Patents

Literature

31results about How to "Improve microwave permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

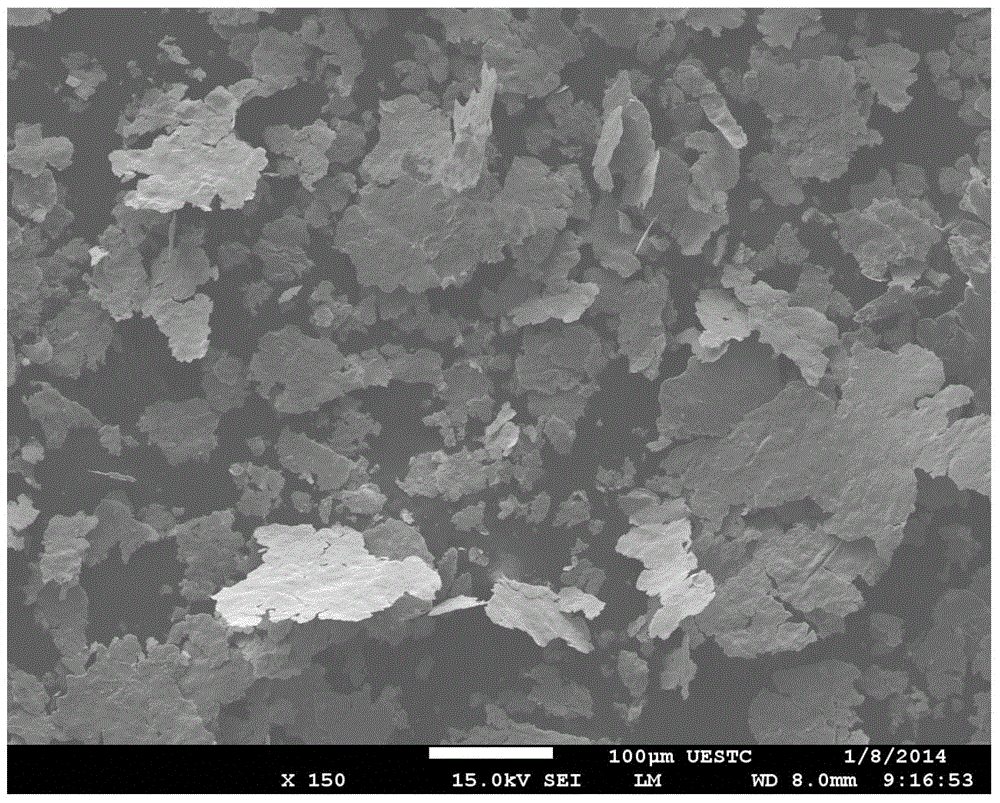

Method for improving electromagnetic wave absorption performance of Fe-Si-Al powder

