A microwave frequency band electromagnetic wave absorber and preparation method thereof

A technology of electromagnetic waves and absorbers, which is applied in the field of electromagnetic wave absorbers in the microwave frequency band and its preparation, can solve the problems of little potential for improvement, low material permeability, poor stability, etc., and achieve skin effect suppression and increase The effect of microwave permeability and high aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

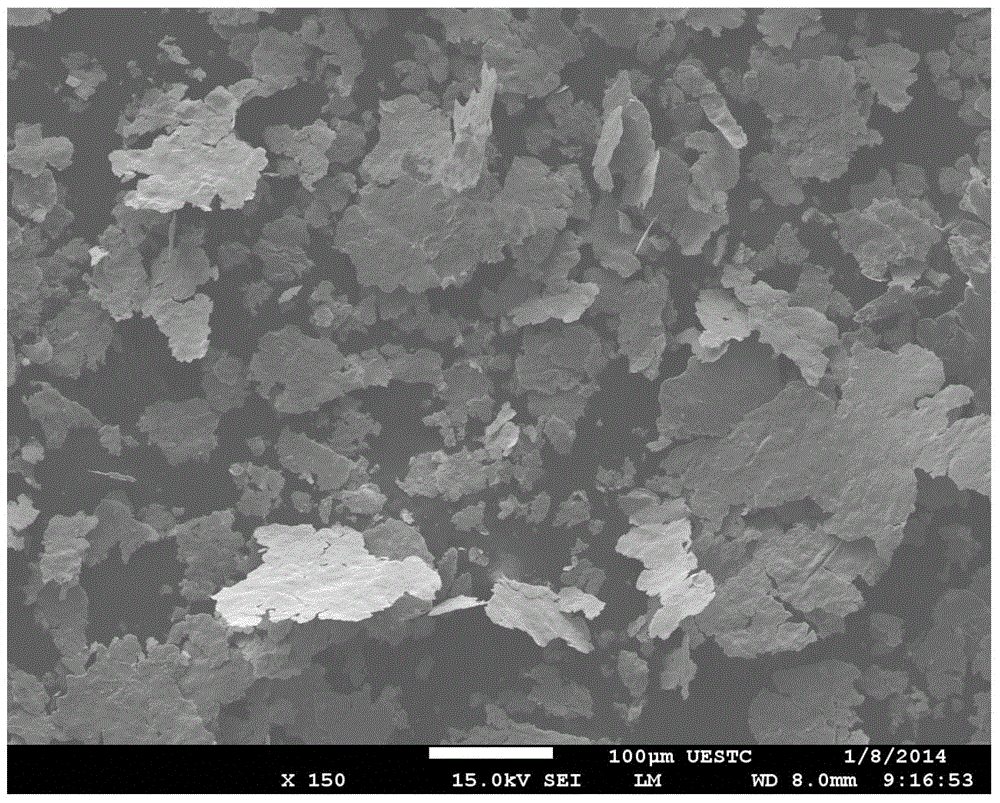

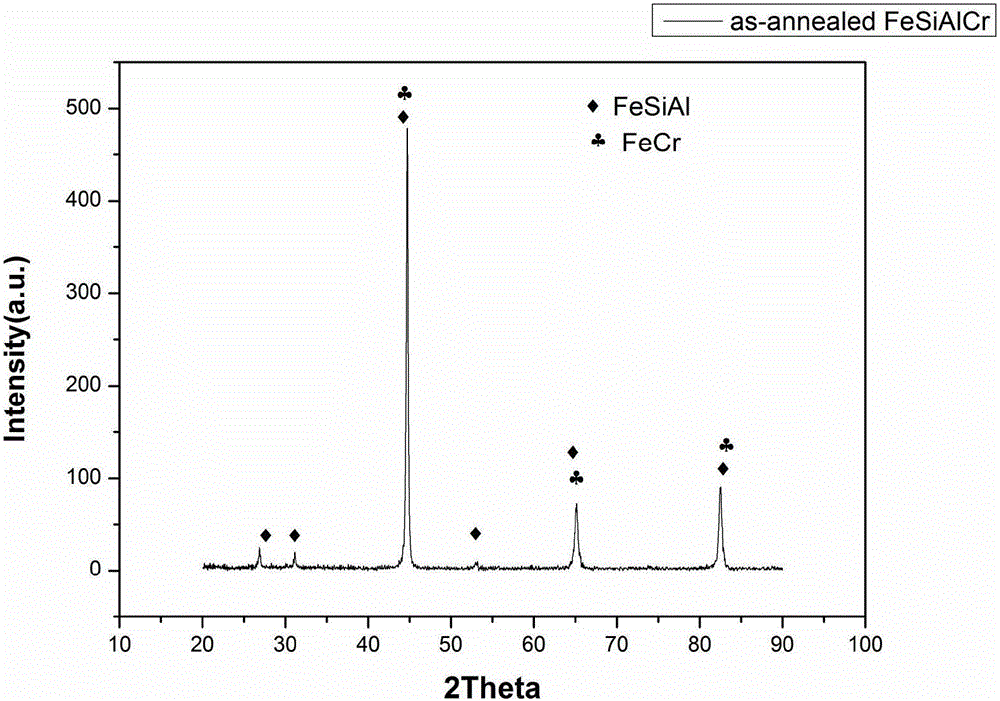

[0022] An electromagnetic wave absorber, which is composed of pure iron rod, pure aluminum rod, pure chromium block and polycrystalline silicon, each component is mutually fused according to the following mass percentage: pure Fe rod-68%, pure aluminum rod-10%, pure chromium block- 10%, polysilicon-12%; and make nanocrystalline / amorphous dual-phase particles with a grain size of 10-50nm.

[0023] The electromagnetic wave absorber can be obtained through the above preparation steps. When the volume content of the absorber is 35%, and the auxiliary material is paraffin to make the electromagnetic wave absorbing material, at a frequency of 0.5GHz to 18GHz, the magnetic permeability μ' max is 7.2, μ″ max is 4.1.

Embodiment 2

[0025] An electromagnetic wave absorber, which is composed of pure iron rod, pure aluminum rod, pure chromium block and polysilicon, each component is mutually fused according to the following mass percentage: pure Fe rod-72%, pure aluminum rod-10%, pure chromium block- 6%, polysilicon-12%; and form nanocrystalline / amorphous dual-phase particles with a grain size of 10-50nm.

[0026] The electromagnetic wave absorber can be obtained through the above preparation steps. When the volume content of the absorber is 35%, and the auxiliary material is paraffin to make the electromagnetic wave absorbing material, at a frequency of 0.5GHz to 18GHz, the magnetic permeability μ' max is 7.4, μ″ max is 4.2.

Embodiment 3

[0028] An electromagnetic wave absorber, which is composed of pure iron rod, pure aluminum rod, pure chromium block and polysilicon, each component is mutually fused according to the following mass percentage: pure Fe rod-76%, pure aluminum rod-10%, pure chromium block- 2%, polysilicon-12%; and form nanocrystalline / amorphous dual-phase particles with a grain size of 10-50nm.

[0029] The electromagnetic wave absorber can be obtained through the above preparation steps. When the volume content of the absorber is 35%, and the auxiliary material is paraffin to make the electromagnetic wave absorbing material, at a frequency of 0.5GHz to 18GHz, the magnetic permeability μ' max 7.5, μ″ max is 4.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com