Patents

Literature

30results about How to "Decreasing remanence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

R-Fe-B Rare Earth Sintered Magnet and Method for Producing Same

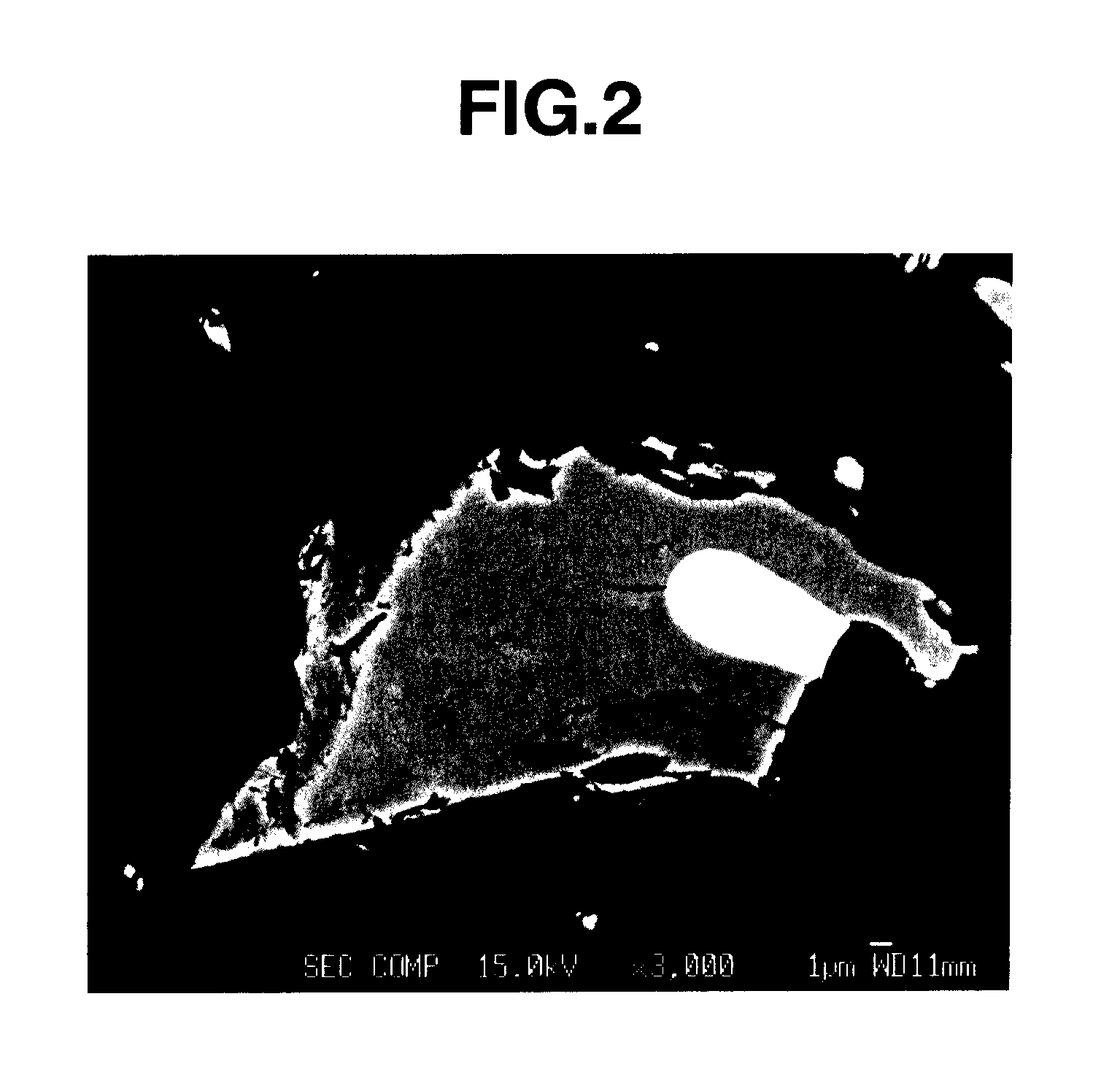

ActiveUS20080286595A1Decrease in remanence Br minimizedCoercivity HcJ can be increasedInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementMetallurgy

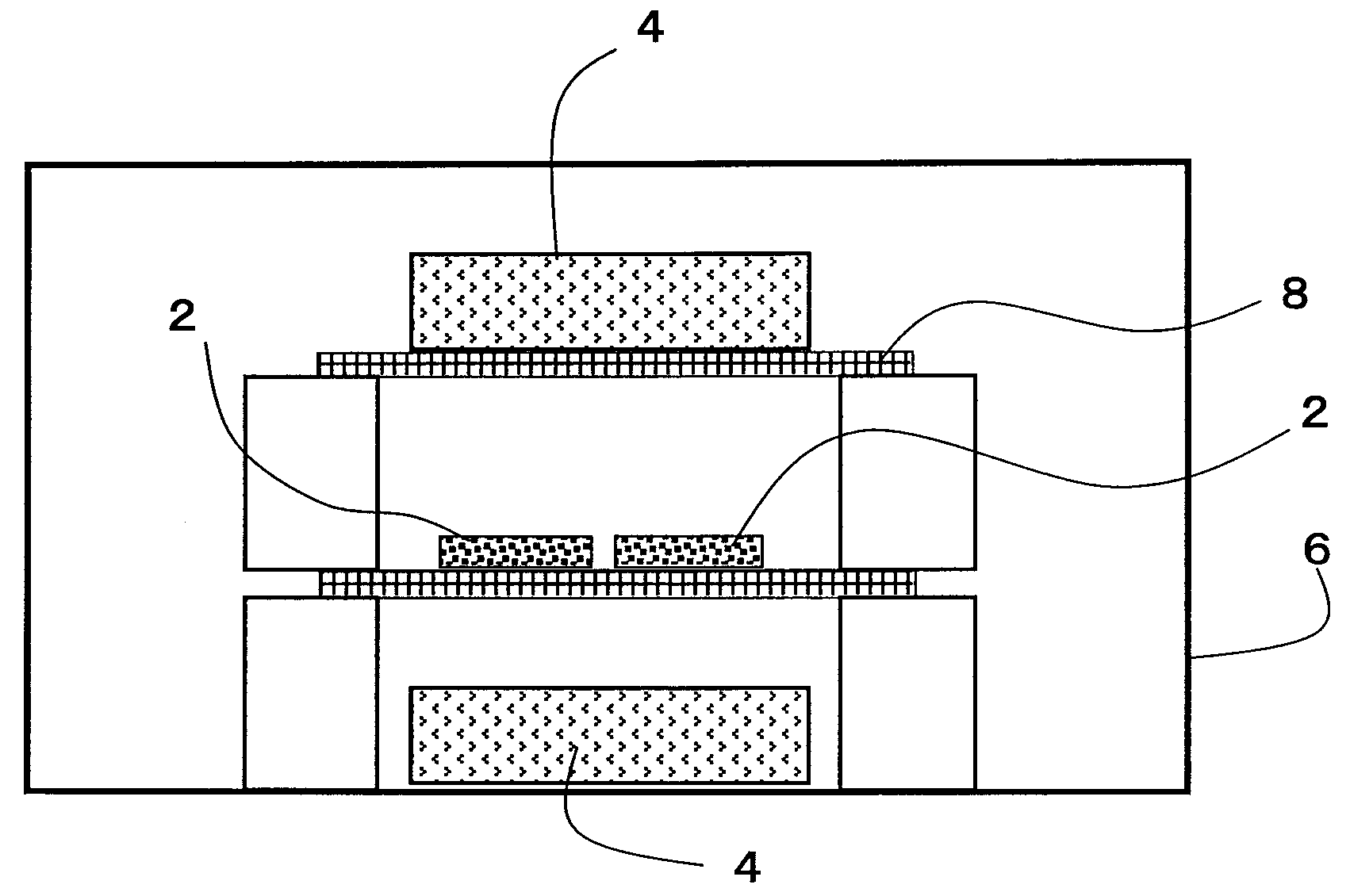

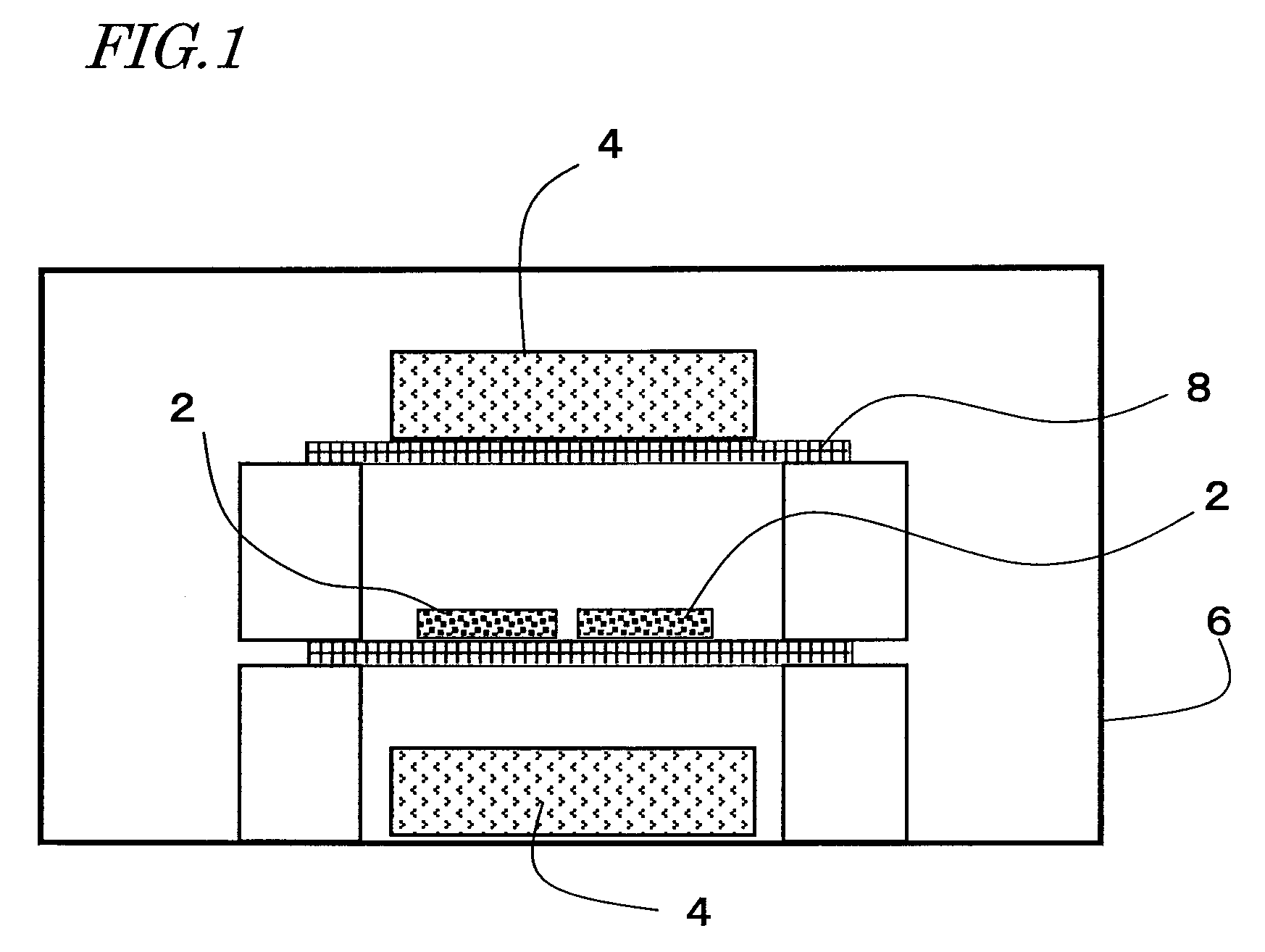

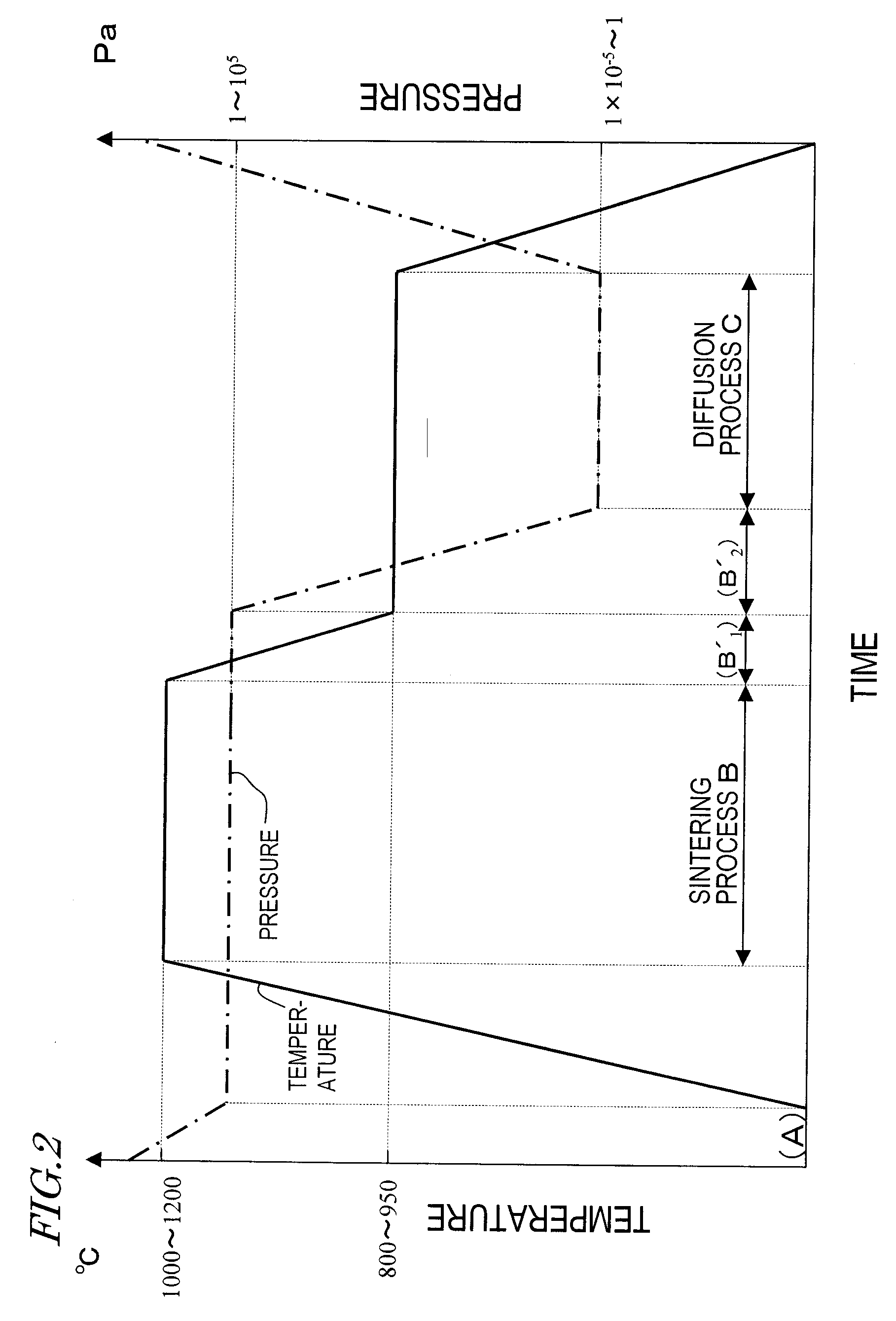

In a method for producing an R—Fe—B based rare-earth sintered magnet according to the present invention, first, provided is an R—Fe—B based rare-earth sintered magnet body including, as a main phase, crystal grains of an R2Fe14B type compound that includes a light rare-earth element RL, which is at least one of Nd and Pr, as a major rare-earth element R. Thereafter, the sintered magnet body is heated while a heavy rare-earth element RH, which is at least one element selected from the group consisting of Dy, Ho and Tb, is supplied to the surface of the sintered magnet body, thereby diffusing the heavy rare-earth element RH into the rare-earth sintered magnet body.

Owner:HITACHI METALS LTD

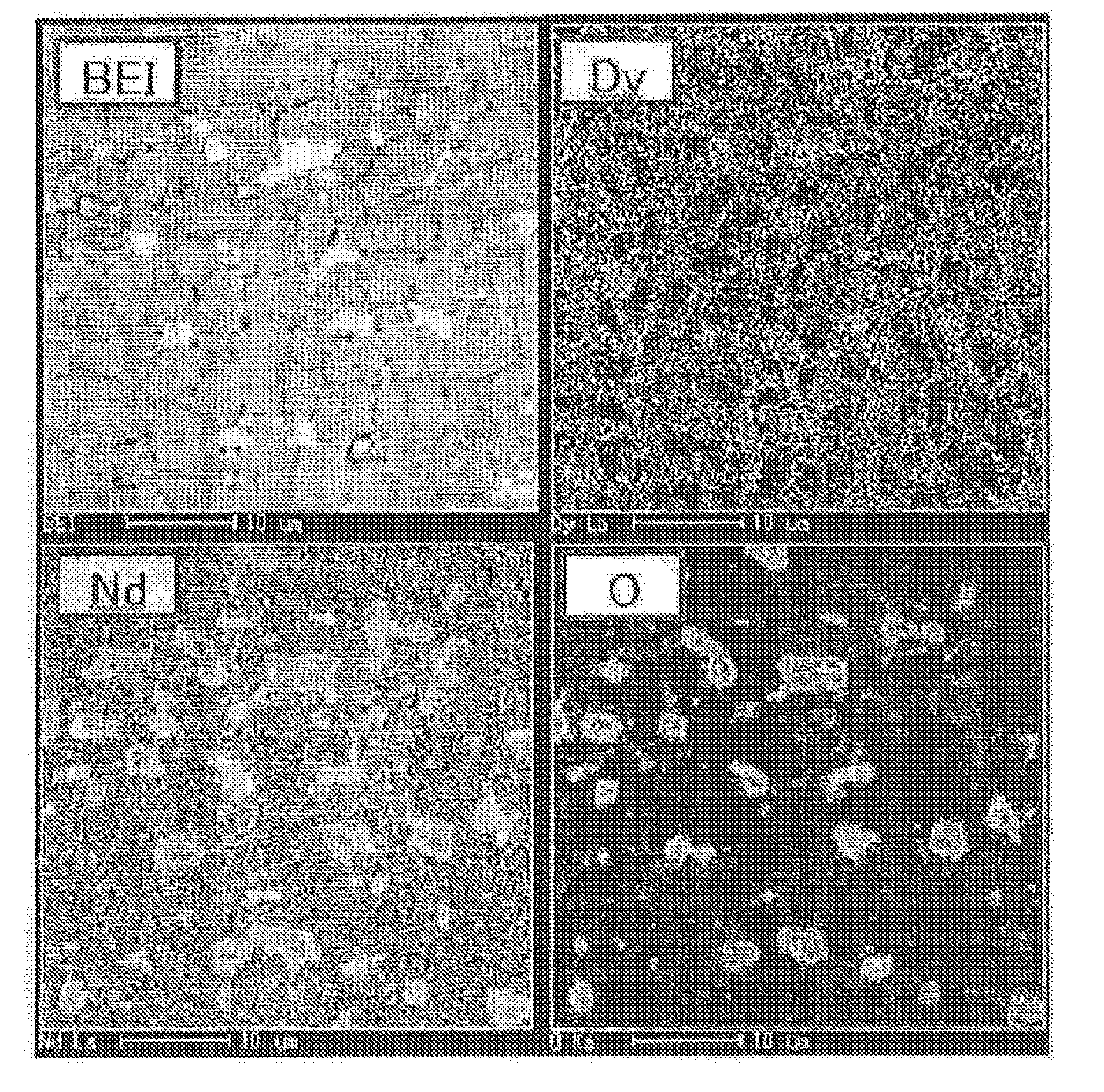

Rare earth magnet and its preparation

ActiveUS20110000586A1Prevent oxidationMinimal hazardTransportation and packagingMetal-working apparatusRare-earth elementRare-earth magnet

A rare earth magnet is prepared by disposing a R1-T-B sintered body comprising a R12T14B compound as a major phase in contact with an R2-M alloy powder and effecting heat treatment for causing R2 element to diffuse into the sintered body. The alloy powder is obtained by quenching a melt containing R2 and M. R1 and R2 are rare earth elements, T is Fe and / or Co, M is selected from B, C, P, Al, Si, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ga, Ge, Zr, Nb, Mo, Ag, In, Sn, Sb, Hf, Ta, W, Pt, Au, Pb, and Bi.