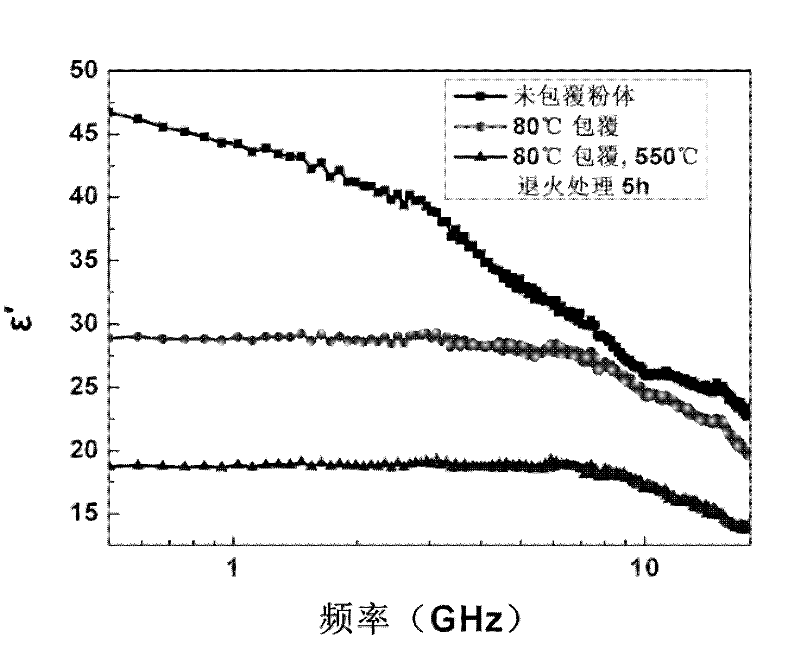

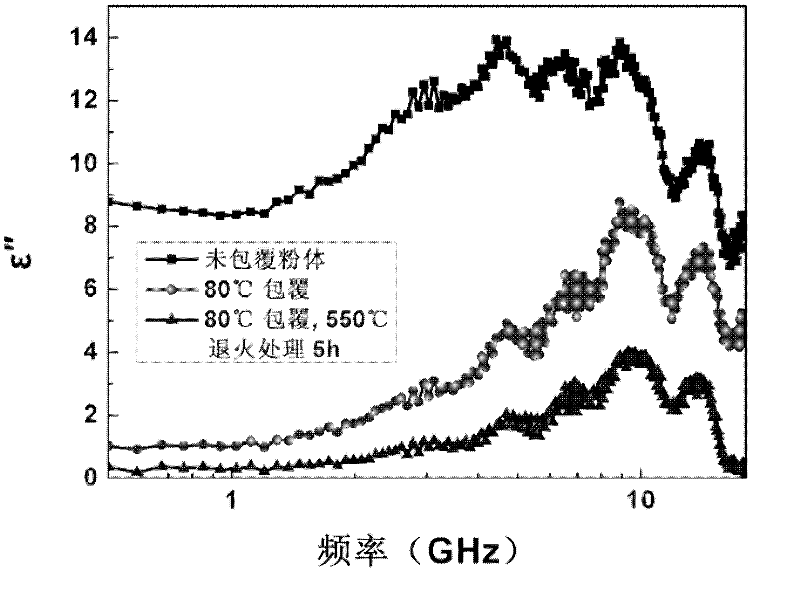

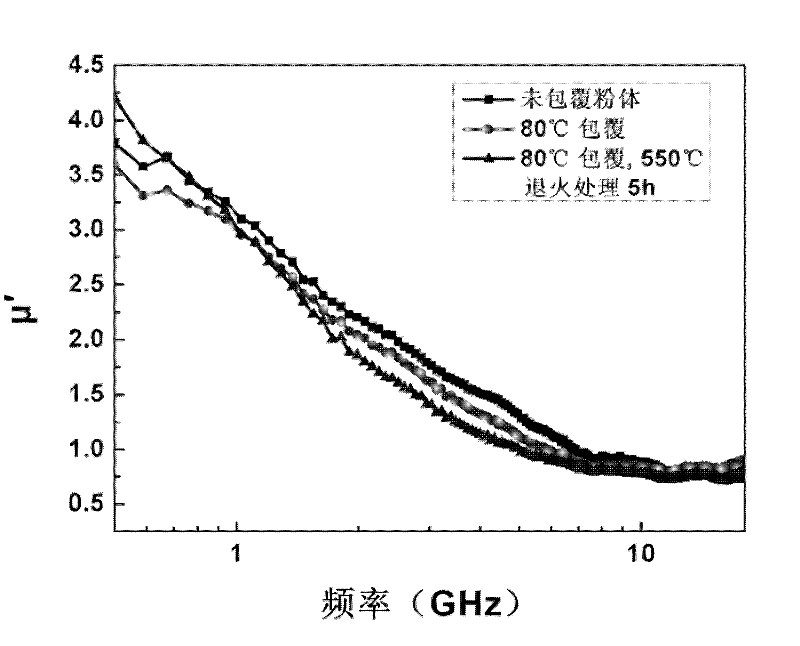

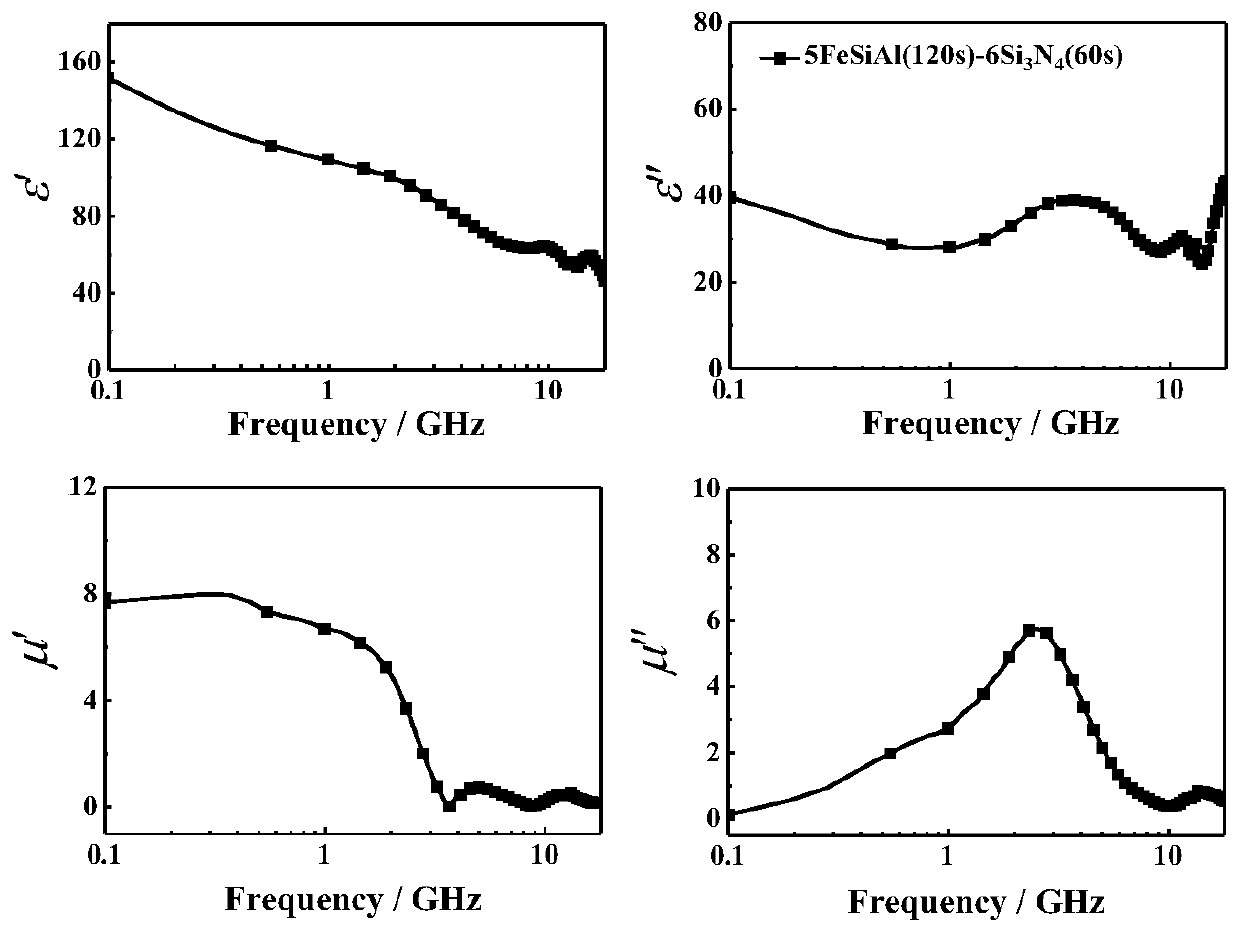

InactiveCN102528022AImprove microwave permeabilityLow dielectric constantInorganic material magnetismAl powderWater baths

A method for improving electromagnetic wave absorption performance of Fe-Si-Al powder relates to the technology of electromagnetic wave absorption and comprises the following steps: 1) performing ball mill flattening treatment on Fe-Si-Al soft magnetic alloy powder; 2) fast and mechanically stirring the powder obtained through the step 1) and scattering the powder into water and leading in air from the bottom of a container; 3) respectively preparing mixed salt solution with the corresponding molar ratio according to spinel ferrites to be wrapped, and preparing strong alkali solution according to the corresponding molar ratio; 4) stirring the scattered solution obtained by the step 2) under water bath heating at the temperature of 25-80 DEG C; 5) adding the salt solution and the strong alkali solution which are prepared through the step 3) into treated solution treated by the step 4); and 6) finishing reaction, cleaning the powder, drying and annealing. The method for improving the electromagnetic wave absorption performance of the Fe-Si-Al powder greatly reduces dielectric constant and simultaneously improves the microwave magnetic conductance of the powder.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High-elastic wave-absorbing heavy-duty anticorrosive nano-coating

Disclosed is high elasticity wave-absorbing anticorrosion nanometer coating with the weight ratio composition of 1-5% nanometer titanium alloy, 1-10% carbon fiber, 1-10% copper powder, 13-25% T-ZnO, 15-30% magneto plumbite type ferrite and 25-68% epoxy modified acrylic acid elastic resin; the radius of nanometer titanium alloy is 20- 50nm; the radius of carbon fiber is 20-30nm and the length of carbon fiber is 100-500nm; the radius of the particle of copper powder is 20-30nm; the radius of the particle of T-ZnO is 40-70nm; the radius of magneto plumbite type ferrite is 20-100nm and the length is 100-300nm; the Rho of epoxy modified acrylic acid elastic resin is equal to 1.1-1.2. The high elasticity wave-absorbing anticorrosion nanometer coating has super strong anticorrosion property and avoids the device from corrosion when the device operates under badly corrosive environment for long time; the anticorrosion nanometer coating is bonded firmly with the substrate and has the advantages of high elasticity and good wave-absorbing performance.

