Preparation method of laminated magnetic bead

A multi-layer chip and magnetic bead technology, applied in the application of magnetic film to substrate, inductance/transformer/magnet manufacturing, coil manufacturing, etc., can solve the problems of low efficiency, long production cycle, large shrinkage rate, etc., to achieve The effect of improving production efficiency, reducing magnet shrinkage, and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

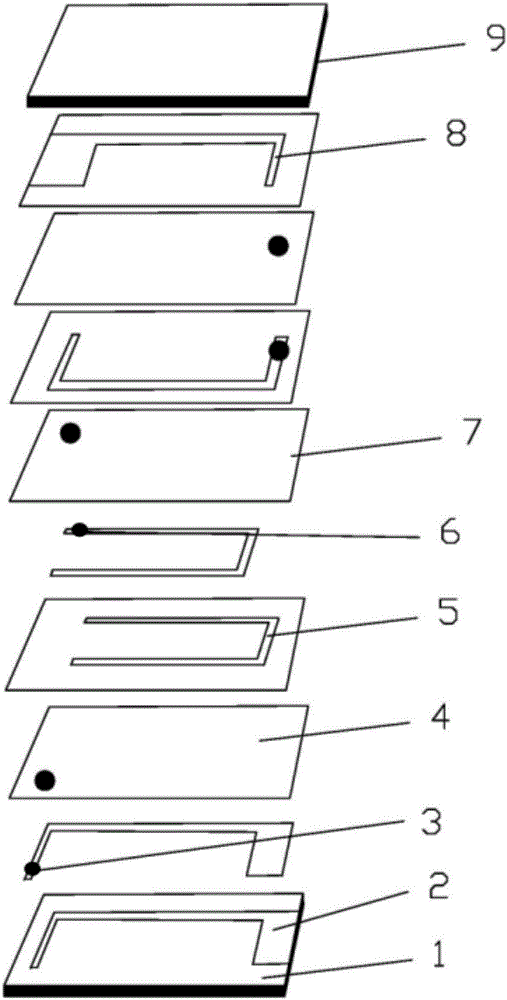

[0040] Embodiment 1: A laminated chip magnetic bead, its structure is as follows figure 1 As shown, the lower substrate 1 and the upper substrate 9 are produced by a dry casting process, the intermediate dielectric films 4 and 7 are produced by a wet casting process, the lower lead-out 2, the upper lead-out 8, the coil 5, the printing point 3 and the 6 are all printed alternately by two screen printing machines. The preparation method comprises the steps of:

[0041] (1) Preparation of slurry:

[0042] Evenly mix the ferrite powder with uniform magnetic permeability and organic solvent, add dispersant, plasticizer and defoamer at the same time, mix the slurry evenly through high-energy ball milling; then add binder and perform secondary ball milling, The mass percentage of each substance is: 56% of ferrite magnetic powder, 5% of PVB adhesive, 35% of organic solvent, 1% of dispersant, 2% of plasticizer, and 1% of defoamer;

[0043] (2) Dry casting:

[0044] Use a high-preci...

Embodiment 2

[0065] Embodiment 2: A laminated chip magnetic bead, its structure is as follows figure 1 As shown, the lower substrate 1 and the upper substrate 9 are produced by a dry casting process, the intermediate dielectric films 4 and 7 are produced by a wet casting process, the lower lead-out 2, the upper lead-out 8, the coil 5, the printing point 3 and the 6 are all printed alternately by two screen printing machines. The preparation method comprises the steps of:

[0066] (1) Preparation of slurry:

[0067] Evenly mix the ferrite powder with uniform magnetic permeability and organic solvent, add dispersant, plasticizer and defoamer at the same time, mix the slurry evenly through high-energy ball milling; then add binder and perform secondary ball milling, The mass percentage of each substance is: ferrite magnetic powder 44%, PVB adhesive 8%, organic solvent 45%, dispersant 1%, plasticizer 1%, defoamer 1%;

[0068] (2) Dry casting:

[0069] A high-precision steel belt casting ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com