[0031]While there are many advantages of the apparatus and methods disclosed herein, only some will be discussed or alluded to herein. One

advantage of the present invention is the incorporation of several tools and methods into a single operation to allow the efficient and cost

effective treatment in a high-temperature high-pressure (“HTHP”) well. In an embodiment, the use of a hydraulic workover unit may allow the workover of the HTHP well to be completed under conditions of

high pressure in a safe and efficient manner. Utilizing a hydraulic workover unit may allow fluid to be transferred in and out of the well bore through both a tubing string and the annular space between the tubing and casing. In addition, the present disclosure includes methods of using the apparatus to perforate, fracture, and treat multiple formation intervals in a single trip with jointed tubing into the well bore. This may be advantageous for HTHP wells. For deep wells, a single trip with jointed tubing may take a considerable amount of time, making any workover operation with several trips in and out of the well bore expensive and inefficient. The efficiencies gained by the unique deployment of these tools may allow for an efficient replacement of tools in the event of unplanned events such as the

premature failure of the tools or remediation of early screen-outs during multiple interval stimulation treatments

[0032]In an embodiment, the apparatus of the present disclosure may comprise a downhole tool

system disposed on tubing string with an interchangeable set of tools for performing treatment operations.

[0033]In one embodiment, the present invention provides a downhole tool

system comprising: a profile nipple disposed on a tubing string, wherein the profile nipple comprises a locking receptacle; and a tool

assembly, wherein the tool

assembly has a locking lug, wherein the locking lug engages the locking lug receptacle, wherein the tool

assembly may be passed through the tubing string to engage the profile nipple. In some embodiments, the tool assembly comprises at least one tool selected from the group consisting of: a perforating gun, and a washing tool. In some embodiments, the tool comprises a hydrajetting tool. In some embodiments, the hydrajetting tool comprises dual check valves. In some embodiments, the tool assembly may be engaged and retrieved by a

wireline, a slickline, or

coiled tubing. These embodiments are discussed below.

[0034]In an embodiment, a locking device may be disposed on the end of a tubing string within a subterranean formation. A variety of tools utilizing locking lugs for engaging the locking device may be used to treat the formation by passing the tools through the interior of the tubing string until they lockingly engage the locking device on the end of the tubing string. In an embodiment, a hydraulic workover unit may be utilized to allow the treatment operations to proceed while the well is under pressure. The downhole tool

system and the various tools that may be used are described in more detail below.

