Method for improving electromagnetic wave absorption performance of Fe-Si-Al powder

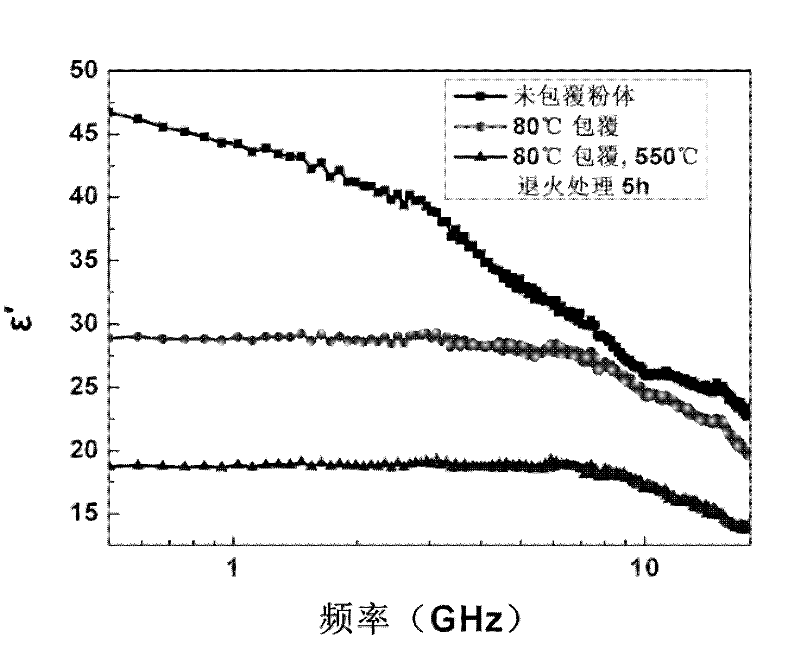

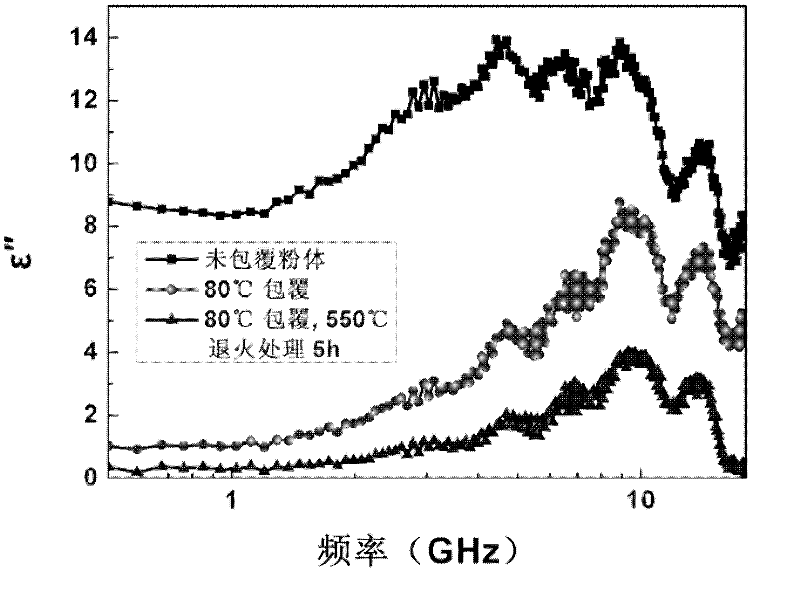

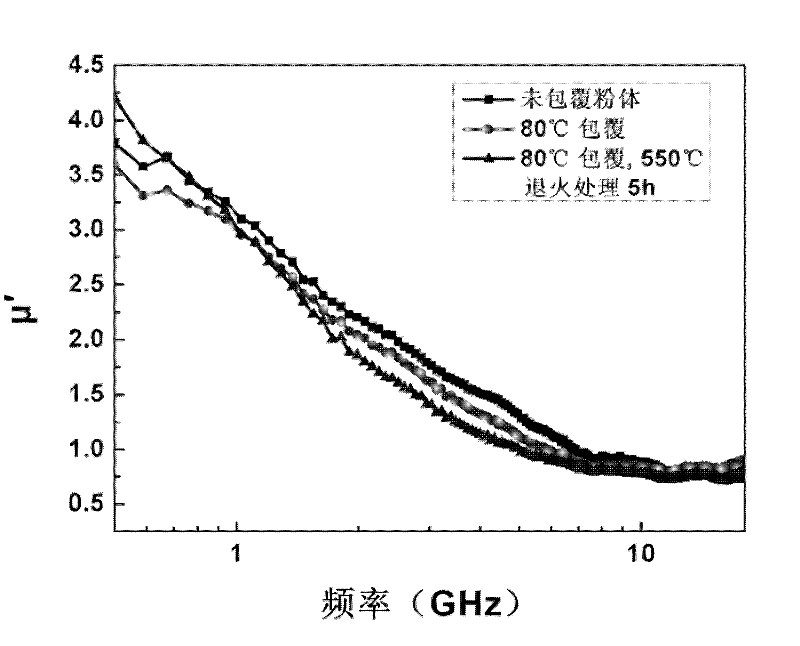

A technology of fe-si-al and absorption performance, which is applied in the direction of magnetism of inorganic materials, can solve the problems that the absorption performance of electromagnetic waves cannot be brought into play, the absorption performance cannot be improved well, and the dielectric constant can be reduced, so as to improve the anti-corrosion Electromagnetic interference ability, improvement of microwave absorption performance, and effect of reducing dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Specifically, what the present invention provides is a method for preparing soft magnetic spinel ferrite coated with high resistivity on the flaky particles of a soft magnetic alloy Fe-Si-Al, comprising the following steps:

[0025] 1. Fe-Si-Al soft magnetic alloy powder (average diameter 1-100μm, thickness 0.1-5μm) after ball mill flattening treatment is used as an electromagnetic wave absorber that can work in the range of 0.5GHz-18GHz raw material.

[0026] 2. Take the powder in step 1 and add it to deionized water, and stir it quickly to make it fully dispersed in the aqueous solution.

[0027] 3. According to the coating of spinel ferrite, that is (Me1 x Me2 y Me3 z )Fe 2 o 4 Components, respectively configure the corresponding molar ratio of Me-containing mixed salt solution, Me1, Me2 and Me3 are respectively Ni 2+ 、Co 2+ , Zn 2+ 、Cu 2+ , Fe 2 One of them, Me1, Me2 and Me3 may be three different elements, or two of them may be the same element, or all th...

Embodiment 1

[0035] Example 1: NiFe 2 o 4 Coated flaky Fe-Si-Al soft magnetic powder