Owner:中油新星纳米工程技术有限公司

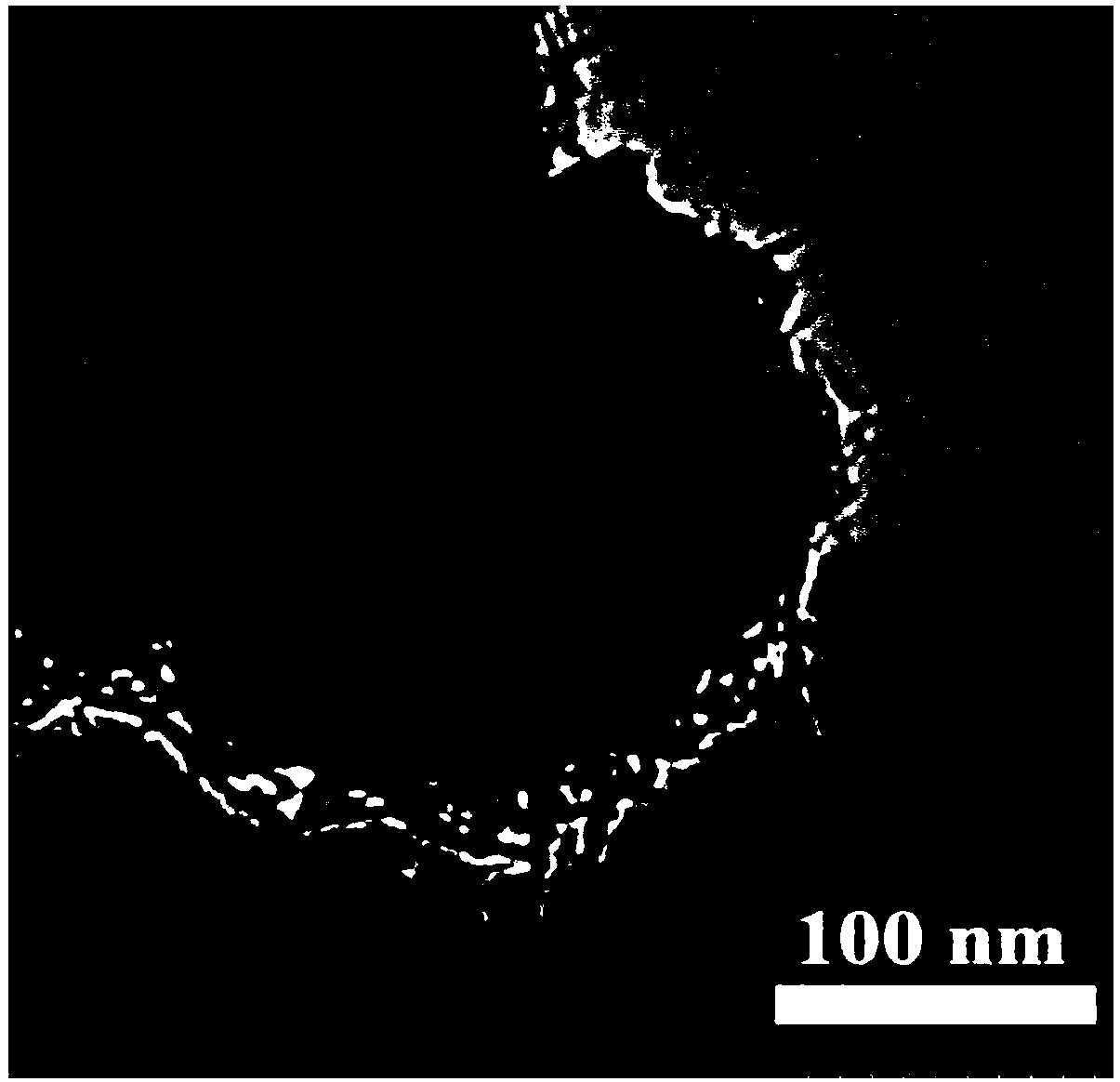

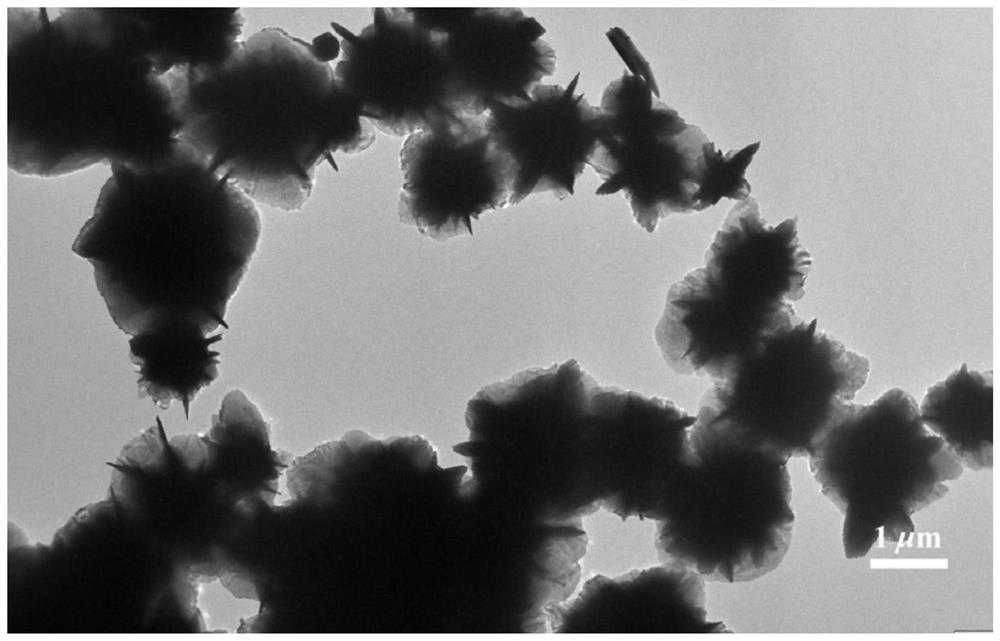

Preparation method of nanometer chain-like core-shell type nickel/polyaniline composite wave absorption material

ActiveCN108102364AImprove microwave permeabilityImproving Impedance MatchingMaterial nanotechnologyTransportation and packagingNickel saltConductive polymer

The invention discloses a preparation method of a nanometer chain-like core-shell type nickel / polyaniline composite wave absorption material. The preparation method comprises the following steps of utilizing the reducibility of hydrazine hydrate, reducing nickel salt with liquid phase under normal pressure, and preparing a nickel nanometer chain which is formed by self assembling spherical particles in uniform size; then coating the surface of the nanometer chain with polyaniline by using an in-situ polymerization method, and acquiring the nanometer chain-like core-shell type nickel / polyaniline composite wave absorption material, wherein the nanometer chain-like core-shell type nickel / polyaniline composite wave absorption material is of a core-shell structure and takes a magnetic metal nickel nanometer chain as a core and the polyaniline as a conductive polymer as a shell layer. According to the preparation method provided by the invention, the nanometer chain which is formed by self assembling the nickel nanospheres is utilized as a magnetic core, the magnetic anisotropy is strengthened through the geometric effect, and the microwave permeability of a core-shell structure whole body is further improved in the premise of ensuring dielectric loss, so that impedance matching of the wave absorption material is improved, surface reflection of electromagnetic waves is lowered, and the wave absorption performance of the material is improved.