Owner:SHIN ETSU CHEM IND CO LTD

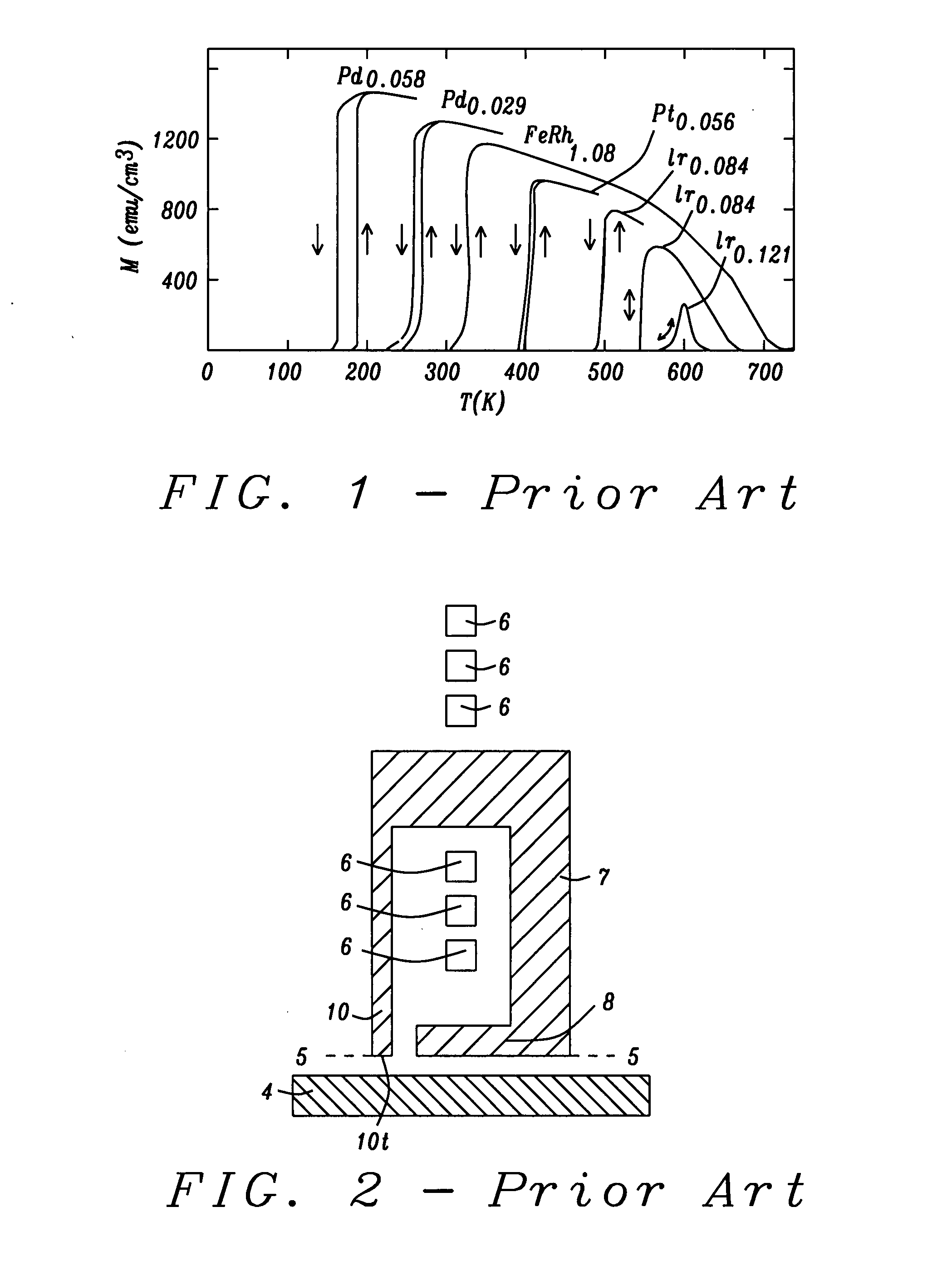

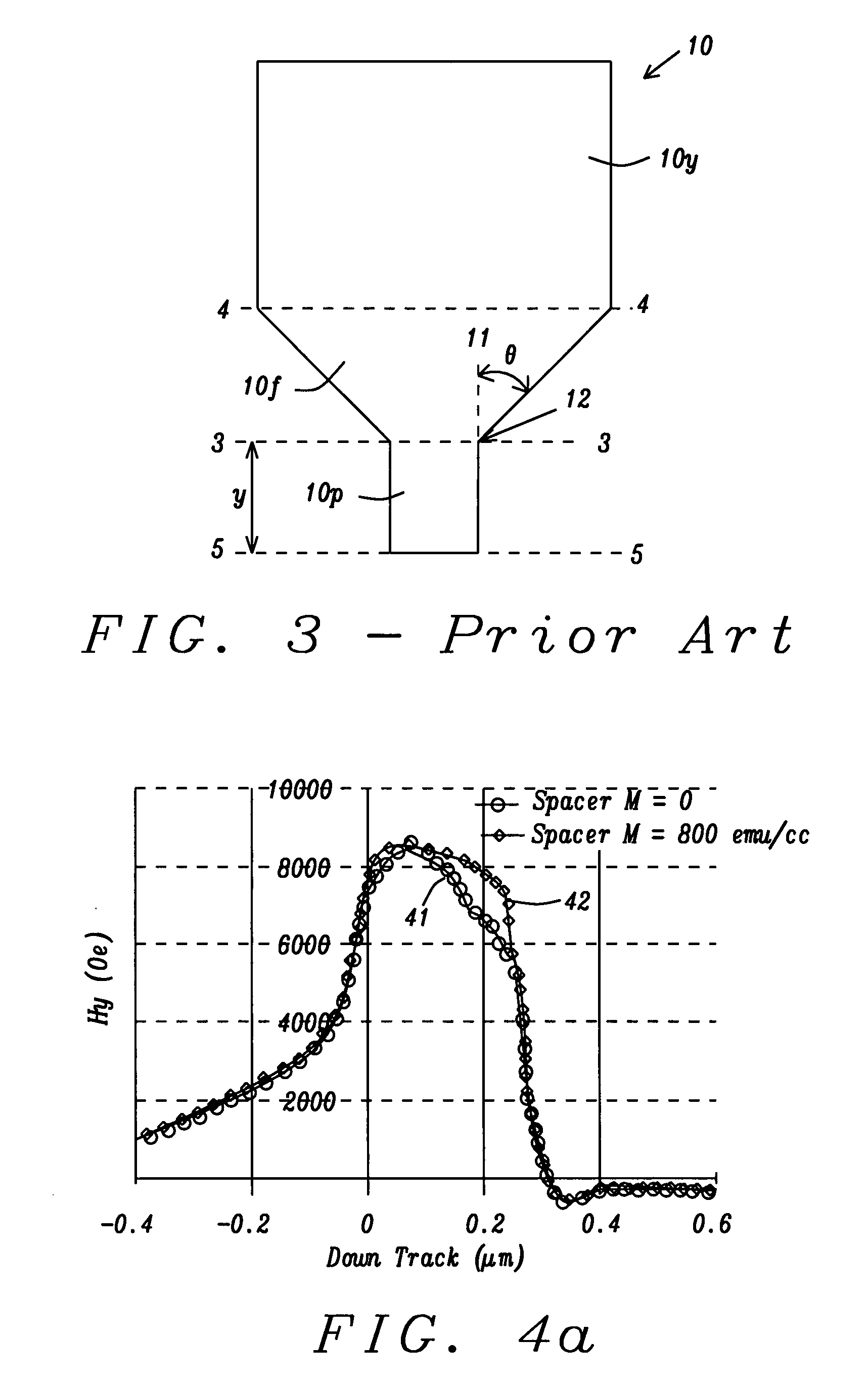

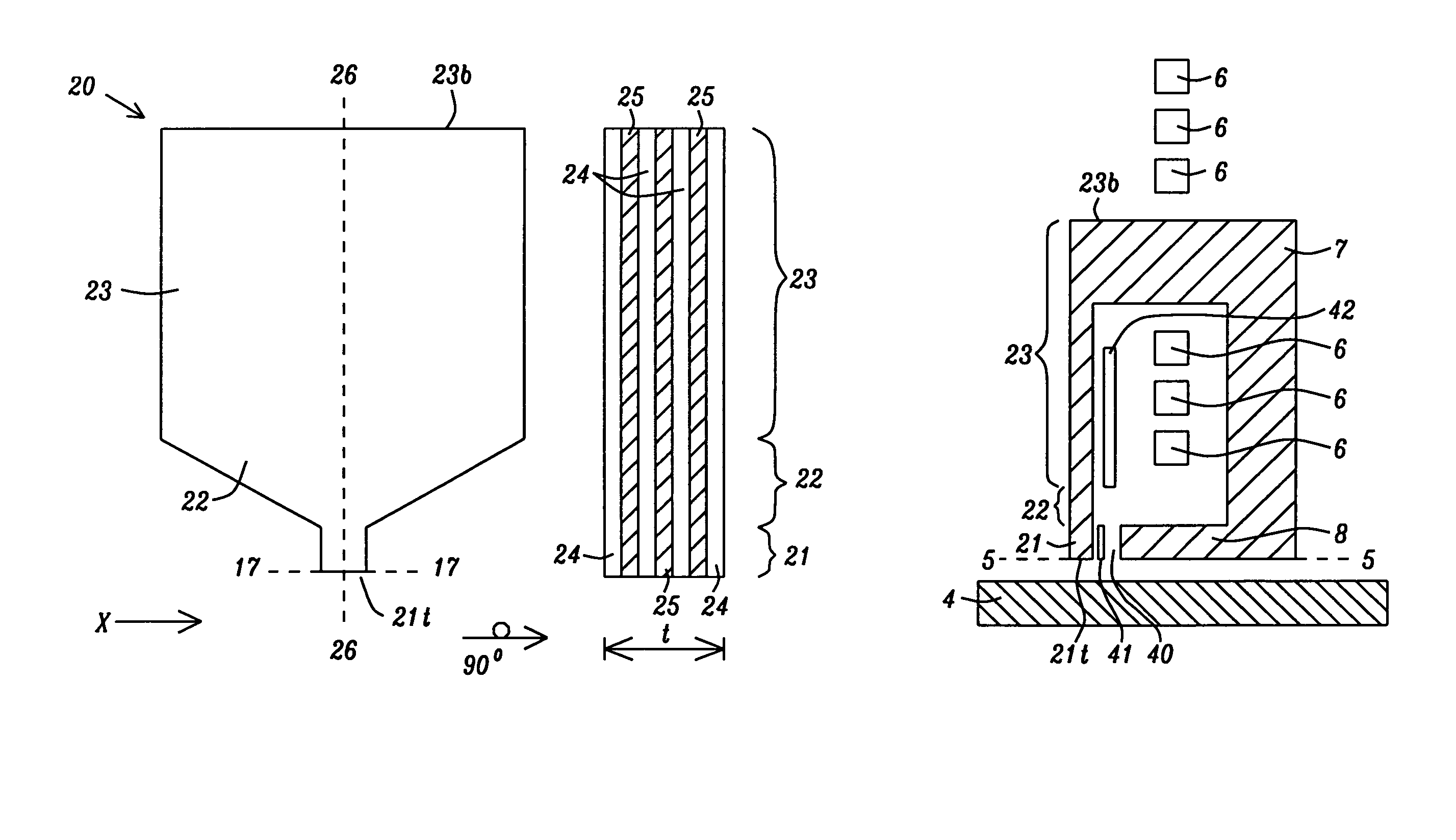

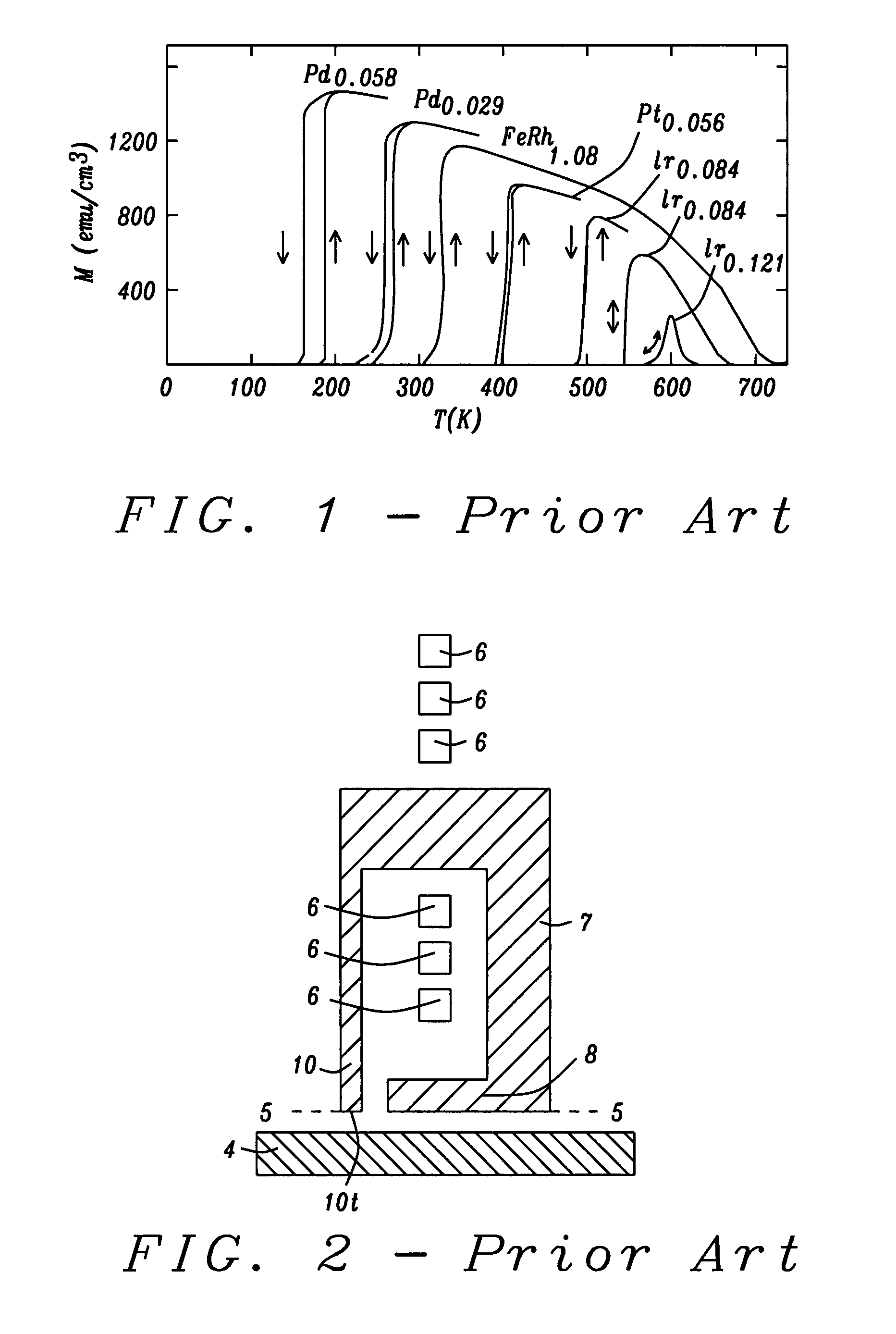

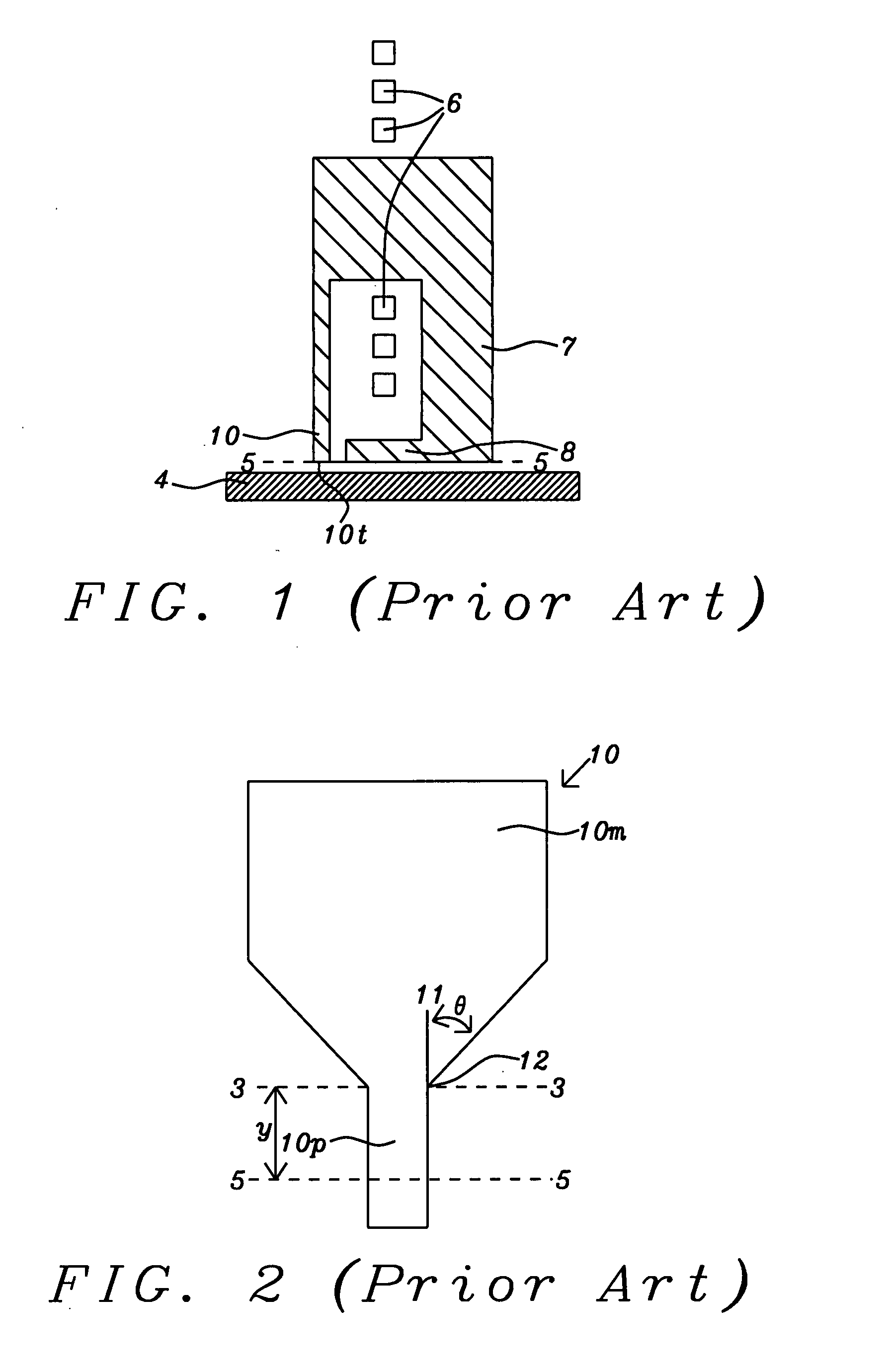

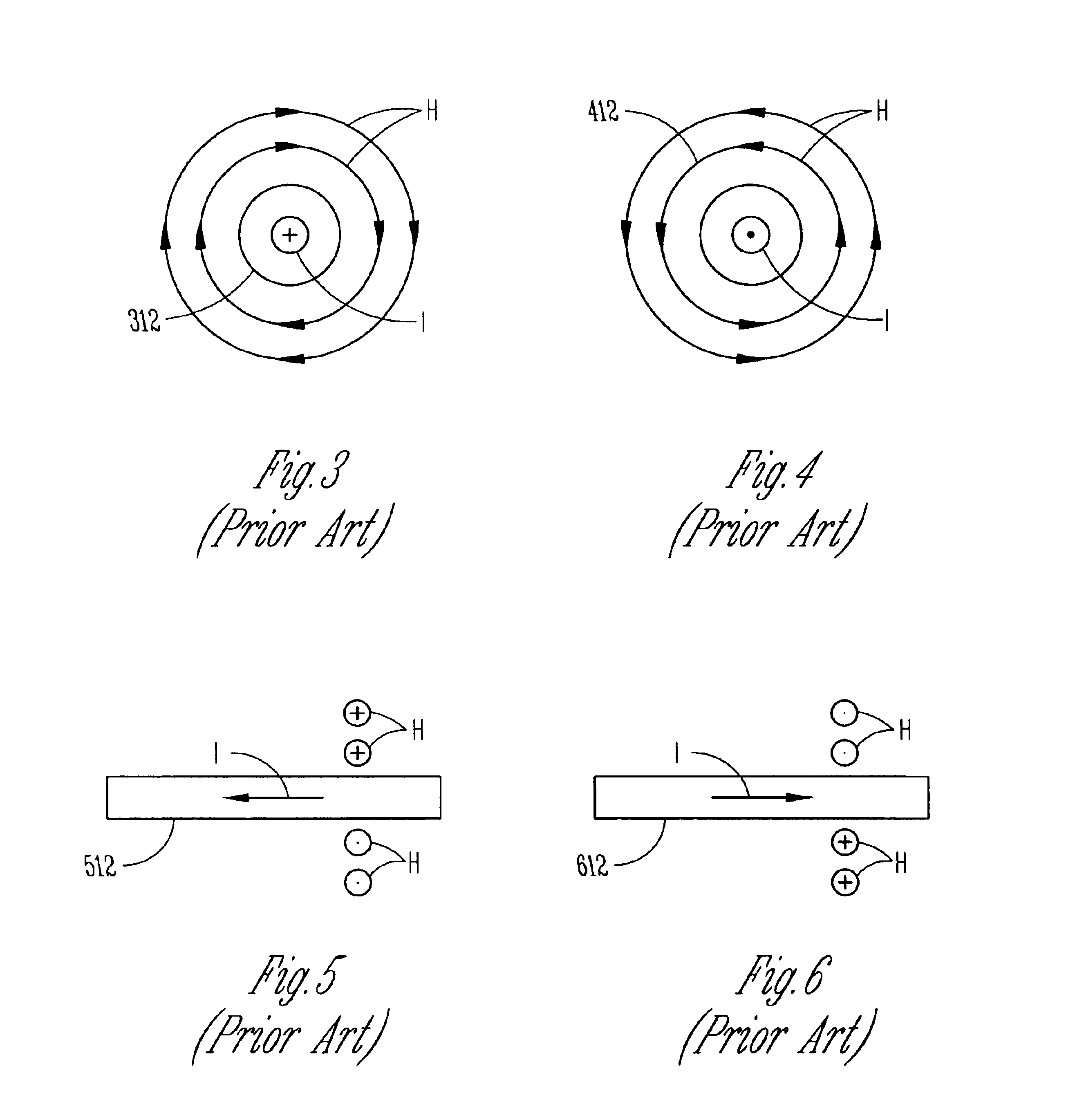

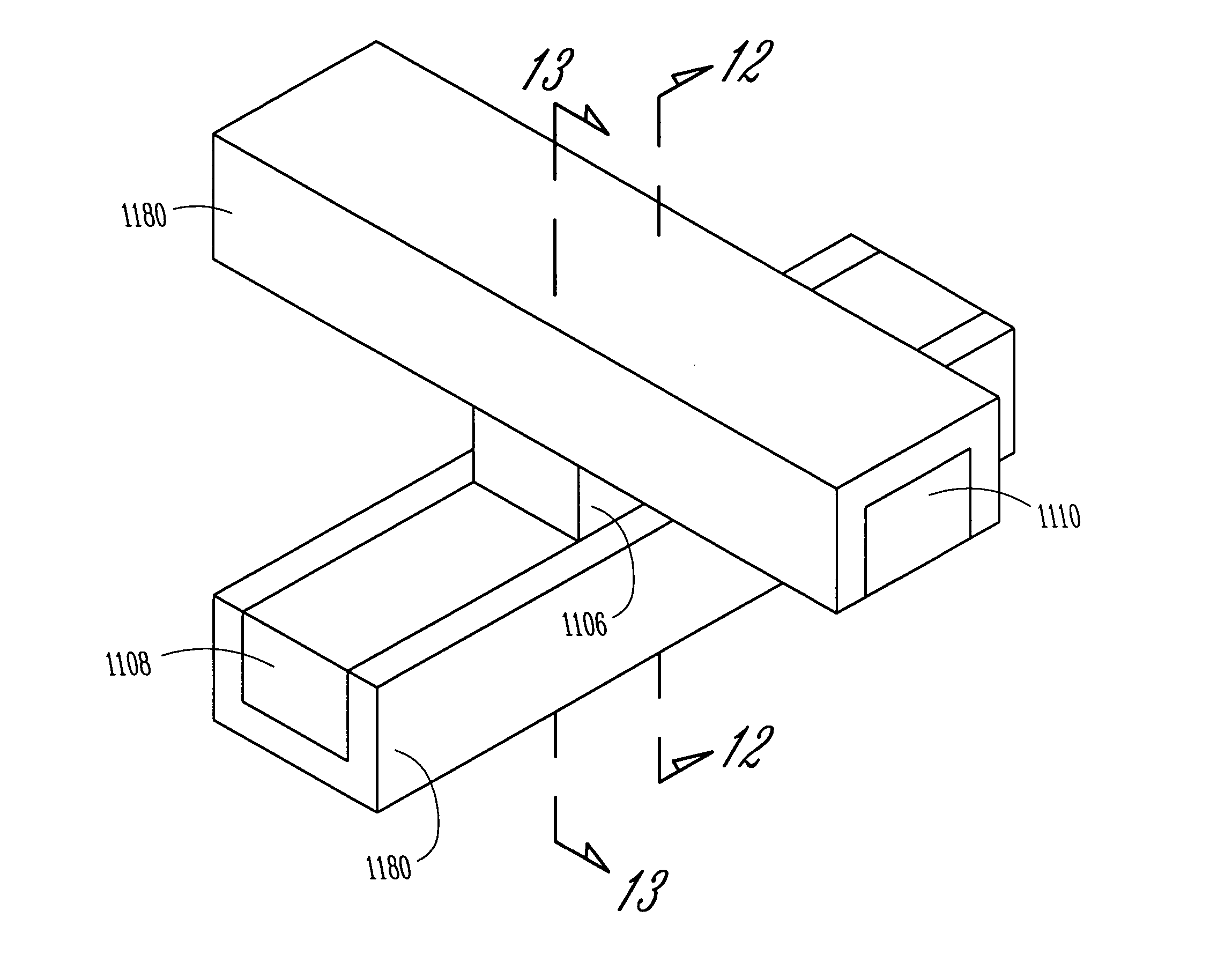

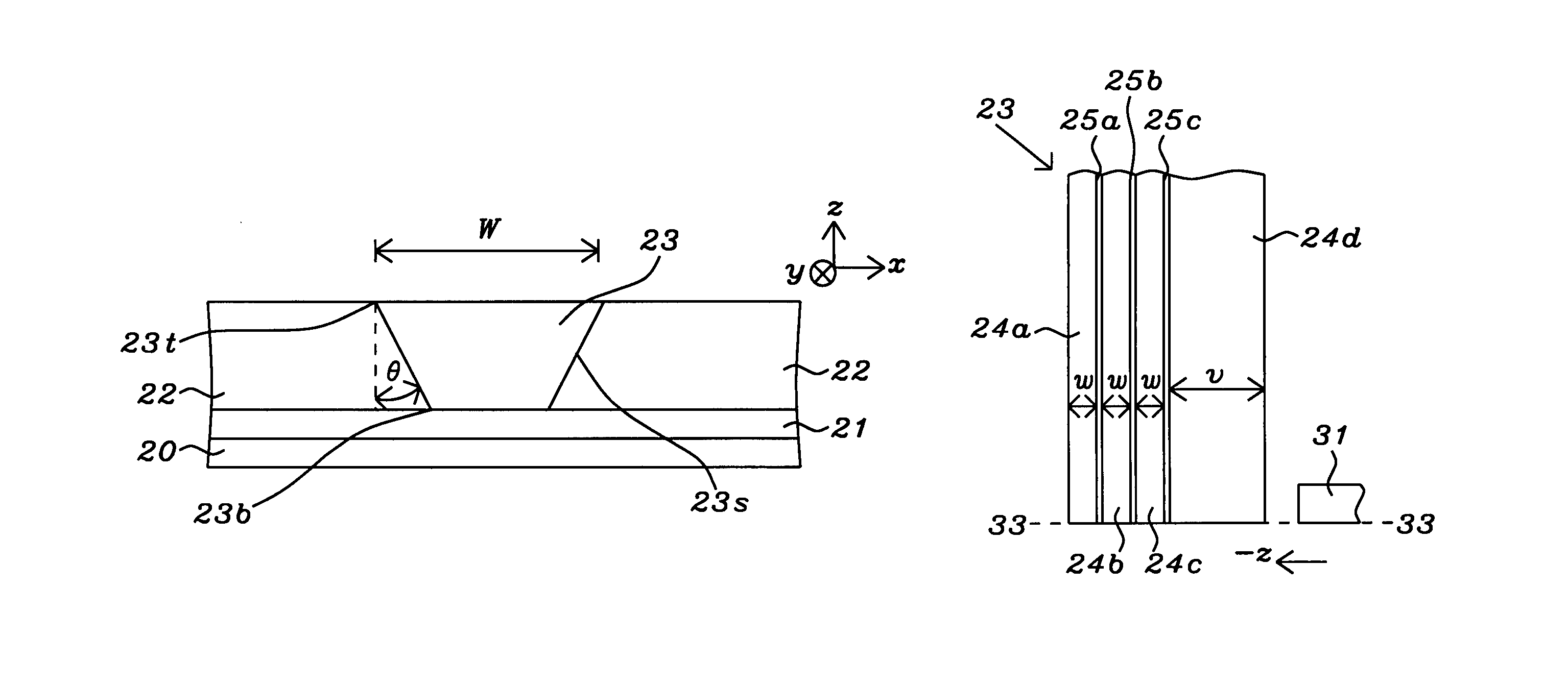

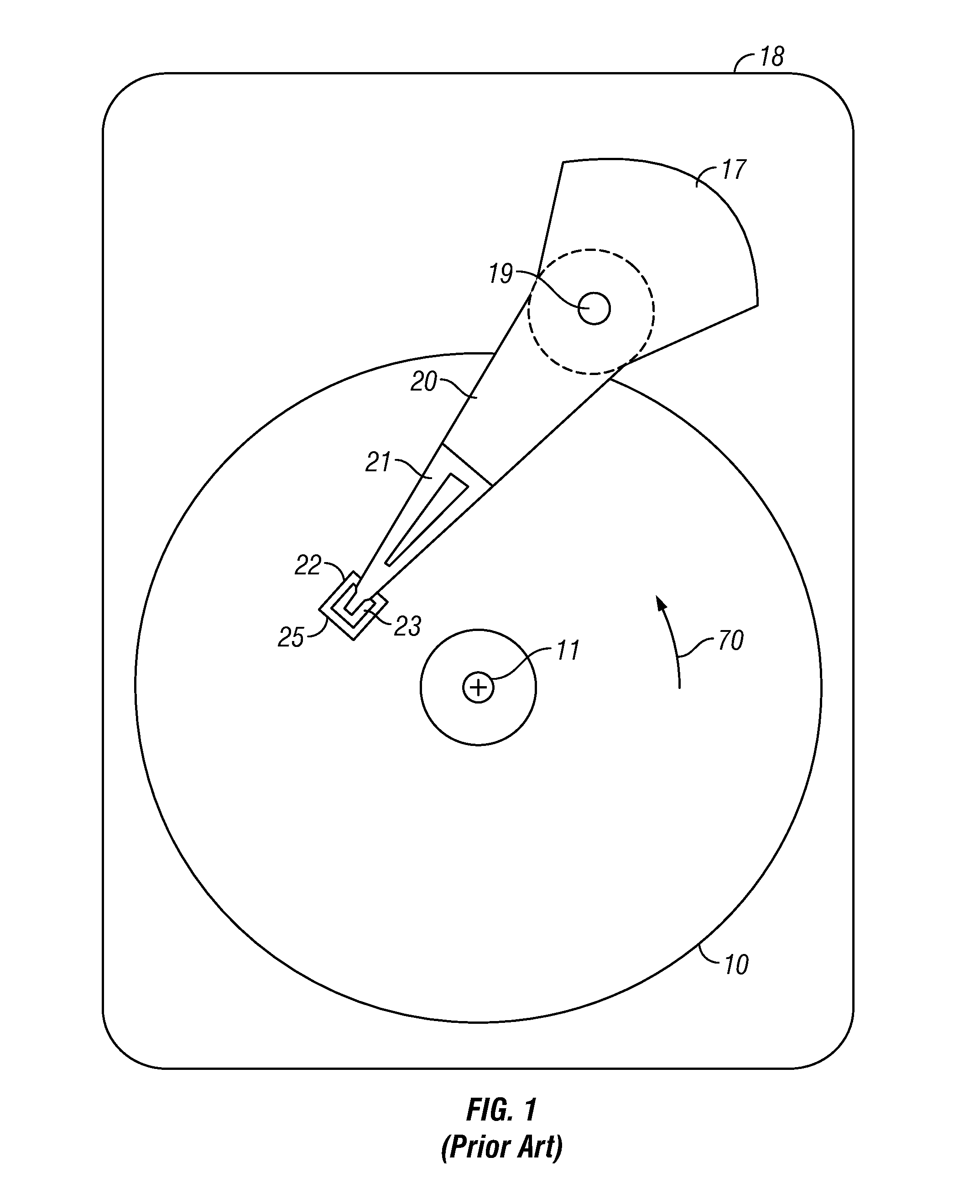

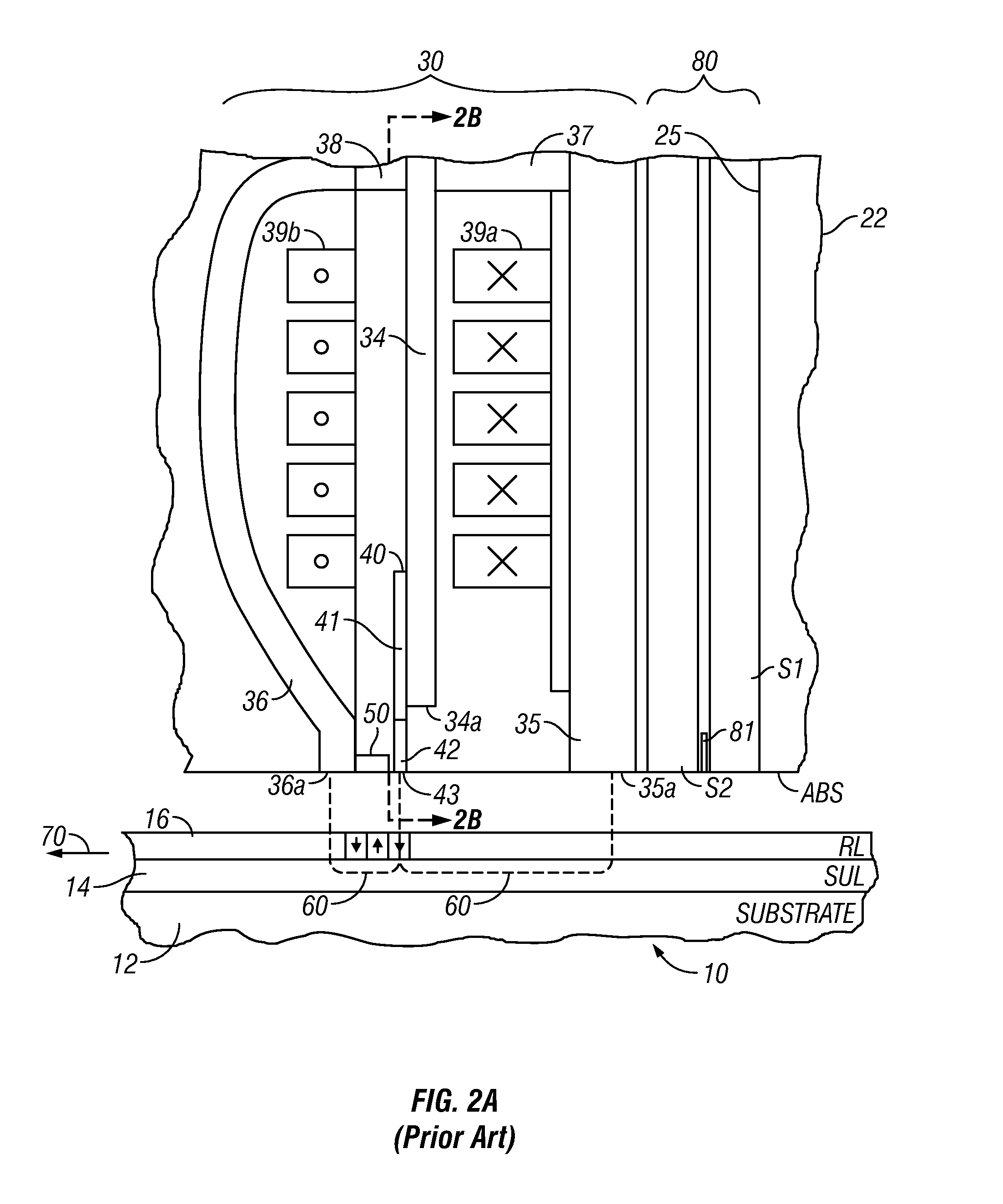

Perpendicular magnetic recording head laminated with AFM-FM phase change material

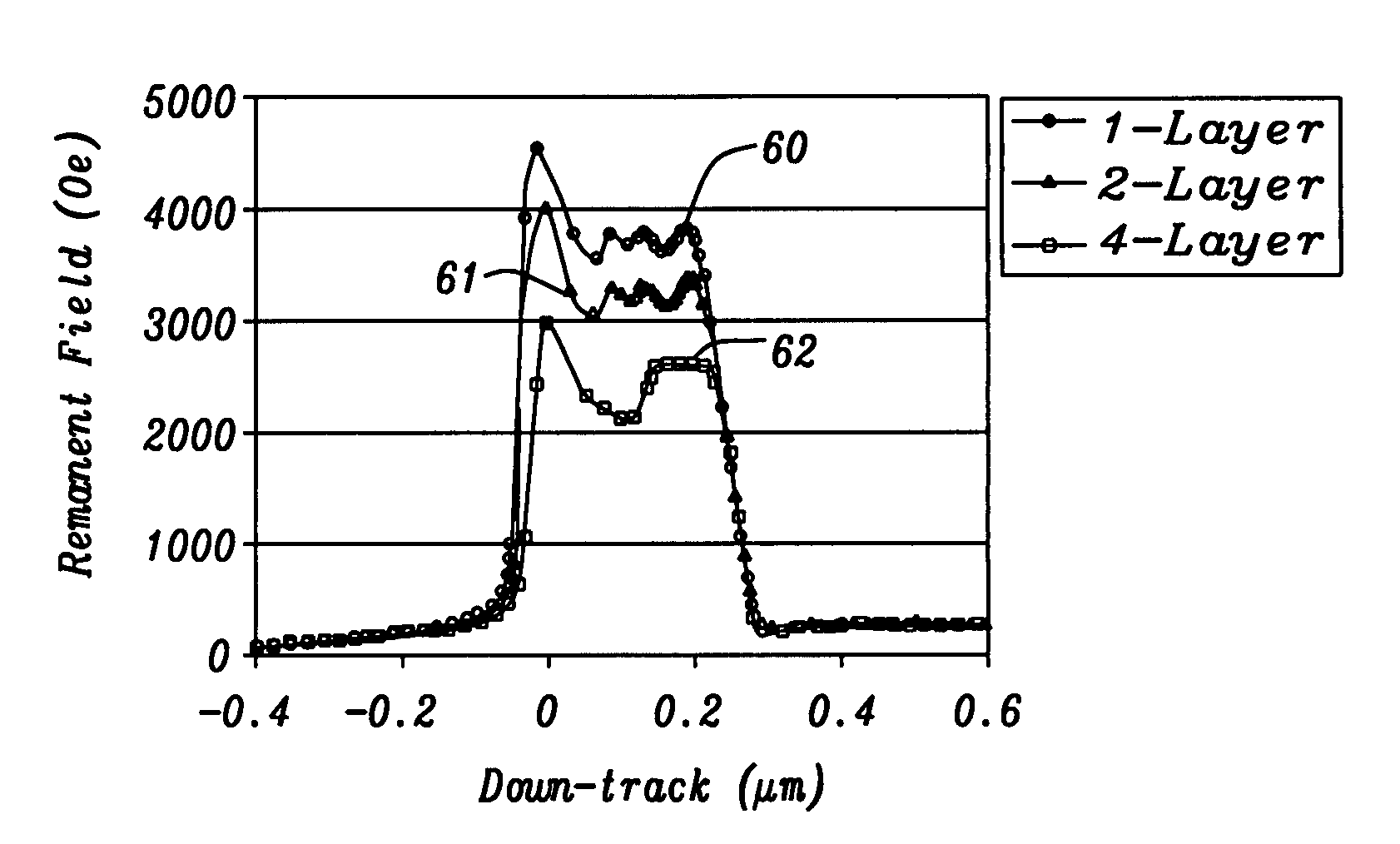

InactiveUS20090052092A1Decreasing remanenceMinimize pole erasureRecord information storageManufacture of flux-sensitive headsAlloyPhase-change material

A PMR writer is disclosed that minimizes pole erasure during non-writing and maximize write field during writing through an AFM-FM phase change material that is in an AFM state during non-writing and switches to a FM state by heating during writing. The main pole layer including the write pole may be comprised of a laminated structure having a plurality of “n” ferromagnetic layers and “n-1” AFM-FM phase change material layers arranged in an alternating manner. The AFM-FM phase change material is preferably a FeRh or FeRhX alloy (X=Pt, Pd, or Ir) having a Rh content >35 atomic %. AFM-FM phase change material may also be used as a flux gate to prevent yoke flux from leaking into the write pole tip. Heating for the AFM to FM transition is provided by write coils and / or a coil located near the AFM-FM phase change material to enable faster transition times.

