Yttrium-iron-garnet film structure and preparation method

A technology of yttrium iron garnet and thin film structure, applied in chemical instruments and methods, application of magnetic films to substrates, magnetic layers, etc., can solve problems such as the gap between magnetic properties and magneto-optical properties, and reduce surface roughness. , Coercive force reduction, surface improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

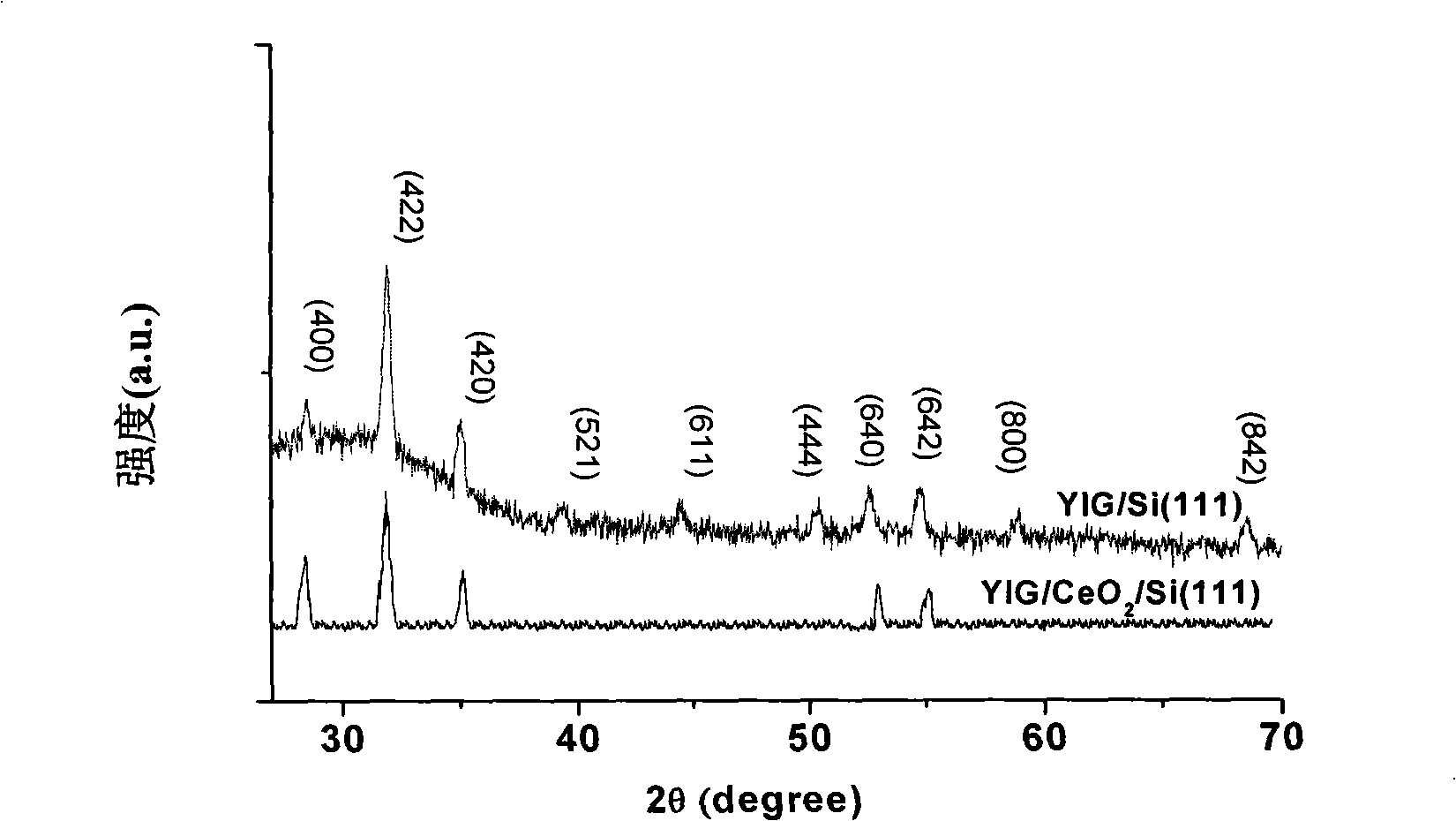

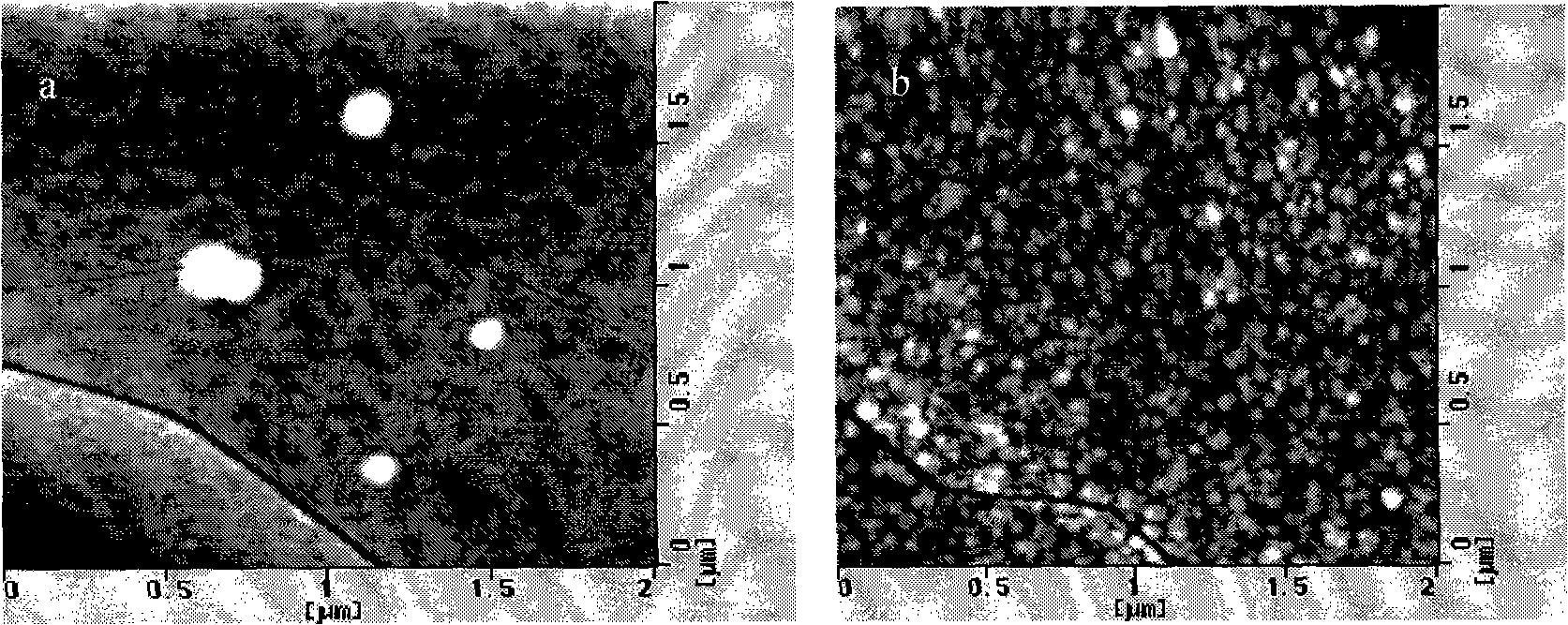

[0030] The invention provides a yttrium-iron garnet film structure, comprising a Si substrate and a yttrium-iron garnet film layer thereon, and CeO between the Si substrate and the yttrium-iron garnet film layer 2 transition layer. CeO 2 The transition layer is plated on the Si substrate.