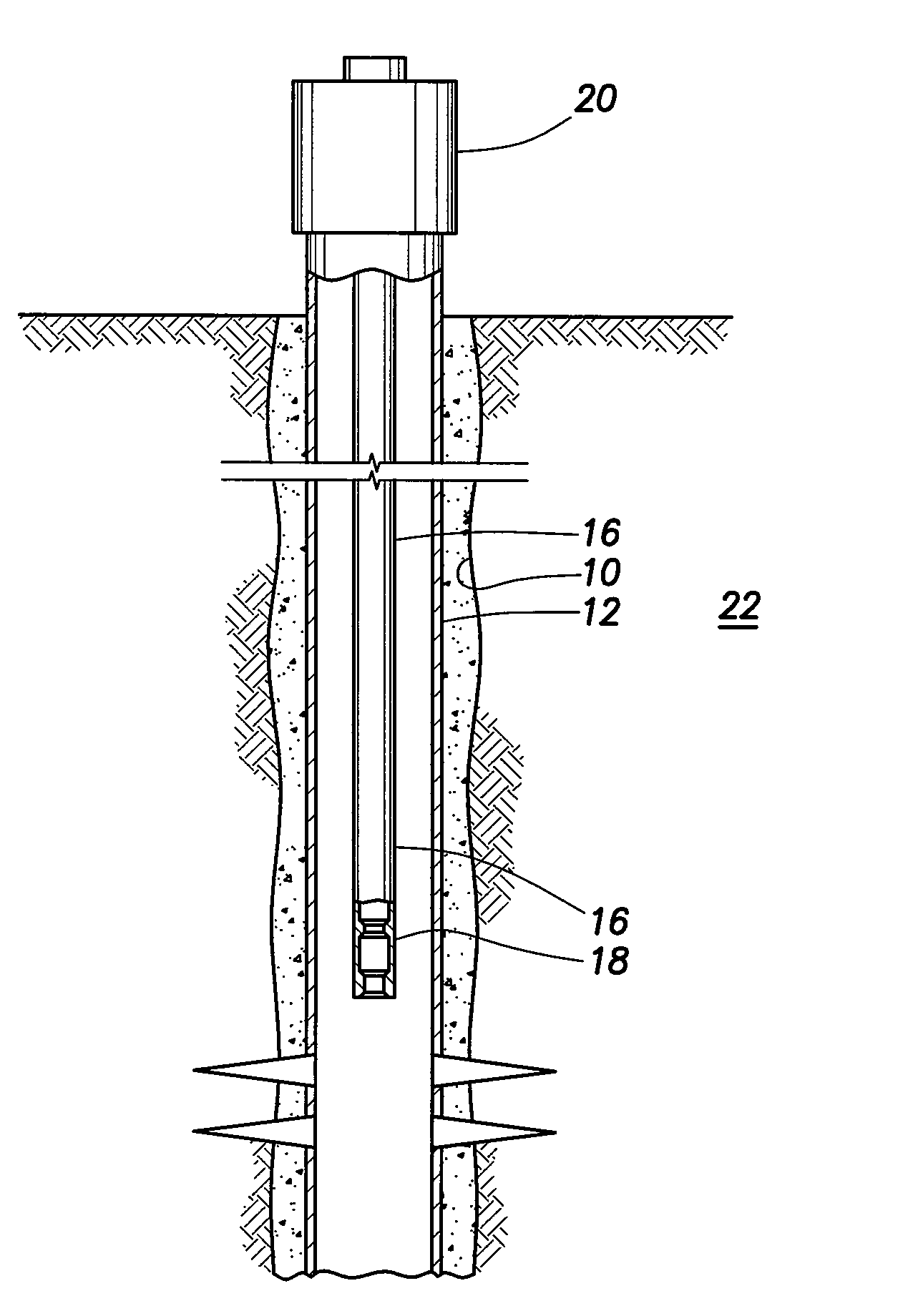

[0035]In an embodiment, the apparatus of the present disclosure may be used in a well bore disposed in a subterranean formation. In an embodiment shown in FIG. 1, a well bore 10 may be created so as to extend into a subterranean formation 22. A casing 12 may be disposed within the well bore and

cement 14 may be introduced between the casing 12 and the well bore 10 walls in order to hold the casing 12 in place and prevent the migration of fluids between the casing 12 and the well bore 10 walls. A tubing string 16 may be disposed within the casing 12. In an embodiment, the tubing string 16 may be jointed tubing,

coiled tubing, or any other type of tubing suitable for use in a subterranean well environment. Suitable types of tubing and an appropriate choice of tubing

diameter and thickness may be known to one skilled in the art, considering factors such as well depth, pressure, temperature, chemical environment, and suitability for its intended use. In an embodiment, a hydraulic workover unit 20 may be disposed at or near the top of the tubing string 16, the casing 12, or both. The hydraulic workover unit 20 may allow for tubing and other items to be introduced into the well bore 10 while a pressure exists and is maintained within the well bore 10 and tubing string 16. The existence of a pressure within the well bore may be referred to as a live well condition.