Owner:HEADWAY TECH INC

Perpendicular magnetic recording head laminated with AFM-FM phase change material

InactiveUS8004794B2Decreasing remanenceMinimize pole erasureRecord information storageManufacture of flux-sensitive headsEngineeringAlloy

Owner:HEADWAY TECH INC

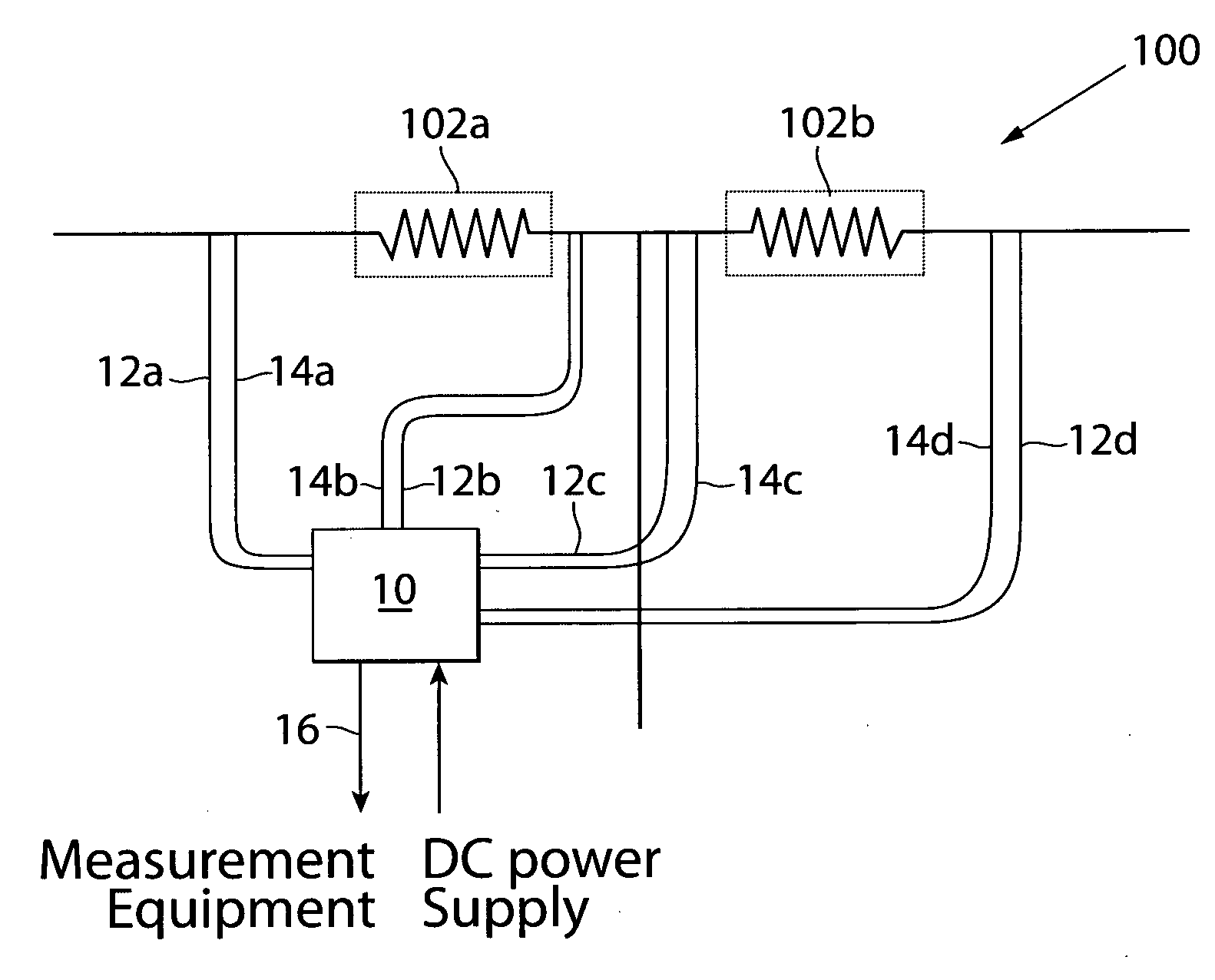

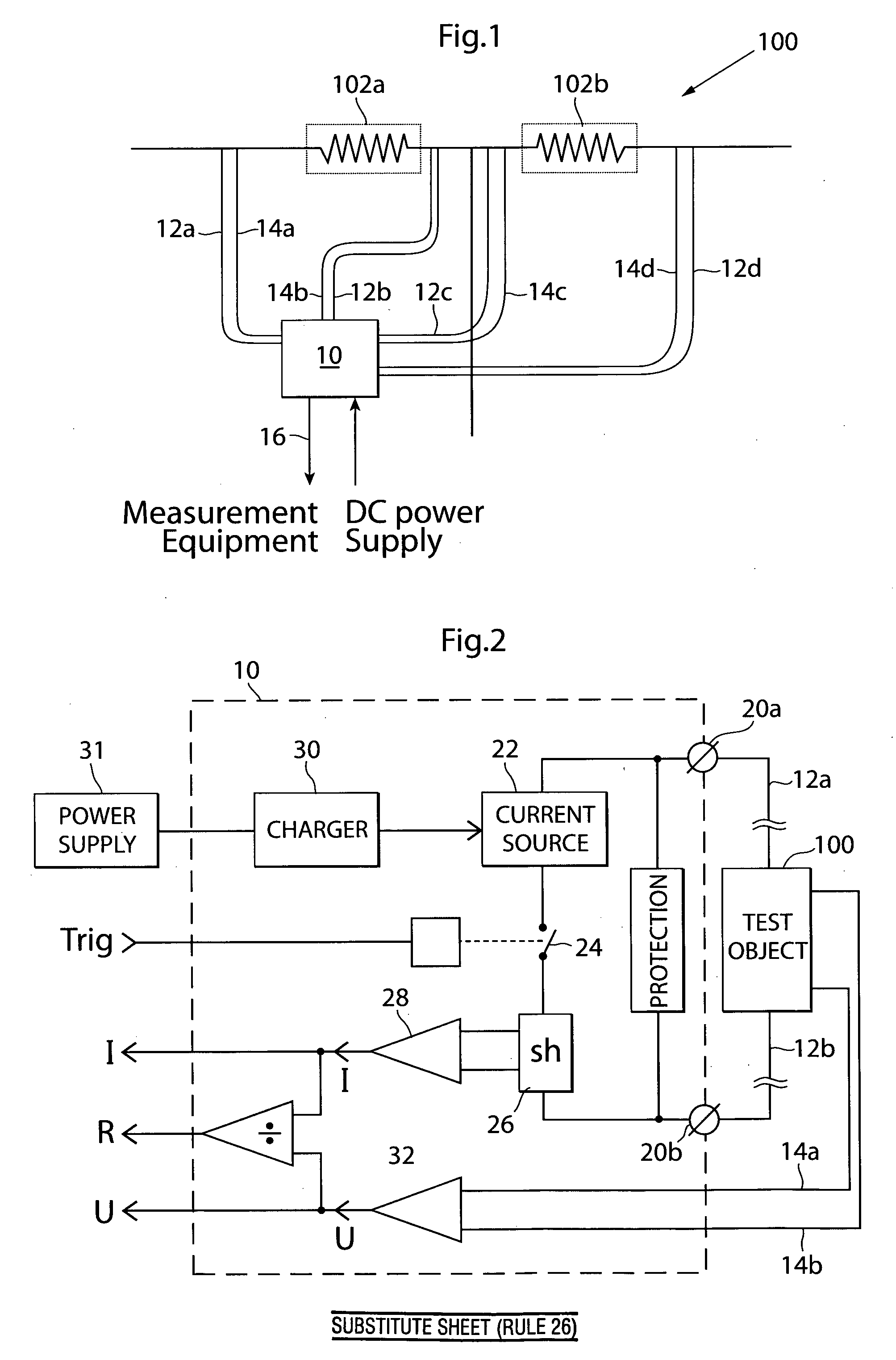

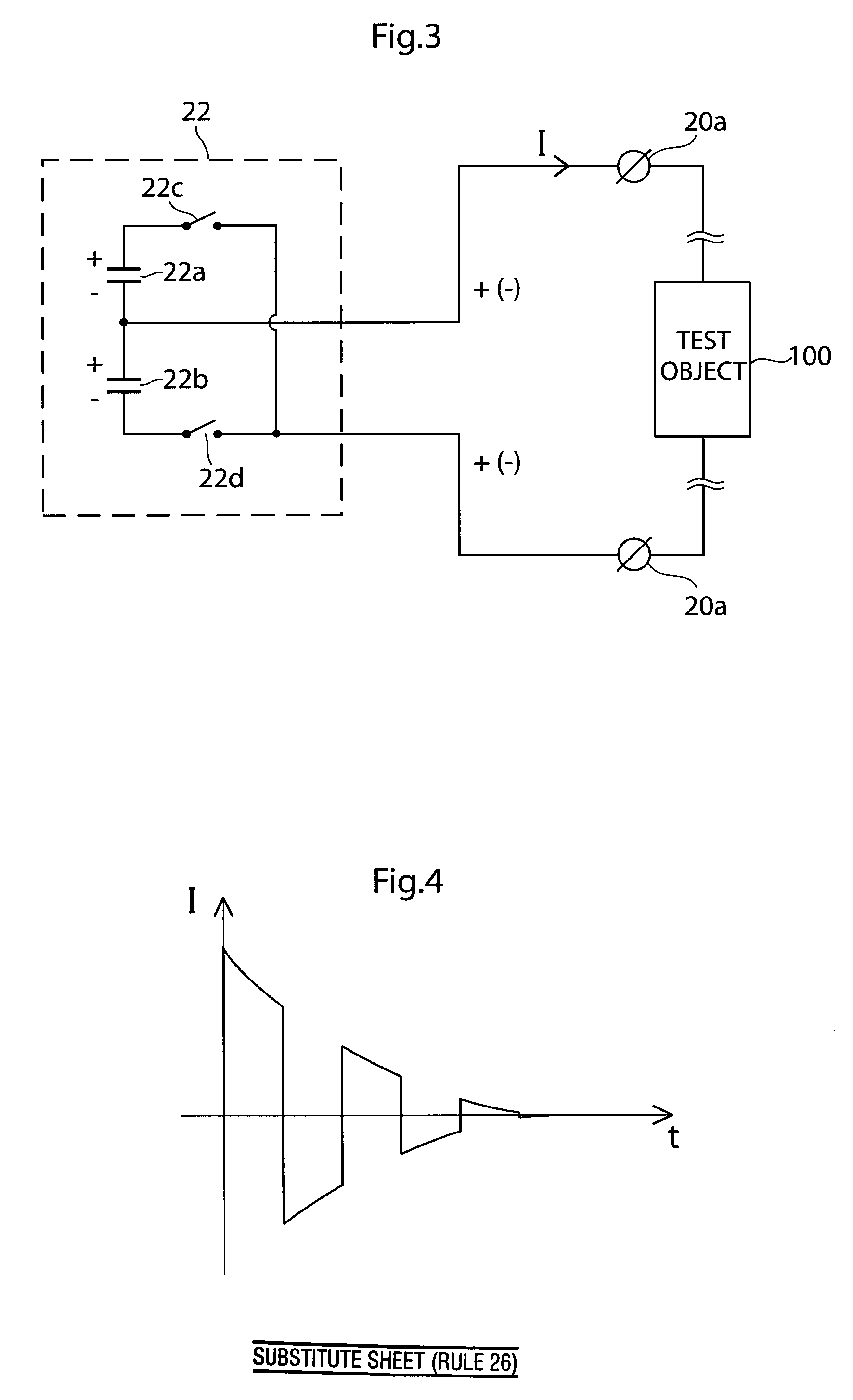

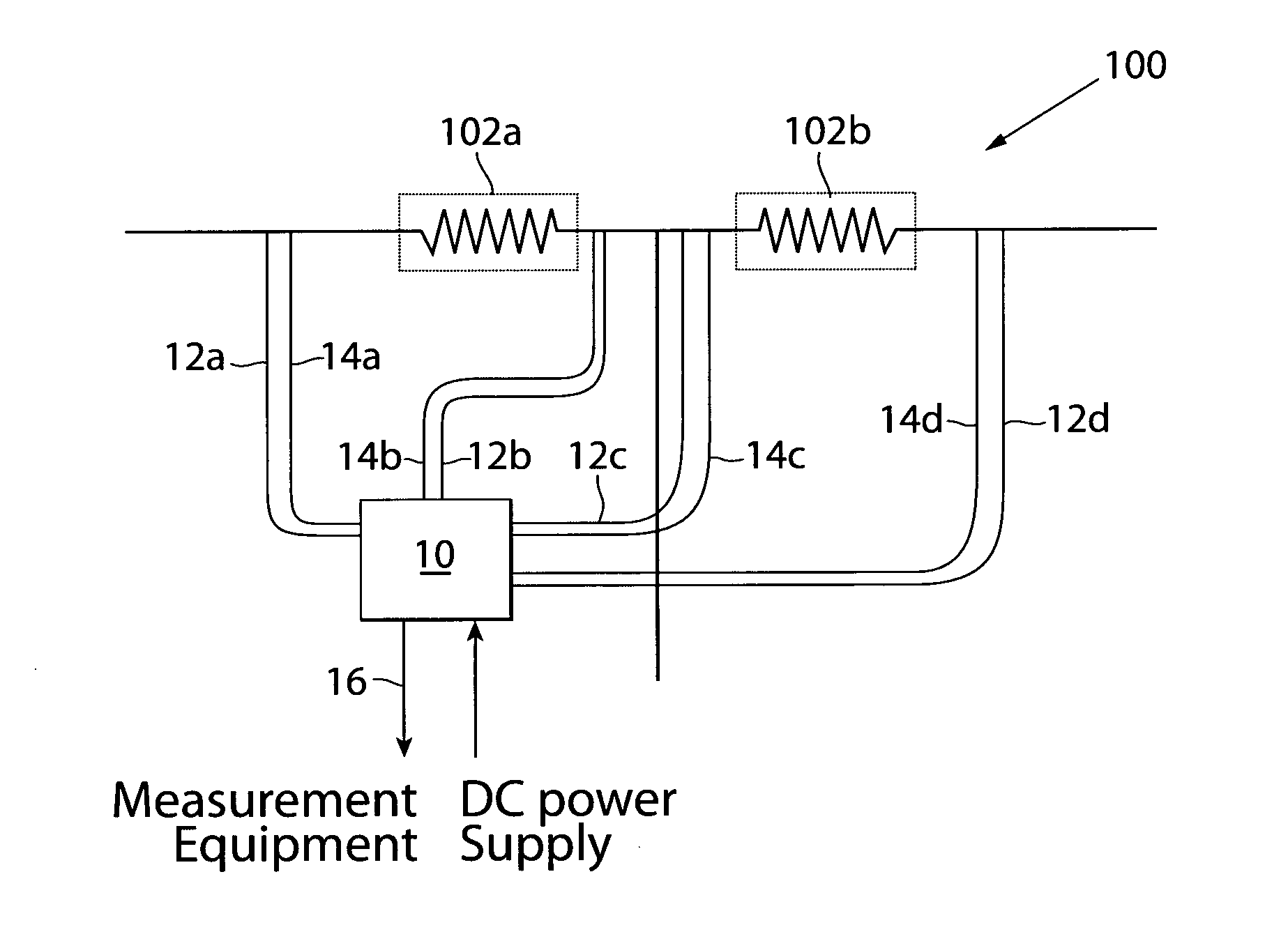

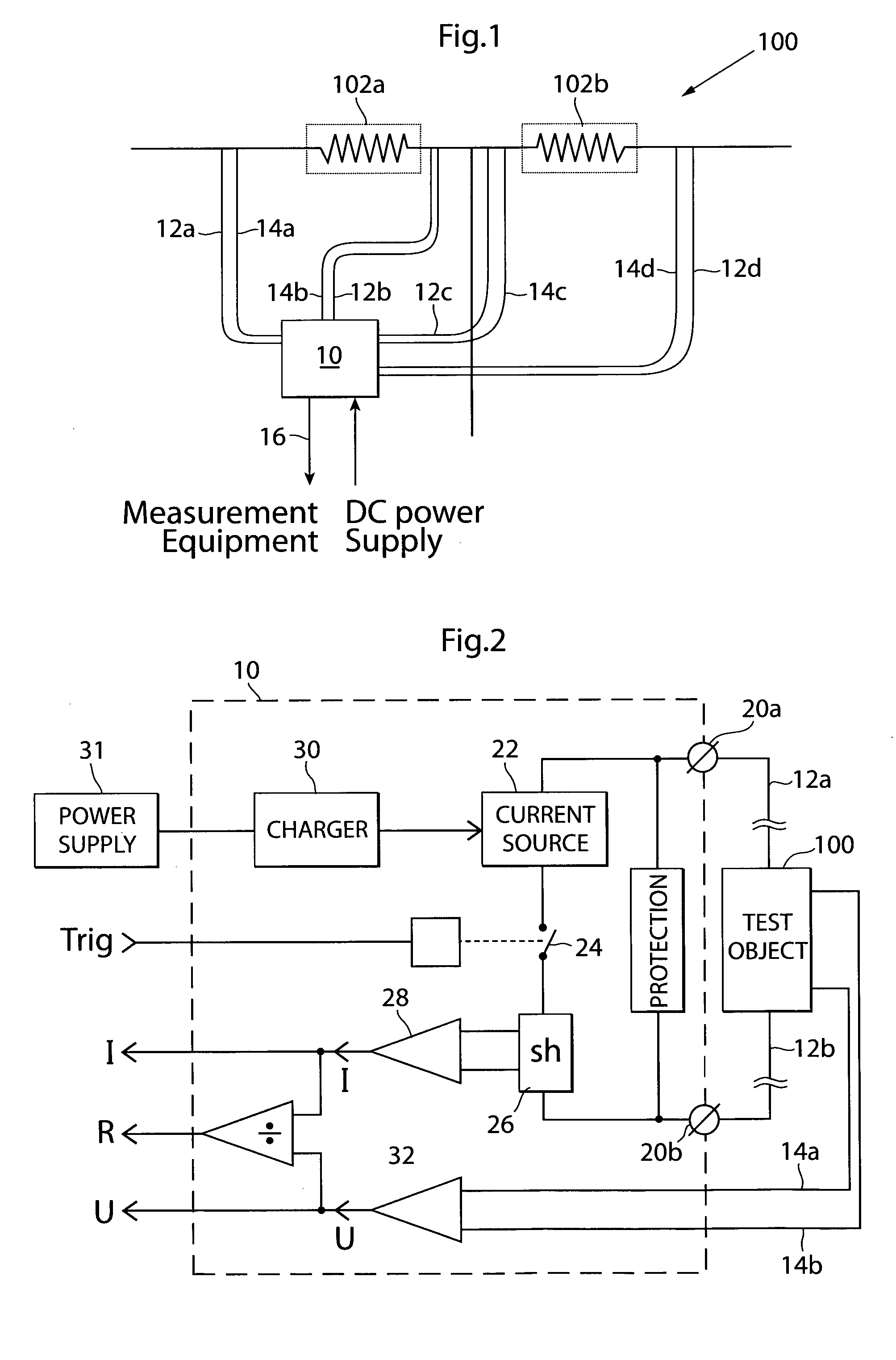

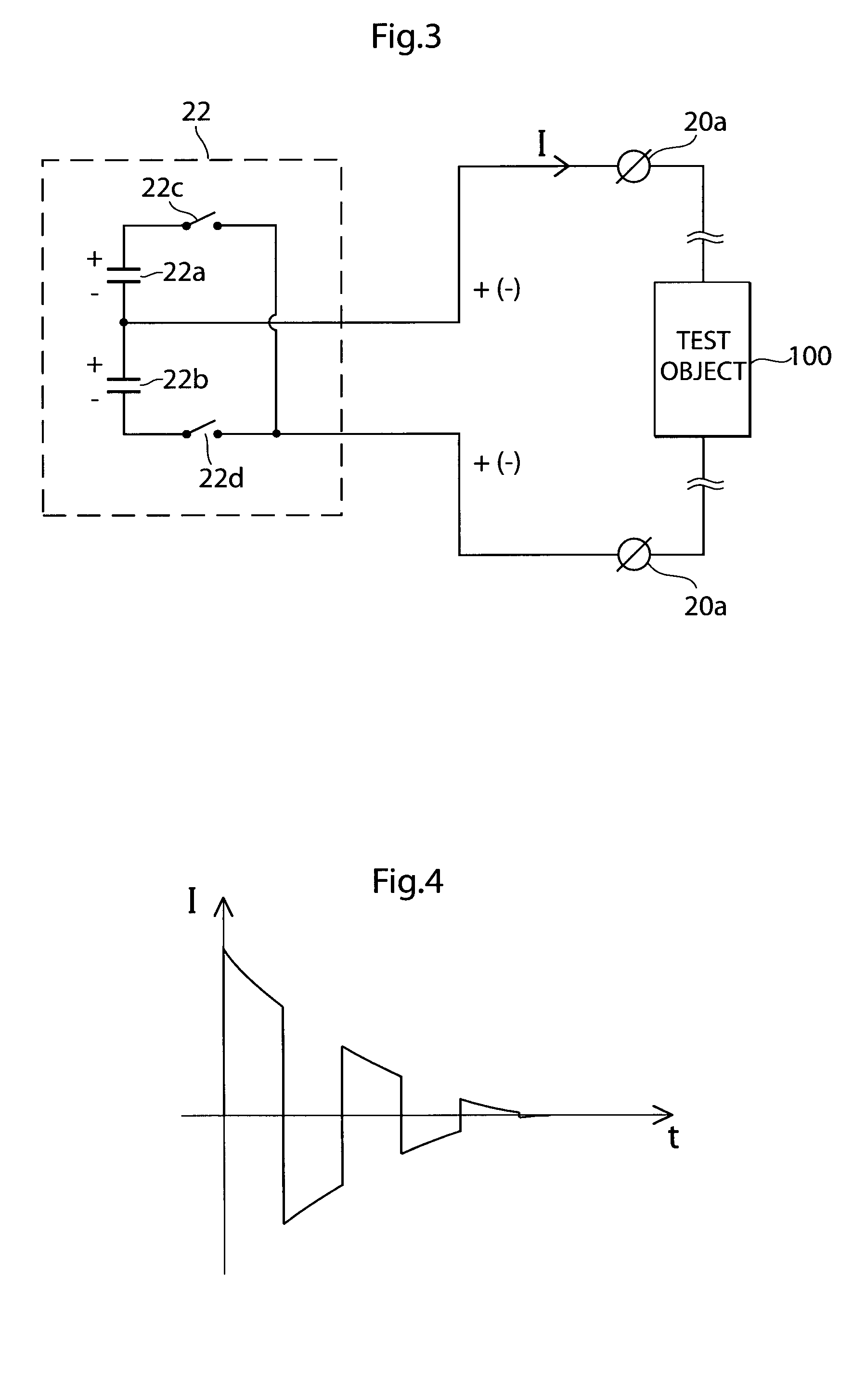

Resistance Measurement in High Power Apparatus Environments

ActiveUS20110084715A1Easy to useContinuous operationResistance/reactance/impedenceFault locationPhysicsTest object

A measuring device for measuring the resistance of high power apparatuses comprises a current source connect-able to a test object, and means for measuring, wherein the current source is a capacitor. By providing the current source as a capacitor, a light weight device is obtained which can be used essentially continuously without periods of non-use during recharging.

Owner:MEGGER SWEDEN

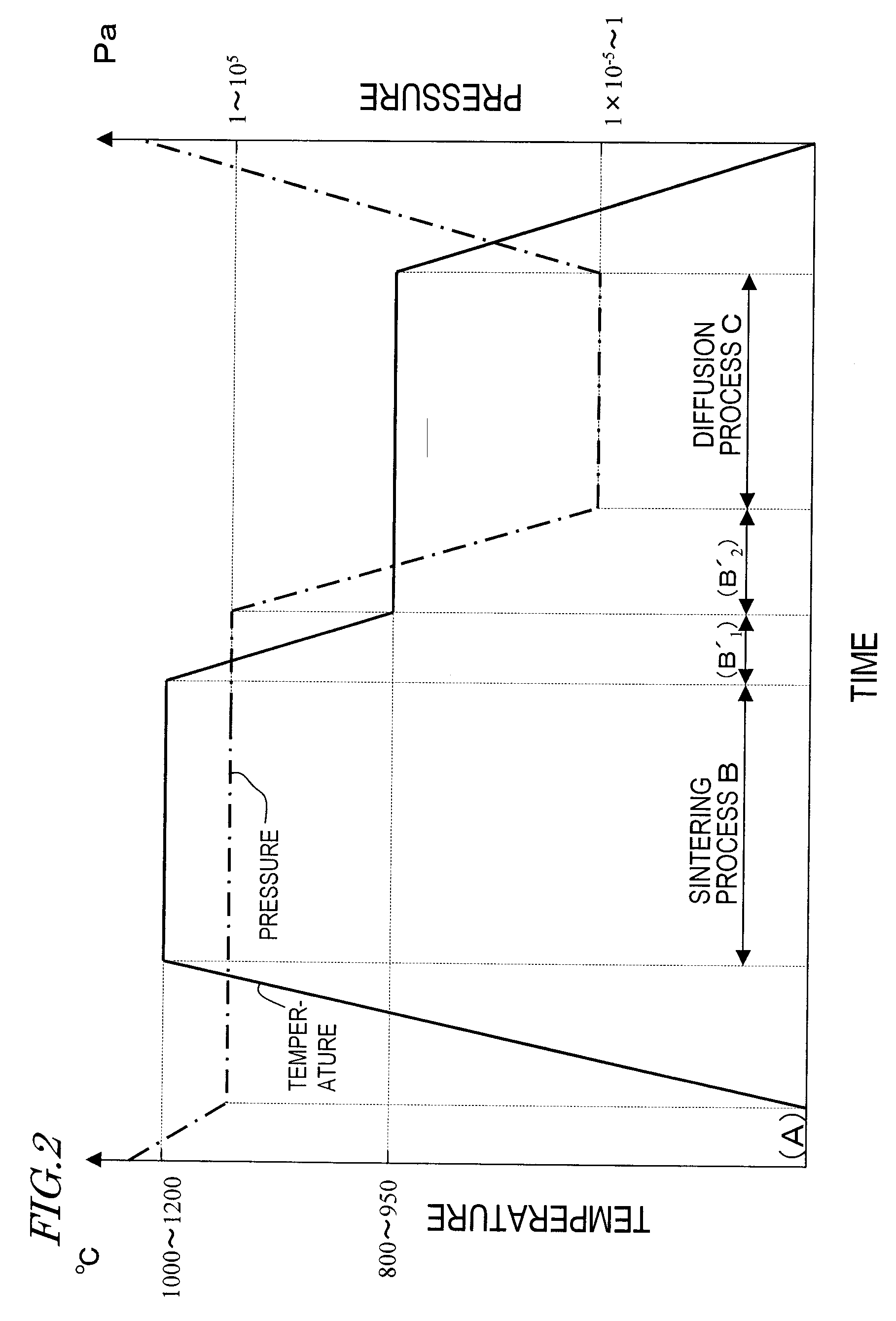

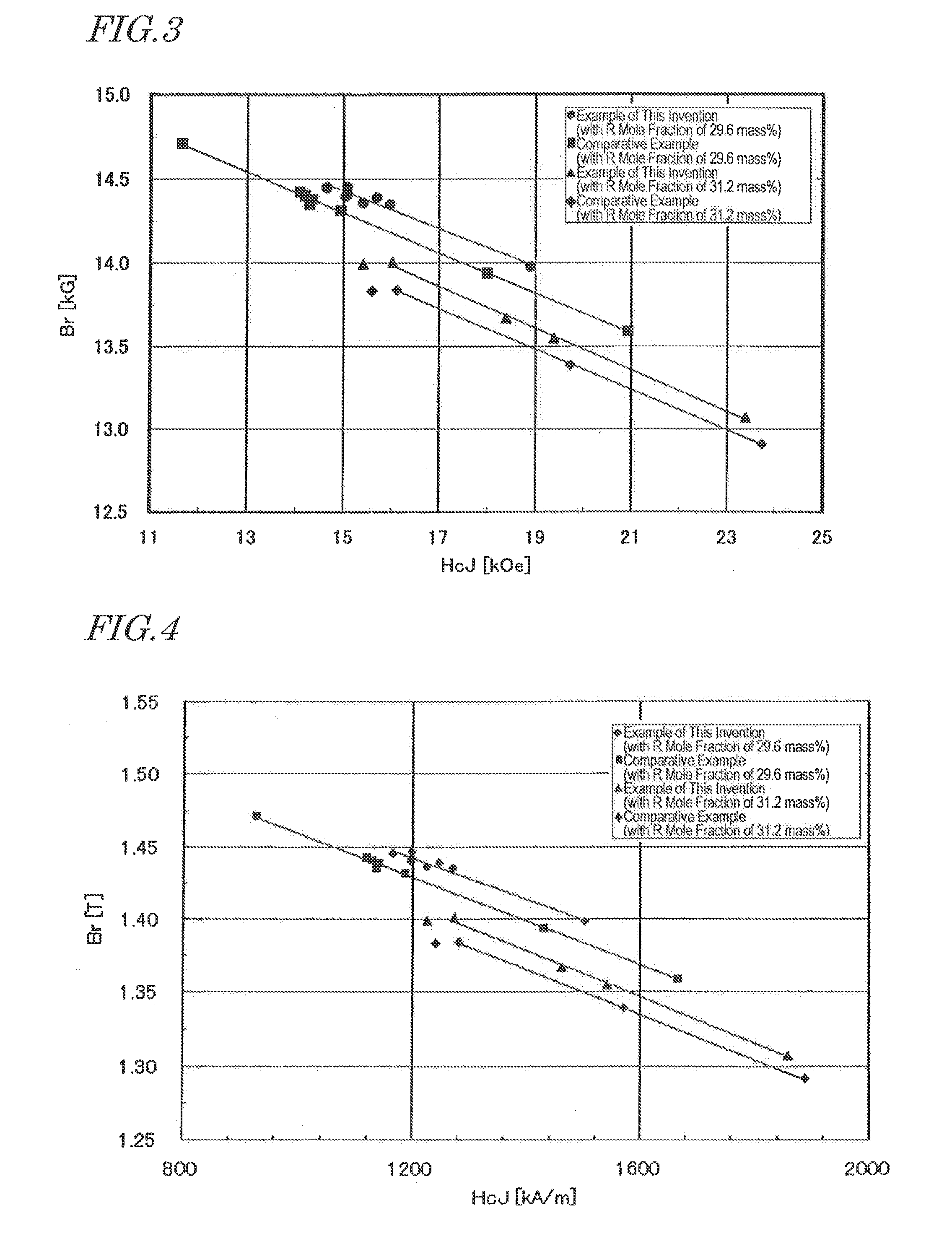

R—Fe—B rare earth sintered magnet and method for producing same

ActiveUS8206516B2Increase in coercivityDecreasing remanenceInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementMetallurgy

In a method for producing an R—Fe—B based rare-earth sintered magnet according to the present invention, first, provided is an R—Fe—B based rare-earth sintered magnet body including, as a main phase, crystal grains of an R2Fe14B type compound that includes a light rare-earth element RL, which is at least one of Nd and Pr, as a major rare-earth element R. Thereafter, the sintered magnet body is heated while a heavy rare-earth element RH, which is at least one element selected from the group consisting of Dy, Ho and Tb, is supplied to the surface of the sintered magnet body, thereby diffusing the heavy rare-earth element RH into the rare-earth sintered magnet body.

