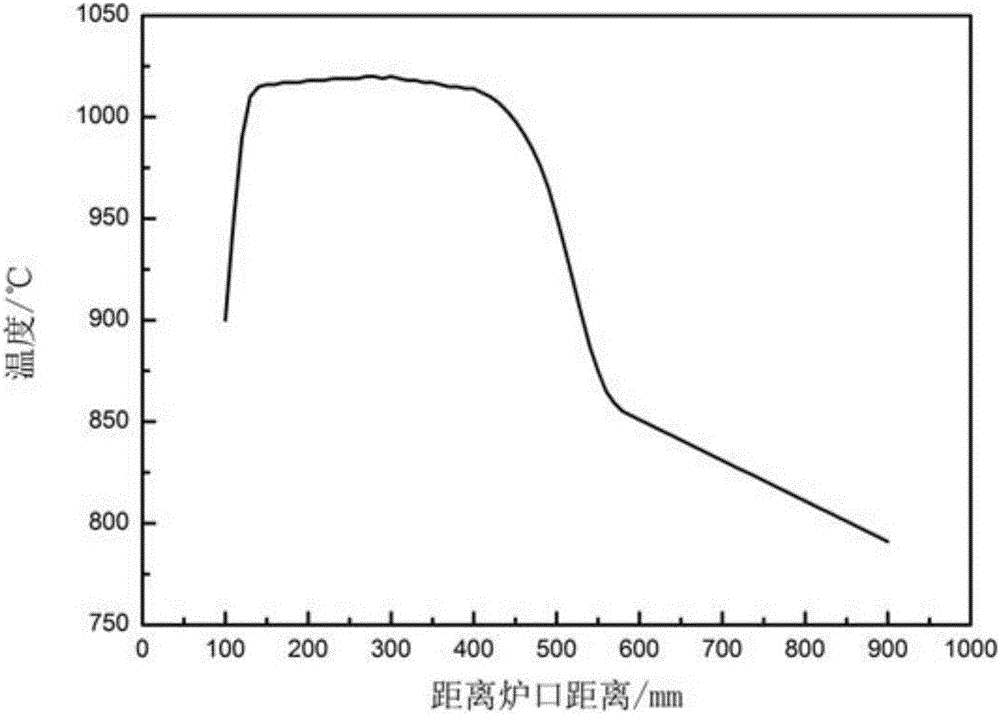

[0041] a kind of like figure 1 and figure 2 The large-gradient visualized tubular single crystal growth furnace shown includes an upper furnace, a lower furnace, and a middle observation area; the upper furnace includes an upper furnace shell 21, an upper insulation cotton 11, and an upper heating resistance wire 31 from outside to inside. , the lower furnace from outside to inside is the lower furnace shell 22, the lower insulation cotton 12 and the lower heating resistance wire 32; Head 5; in the middle observation area between the upper furnace and the lower furnace, a gold-plated quartz inner tube 6 and a non-gold-plated quartz outer tube 7 are sequentially arranged from the inside to the outside, and the gold-plated quartz inner tube 6 and the non-gold-plated quartz outer tube 7 There is a gap between them; the upper furnace shell 21, the upper thermal insulation cotton 11, the upper heating resistance wire 31, the lower furnace shell 22, the lower thermal insulation co...

Embodiment 2

[0044] a kind of like figure 1 and figure 2 The large-gradient visualized tubular single crystal growth furnace shown includes an upper furnace, a lower furnace, and a middle observation area; the upper furnace includes an upper furnace shell 21, an upper insulation cotton 11, and an upper heating resistance wire 31 from outside to inside. , the lower furnace from outside to inside is the lower furnace shell 22, the lower insulation cotton 12 and the lower heating resistance wire 32; Head 5; in the middle observation area between the upper furnace and the lower furnace, a gold-plated quartz inner tube 6 and a non-gold-plated quartz outer tube 7 are sequentially arranged from the inside to the outside, and the gold-plated quartz inner tube 6 and the non-gold-plated quartz outer tube 7 There is a gap between them; the upper furnace shell 21, the upper thermal insulation cotton 11, the upper heating resistance wire 31, the lower furnace shell 22, the lower thermal insulation co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com