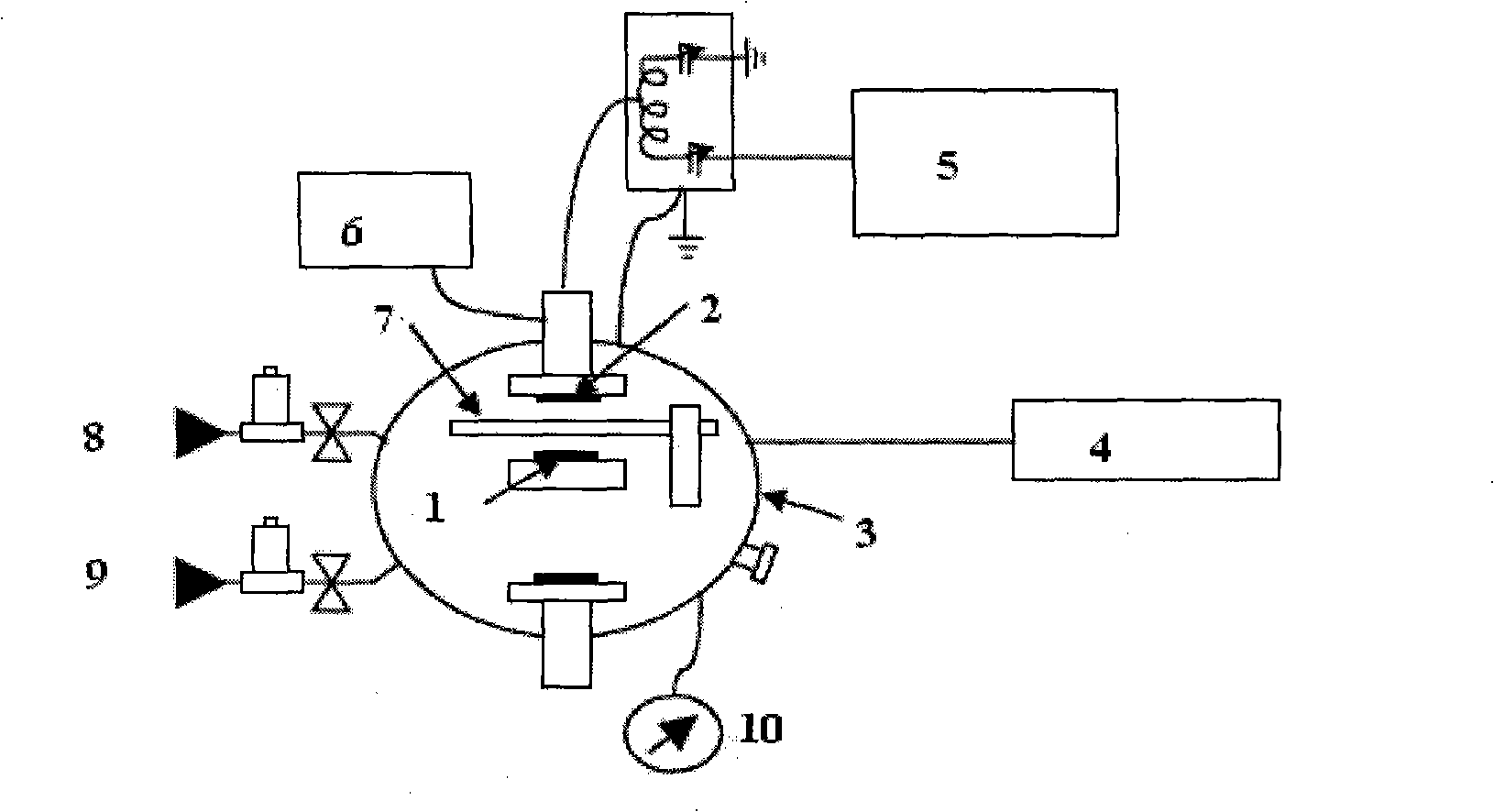

[0031] The present invention adopts figure 1 device shown. The preparation method of the yttrium iron garnet film structure is as follows:

[0032] Step 1. First, the surface of the substrate is pretreated, and the cleaning steps are:

[0033] (1) Ultrasonic cleaning with deionized water for 15 minutes;

[0034] (2) Repeat (1);

[0035] (3) Ultrasonic cleaning with acetone for 15 minutes;

[0036] (4) Repeat (3);

[0037] (5) Ultrasonic cleaning with wine for 15 minutes.

[0038] (6) Repeat (5); (7) Rinse and dry with a large amount of pure water.

[0039] Step 2, fixing the cleaned substrate on the tray and placing it on the sputtering table in the vacuum chamber. First start th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com