Owner:HITACHI METALS LTD

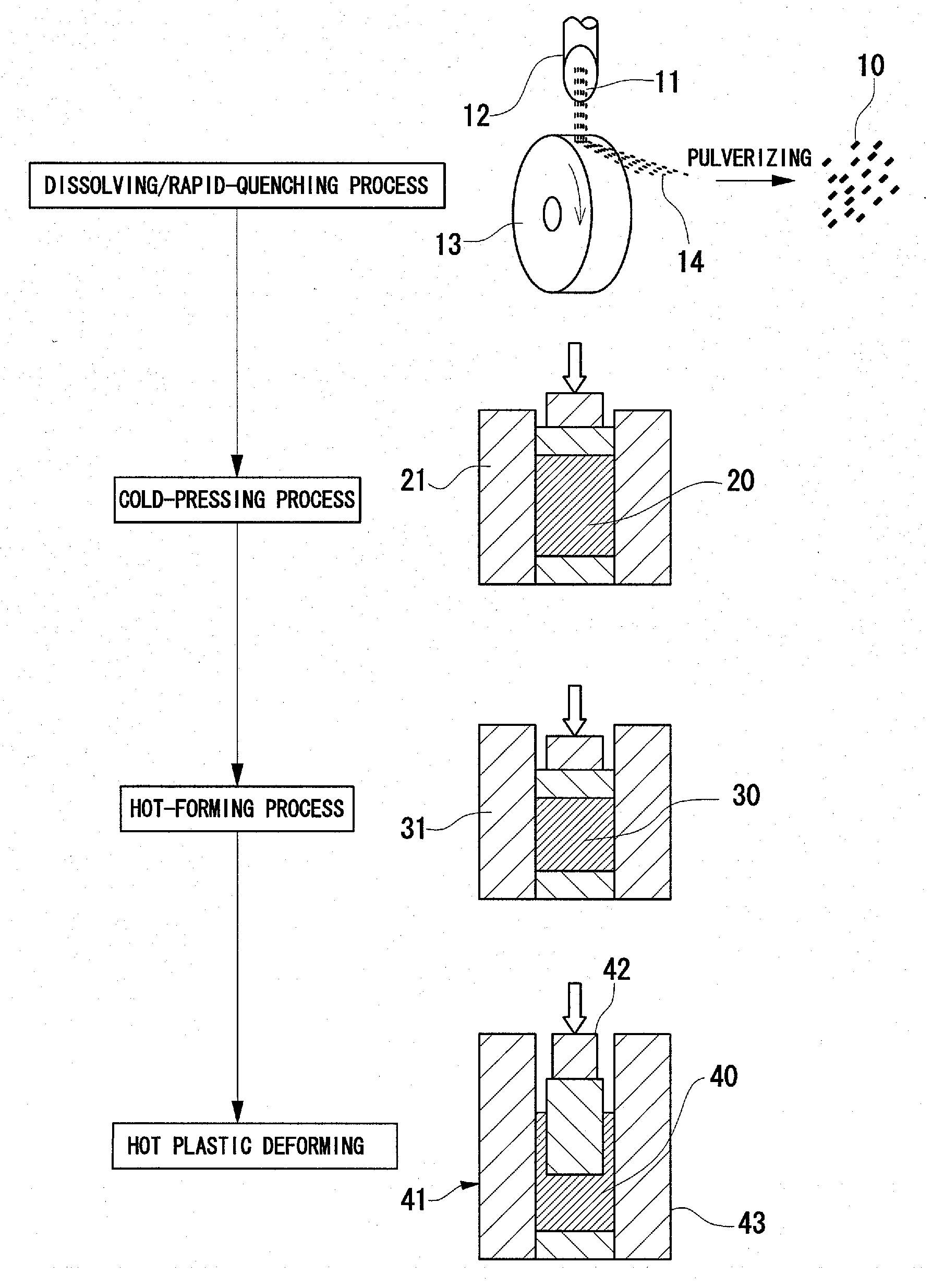

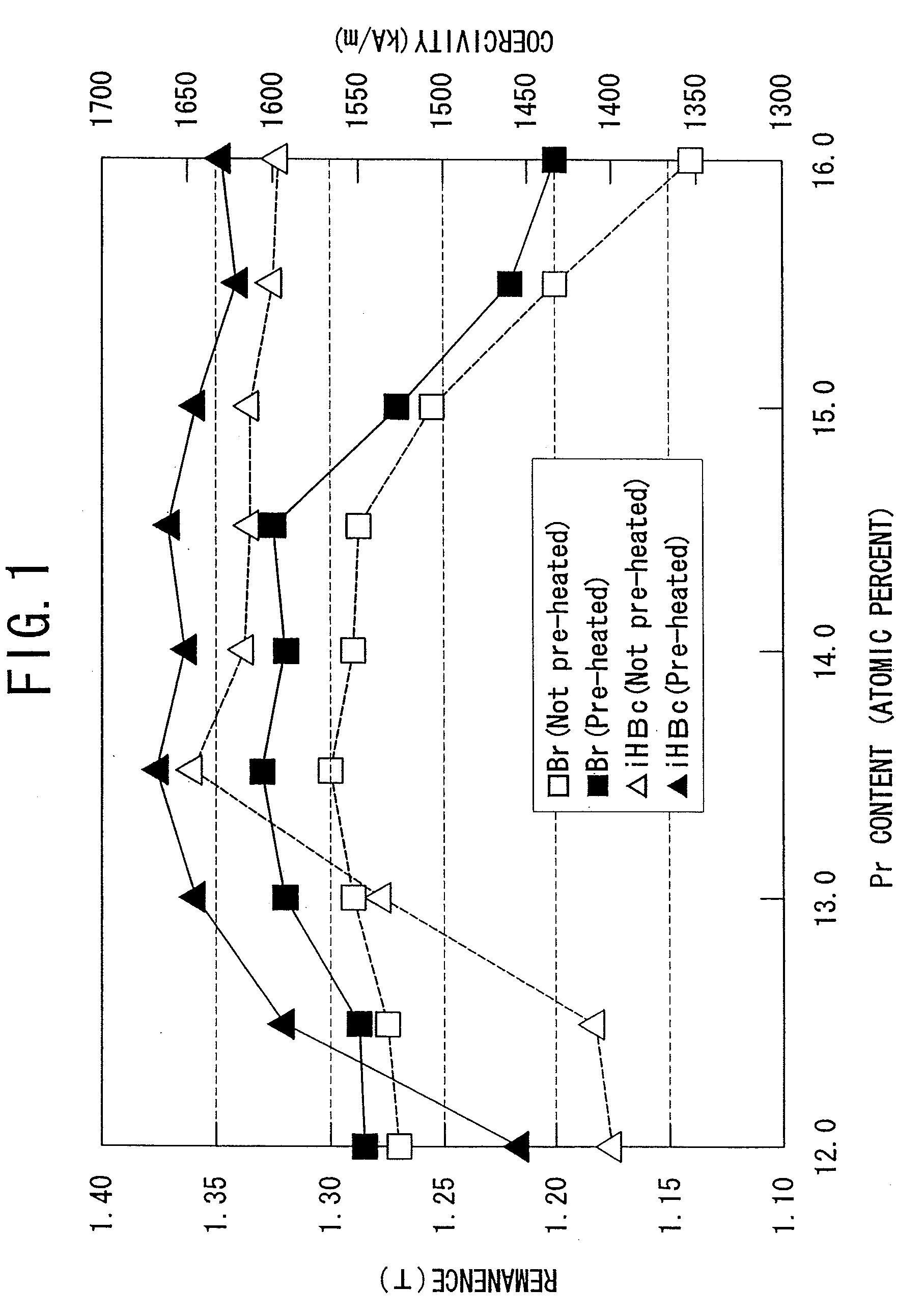

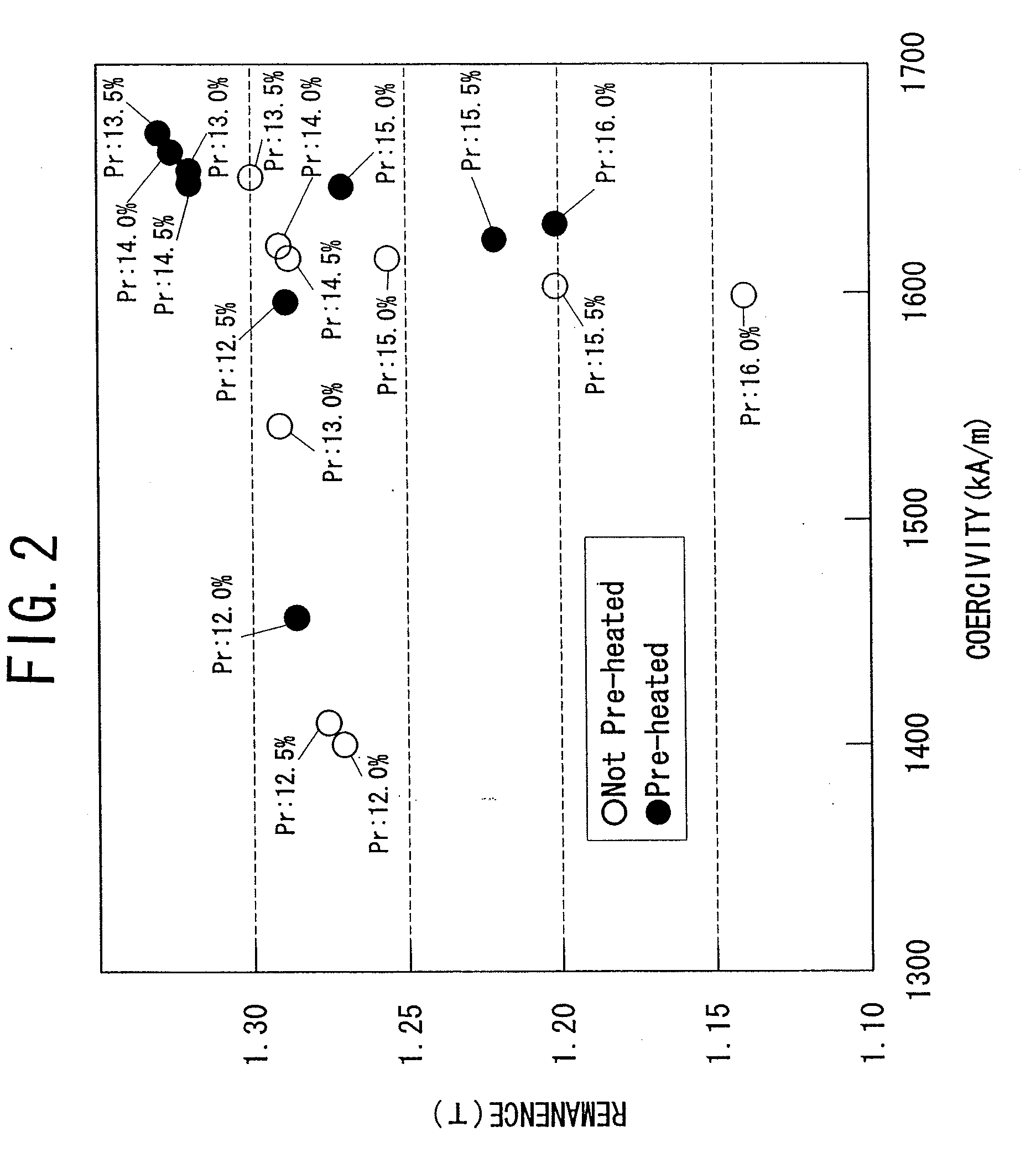

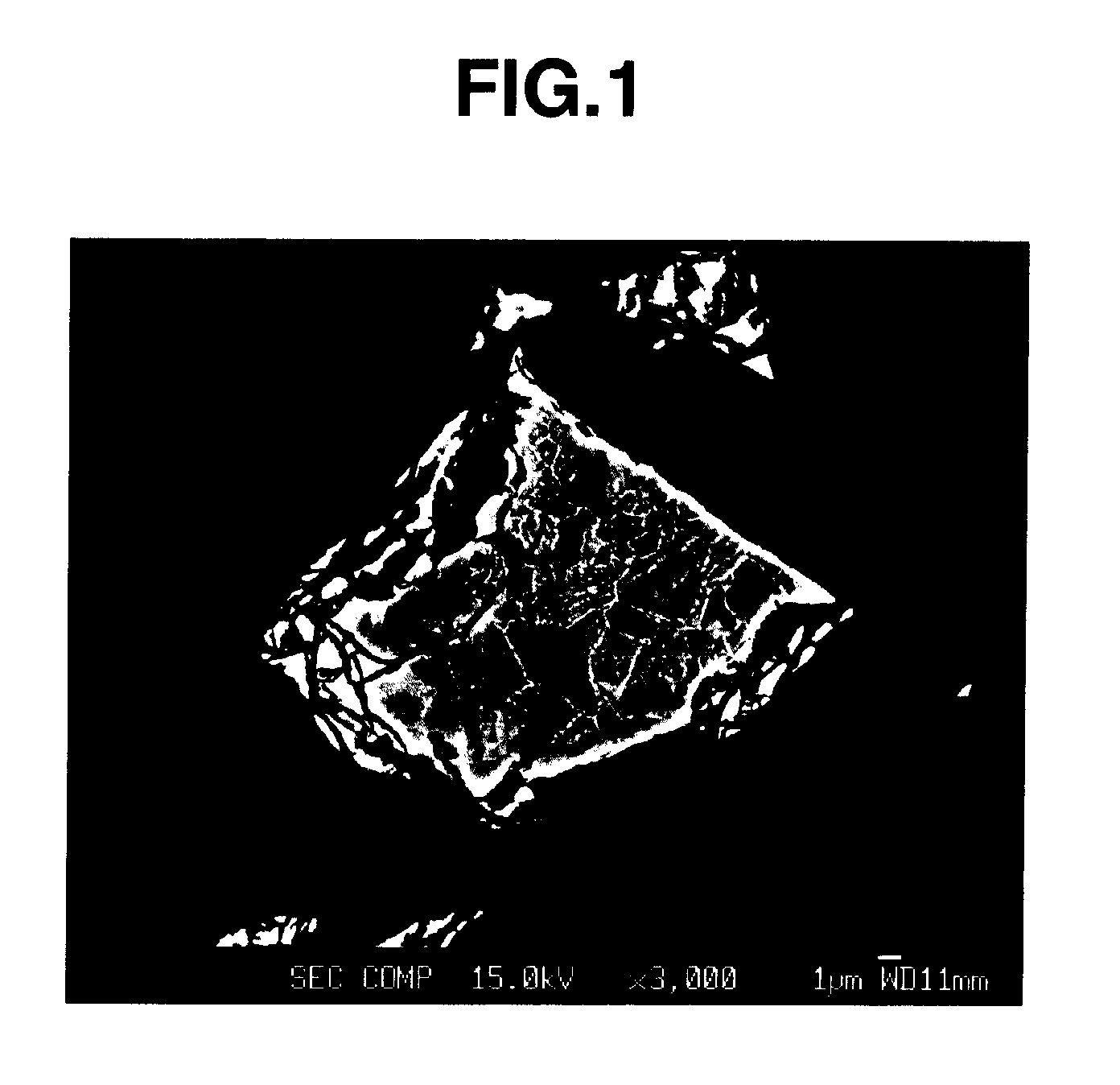

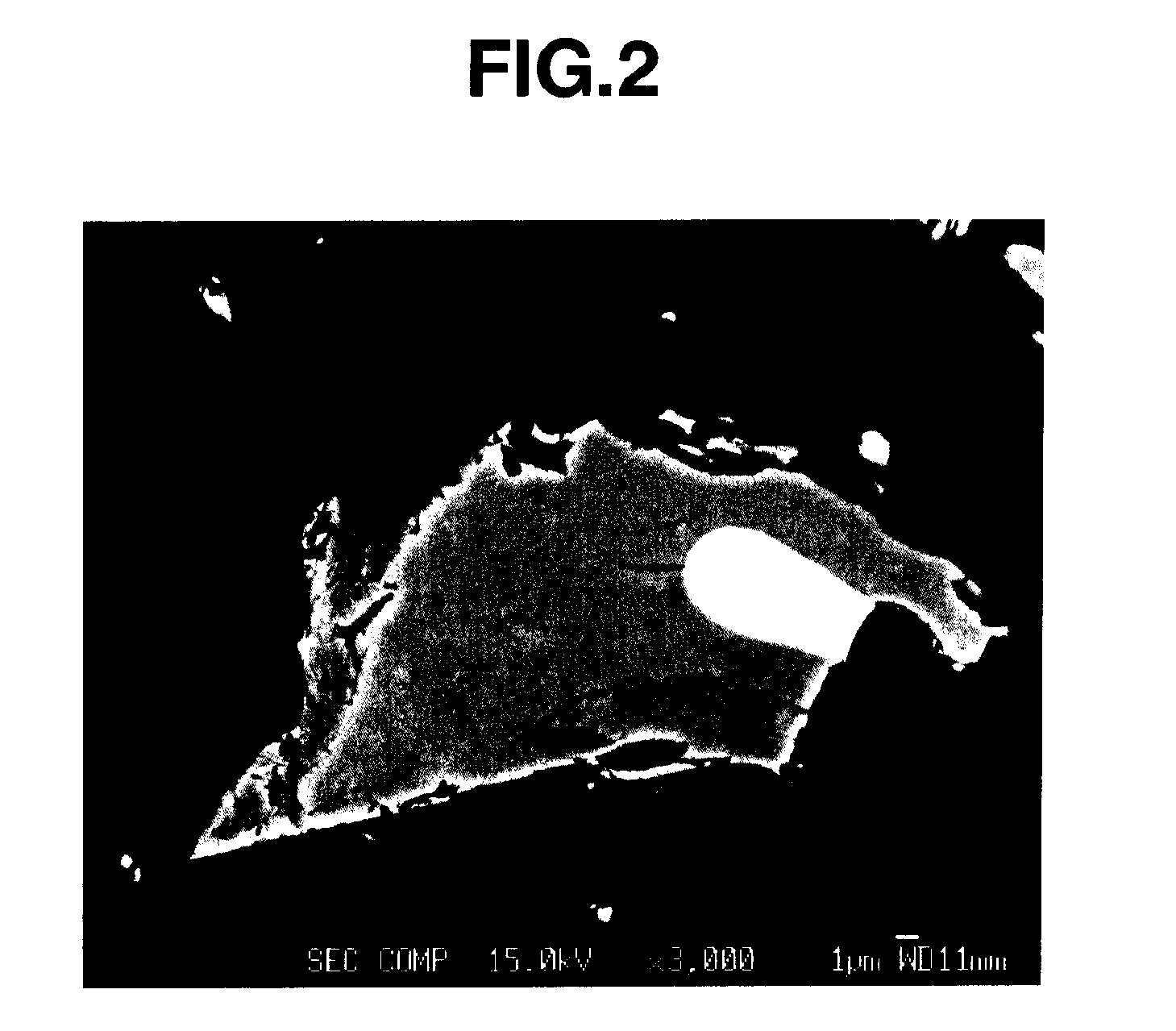

Material for Anisotropic Magnet and Method of Manufacturing the same

ActiveUS20100172783A1Increase in coercivityDecreasing remanenceTransportation and packagingMetal-working apparatusRemanenceMetallurgy

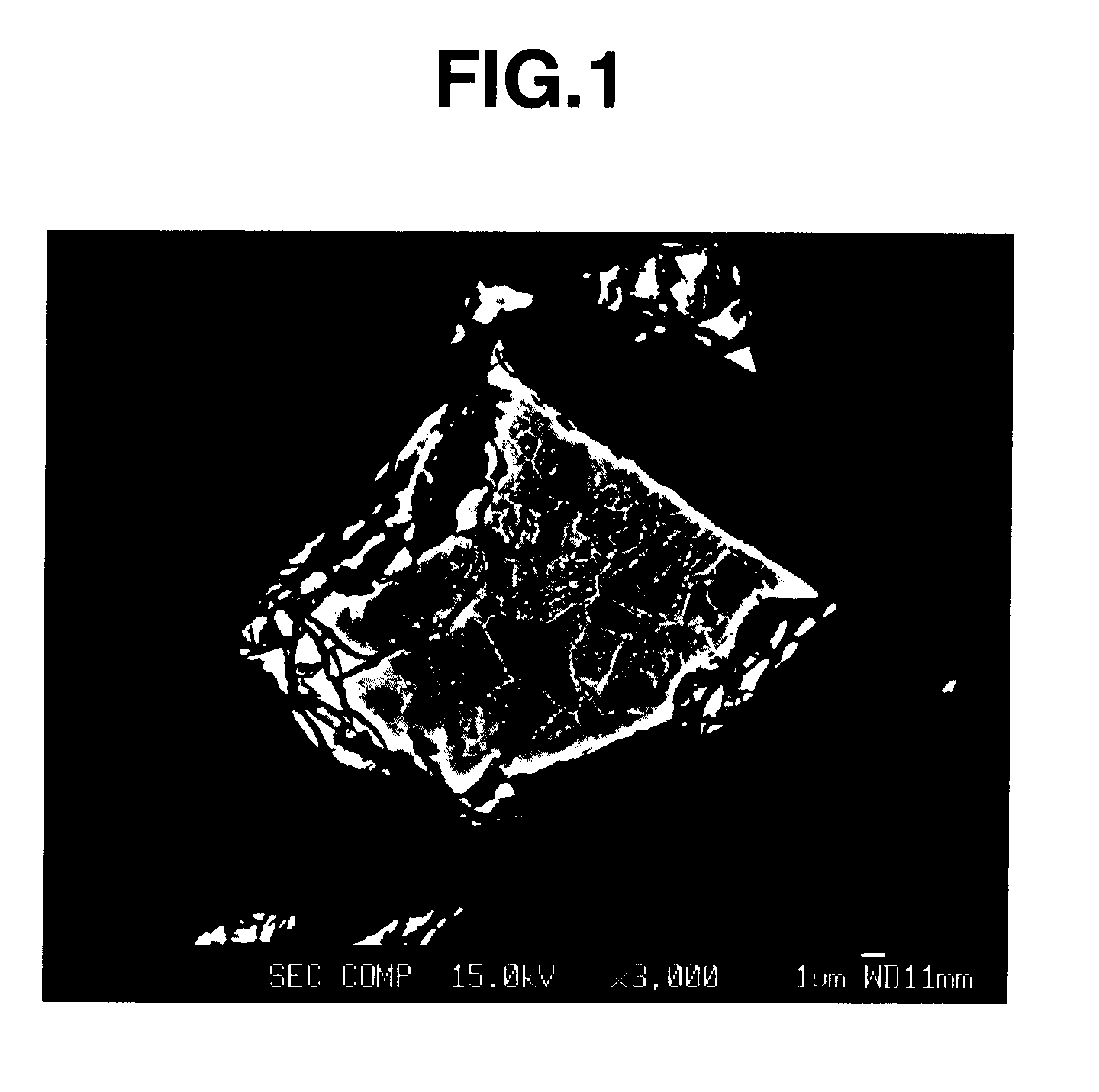

A material for anisotropic magnet, comprising,(1) a Pr-T-B—Ga-based composition containing Pr: 12.5 to 15.0 atomic percent, B: 4.5 to 6.5 atomic percent, Ga: 0.1 to 0.7 atomic percent, and the balance of T and inevitable impurities, wherein T is Fe or obtained by substituting Co for a portion of the Fe; and having,(2) a degree of magnetic alignment of 0.92 or more, wherein the degree of magnetic alignment is defined by remanence (Br) / saturation magnetization (Js); and(3) a crystal grain diameter of 1 μm or less.

Owner:DAIDO STEEL CO LTD

R-Fe-B ANISOTROPIC SINTERED MAGNET

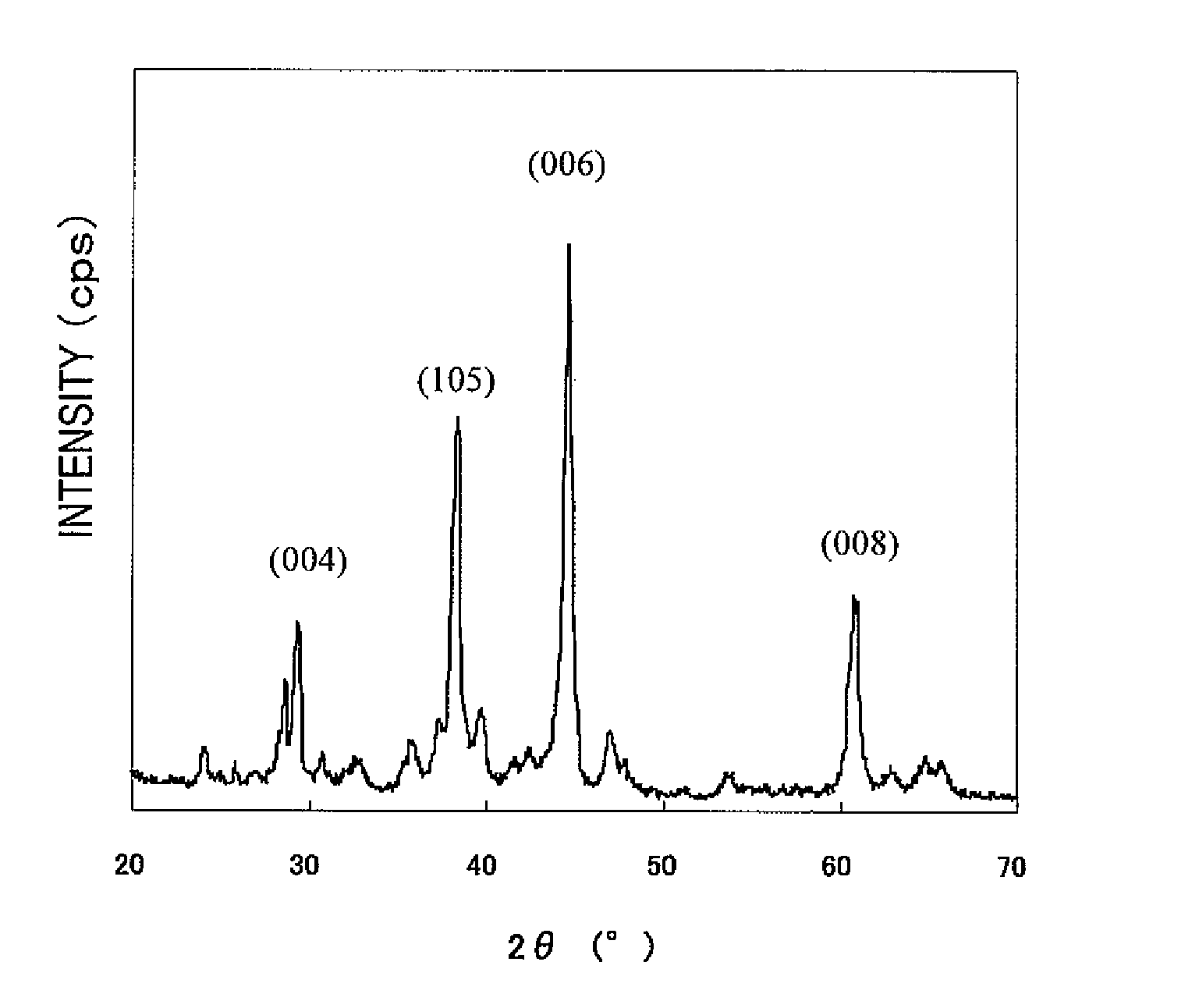

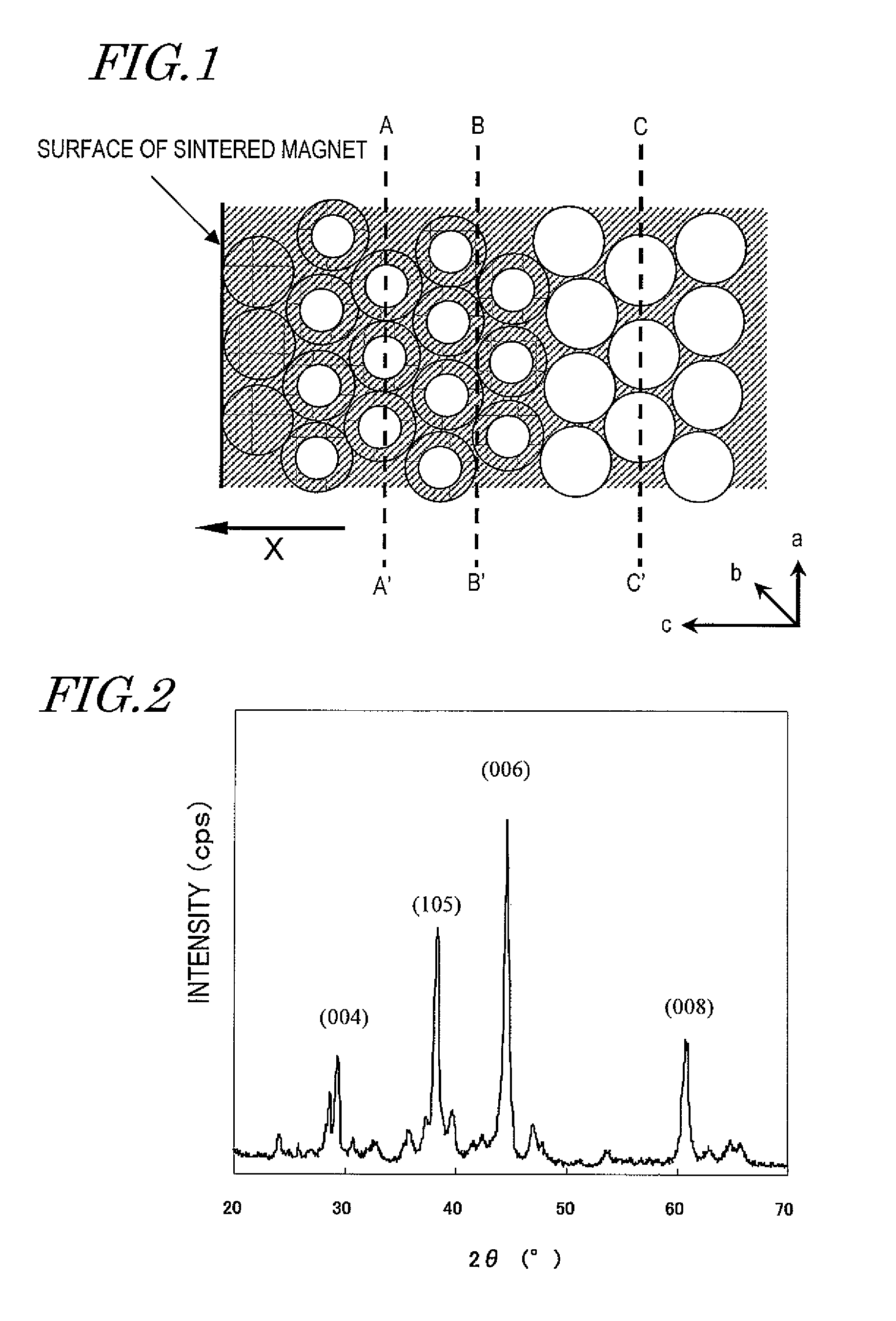

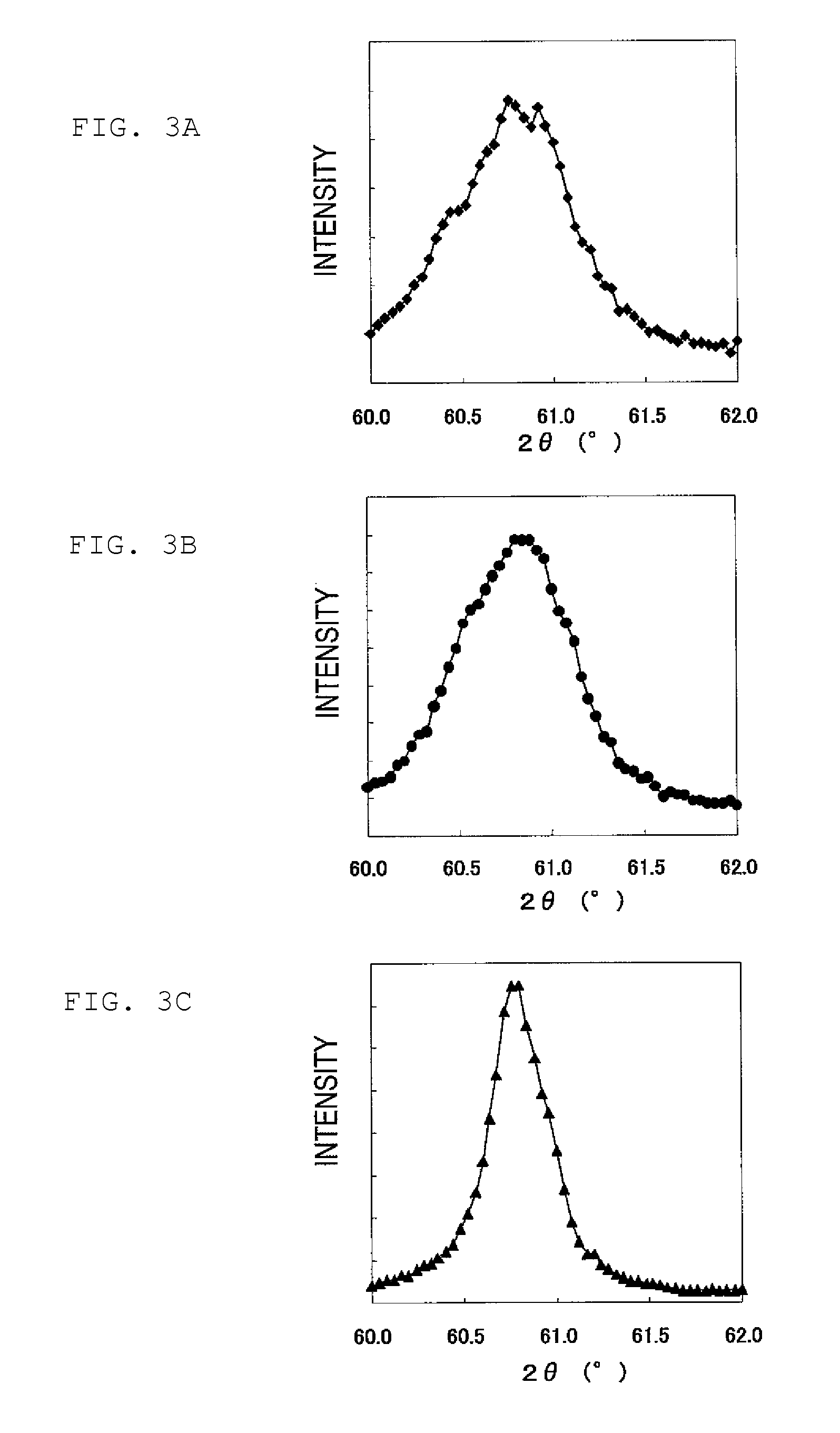

ActiveUS20110205006A1Remanence Br decreasedCoercivity HcJ can be increasedPermanent magnetsInorganic material magnetismRare-earth elementX-ray