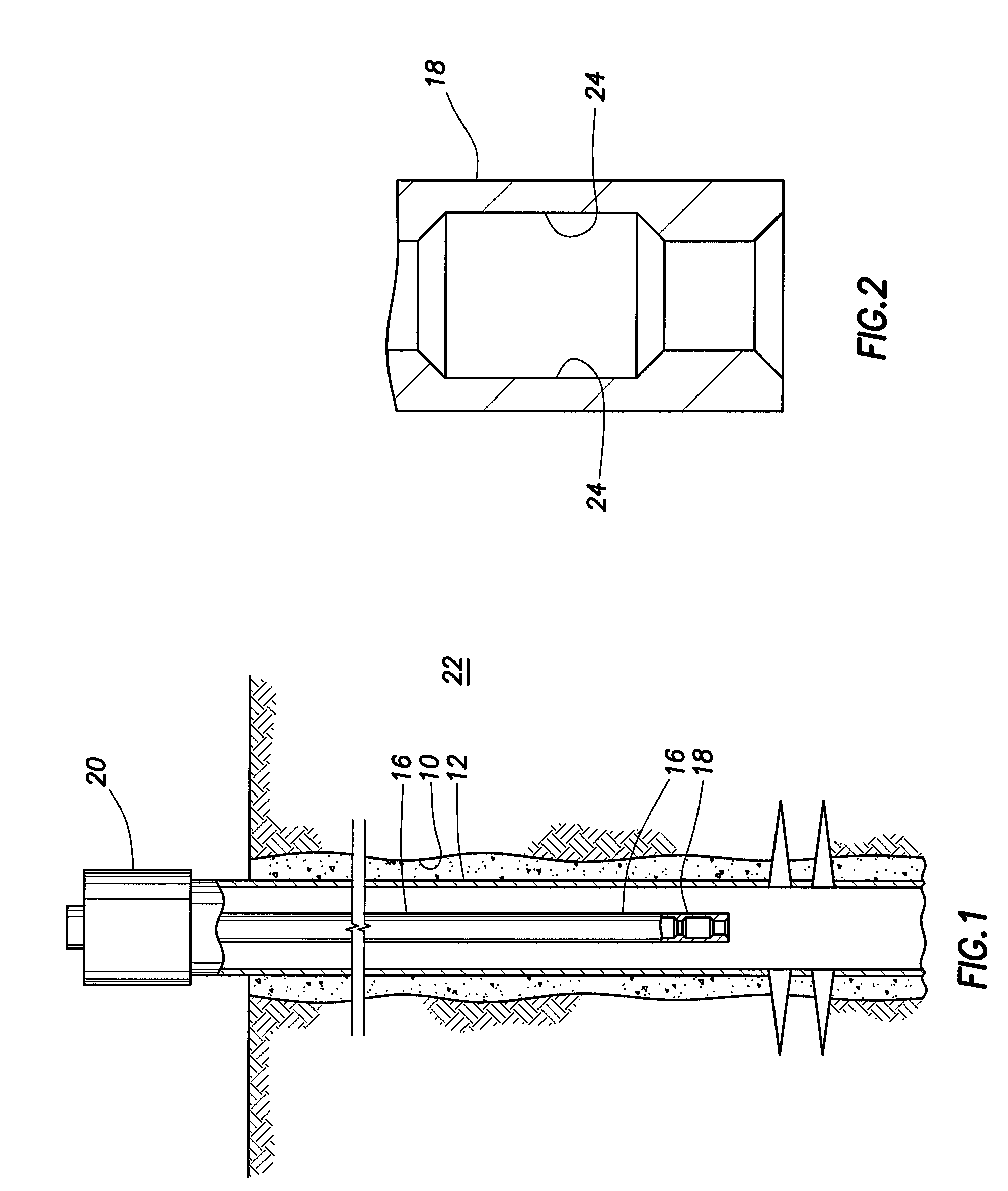

[0036]In an embodiment shown in FIG. 2, the end of the tubing string 16 may contain a locking device that may allow a connection with a tool. In an embodiment, the locking device may be a profile nipple 18. The profile nipple 18 may be designed to allow a variety of tools to be connected to the tubing string such that they may lock into a locking receptacle 24 on the profile nipple 10. In this embodiment, the variety of tools may be passed through the tubing string until locking lugs on the tools lockingly engage the locking receptacles 24 on the profile nipple. The tool may then be utilized on the end of the tubing string to perform a treatment operation. While the terms locking receptacle and locking lugs are used herein, the tools may engage the tubing string using any type of locking device and should not be limited to locking devices with lugs. As used herein, the term locking lugs refers to any device capable of providing a temporary fixed relationship between a tool and tubing. The locking lugs can be released from their temporary fixed relationship through manipulation with a retrieving device on slickline,

wireline,

coiled tubing, or through the

exertion of a physical force on the locking lugs such as pressure in the tubing or a set down force on the tool itself.

Login to View More

Login to View More  Login to View More

Login to View More