Owner:合肥迈微新材料技术有限公司

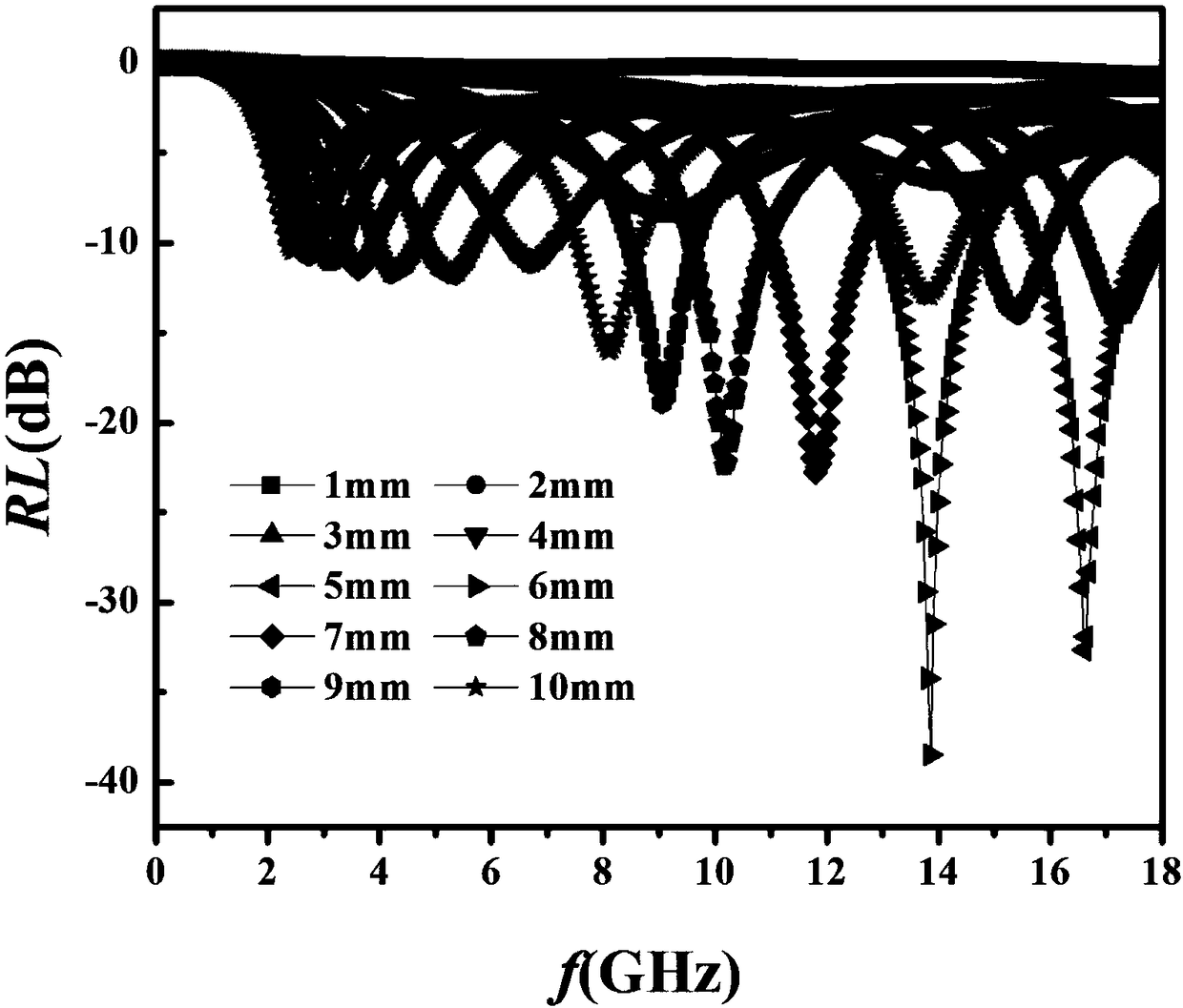

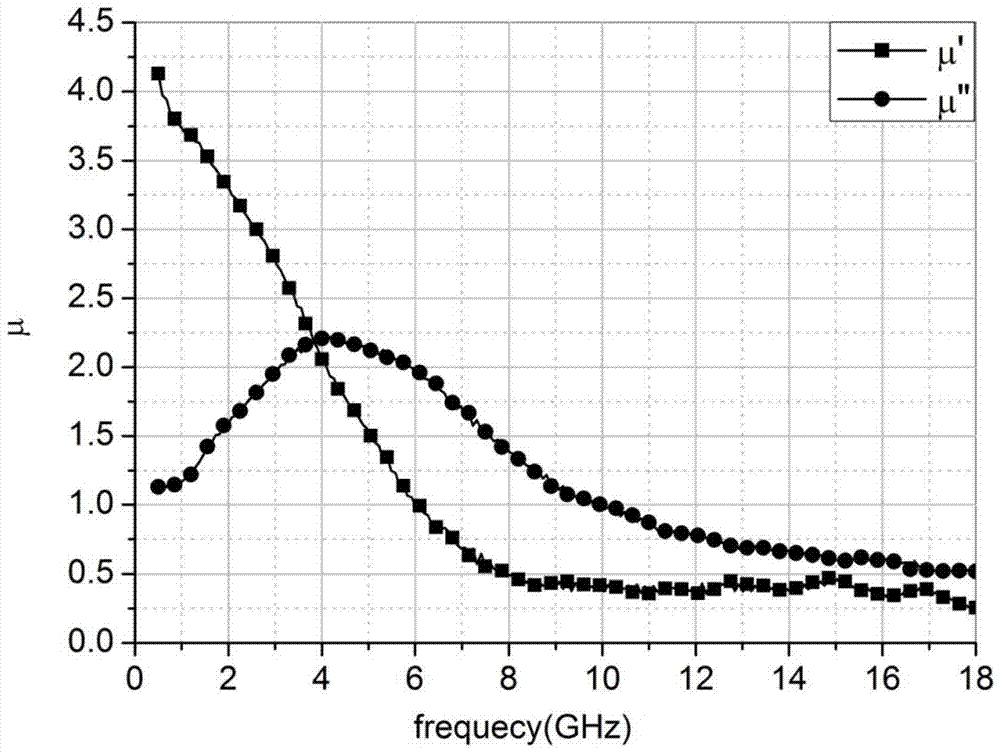

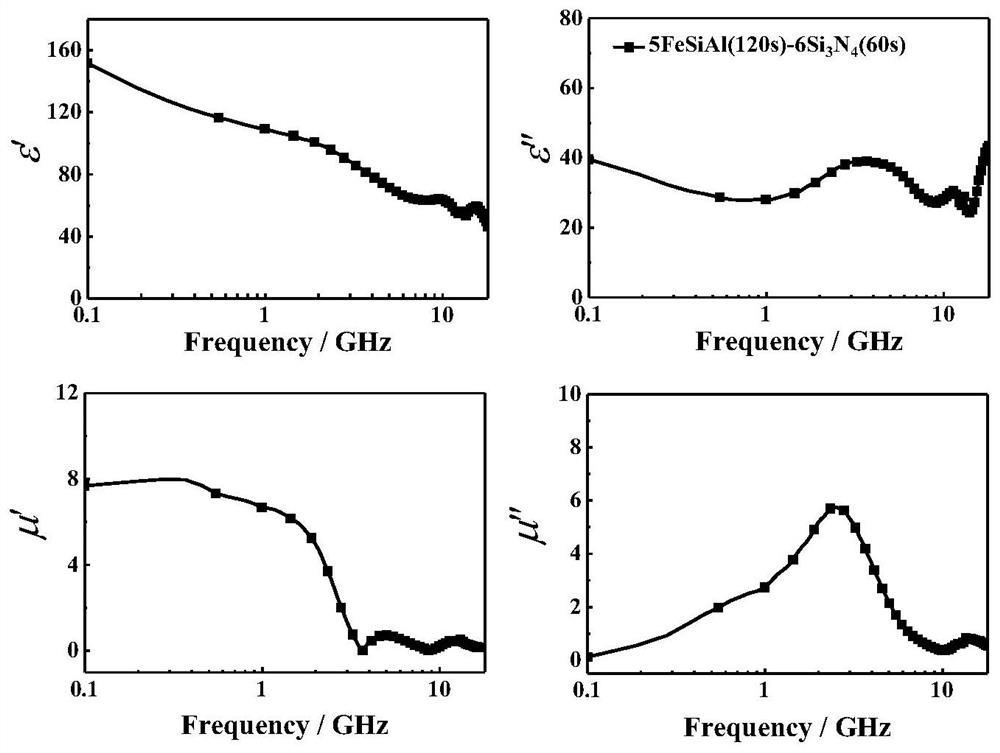

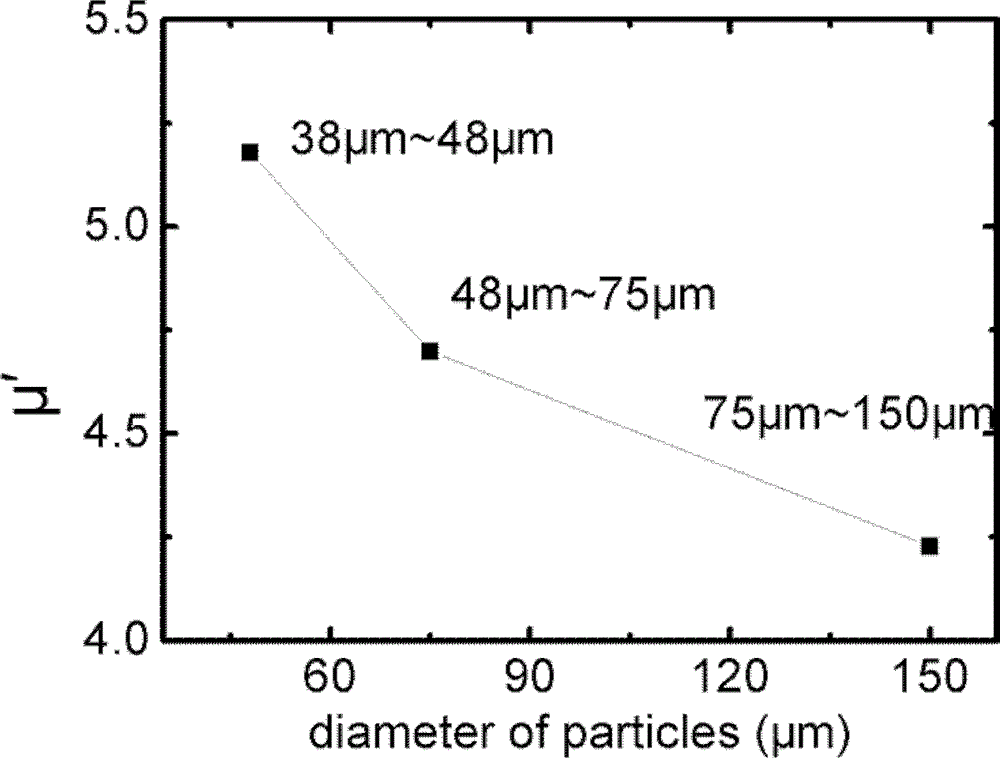

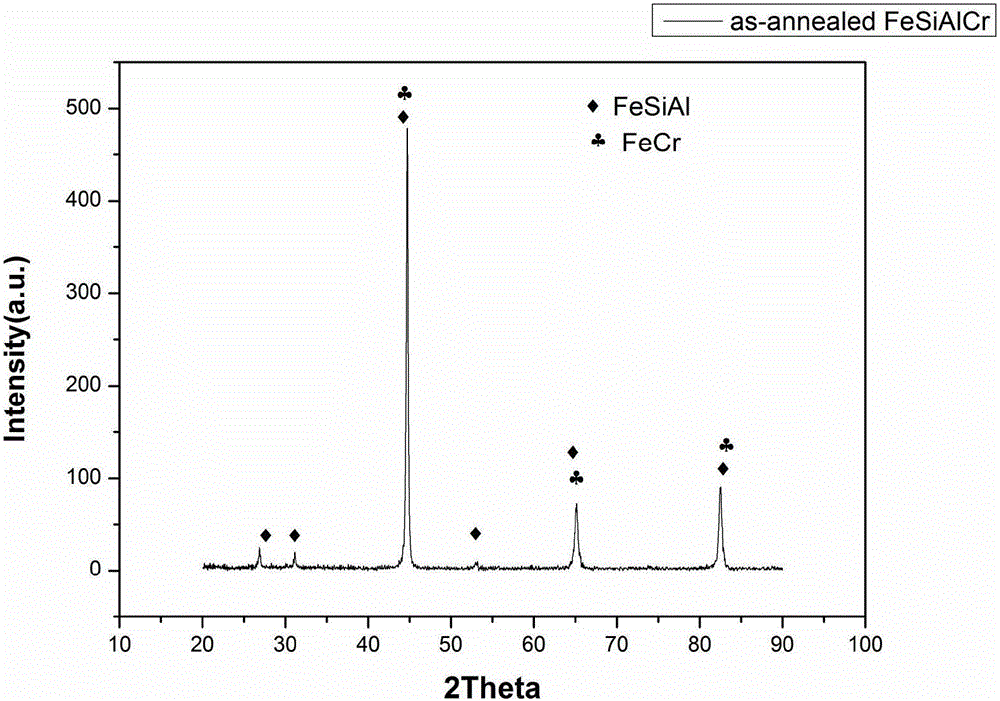

Microwave frequency band electromagnetic wave absorbent and preparing method thereof