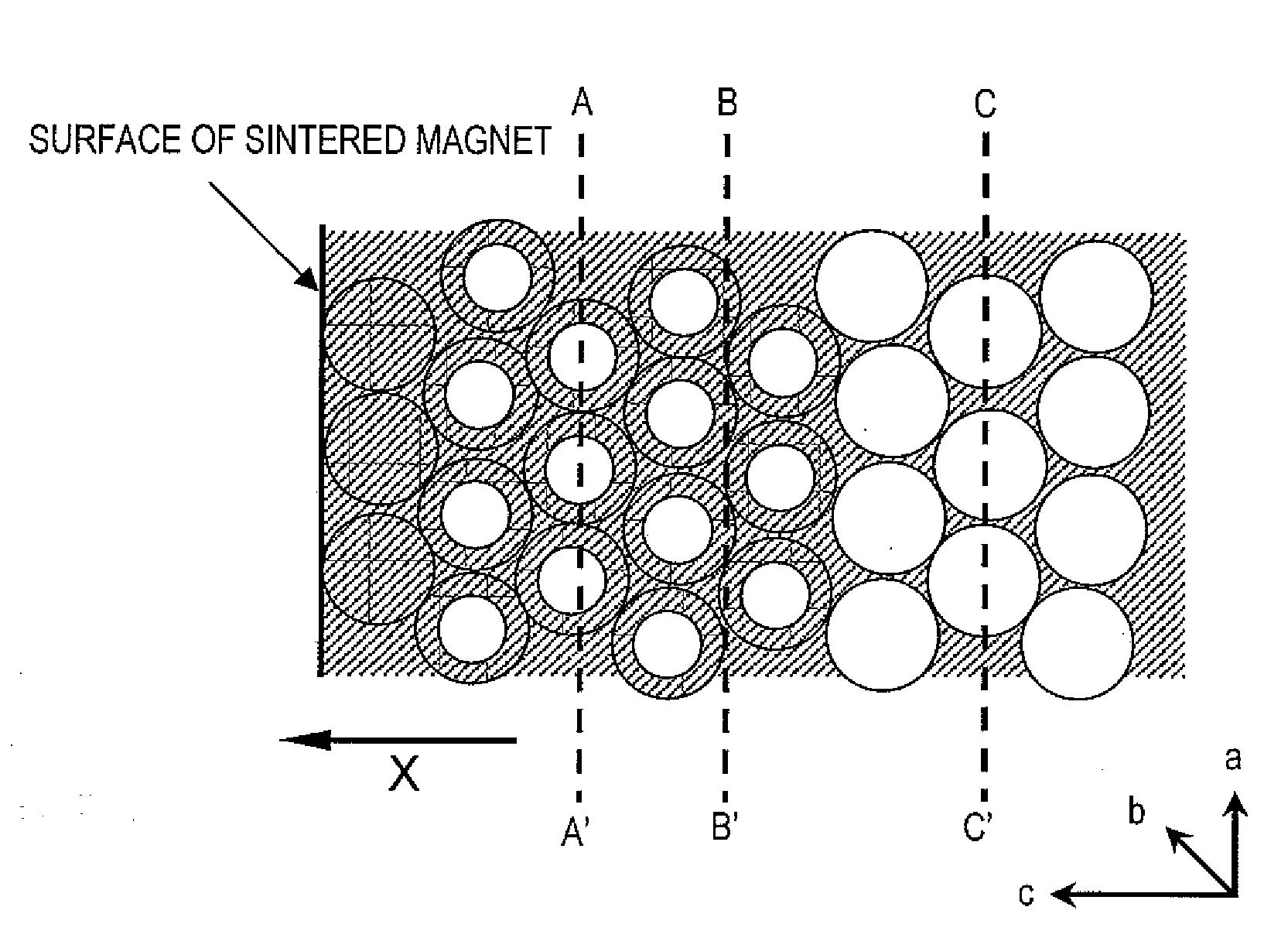

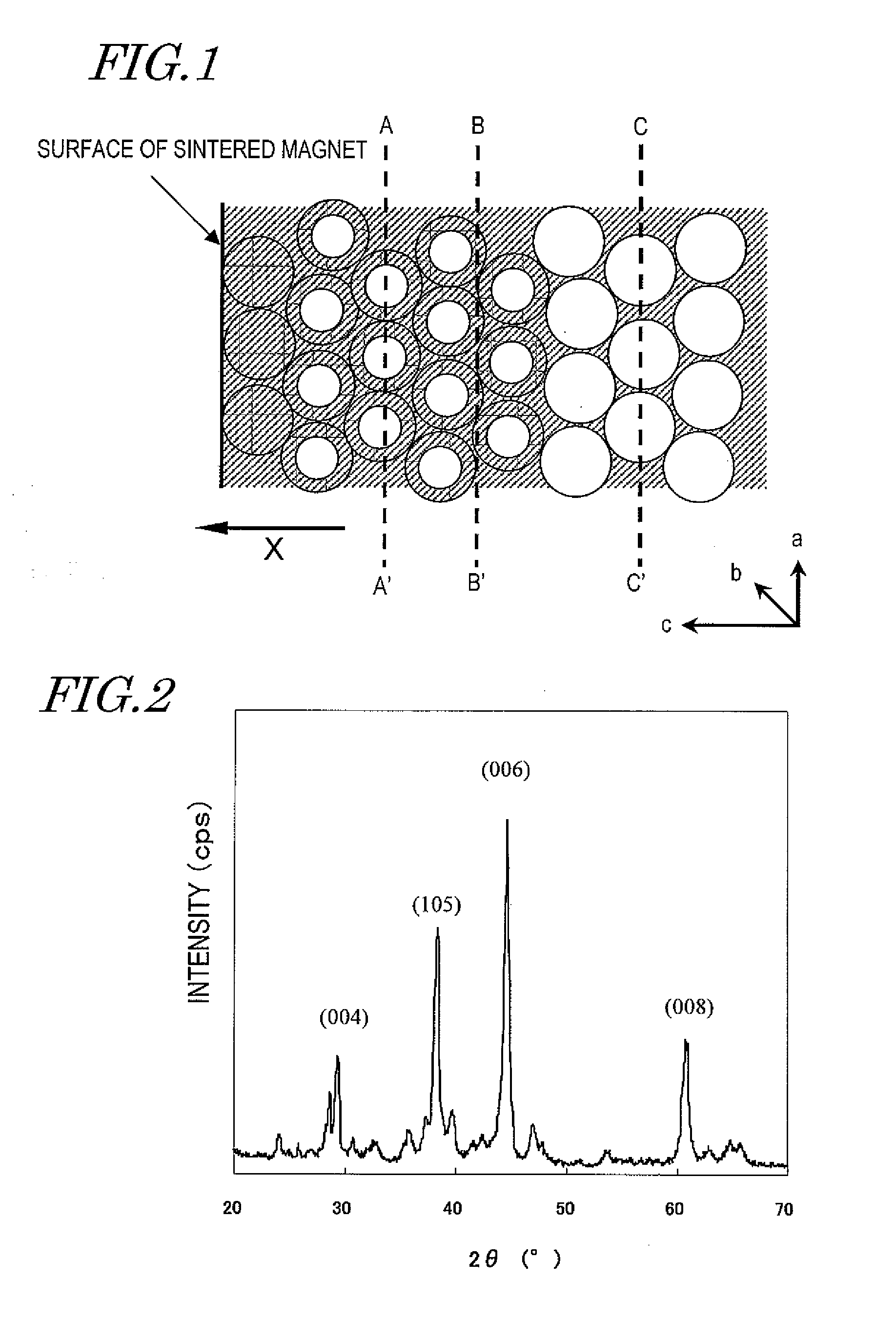

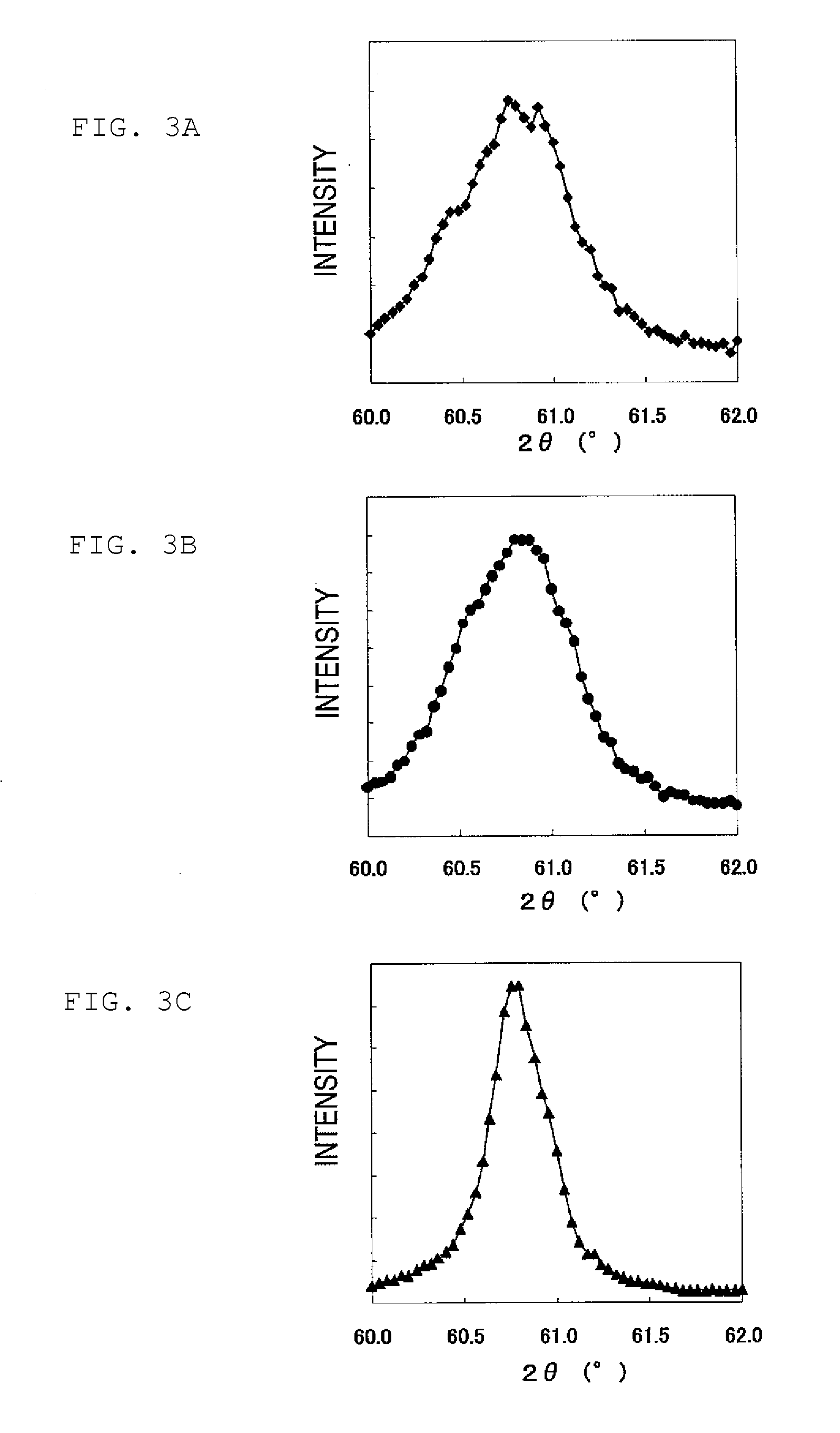

An R—Fe—B based anisotropic sintered magnet according to the present invention has, as a main phase, an R2Fe14B type compound that includes a light rare-earth element RL (which is at least one of Nd and Pr) as a major rare-earth element R, and also has a heavy rare-earth element RH (which is at least one element selected from the group consisting of Dy and Tb). In the crystal lattice of the main phase, the c-axis is oriented in a predetermined direction. The magnet includes a portion in which at least two peaks of diffraction are observed within a 2θ range of 60.5 degrees to 61.5 degrees when an X-ray diffraction measurement is carried out using a CuK α ray on a plane that is located at a depth of 500 μm or less under a pole face of the magnet and that is parallel to the pole face.

Owner:HITACHI METALS LTD

Rare earth permanent magnet and its preparation

ActiveUS20110036458A1Efficient productivityGood magnetic performancePermanent magnetsInorganic material magnetismRemanenceProduction rate

A rare earth permanent magnet is prepared by disposing a powdered metal alloy containing at least 70 vol % of an intermetallic compound phase on a sintered body of R—Fe—B system, and heating the sintered body having the powder disposed on its surface below the sintering temperature of the sintered body in vacuum or in an inert gas for diffusion treatment. The advantages include efficient productivity, excellent magnetic performance, a minimal or zero amount of Tb or Dy used, an increased coercive force, and a minimized decline of remanence.

Owner:SHIN ETSU CHEM CO LTD

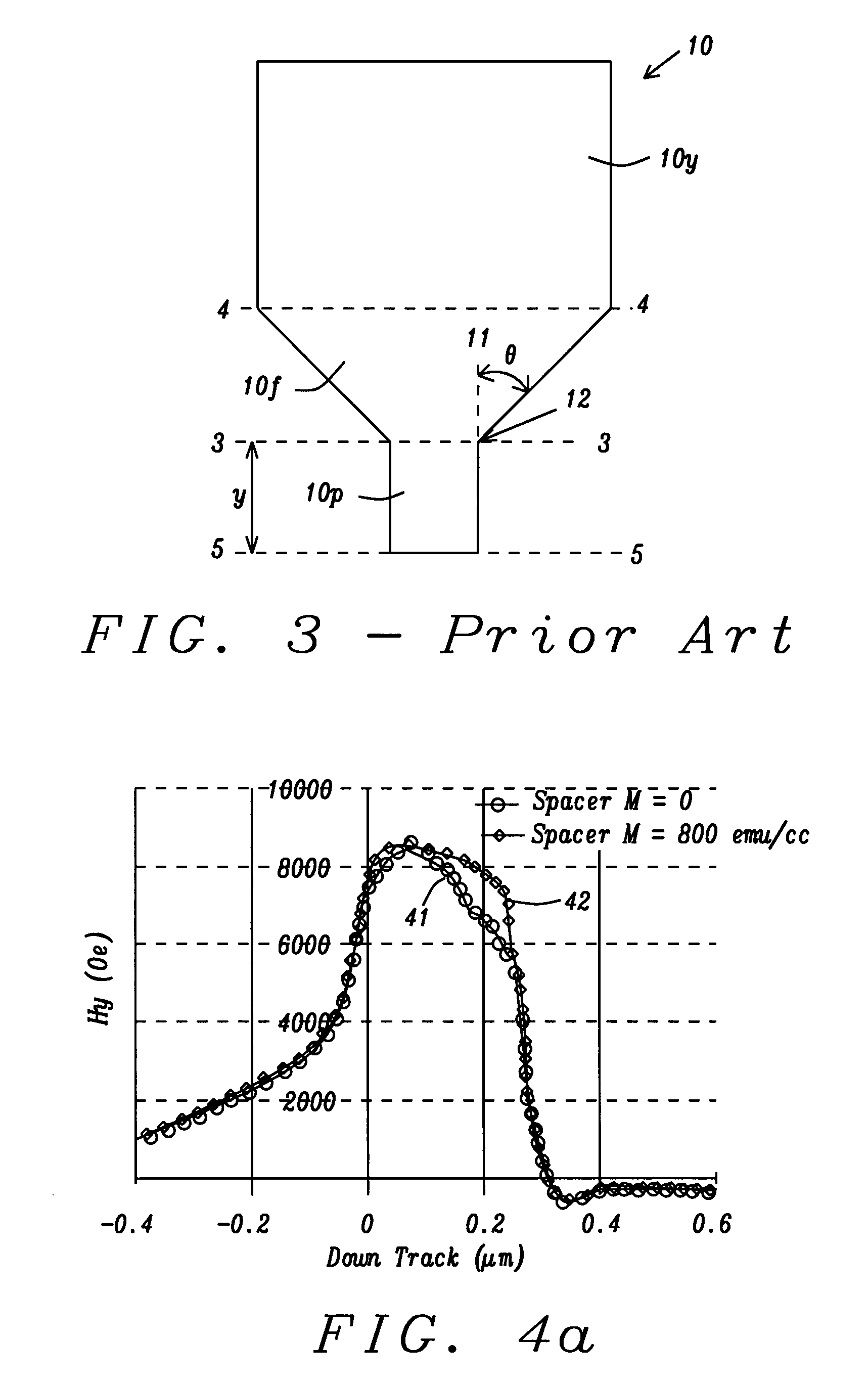

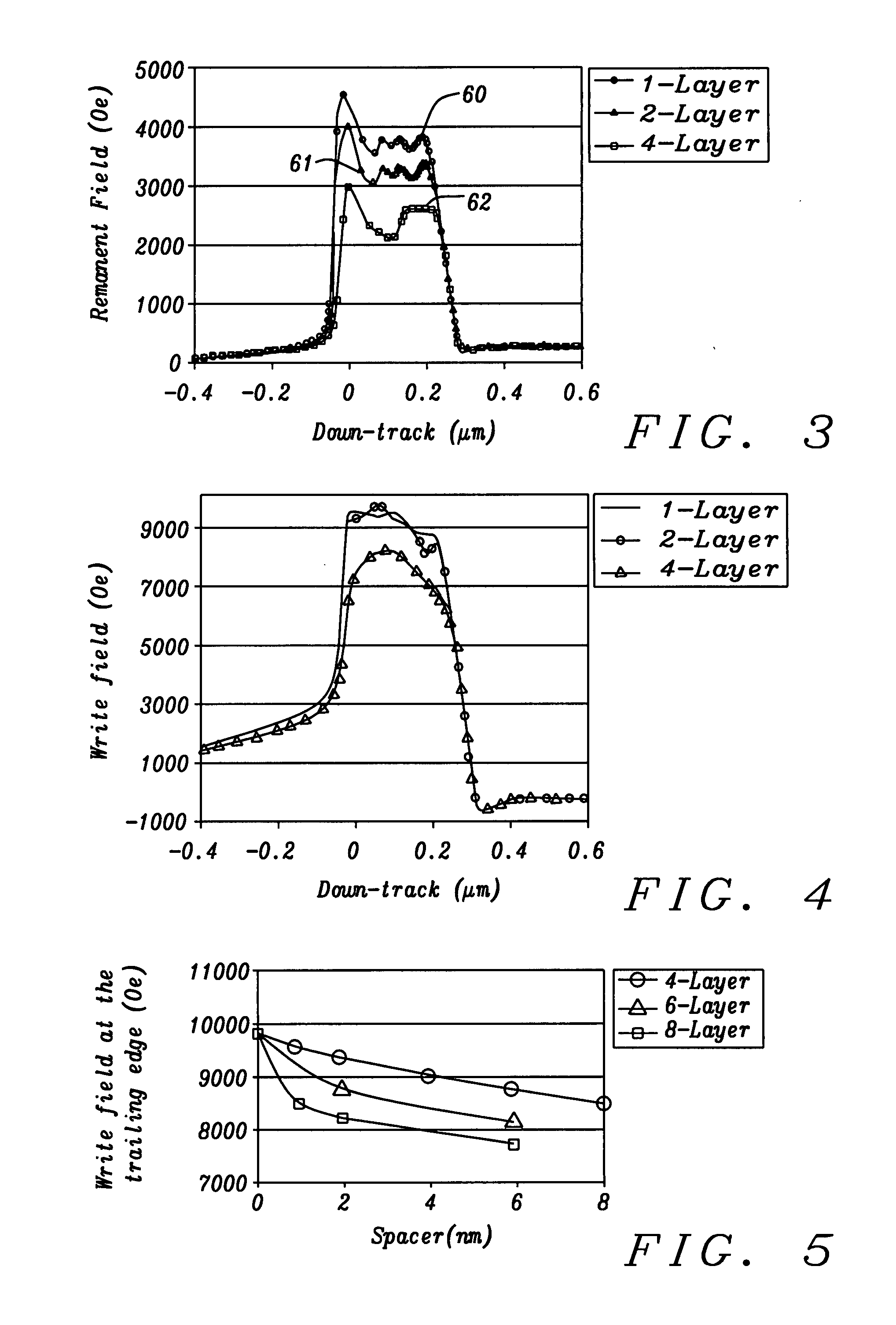

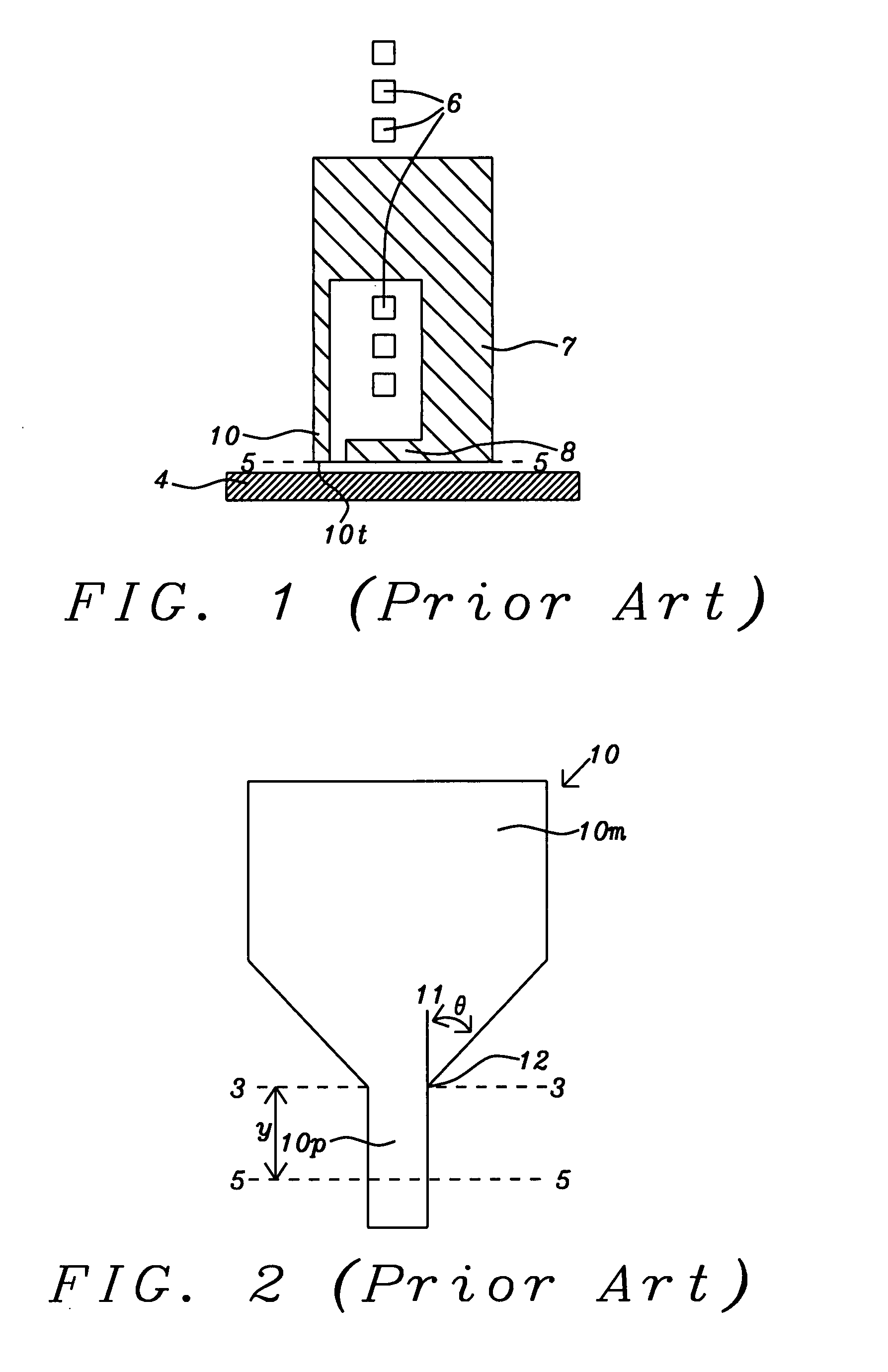

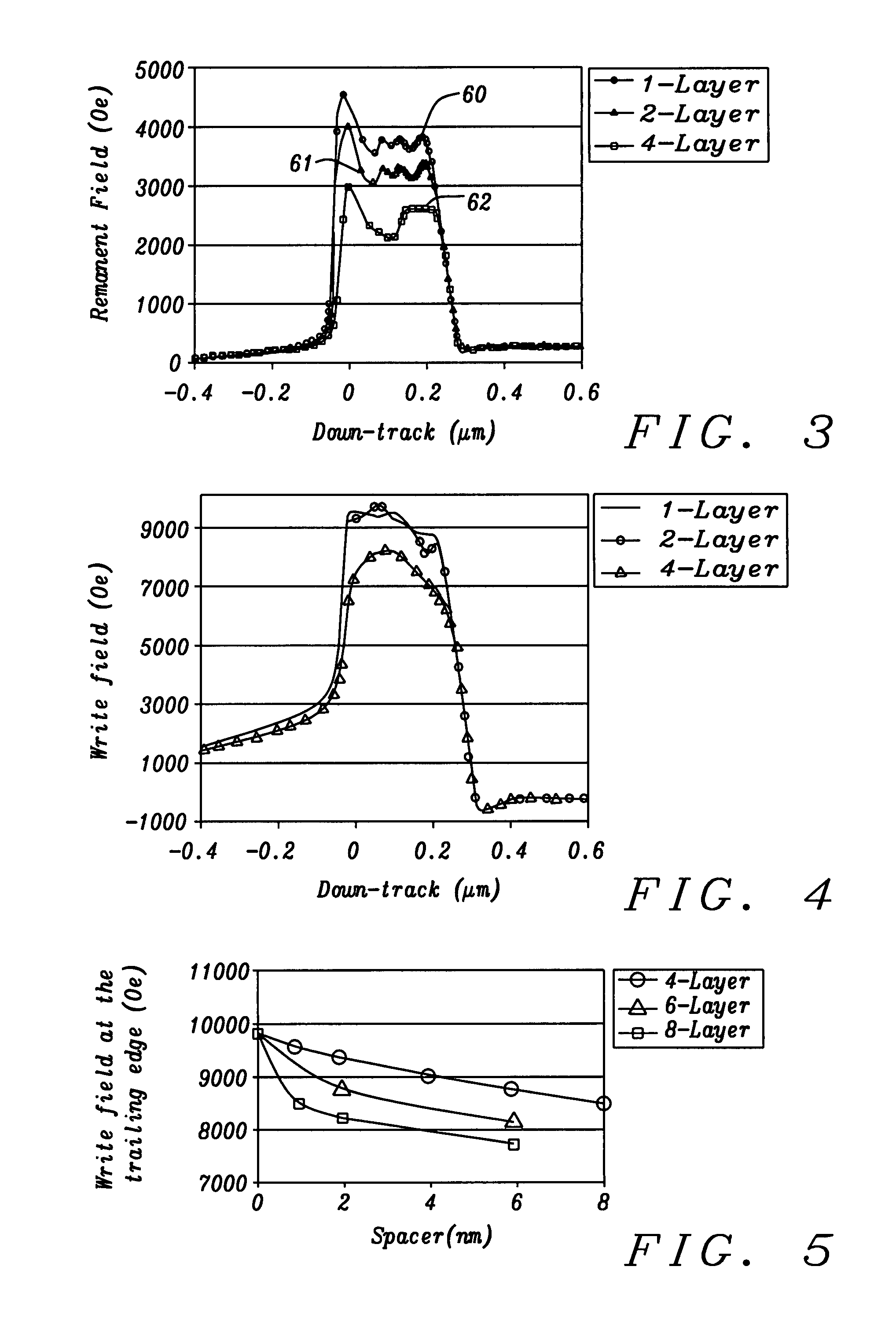

Perpendicular magnetic recording head with a laminated pole

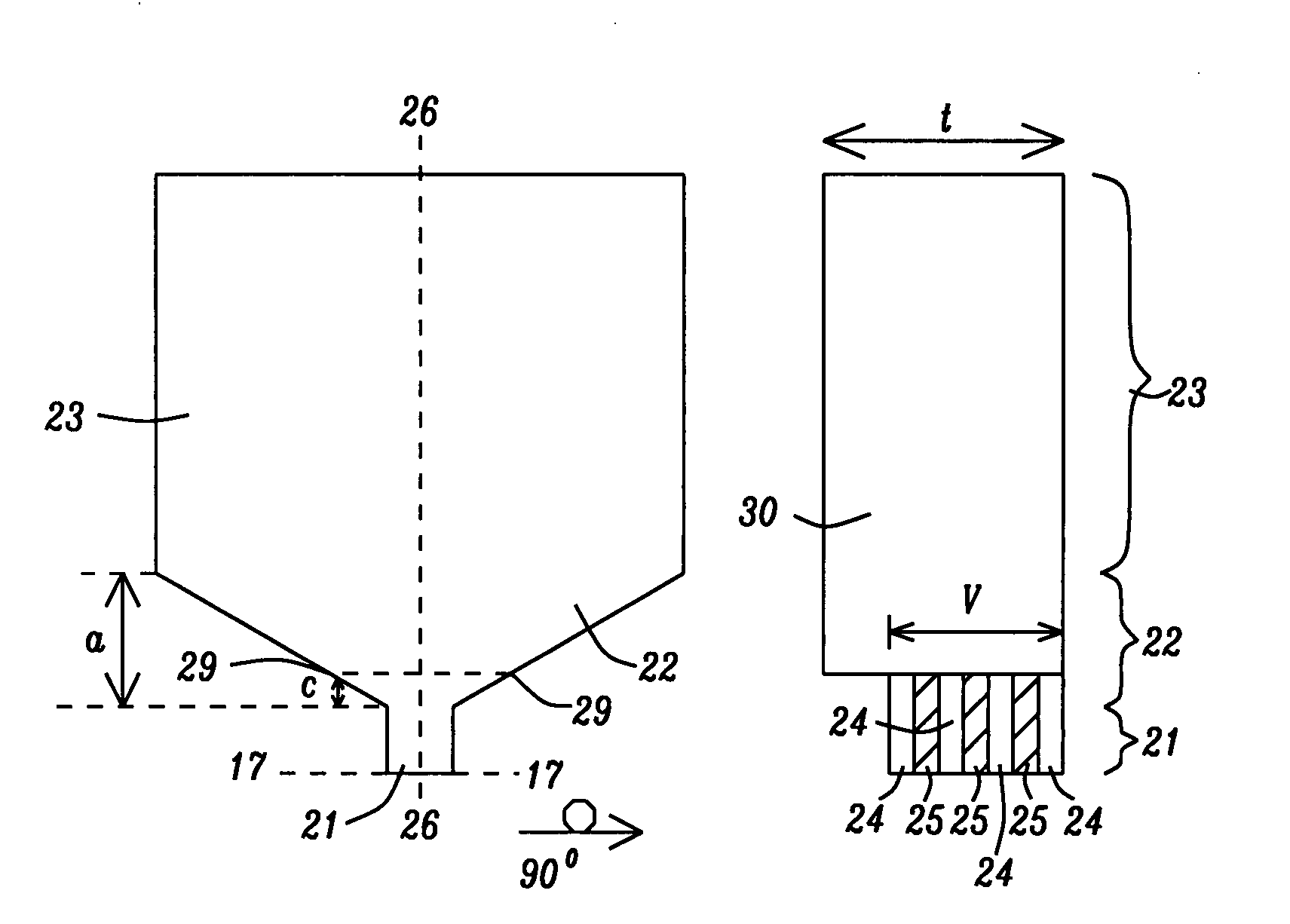

ActiveUS20090021868A1Increase coverageDecreasing remanenceRecord information storageManufacture of flux-sensitive headsAntiferromagnetic couplingNon magnetic

A laminated write pole layer for a PMR write head is disclosed in which a plurality of “n” magnetic layers and “n−1” non-magnetic spacers are formed in an alternating fashion on a substrate. The non-magnetic spacers promote exchange decoupling or antiferromagnetic coupling between adjacent magnetic layers. Writability is improved when the trailing magnetic layer has a thickness greater than the thickness of other magnetic layers and preferably >25% of the total thickness of the magnetic layers. The thicknesses of the other magnetic layers may be equal or may become progressively smaller with increasing distance from the trailing magnetic layer. In another embodiment, the non-magnetic spacer between the trailing magnetic layer and the nearest magnetic layer is replaced by a magnetic spacer made of a soft magnetic material to promote magnetic coupling and effectively increase the thickness of the trailing magnetic layer.