[0036] 1. Weigh 5.0g of flaky Fe-Si-Al soft magnetic powder and add it to 250ml of deionized water, and stir it mechanically quickly to make it evenly dispersed in the aqueous solution.

[0037] 2. Configure 0.3mol / LNiCl 2 and 0.6mol / LFeCl 2 Mixed solution 100ml, 1.8mol / L KOH strong alkali solution 100ml. Put the prepared mixed solution and strong alkali solution in the titration funnel respectively, and fix it on the iron stand.

[0038] 3. Place the container containing the dispersion solution in step 1 in a water bath, adjust the temperature at 80°C, let air flow into the bottom of the container and stir it mechanically quickly.

[0039] 4. Titrate the solutions of the two titration funnels in step 2 into the dispersion solution at a titration rate of 3ml / min at the same time.

[0040] 5. After the titration is completed, keep warm in a water bath at 80°C for 3 hours. After the reaction is fini...

Embodiment 2

[0042] Example 2: Ni 0.7 Zn0 .3 Fe 2 o 4 Coated flaky Fe-Si-Al soft magnetic powder

[0043] 1. Weigh 4.5g of flaky Fe-Si-Al soft magnetic powder and add it to 200ml of deionized water, and stir it mechanically quickly to make it evenly dispersed in the aqueous solution.

[0044] 2. Configure 0.14mol / L Ni(NO 3 ) 2 , 0.07mol / L Zn(NO 3 ) 2 and 0.4mol / L Fe(NO 3 ) 2 Mixed solution 80ml, 1.2mol / L NaOH strong alkali solution 80ml. Put the prepared mixed solution and strong alkali solution in the titration funnel respectively, and fix it on the iron stand.

[0045] 3. Place the container containing the dispersion solution in step 1 in a water bath, adjust the temperature at 25°C, and let air flow into the bottom of the container and stir it mechanically quickly.

[0046] 4. Titrate the solutions of the two titration funnels in step 2 into the dispersion solution at a titration rate of 1 ml / min at the same time.

[0047] 5. After the titration is finished, the modified Fe-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com