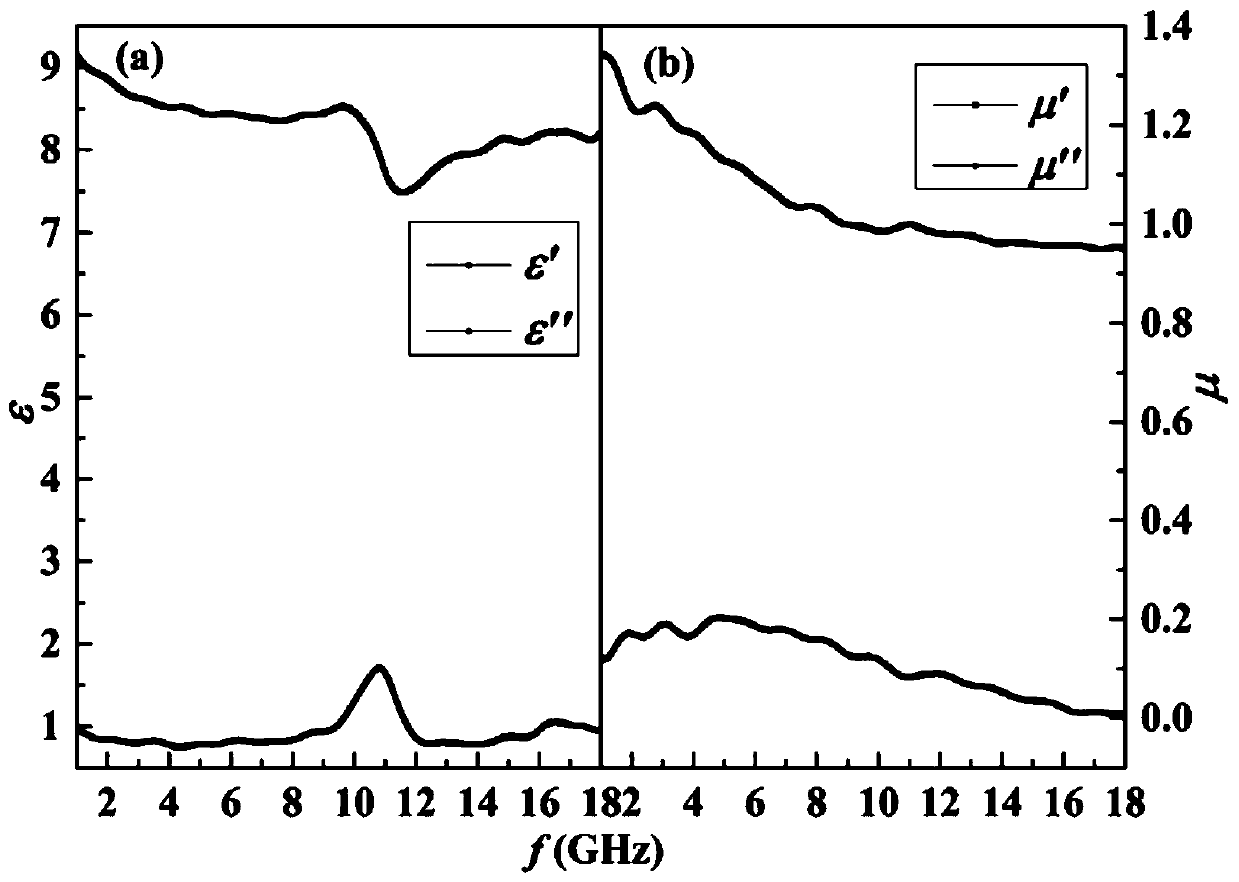

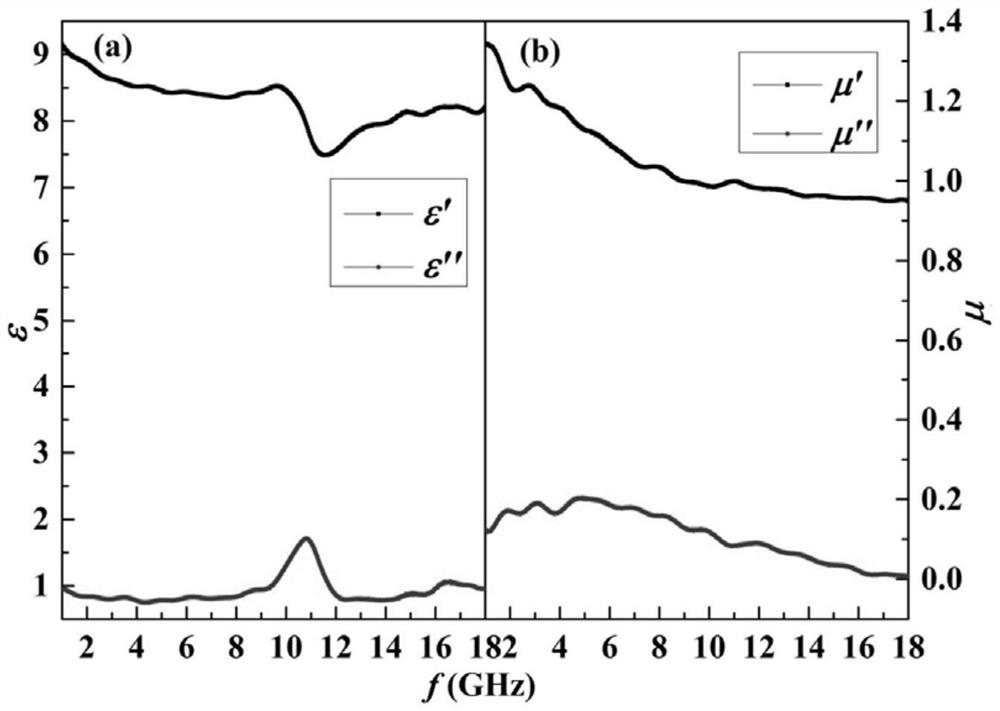

ActiveCN105088109AReduce effective anisotropyImprove microwave permeabilityParaffin oilsElectronic materials

The invention belongs to the technical field of electronic materials, and particularly relates to a microwave frequency band (0.5GHz-18GHz) electromagnetic wave absorbent and a preparing method thereof. The absorbent is made of pure ferrum, pure aluminum, pure chromium and polycrystalline silicon. By mass, larger than or equal to 65% but smaller than or equal to 78% of pure Fe, larger than or equal to 5% but smaller than or equal to 12% of pure aluminum, larger than or equal to 2% but smaller than or equal to 12% of pure chromium and larger than or equal to 8% but smaller than or equal to 16% of polycrystalline silicon are molten, and nanocrystalline / amorphous biphase particles with the grain size of 10-50 nm are formed. According to the prepared absorbent, when an electromagnetic absorption material is prepared with the 30-40% of absorbent and paraffin as an auxiliary material, on the frequency band of 0.5 GHz-18 GHz, magnetic conductivity [mu]'max is larger than or equal to 7 but smaller than or equal to 8, and [mu]''max is larger than or equal to 4 but smaller than or equal to 5. The technology is simple, operability is high, and cost is low. The absorbent is suitable for batched production.

Owner:成都佳驰电子科技股份有限公司

High-elastic wave-absorbing heavy-duty anticorrosive nano-coating

Disclosed is high elasticity wave-absorbing anticorrosion nanometer coating with the weight ratio composition of 1-5% nanometer titanium alloy, 1-10% carbon fiber, 1-10% copper powder, 13-25% T-ZnO, 15-30% magneto plumbite type ferrite and 25-68% epoxy modified acrylic acid elastic resin; the radius of nanometer titanium alloy is 20- 50nm; the radius of carbon fiber is 20-30nm and the length of carbon fiber is 100-500nm; the radius of the particle of copper powder is 20-30nm; the radius of the particle of T-ZnO is 40-70nm; the radius of magneto plumbite type ferrite is 20-100nm and the lengthis 100-300nm; the Rho of epoxy modified acrylic acid elastic resin is equal to 1.1-1.2. The high elasticity wave-absorbing anticorrosion nanometer coating has super strong anticorrosion property and avoids the device from corrosion when the device operates under badly corrosive environment for long time; the anticorrosion nanometer coating is bonded firmly with the substrate and has the advantages of high elasticity and good wave-absorbing performance.