Owner:HEADWAY TECH INC

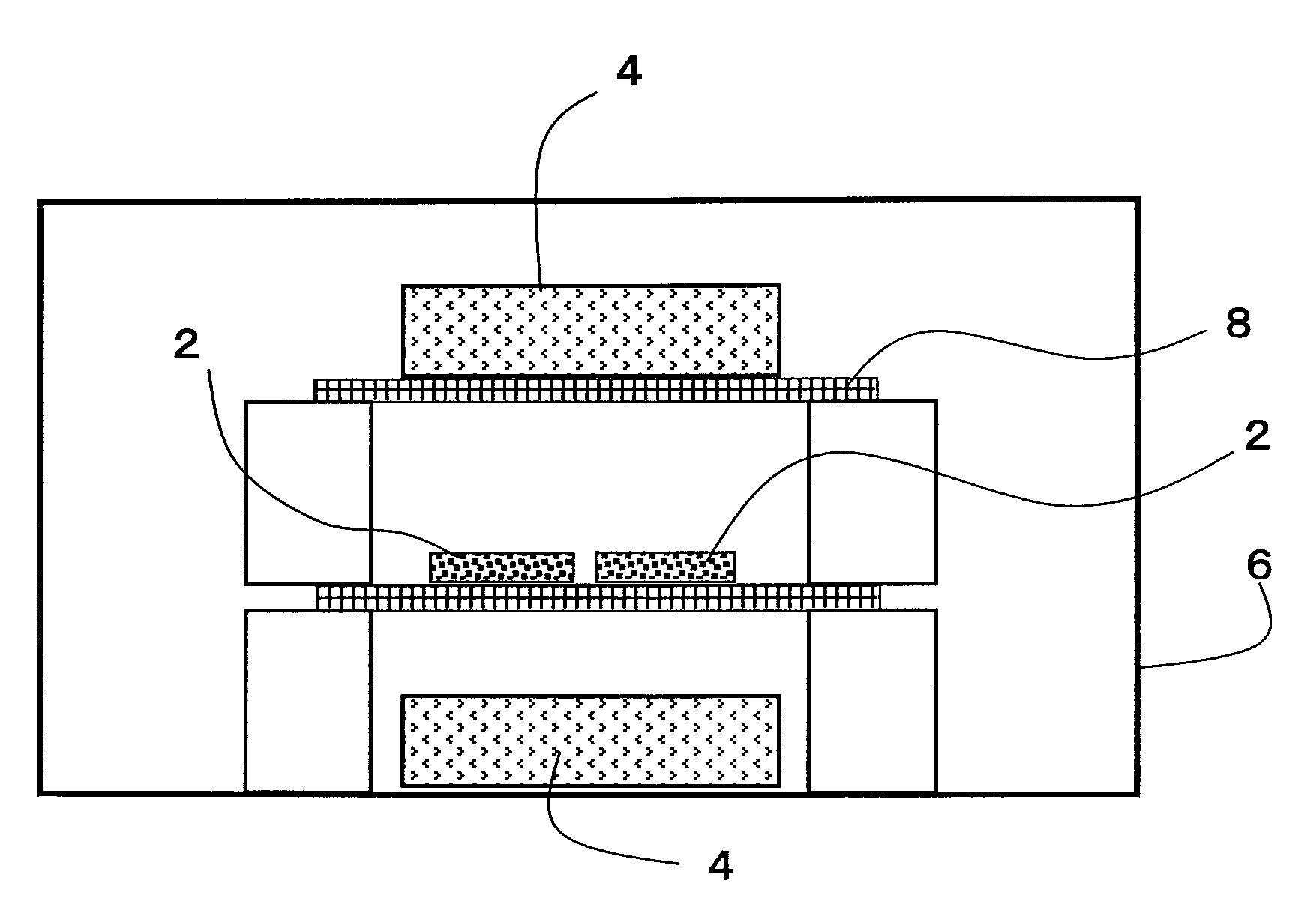

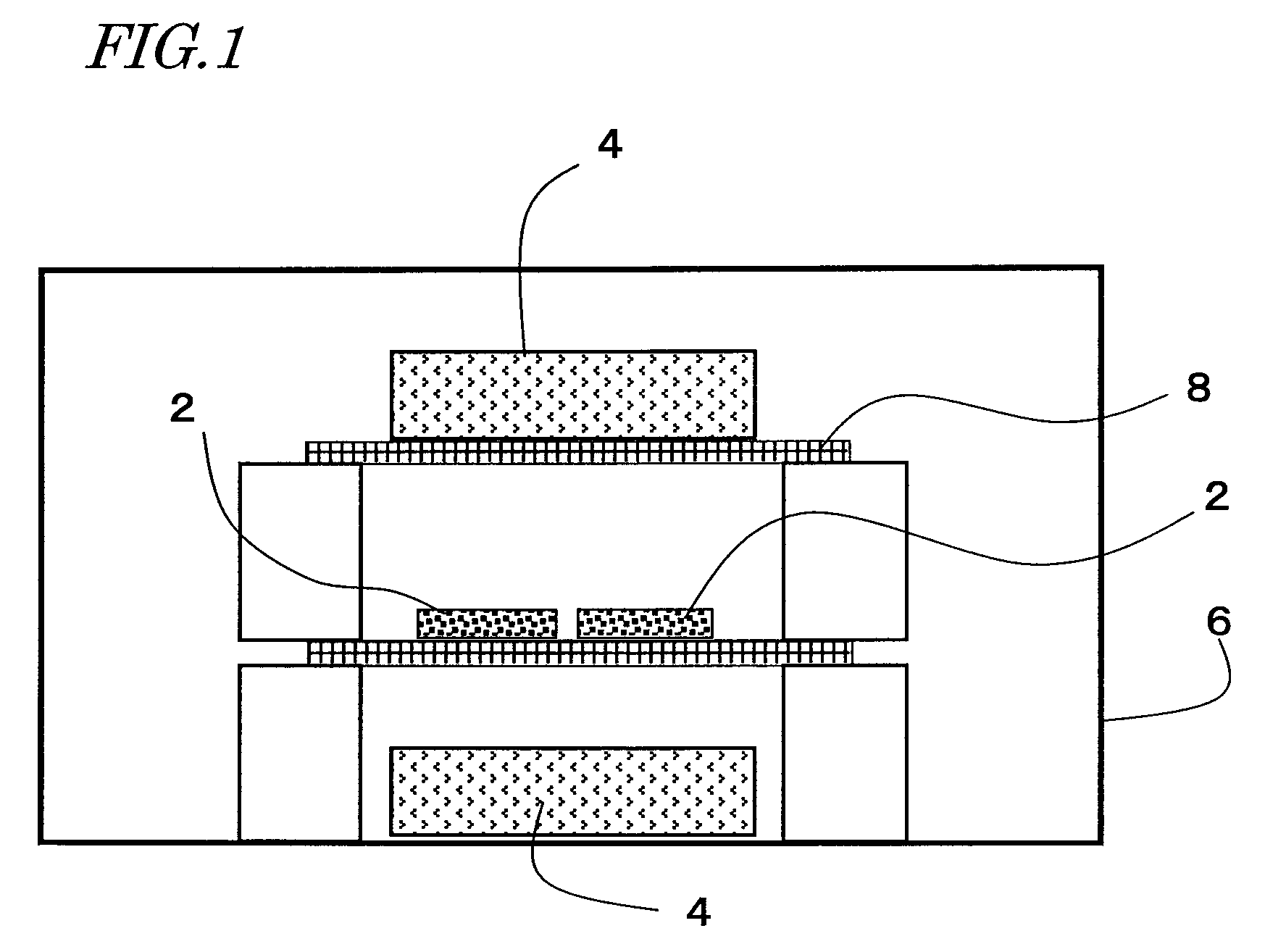

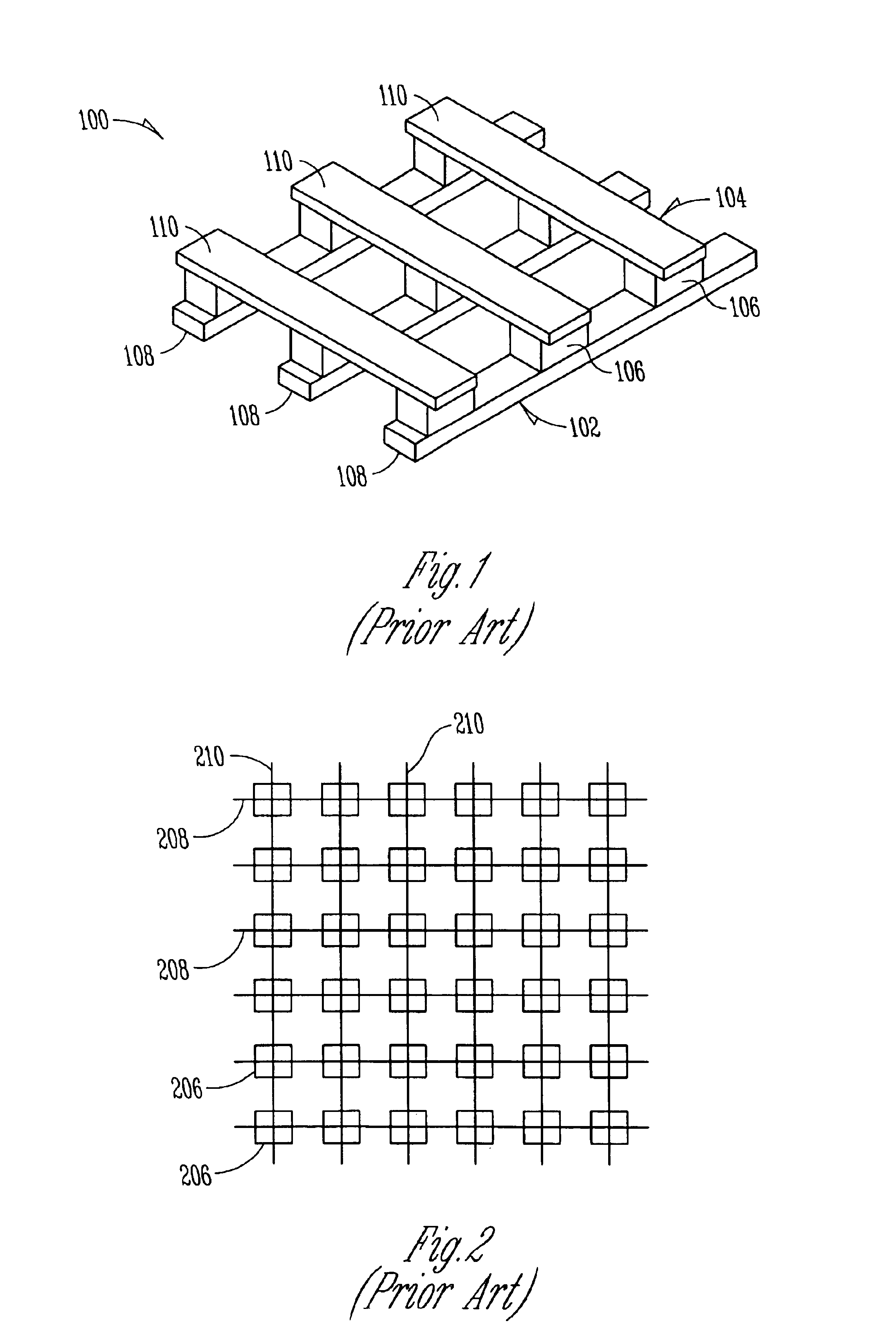

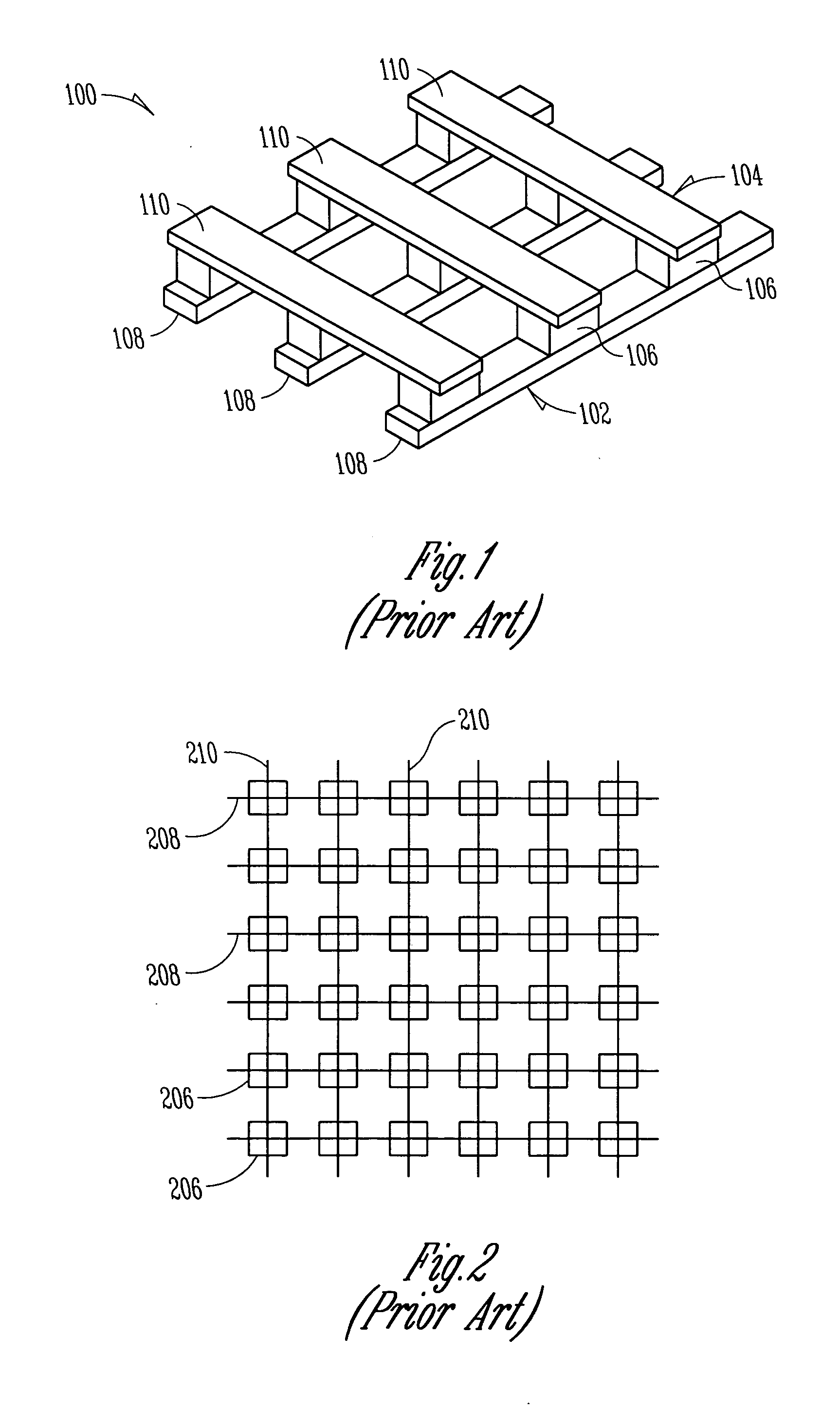

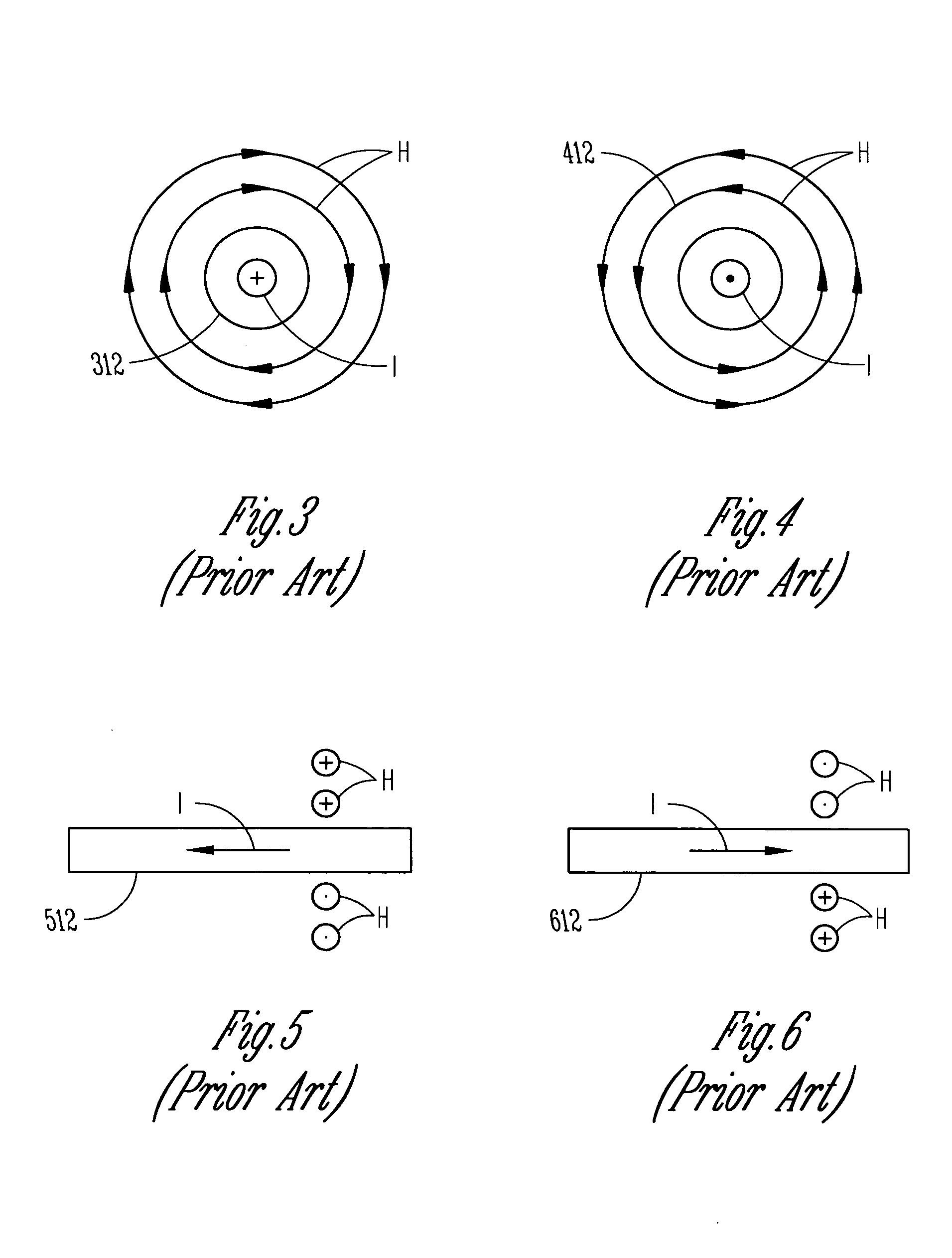

Low remanence flux concentrator for MRAM devices

InactiveUS6833278B2Low remanenceMinimise currentMagnetic-field-controlled resistorsSolid-state devicesRemanenceElectrical conductor

Systems, devices and methods are provided for magnetic memory elements with low remanence flux concentrators. Improved bit yield is attributable to reduced remanence in the flux concentrator. Remanence provides the memory element with a biasing magnetic field. The flux concentrator includes anisotropy aligned with an appropriate conductor. One aspect of the present subject matter is a memory cell. One memory cell embodiment includes a magnetic memory element and a flux concentrator operably positioned with respect to a conductor. The conductor is adapted to provide a current-induced magnetic flux to the magnetic memory element. The flux concentrator includes an easy axis of magnetization aligned with the conductor and a hard axis of magnetization orthogonal to the easy axis of magnetization. Other aspects are provided herein.

Owner:MICRON TECH INC

Rare earth permanent magnet and its preparation

ActiveUS20110036457A1Efficient productivityGood magnetic performancePermanent magnetsInorganic material magnetismRemanenceProduction rate

A rare earth permanent magnet is prepared by disposing a powdered metal alloy containing at least 70 vol % of an intermetallic compound phase on a sintered body of R—Fe—B system, and heating the sintered body having the powder disposed on its surface below the sintering temperature of the sintered body in vacuum or in an inert gas for diffusion treatment. The advantages include efficient productivity, excellent magnetic performance, a minimal or zero amount of Tb or Dy used, an increased coercive force, and a minimized decline of remanence.

Owner:SHIN ETSU CHEM CO LTD

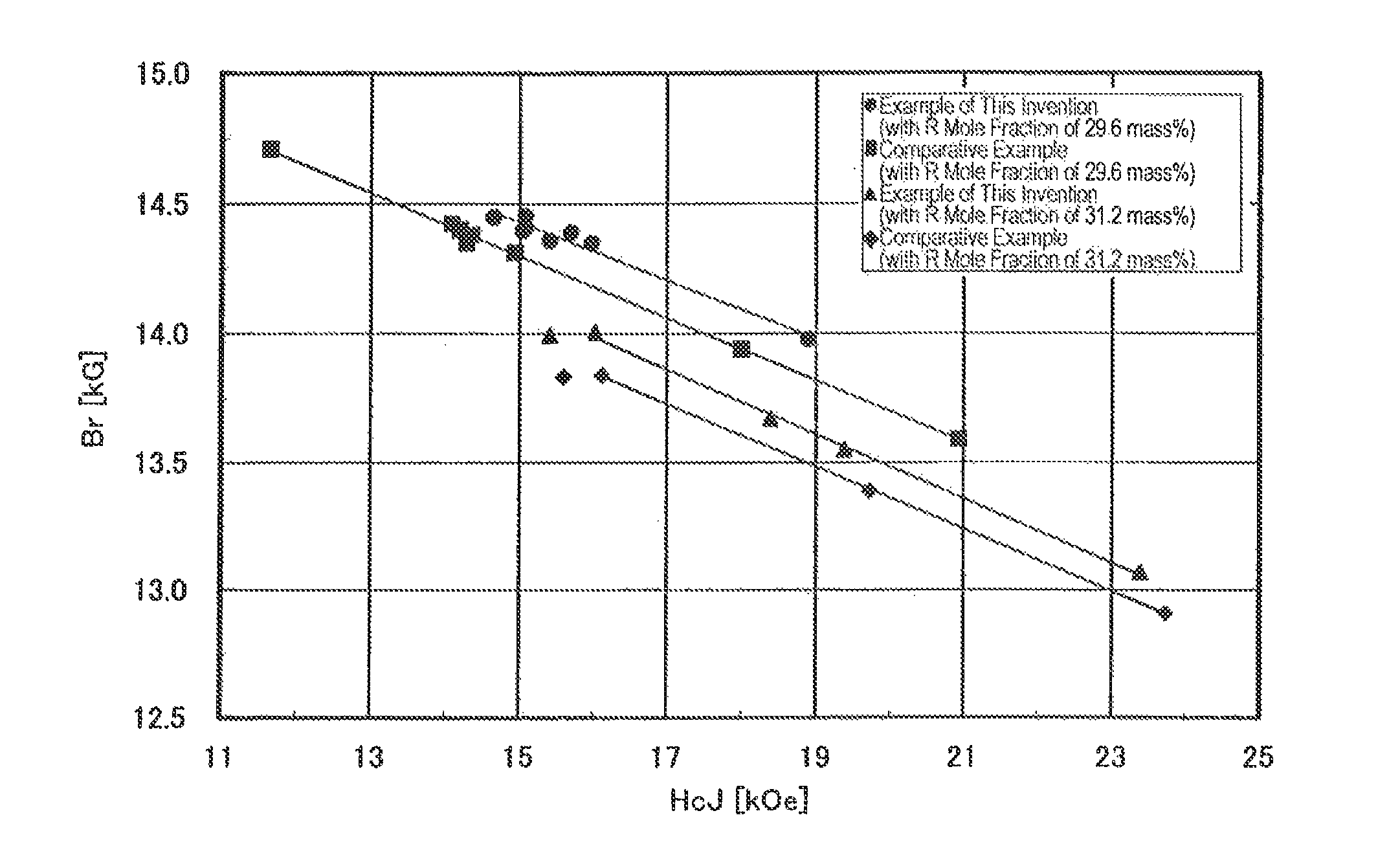

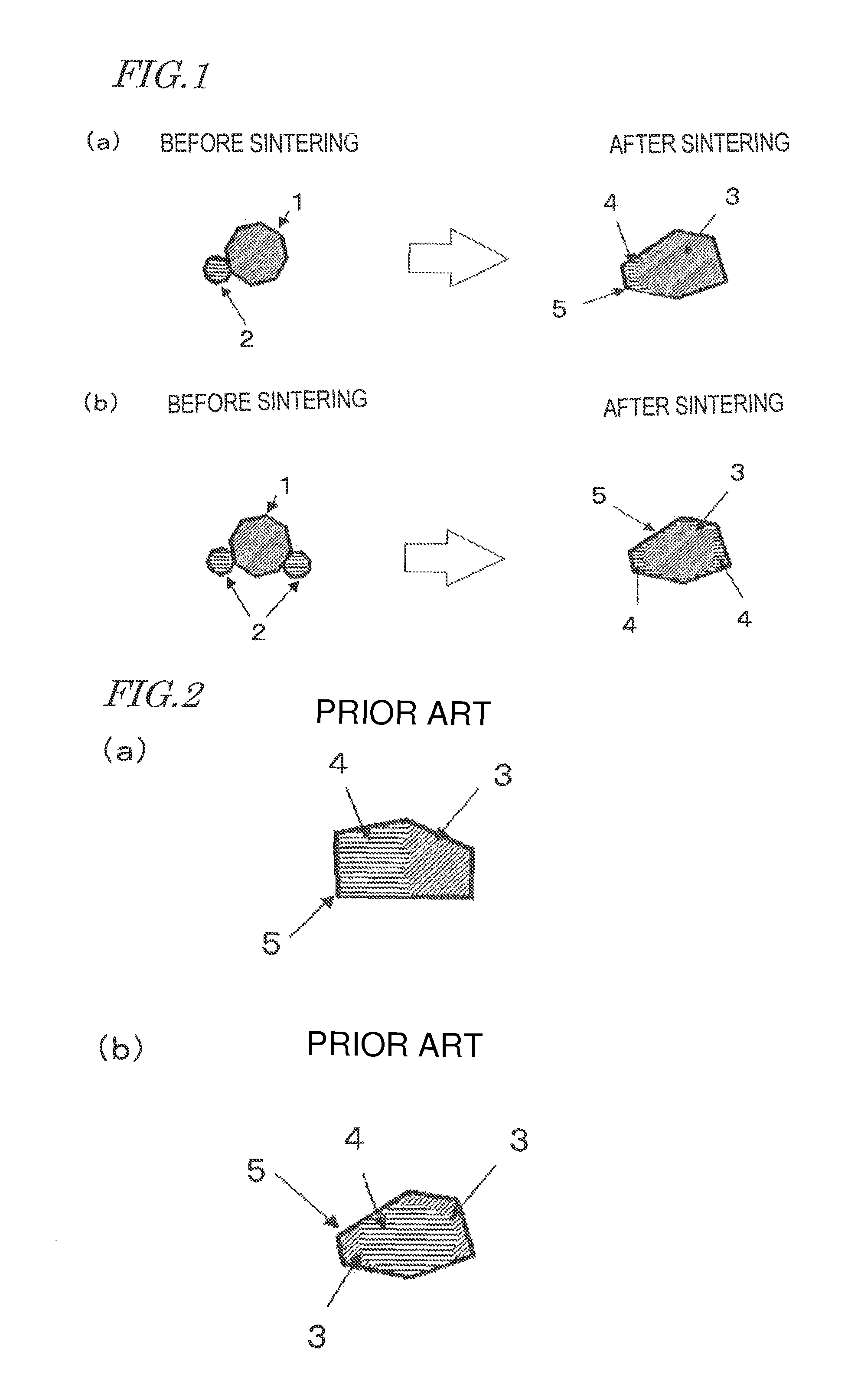

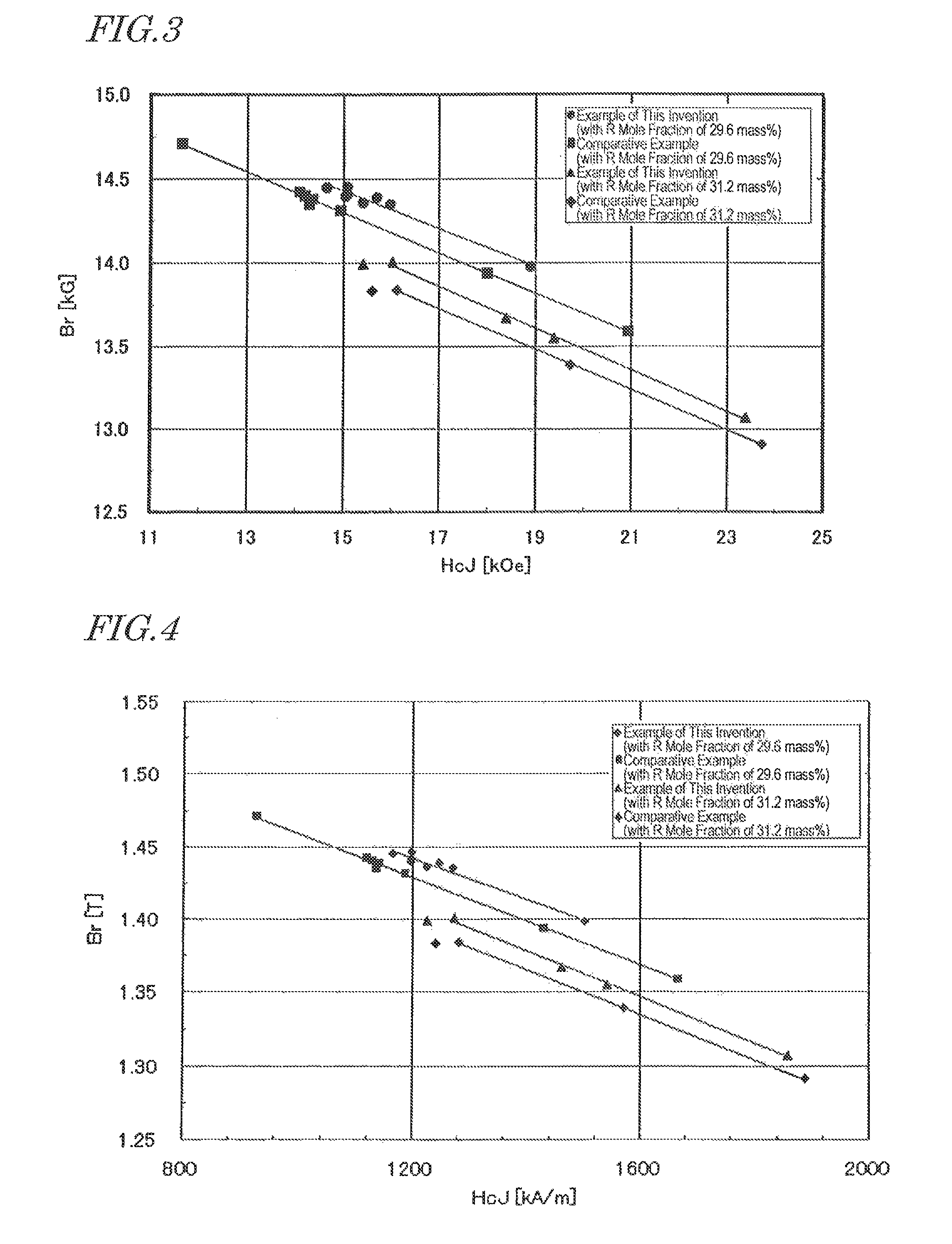

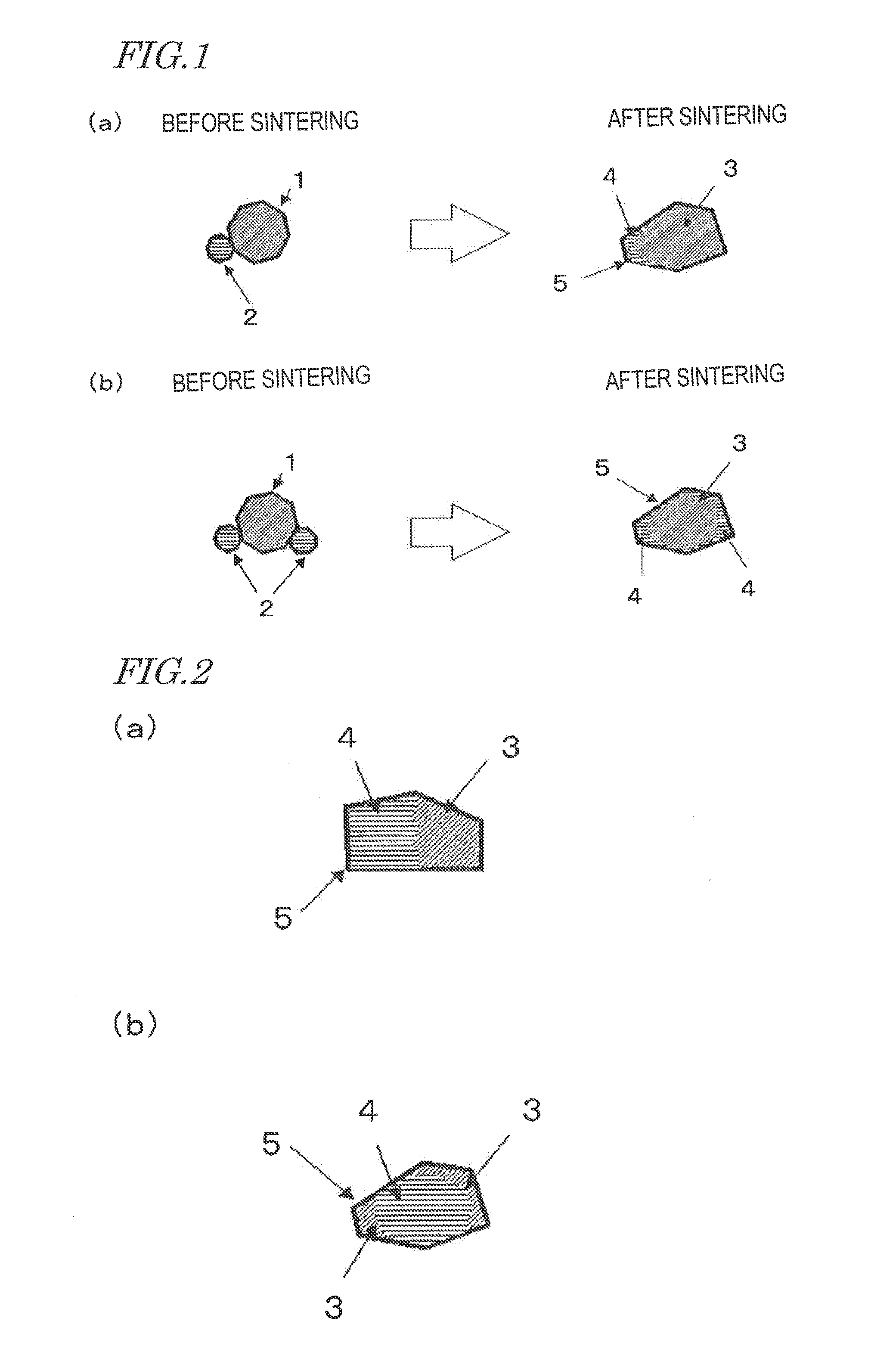

Method for producing R-T-B sintered magnet

ActiveUS8287661B2Decreasing remanenceIncrease in coercivityTransportation and packagingMetal-working apparatusRare-earth elementSintered magnets

A method for producing a sintered R-T-B based magnet includes the steps of: providing R-T-B based alloy powders A and B so that the R-T-B based alloy powder B has a particle size D50 that is smaller by at least 1.0 μm than that of the R-T-B based alloy powder A and that there is a difference ΔRH of at least 4 mass % between the higher content of a heavy rare-earth element RH in the R-T-B based alloy powder B and the lower content of the heavy rare-earth element RH in the R-T-B based alloy powder A; mixing these two R-T-B based alloy powders A and B together; compacting the mixed R-T-B based alloy powder to obtain a compact with a predetermined shape; and sintering the compact.

Owner:HITACHI METALS LTD

Rare earth permanent magnet and its preparation

ActiveUS20110036460A1Efficient productivityGood magnetic performancePermanent magnetsInorganic material magnetismRemanenceProduction rate

A rare earth permanent magnet is prepared by disposing a powdered metal alloy containing at least 70 vol % of an intermetallic compound phase on a sintered body of R—Fe—B system, and heating the sintered body having the powder disposed on its surface below the sintering temperature of the sintered body in vacuum or in an inert gas for diffusion treatment. The advantages include efficient productivity, excellent magnetic performance, a minimal or zero amount of Tb or Dy used, an increased coercive force, and a minimized decline of remanence.

Owner:SHIN ETSU CHEM IND CO LTD

Method for producing r-t-b sintered magnet

ActiveUS20110262297A1Decreasing remanenceIncrease in coercivityTransportation and packagingMetal-working apparatusRare-earth elementSintered magnets

A method for producing a sintered R-T-B based magnet includes the steps of: providing R-T-B based alloy powders A and B so that the R-T-B based alloy powder B has a particle size D50 that is smaller by at least 1.0 μm than that of the R-T-B based alloy powder A and that there is a difference ΔRH of at least 4 mass % between the higher content of a heavy rare-earth element RH in the R-T-B based alloy powder B and the lower content of the heavy rare-earth element RH in the R-T-B based alloy powder A; mixing these two R-T-B based alloy powders A and B together; compacting the mixed R-T-B based alloy powder to obtain a compact with a predetermined shape; and sintering the compact.

Owner:HITACHI METALS LTD

Low remanence flux concentrator for MRAM devices

InactiveUS20050030786A1Low remanenceMinimise currentMagnetic-field-controlled resistorsSolid-state devicesRemanenceElectrical conductor

Systems, devices and methods are provided for magnetic memory elements with low remanence flux concentrators. Improved bit yield is attributable to reduced remanence in the flux concentrator. Remanence provides the memory element with a biasing magnetic field. The flux concentrator includes anisotropy aligned with an appropriate conductor. One aspect of the present subject matter is a memory cell. One memory cell embodiment includes a magnetic memory element and a flux concentrator operably positioned with respect to a conductor. The conductor is adapted to provide a current-induced magnetic flux to the magnetic memory element. The flux concentrator includes an easy axis of magnetization aligned with the conductor and a hard axis of magnetization orthogonal to the easy axis of magnetization. Other aspects are provided herein.

Owner:MICRON TECH INC

Rare earth magnet and its preparation

ActiveUS20150093501A1Prevent oxidationMinimal hazardTransportation and packagingMetal-working apparatusRare-earth elementRare-earth magnet

A rare earth magnet is prepared by disposing a R1-T-B sintered body comprising a R12T14B compound as a major phase in contact with an R2-M alloy powder and effecting heat treatment for causing R2 element to diffuse into the sintered body. The alloy powder is obtained by quenching a melt containing R2 and M. R1 and R2 are rare earth elements, T is Fe and / or Co, M is selected from B, C, P, Al, Si, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ga, Ge, Zr, Nb, Mo, Ag, In, Sn, Sb, Hf, Ta, W, Pt, Au, Pb, and Bi.

Owner:SHIN ETSU CHEM IND CO LTD

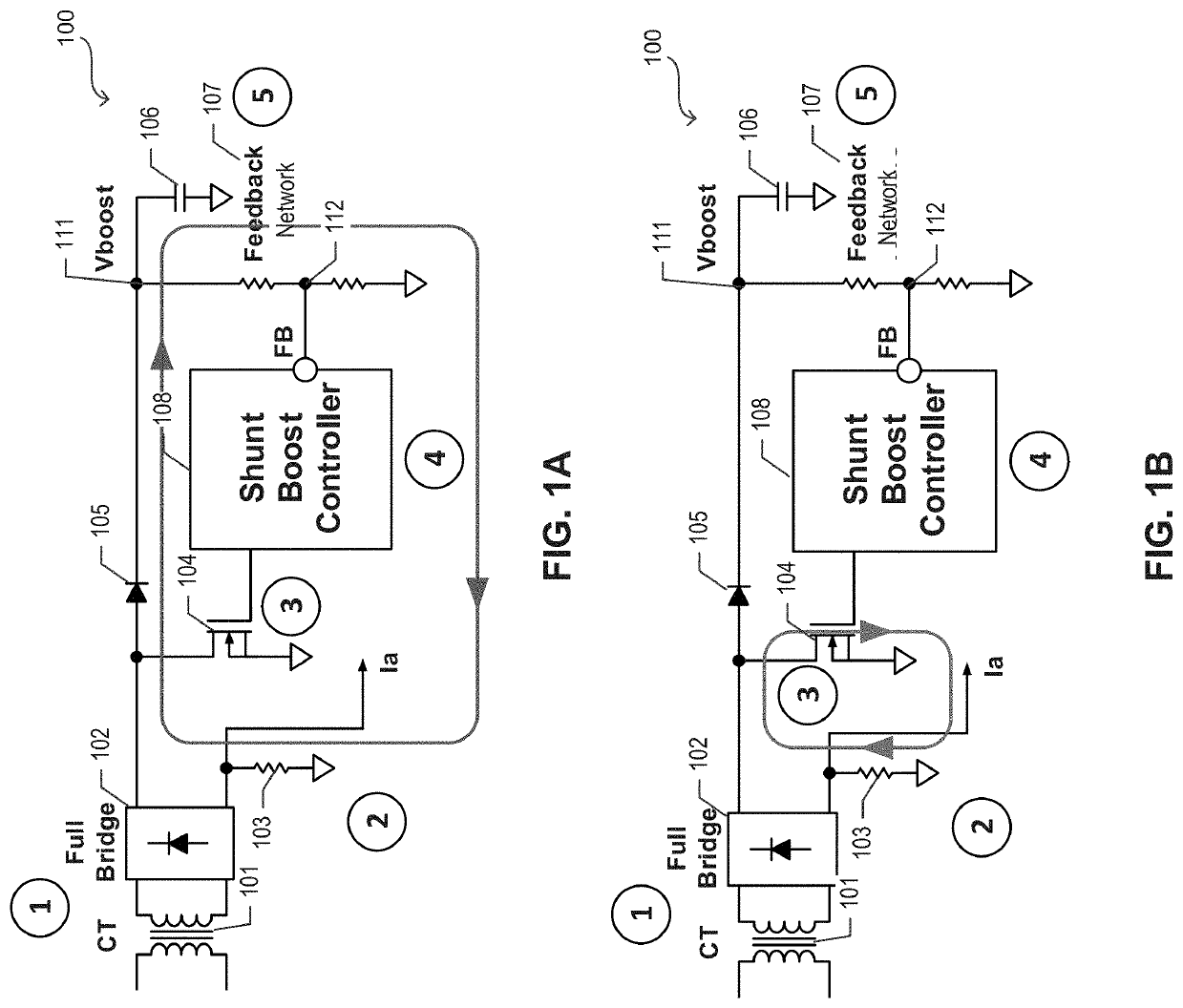

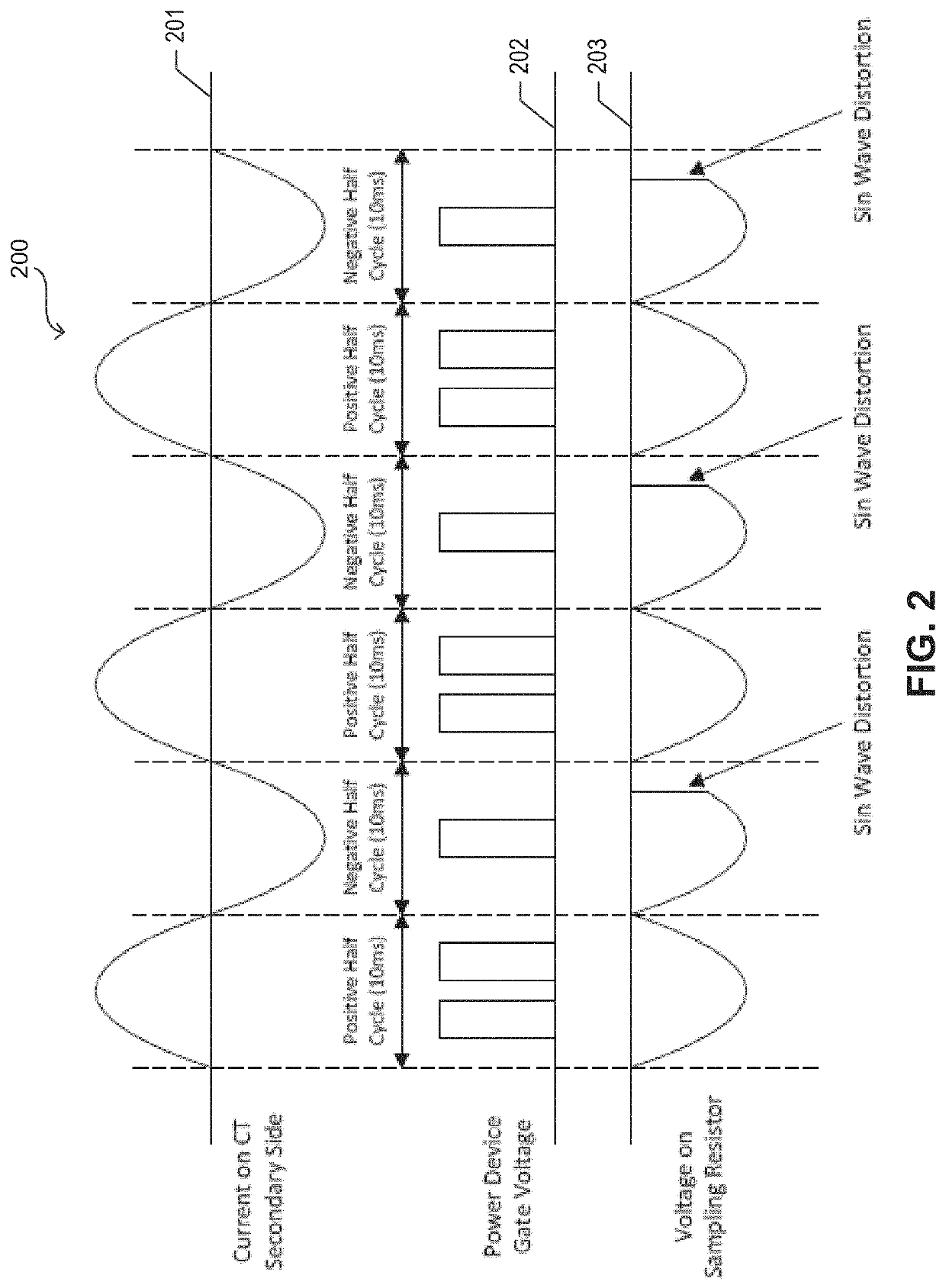

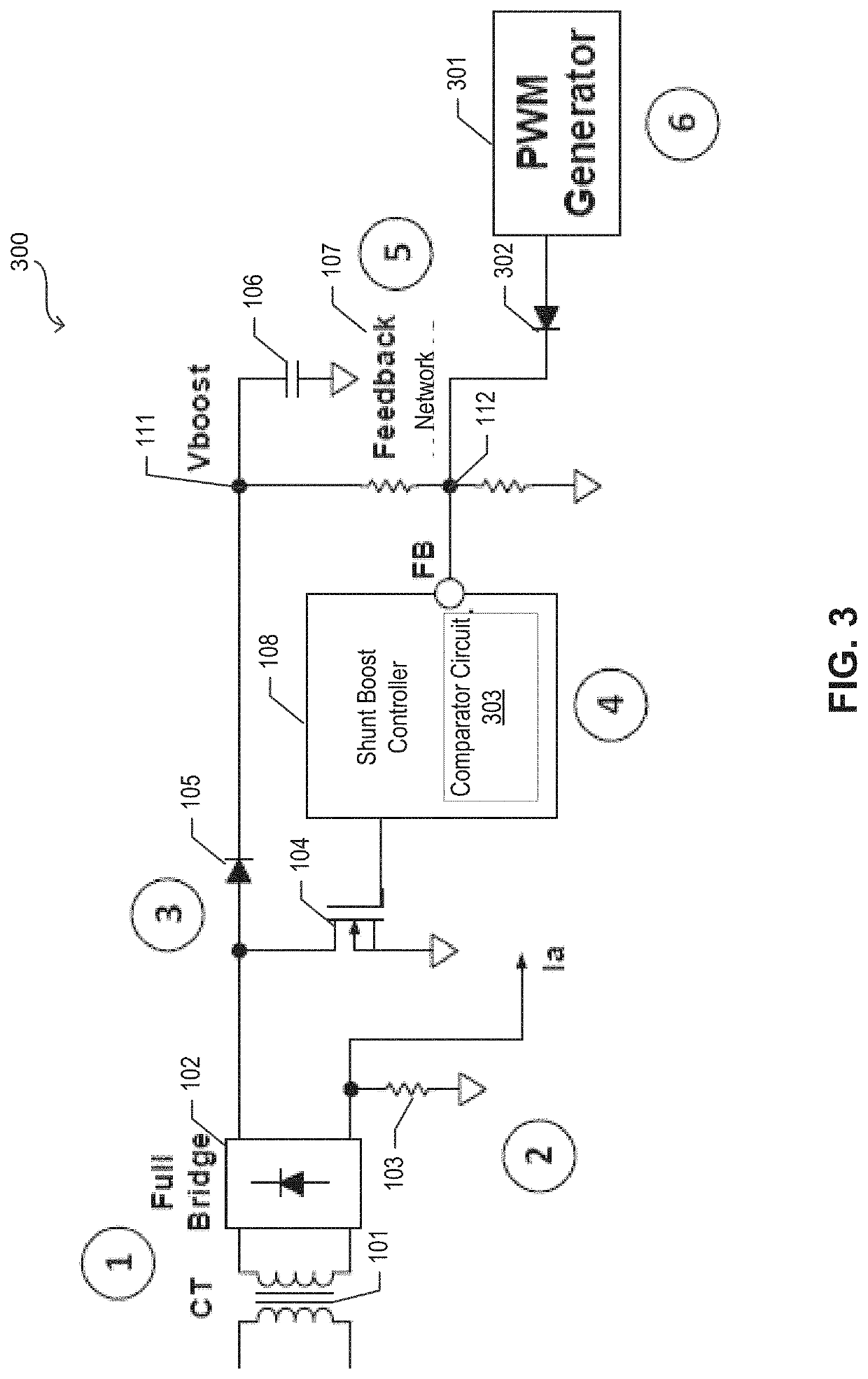

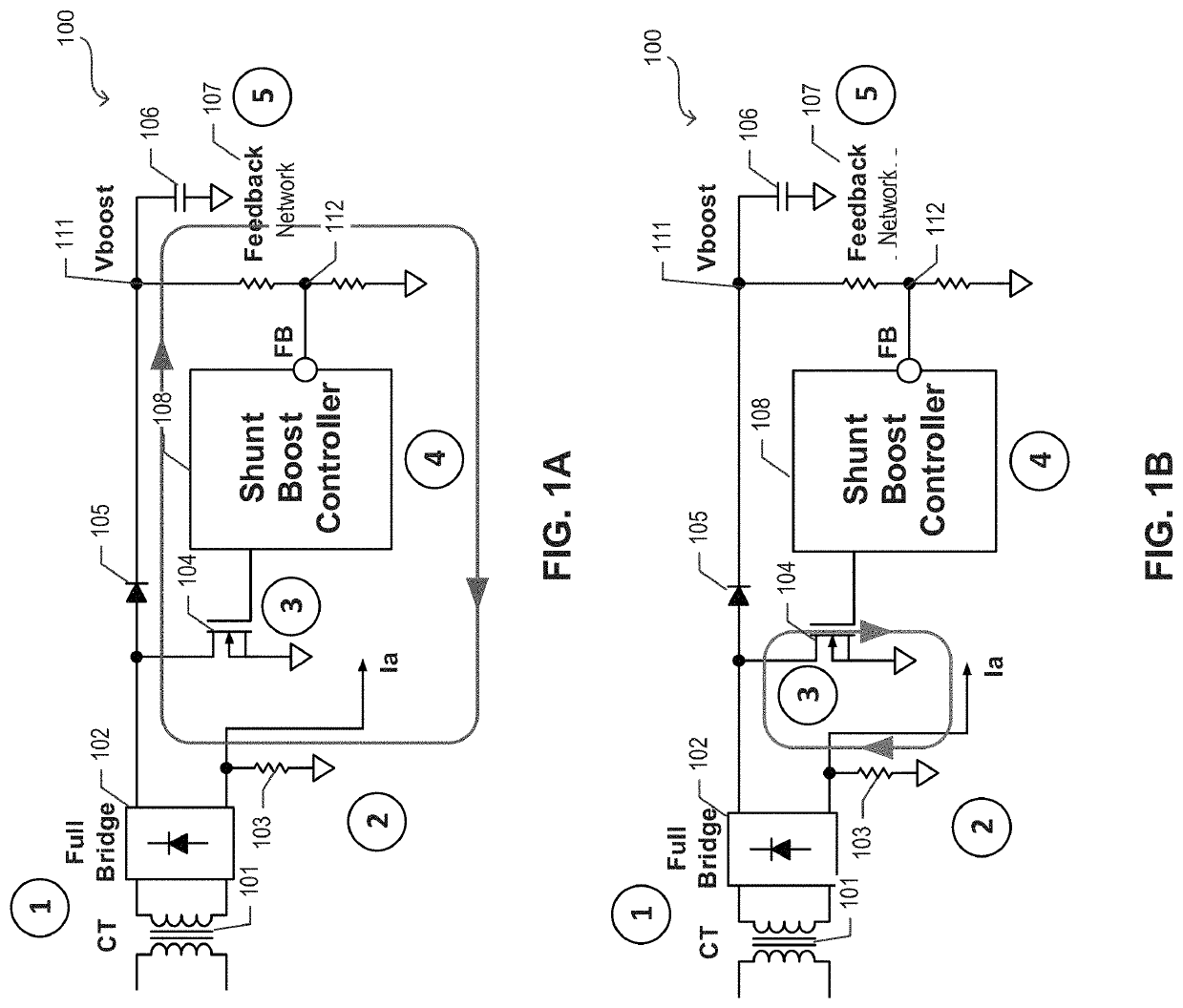

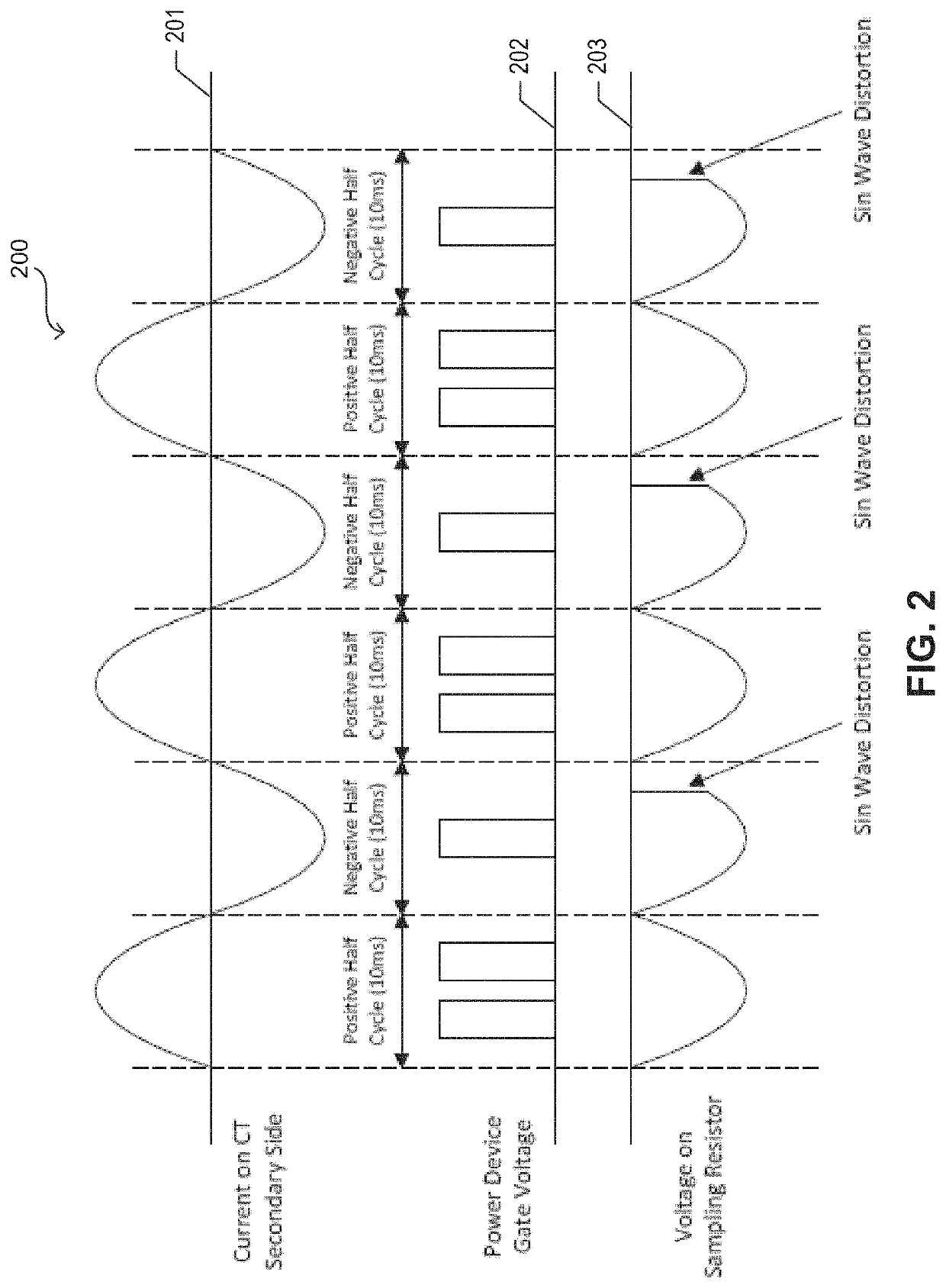

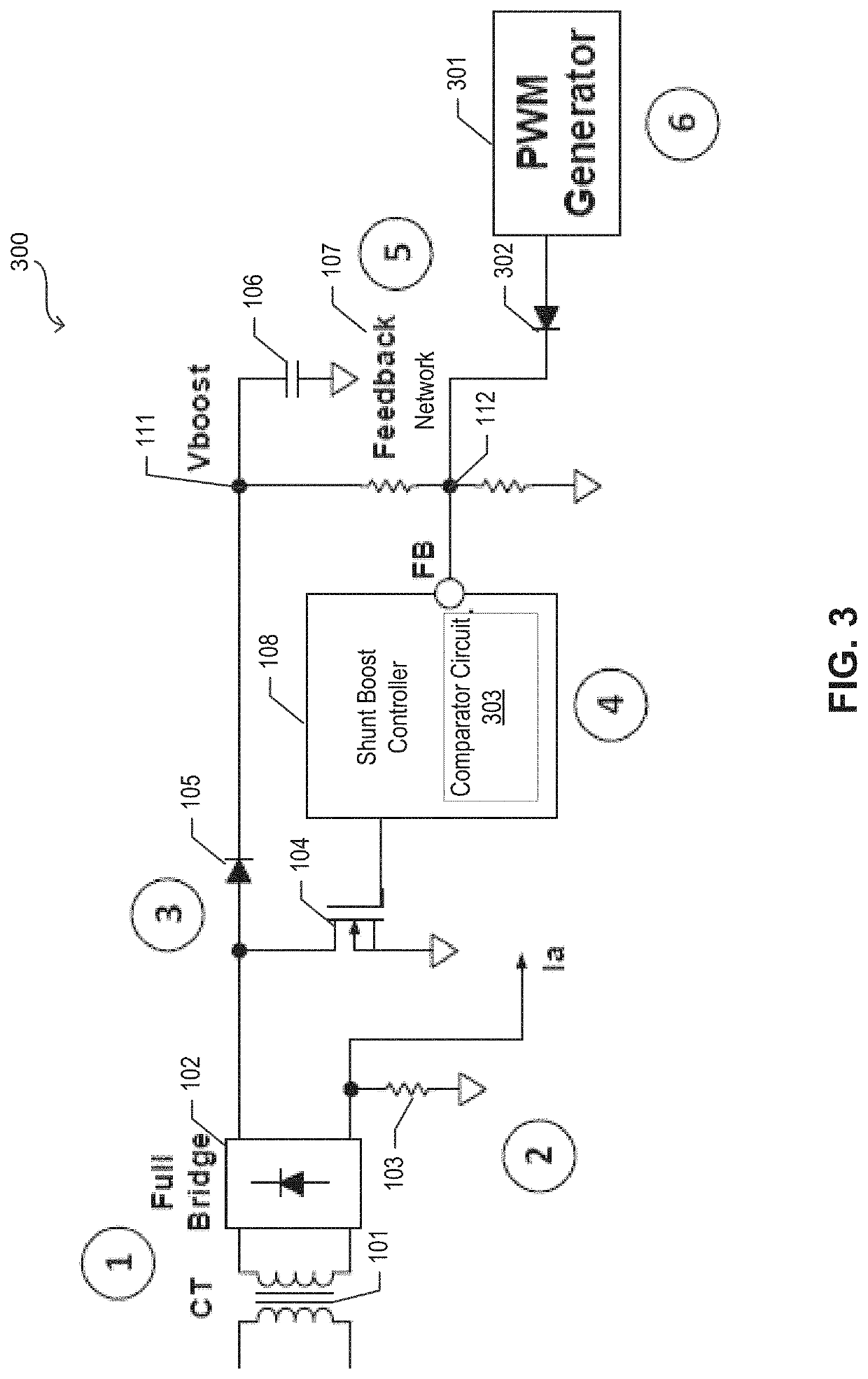

Saturation prevention of current transformer

ActiveUS20200090861A1Avoid saturationReduce imbalanceAc-dc conversion without reversalTransformersControl signalBoost controller

The subject disclosure provides for utilizing pulse width modulation (PWM) signaling to influence a closed loop of a shunt boost controller and reduce an imbalance of a load. The imbalance reduction helps reduce remanence of a current transformer (CT) and thereby prevent saturation of the CT. A shunt boost controller provides the control signal to control flow of current to the load. A feedback network provides a feedback signal to the shunt boost controller based on a direct current (DC) voltage and causes a power switch circuit to turn on when a magnitude of the feedback signal exceeds a threshold magnitude. The PWM generator supplies a PWM signal to cause the control signal to be provided more symmetrical to the power switch circuit and causes the power switch circuit to turn on more frequently with the control signal to reduce the imbalance of the load.

Owner:ANALOG DEVICES GLOBAL UNLTD

Rare earth permanent magnet and its preparation

ActiveUS20110036459A1Efficient productivityGood magnetic performancePermanent magnetsInorganic material magnetismRemanenceProduction rate

A rare earth permanent magnet is prepared by disposing a powdered metal alloy containing at least 70 vol % of an intermetallic compound phase on a sintered body of R—Fe—B system, and heating the sintered body having the powder disposed on its surface below the sintering temperature of the sintered body in vacuum or in an inert gas for diffusion treatment. The advantages include efficient productivity, excellent magnetic performance, a minimal or zero amount of Tb or Dy used, an increased coercive force, and a minimized decline of remanence.

Owner:SHIN ETSU CHEM IND CO LTD

Perpendicular magnetic recording head with a laminated pole

ActiveUS8059366B2Increase coverageDecreasing remanenceRecord information storageHeads for perpendicular magnetisationsAntiferromagnetic couplingNon magnetic

A laminated write pole layer for a PMR write head is disclosed in which a plurality of “n” magnetic layers and “n−1” non-magnetic spacers are formed in an alternating fashion on a substrate. The non-magnetic spacers promote exchange decoupling or antiferromagnetic coupling between adjacent magnetic layers. Writability is improved when the trailing magnetic layer has a thickness greater than the thickness of other magnetic layers and preferably >25% of the total thickness of the magnetic layers. The thicknesses of the other magnetic layers may be equal or may become progressively smaller with increasing distance from the trailing magnetic layer. In another embodiment, the non-magnetic spacer between the trailing magnetic layer and the nearest magnetic layer is replaced by a magnetic spacer made of a soft magnetic material to promote magnetic coupling and effectively increase the thickness of the trailing magnetic layer.