Owner:中油新星纳米工程技术有限公司

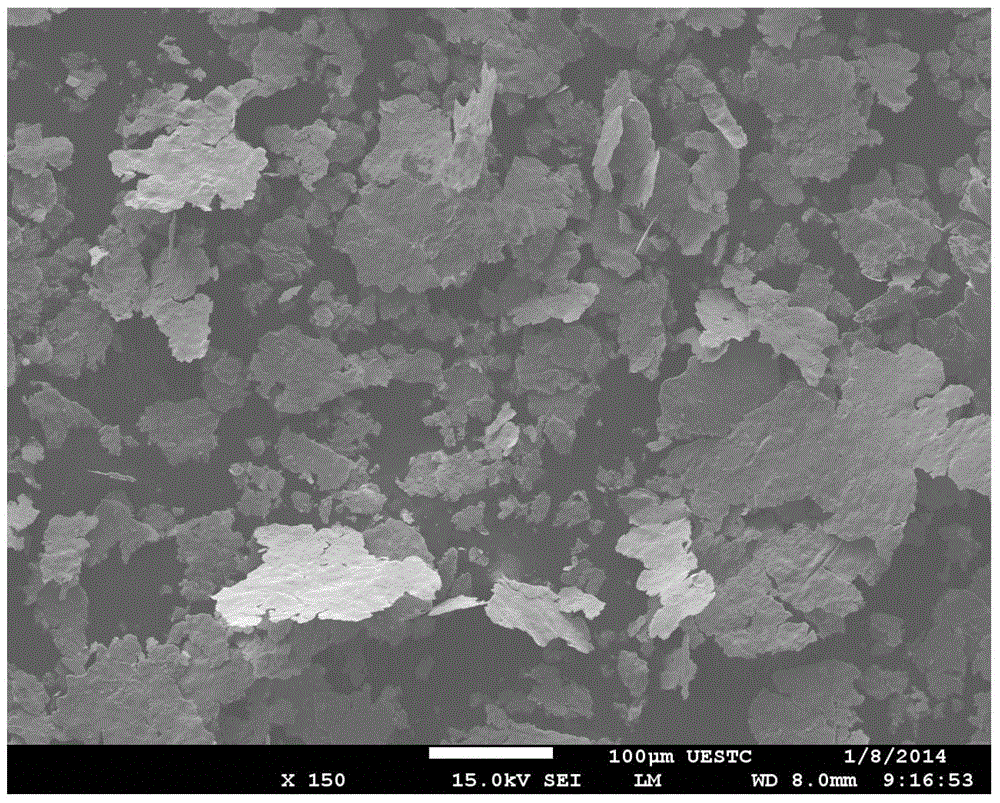

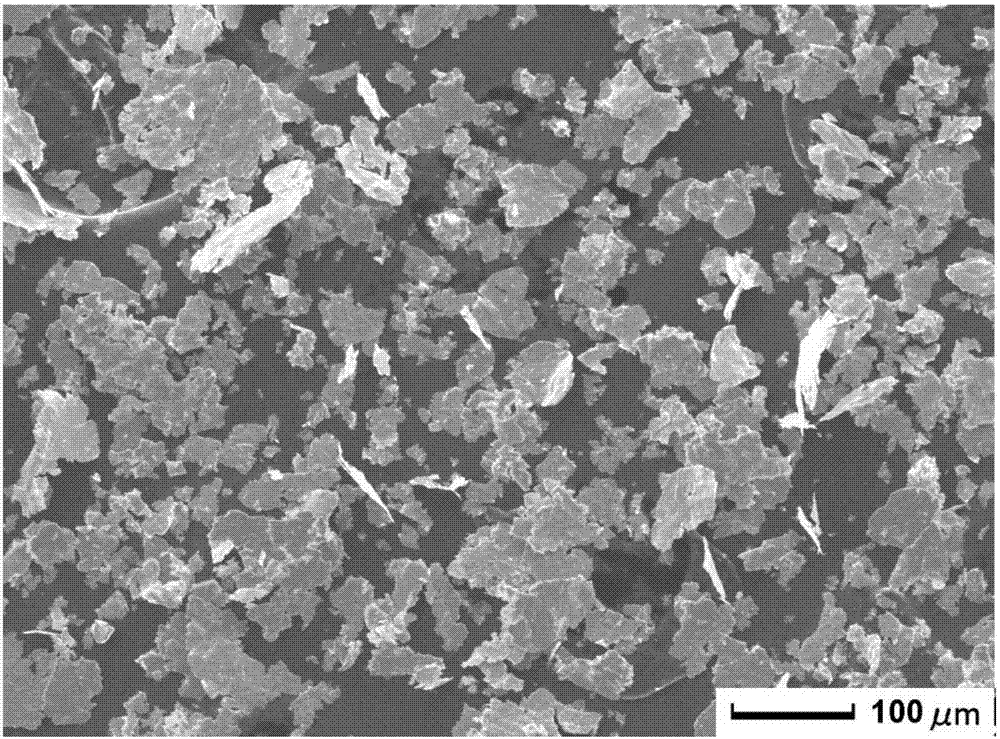

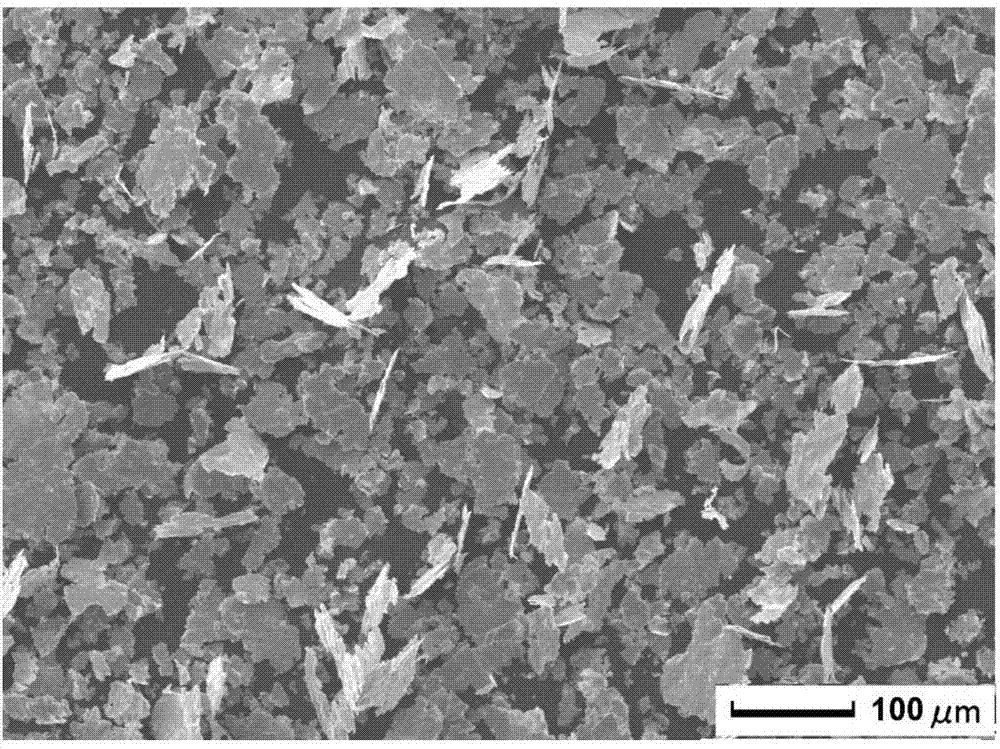

Alloy micropowder electromagnetic wave absorbent and preparation method thereof

InactiveCN103173683AImprove microwave permeabilityHigh degree of flakinessHigh volume manufacturingAlloy

The invention relates to an alloy micropowder electromagnetic wave absorbent and a preparation method of the absorbent. The main ingredients of the alloy micropowder electromagnetic wave absorbent comprise Fe, Si and Cr. The prepared alloy micropowder electromagnetic wave absorbent has an excellent dynamic magnetic property, and the preparation method is simple in preparation process, low in equipment requirements, and suitable for mass production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

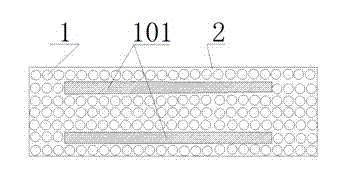

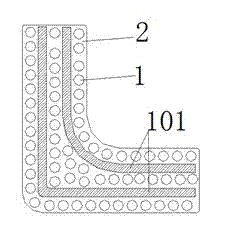

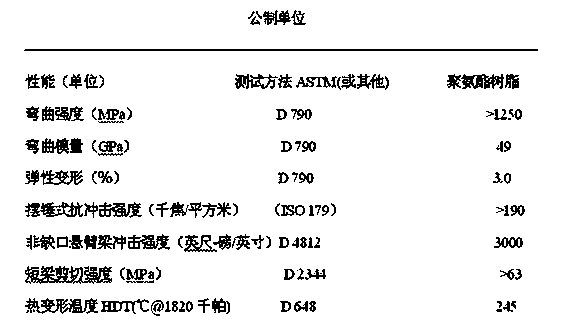

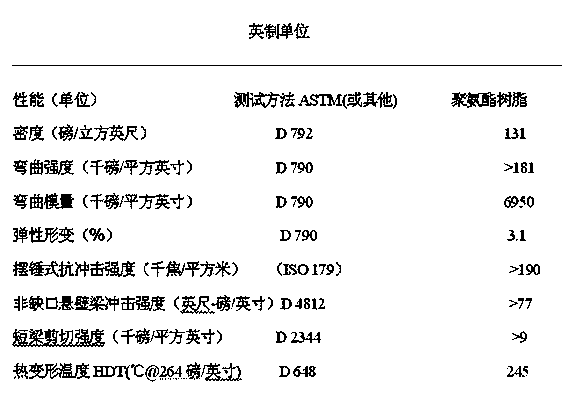

Energy-saving window frame or window sash profile of polyurethane composite material and forming method

InactiveCN102031913ASolution to short lifeExcellent corrosion-resistant materialWindow/door framesWing framesGlass fiberSash window

The invention relates to an energy-saving window frame or window sash profile of a polyurethane composite material consisting of polyurethane resin and glass fibers and a forming method. The profile comprises the glass fibers; a plurality of bundles of glass fibers are densely distributed to form a window frame or window sash profile forming skeleton; and the polyurethane is compounded on the inner and outer surfaces of the window frame or window sash profile forming skeleton to form the polyurethane window frame or window sash profile. The profile has the advantages that: the profile has light weight, high strength, energy conservation, heat insulation, health, environmental friendliness, remarkable energy-saving effect, corrosion and ageing resistance, long service life, good dimensional stability, good weather resistance, good high temperature resistance, better low temperature resistance, good insulating performance, good shock absorption performance and rich colors; the polyurethane composite material has high hardness and can be used for coating various paints to prepare the profiles of various colors to adapt the application of different styles and grades; and the profile has fatigue resistance, and the polyurethane composite material has high fatigue resistance so as to ensure use safety and reliability of the material.

Owner:OUCHUANG PLASTIC BUILDING MATERIAL ZHEJIANG

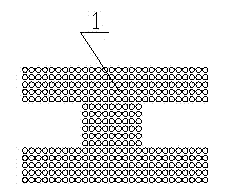

Reinforcing rib section for polyurethane composite material energy-saving door and door sash frame or window and window sash frame

InactiveCN102031914ASolution to short lifeExcellent corrosion-resistant materialWindow/door framesWing framesFiberEngineering

The invention relates to a reinforcing rib section for a polyurethane composite material energy-saving door frame or door sash frame or window frame or window sash frame, which is made from polyurethane resin and glass fiber, and a molding method. The reinforcing rib section comprises glass fibers, wherein a reinforcing rib section molding framework for a door frame / sash or a window frame / sash consists of a plurality of bundles of densely covered glass fibers; and polyurethane resin is compounded with the inner and outer surfaces of the reinforcing rib section molding framework for the door frame / sash or the window frame / sash. The reinforcing rib section has the advantages of light weight, high intensity, energy conservation, heat preservation, heat insulation, health, environmental friendliness, remarkable energy-saving effect, corrosion resistance, ageing resistance, long service life, high size stability, high weather resistance, high high-temperature resistance, higher low-temperature resistance, good insulating property, high damping performance and rich color; a polyurethane composite material has high hardness; and the reinforcing rib section can be painted with various paints to obtain sections of various colors so as to adapt to different styles and grades.

Owner:OUCHUANG PLASTIC BUILDING MATERIAL ZHEJIANG

Preparation method for high temperature-resistant microwave-permeable aluminum hydroxide/polyethersulfone composite material

ActiveCN103554539AImprove microwave permeabilityImprove high temperature resistanceCoatingsEmulsionPhosphoric acid

The invention discloses a preparation method for a high temperature-resistant microwave-permeable aluminum hydroxide / polyethersulfone composite material. The method comprises the following steps: dissolving polyethersulfone powder in an N,N-dimethylacetamide solvent and carrying out drying to prepare a polyethersulfone support; uniformly dispersing aluminum hydroxide powder in a mixed solution of N,N-dimethylacetamide and phosphoric acid to prepare an aluminum hydroxide emulsion; and dumping the aluminum hydroxide emulsion into a culture dish filled with the polyethersulfone support and carrying out a series of heat treatment at a temperature of 80 to 200 DEG C so as to prepare the aluminum hydroxide / polyethersulfone composite material with excellent high temperature resistance and microwave permeability. The aluminum hydroxide / polyethersulfone composite material prepared in the invention has high mechanical strength and excellent microwave permeability and can meet requirements for the working condition of an instant high temperature of 900 to 1000 DEG C. The preparation method provided by the invention has the advantages of simple procedures, easy operation and low cost.

Owner:YANSHAN UNIV

Polyurethane composite material energy-saving window frame or door leaf frame or door profile or door sheet

InactiveCN102080490ASolution to short lifeExcellent corrosion-resistant materialWindow/door framesWing framesGlass fiberWeather resistance

The invention relates to a polyurethane composite material energy-saving window frame or a door leaf frame or a door profile or a door sheet which is formed by polyurethane resins and glass fibers, and comprises the glass fibers, and a shaping method, wherein a plurality of clusters of glass fibers are closely distributed to form shaping skeletons of the door frame or the door leaf frame profile; the polyurethane is compounded with the inner and outer surfaces of the shaping skeletons of the door frame or the door leaf frame profile. The polyurethane composite material energy-saving window frame or door leaf frame or door profile or door sheet is: 1, light in weight, and high in strength; 2, energy-saving, heat preservation and heat insulation; 3, healthy, environment-friendly, and obvious in energy-saving effect; 4, corrosion-resistant, ageing-resistant and long in service life; 5, excellent in size stability; 6, excellent in weather resistance, excellent in high temperature resistance, and better in low temperature resistance; 7, excellent in insulating property; 8, excellent in damping performance; 9, rich in color, high in hardness of a polyurethane composite material, capable of coating various paints and made into profiles with various colors; and 10, fatigue resistance; the polyurethane composite material is excellent in fatigue resistance so as to ensure the safety and reliability of using the material.

Owner:OUCHUANG PLASTIC BUILDING MATERIAL ZHEJIANG

Energy-saving door window frame or door window sash or door panel section or door panel made of polyurethane composite material

InactiveCN102518356ASolution to short lifeExcellent corrosion-resistant materialSynthetic resin layered productsWindow/door framesGlass fiberSash window

Owner:OUCHUANG PLASTIC BUILDING MATERIAL ZHEJIANG

Polyurethane composite profile and forming method for same

InactiveCN102518932AExcellent insulation materialSolution to short lifeConstructions elementsGlass fiberWeather resistance

The invention relates to a polyurethane composite profile and a forming method for the same, wherein the polyurethane composite profile is made of polyurethane resins and a plurality of glass fibers. The glass fibers are densely covered to form a profile framework, and the polyurethane resins are composited with the inner surface and the outer surface of the profile framework to form the polyurethane composite profile. The polyurethane composite profile has the advantages that firstly, the profile is light in weight and high in strength; secondly, the profile is energy-saving and heat-insulation; thirdly, the profile is healthful, green, environment-friendly and remarkable in energy-saving effect; fourthly, the profile is corrosion-resistant, aging-resistant and long in service life; fifthly, the profile is fine in dimensional stability; sixthly, the profile is fine in weather resistance, fine in high-temperature resistance and better in low-temperature resistance; seventhly, the profile is fine in insulating property; eighthly, the profile is fine in vibration reducing performance; ninthly, the profile is colorful, and polyurethane composite is high in hardness and can be coated with various coatings to manufacture profiles in various colors, so that the profiles adapt to different styles and grades; and tenthly, the polyurethane composite is extremely high in fatigue resistance so that safety and reliability in use of the polyurethane composite are ensured.