Owner:HEADWAY TECH INC

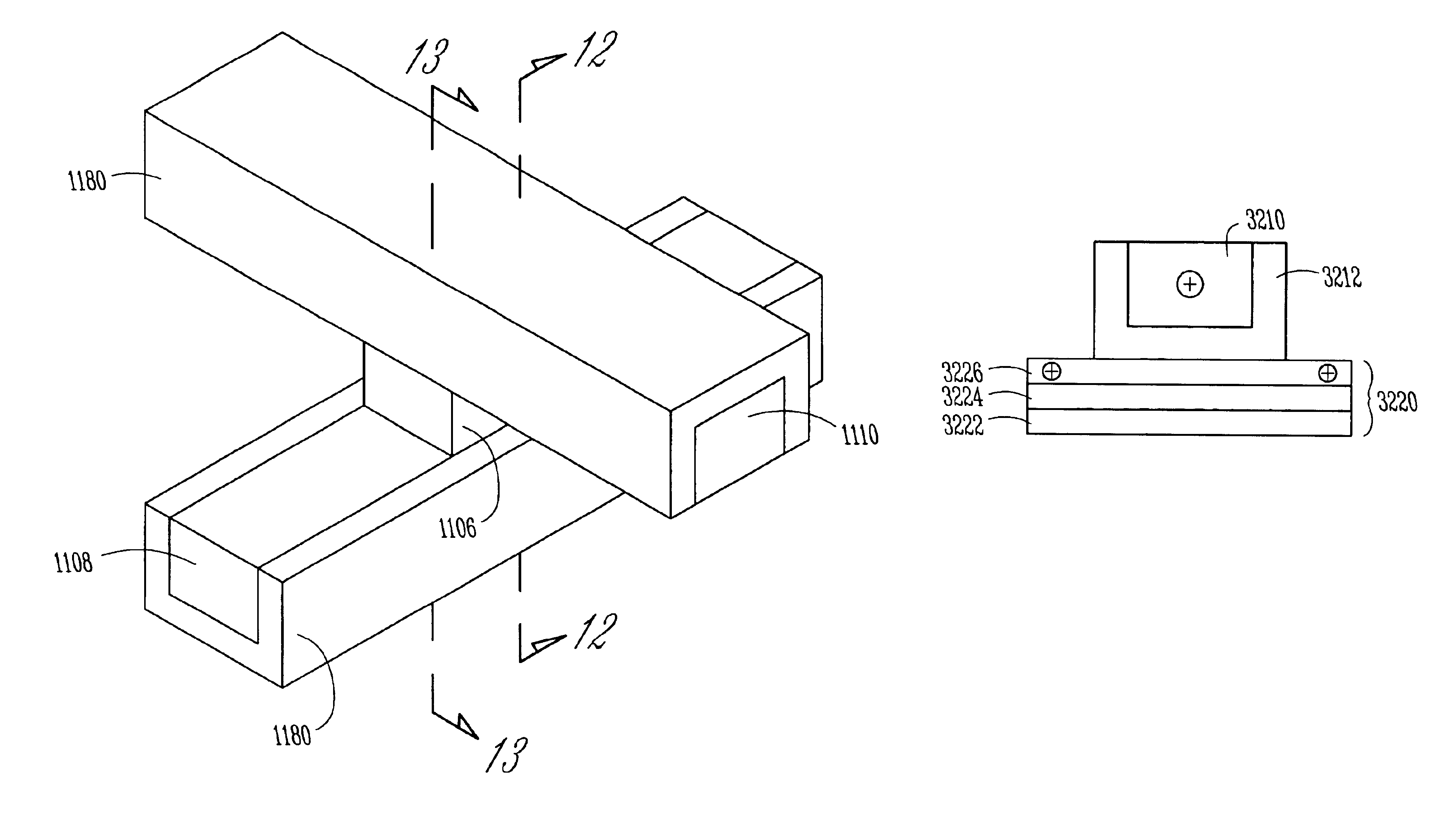

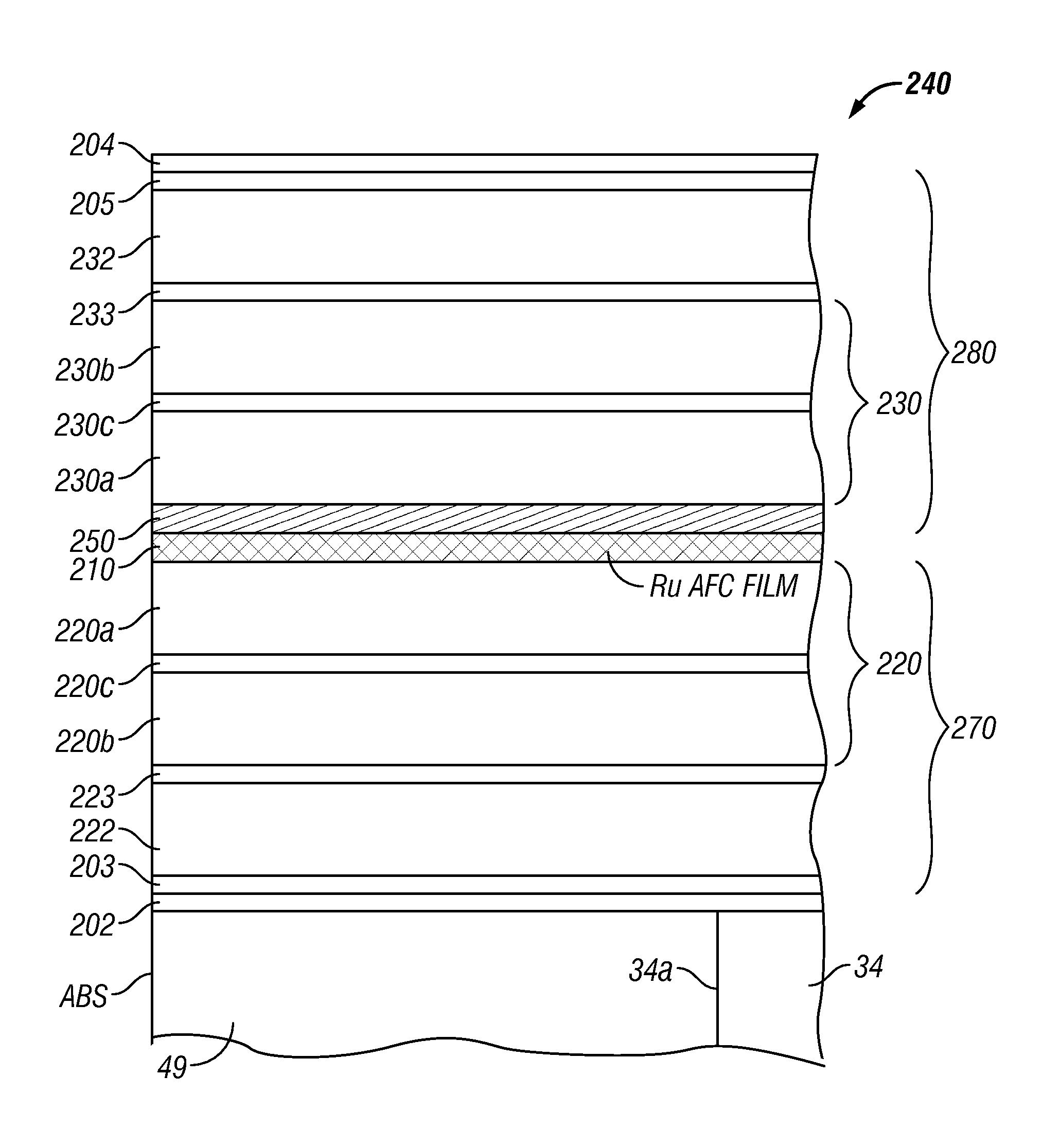

Perpendicular magnetic recording write head with improved laminated main pole

InactiveUS8139321B2Improved antiferromagnetically-coupled laminated main poleDecreasing remanenceManufacture head surfaceDisposition/mounting of recording headsAntiferromagnetic couplingElectrical and Electronics engineering

A perpendicular magnetic recording write head has an improved antiferromagnetically-coupled laminated main pole (MP) formed on a substrate. The MP has two ferromagnetic multilayers, each comprising at least one FeCo / NiFe / FeCo ferromagnetic trilayer, antiferromagnetically coupled across an antiferromagnetically coupling (AFC) film consisting essentially of ruthenium (Ru). The MP has a NiFe layer directly above the AFC film, on the side of the AFC film opposite the side facing the substrate, and in contact with the Ru AFC film and the lower FeCo layer of the upper multilayer. There is no NiFe layer directly below the Ru AFC film so the side of the AFC film facing the substrate is in direct contact with the upper FeCo layer of the lower multilayer.

Owner:WESTERN DIGITAL TECH INC

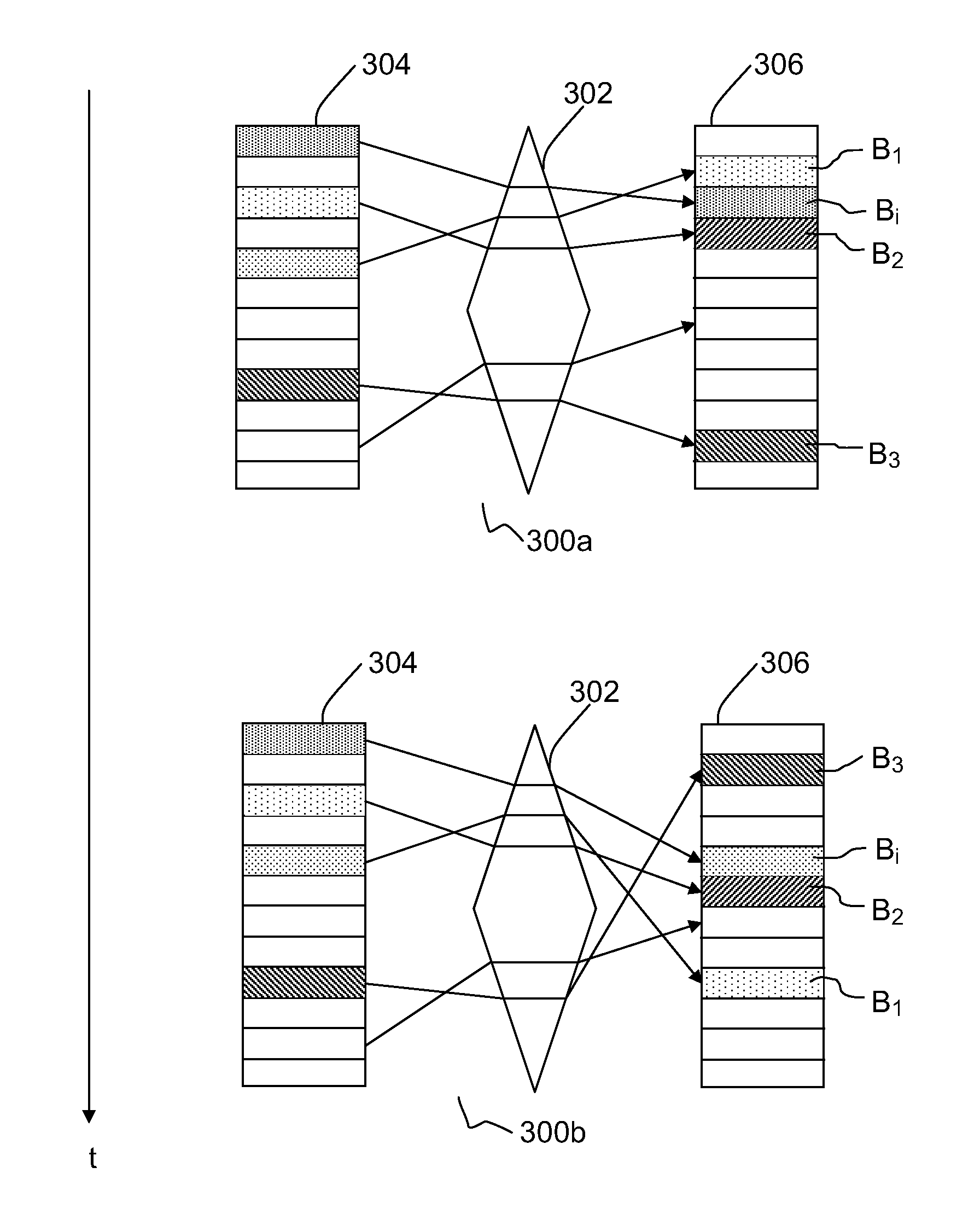

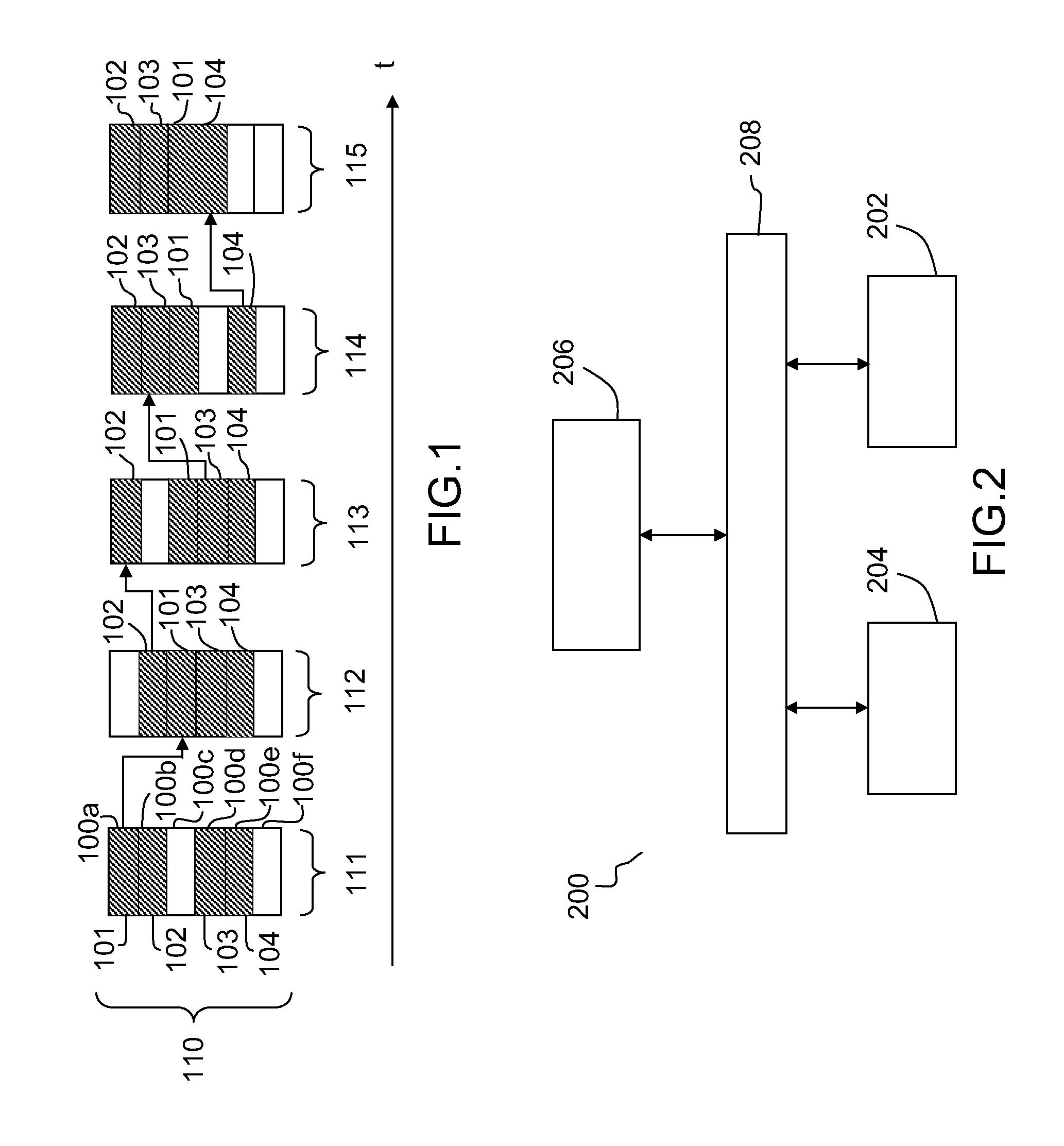

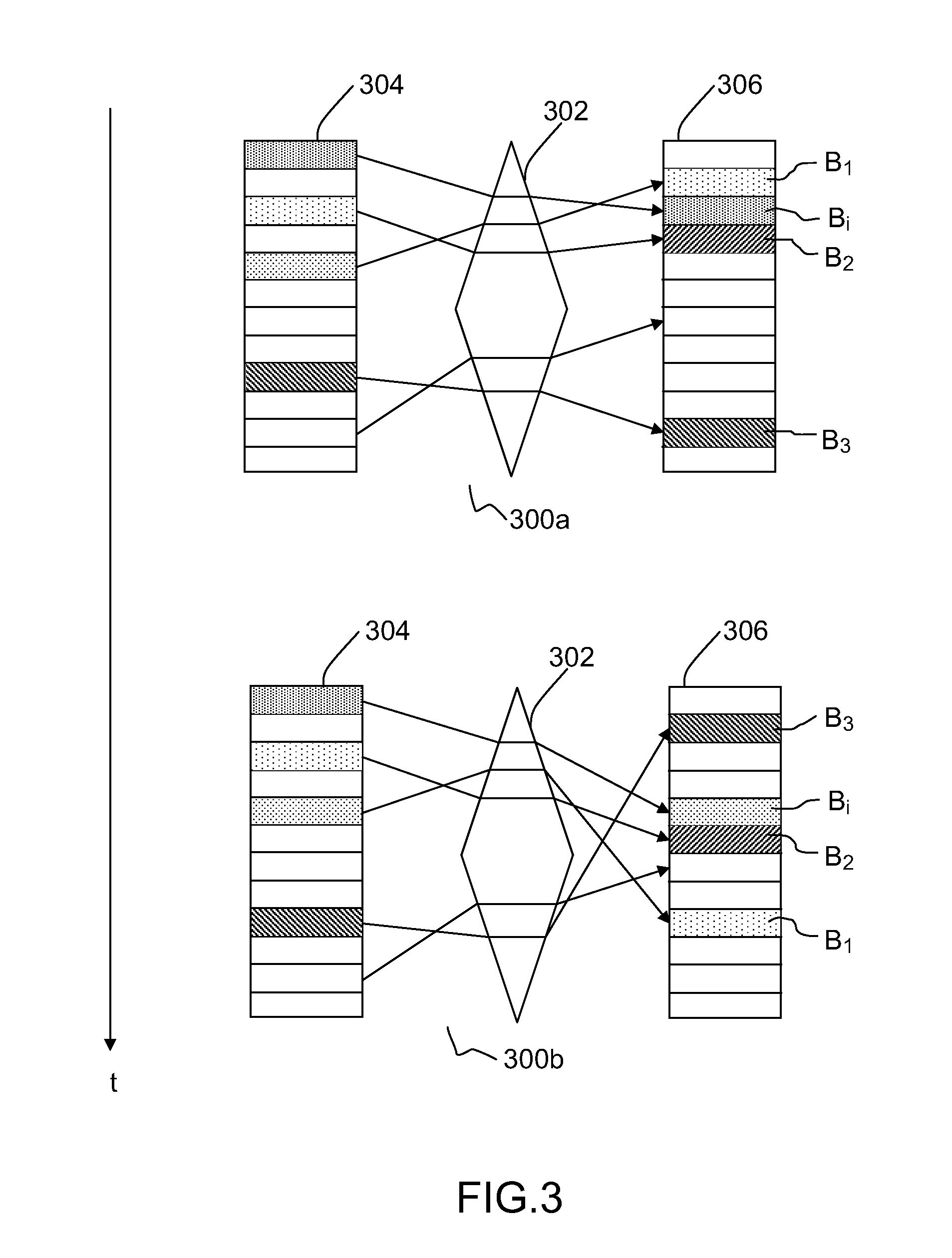

Method and Device for Reducing the Remanence of Data Stored on a Recording Medium

InactiveUS20110314216A1Decreasing remanenceReducing data remanenceMemory adressing/allocation/relocationInternal/peripheral component protectionRemanenceData storing

In a method of reducing the remanence of data stored in the memory space of a recording medium, in which at least a portion of the data stored in the memory space is moved in blocks according to a cycle repeated over time, the cycle includes choosing a number N of data blocks to be moved, and, as long as the number D of blocks moved during the cycle is less than N: a data block Bi to be moved is chosen, a free memory area is chosen; and the data block Bi is moved to this free area.

Owner:THALES SA

Preparation of permanent magnet material

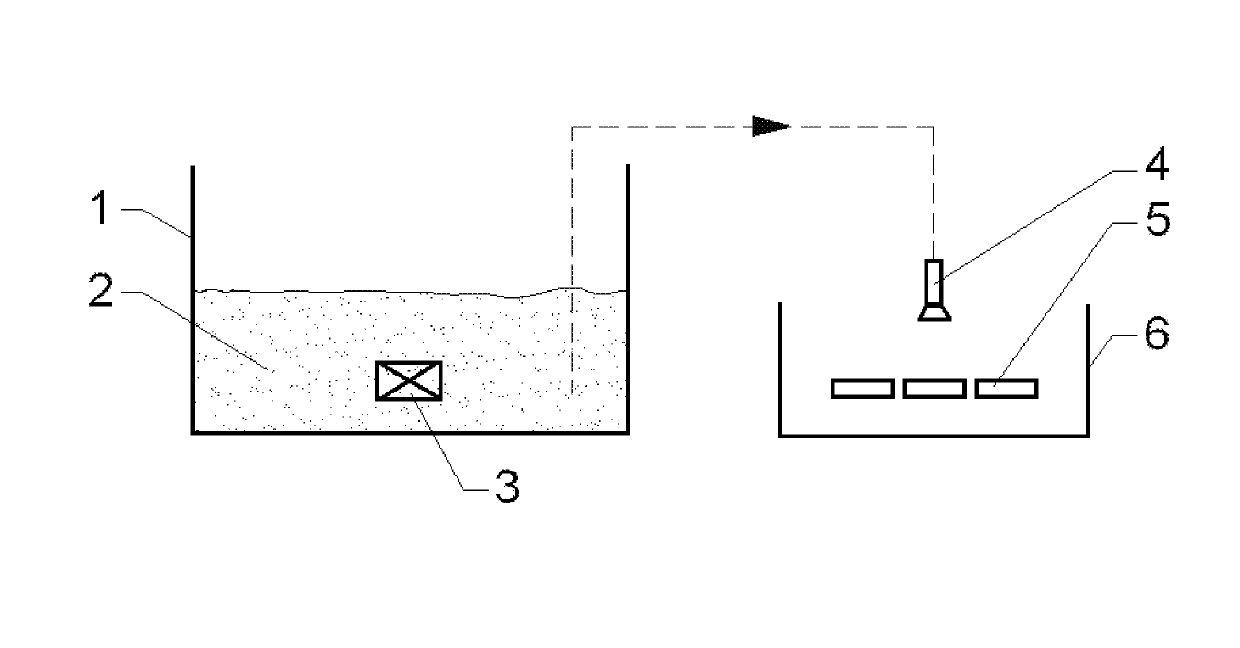

ActiveUS10269488B2Improve efficiencyImprove homogeneityMagnetic materialsEncapsulation/impregnationRare-earth elementRemanence

The present invention provides a method for preparing a permanent magnet material, the method comprising coating step and infiltrating step, wherein, coating a rare earth element-containing substance on the surface of a permanent magnet, the magnet having a thickness of 10 mm or less at least in one direction, then placing the magnet into a container, vacuuming to an atmospheric pressure of below 10 Pa, closing the passageway, and then heat treating the closed container. Using the method of the present invention enables the rare earth element to infiltrate homogeneously with a high permeability. In addition, the present invention may have a lower production cost, significantly increase coercive force of the permanent magnet material, but decrease the remanence very little.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

Saturation prevention of current transformer

ActiveUS10811185B2Reduce imbalanceDecreasing remanenceAc-dc conversion without reversalTransformersControl signalBoost controller

The subject disclosure provides for utilizing pulse width modulation (PWM) signaling to influence a closed loop of a shunt boost controller and reduce an imbalance of a load. The imbalance reduction helps reduce remanence of a current transformer (CT) and thereby prevent saturation of the CT. A shunt boost controller provides the control signal to control flow of current to the load. A feedback network provides a feedback signal to the shunt boost controller based on a direct current (DC) voltage and causes a power switch circuit to turn on when a magnitude of the feedback signal exceeds a threshold magnitude. The PWM generator supplies a PWM signal to cause the control signal to be provided more symmetrical to the power switch circuit and causes the power switch circuit to turn on more frequently with the control signal to reduce the imbalance of the load.

Owner:ANALOG DEVICES GLOBAL UNLTD

Resistance measurement in high power apparatus environments

ActiveUS8497692B2Easy to useContinuous operationResistance/reactance/impedenceFault locationElectrical resistance and conductancePower flow

Systems and methods can be provided for measuring the resistance of high power apparatuses. A device can include a current source connectable to a test object, and the ability for measuring current and / or voltage, wherein the current source is a capacitor. By providing the current source as a capacitor, a light weight device is obtained which can be used essentially continuously without periods of non-use during recharging.

Owner:MEGGER SWEDEN

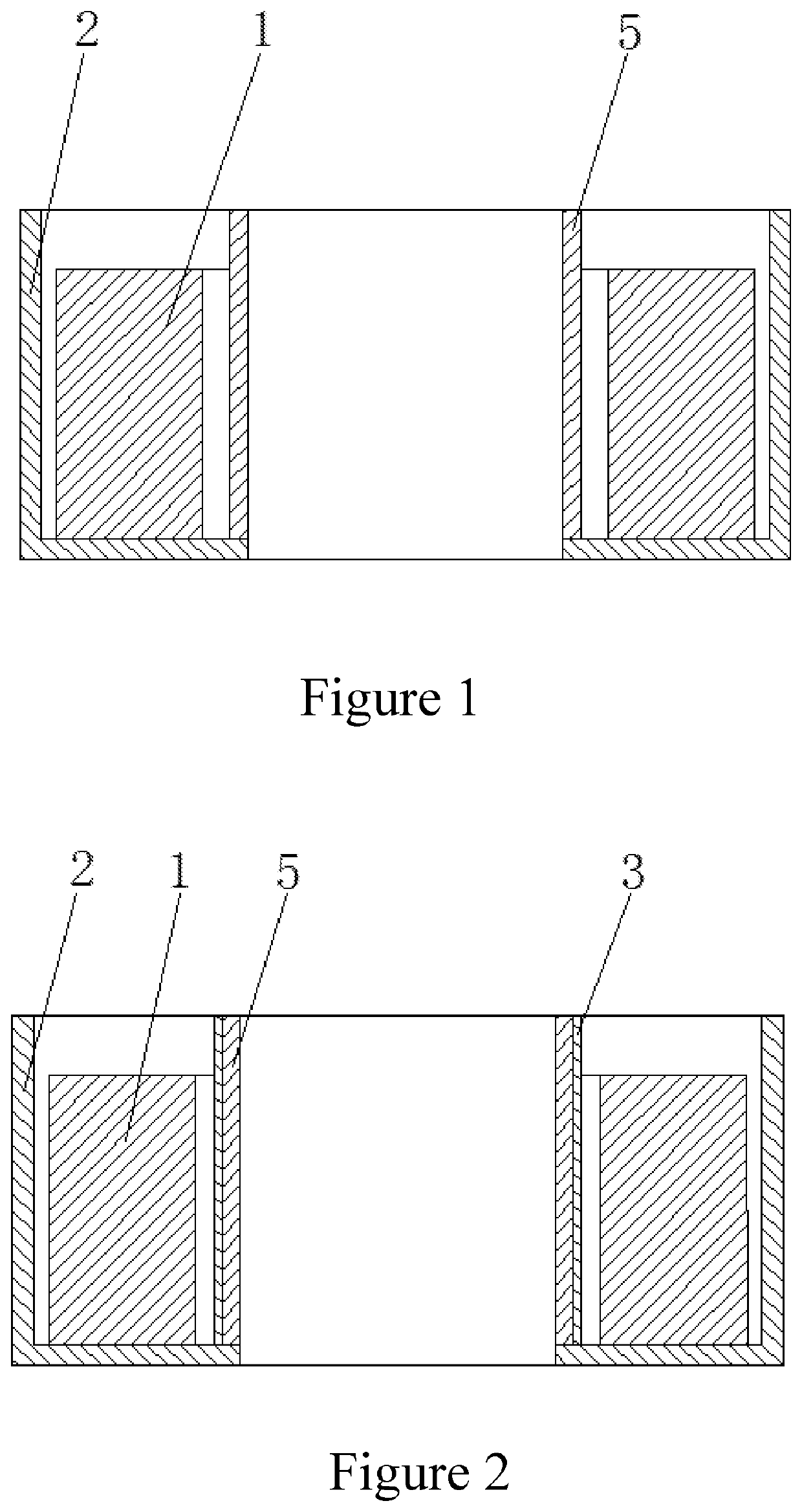

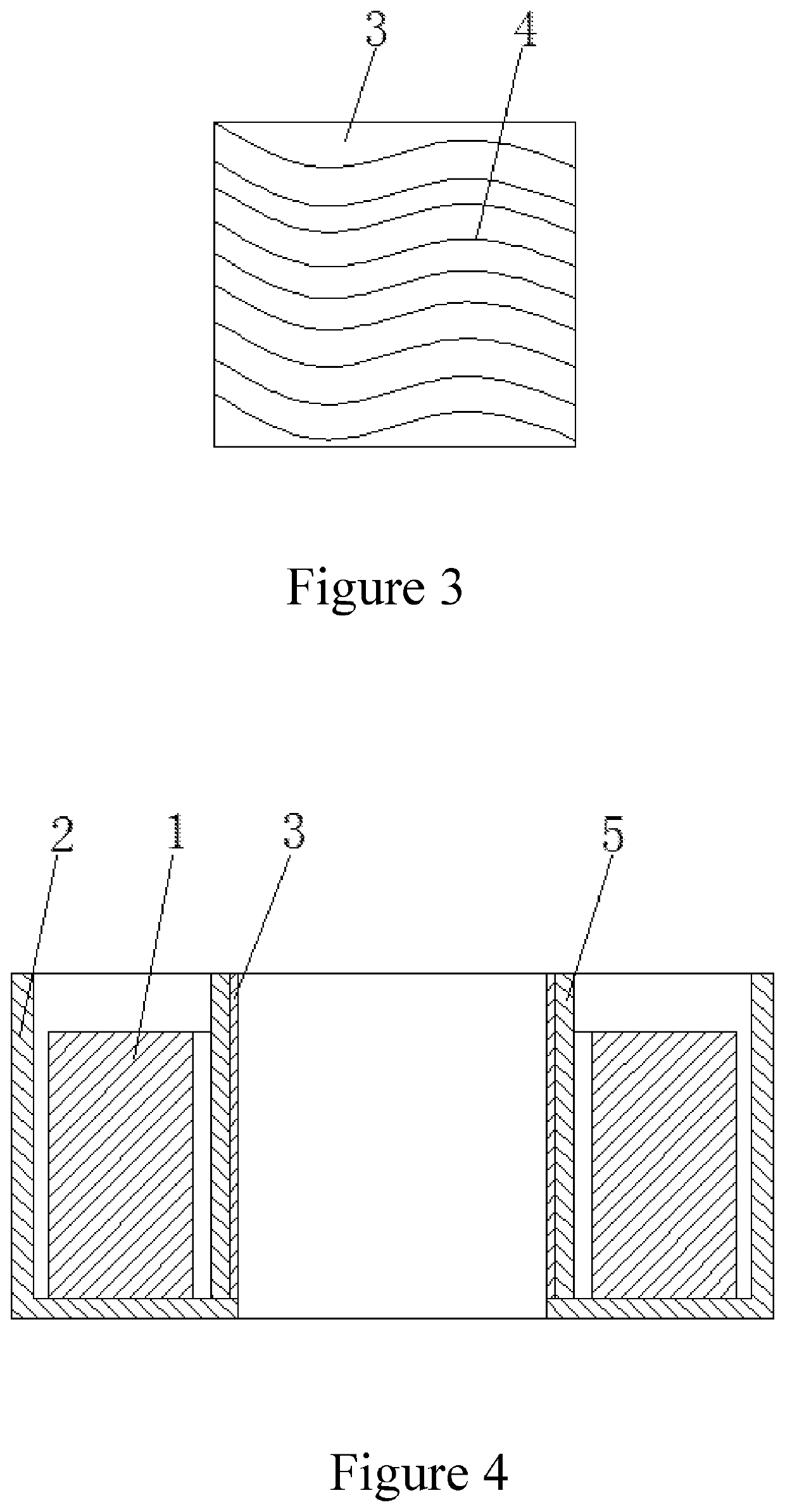

Inductor's Electromagnetic Balance Improvement Method

InactiveUS20190392983A1Reduce gapDecreasing remanenceTransformersTransformers/inductances casingsRemanenceEngineering

This invention proposes an inductor's electromagnetic balance improvement method which equips protective box inside magnet ring with an arc-shaped shield. It can block out electromagnetism of magnet ring from all angles to reduce remanence, improve inductor's electromagnetic balance, and shorten the gap between action current of fire wire and that of naught wire. In this way, product yield rate can be increased.

Owner:SHENZHEN SIMIDE ELECTRONICS TECH CO LTD

Rare earth permanent magnets and their preparation

ActiveUS20170186534A1Delay recessionGood magnetic performanceTransportation and packagingMetal-working apparatusRemanencePowder mixture

A sintered magnet body (RaT1bMcBd) coated with a powder mixture of an intermetallic compound (R1iM1j, R1xT2yM1z, R1iM1jHk), alloy (M1dM2e) or metal (M1) powder and a rare earth (R2) oxide is diffusion treated. The R2 oxide is partially reduced during the diffusion treatment, so a significant amount of R2 can be introduced near interfaces of primary phase grains within the magnet through the passages in the form of grain boundaries. The coercive force is increased while minimizing a decline of remanence.

Owner:SHIN ETSU CHEM IND CO LTD

Preparation of rare earth permanent magnet material

ActiveUS10381140B2Reduce the amount requiredReduce the temperatureBlade accessoriesMachines/enginesRemanenceRare-earth element

The present invention provides a method for preparing a rare earth permanent magnet material. The preparation method of the present invention comprises atomizing spray process and infiltrating process, wherein the atomizing-sprayed sintered rare earth magnet is placed in a closed container before infiltrating. Through the atomizing spray process a solution containing a heavy rare earth element is coated on the surface of a sintered R1-Fe(Co)—B-A-X-M rare earth magnet, and after baking, heat treatment is performed to infiltrate the sprayed heavy rare earth element to the grain boundary phase of the sintered rare earth magnet. This method decreases the amount of a heavy rare earth element used, increases the coercive force of magnets with a little decrease of remanence, decreases the remanence temperature coefficient and coercive force temperature coefficient of the magnet, and improves resistance of the magnet against demagnetization at a high temperature.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

Material for anisotropic magnet and method of manufacturing the same

ActiveUS9281106B2Increase in coercivityDecreasing remanenceTransportation and packagingMetal-working apparatusRemanenceUltimate tensile strength

Owner:DAIDO STEEL CO LTD

R-Fe-B anisotropic sintered magnet

ActiveUS8177922B2Magnetocrystalline anisotropy can be increasedDecreasing remanencePermanent magnetsInorganic material magnetismRare-earth elementX-ray

An R—Fe—B based anisotropic sintered magnet according to the present invention has, as a main phase, an R2Fe14B type compound that includes a light rare-earth element RL (which is at least one of Nd and Pr) as a major rare-earth element R, and also has a heavy rare-earth element RH (which is at least one element selected from the group consisting of Dy and Tb). In the crystal lattice of the main phase, the c-axis is oriented in a predetermined direction. The magnet includes a portion in which at least two peaks of diffraction are observed within a 2θ range of 60.5 degrees to 61.5 degrees when an X-ray diffraction measurement is carried out using a CuK α ray on a plane that is located at a depth of 500 μm or less under a pole face of the magnet and that is parallel to the pole face.

Owner:HITACHI METALS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com