Owner:OUCHUANG PLASTIC BUILDING MATERIAL ZHEJIANG

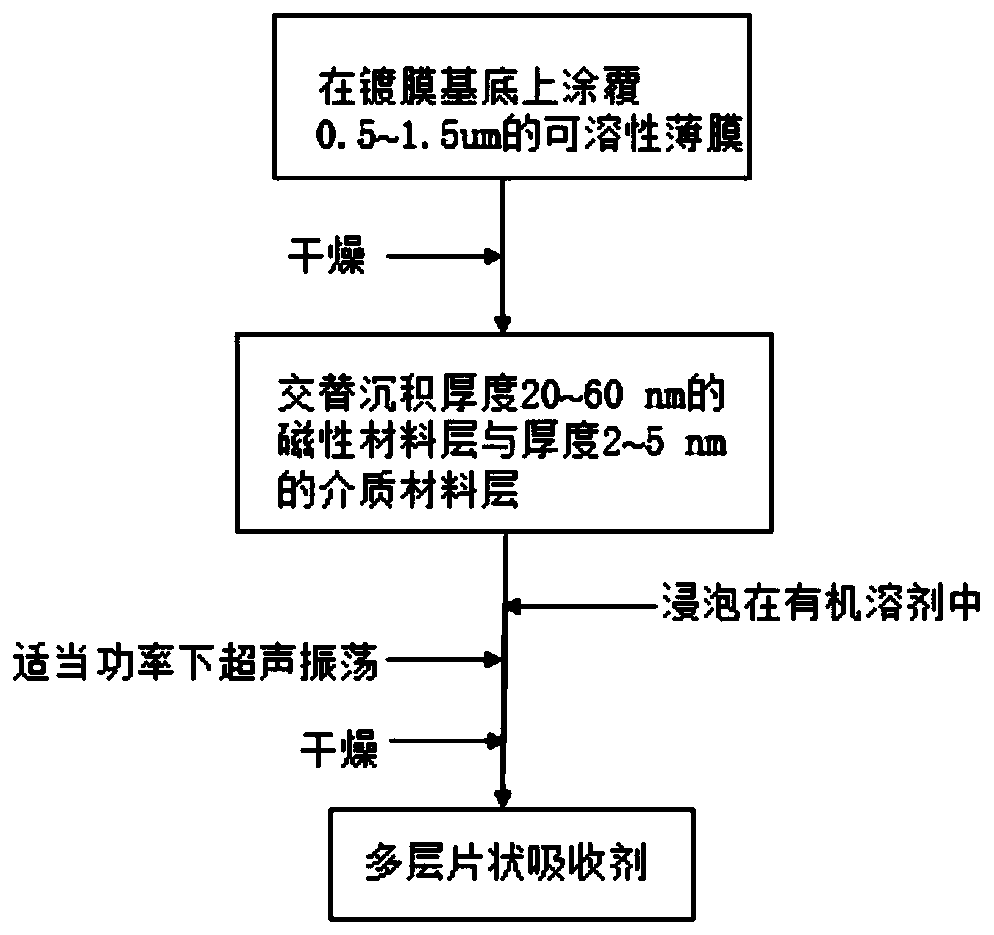

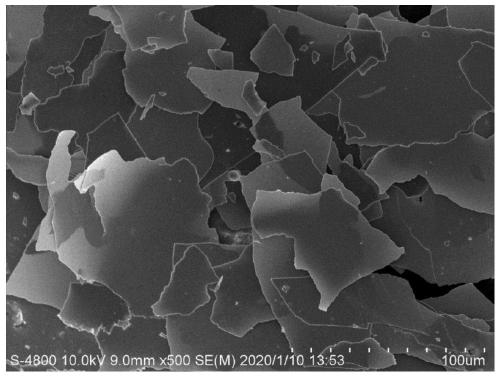

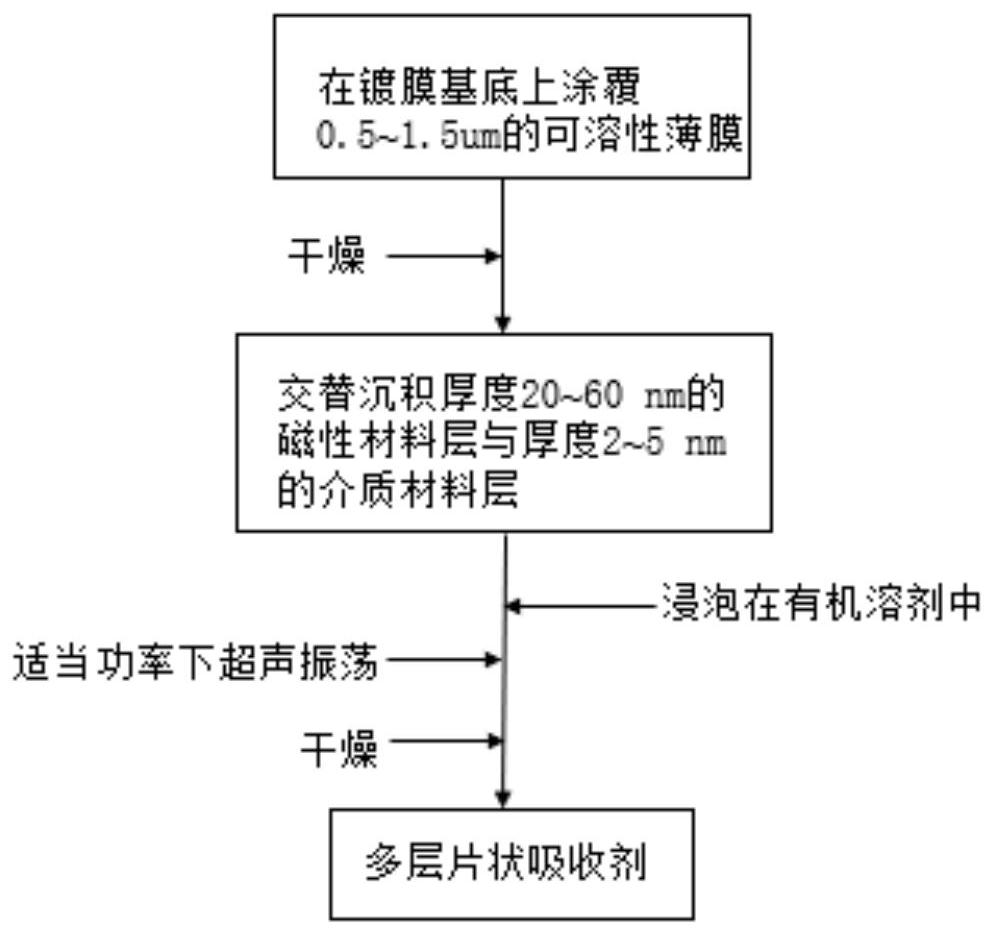

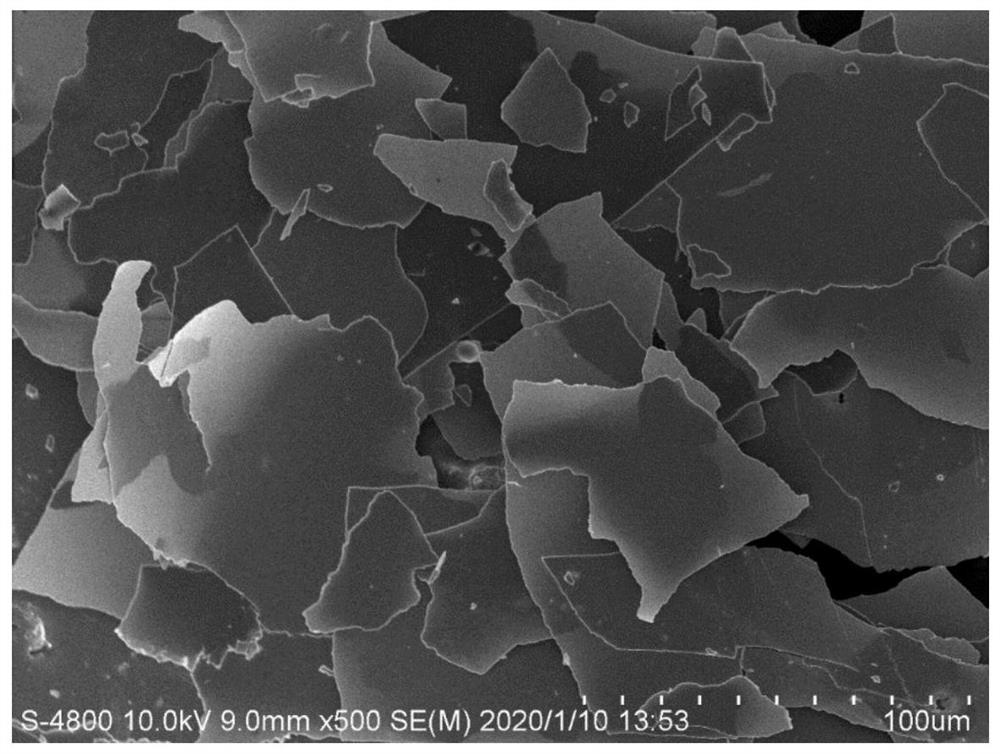

Magnetic nanocrystalline flaky absorbing agent and preparation method thereof

ActiveCN111424235AFlat surfaceReduce internal defectsMagnetic/electric field screeningVacuum evaporation coatingRough surfaceWafering

The invention relates to the technical field of wave absorbing materials, in particular to a magnetic wave absorbing agent and a preparation method thereof. The preparation method comprises the stepsof alternately depositing a magnetic material with a certain thickness and a medium material on a substrate uniformly coated with a sacrificial layer by adopting a vacuum coating method to obtain a multilayer film, removing the sacrificial layer to obtain a multilayer magnetic film, and crushing the multilayer magnetic film to obtain the magnetic nanocrystalline flaky absorbing agent. The preparation process is simple and convenient, the adjustment is easy, the prepared magnetic nanocrystalline flaky absorbing agent is smooth in surface, few in internal defect, small in stress and controllablein magnetic component, and the magnetic nanocrystalline flaky absorbing agent has the characteristics of multilayer structure, large width-thickness ratio and good surface insulating property. The magnetic permeability bottleneck caused by rough surface, large internal defects and stress, poor microstructure control capability and limited width-thickness ratio of a magnetic nanocrystalline absorbing agent prepared by an existing ball milling method can be broken through, the microwave permeability of the flaky magnetic absorbing agent suitable for different frequency bands is improved, and the dielectric constant of the flaky magnetic absorbing agent is inhibited.

Owner:WUHAN UNIV OF TECH

Composite energy-saving door frame or door leaf frame and forming method thereof

InactiveCN102080488ASolution to short lifeExcellent corrosion-resistant materialWindow/door framesWing framesWeather resistanceAging resistance

The invention relates to a composite energy-saving door frame or door leaf frame and a forming method thereof. The composite energy-saving door frame or door leaf frame has high strength, low specific gravity, insulativity, microwave permeability, corrosion resistance, good heat insulation effect and high decoration property. The composite energy-saving door frame or door leaf frame comprises a door frame or a door leaf frame, wherein the door frame or the door leaf frame consists of two component materials; one side of the door frame or the door leaf frame is a glass steel section and the other side of the door frame or the door leaf frame is a wood section; and the glass steel section is in fit with the wood section to form the composite energy-saving door frame or door leaf frame. The composite energy-saving door frame or door leaf frame has the advantages of: 1, light weight and high strength; 2, energy conservation, heat preservation and heat insulation; 3, health, environmental friendliness and good energy-saving effect; 4, corrosion resistance, ageing resistance and long service life; 5, high dimensional stability; 6, high weather resistance, high high-temperature resistance and high low-temperature resistance; 7, high insulating property; 8, high damping performance; and 9, abundant colors and high hardness in a polyurethane composite material, so that sections with various colors can be manufactured by coating various paint and are suitable for different styles and grades.

Owner:OUCHUANG PLASTIC BUILDING MATERIAL ZHEJIANG

Polyurethane composite material special-shaped section for glass curtain wall and forming method

InactiveCN102518233AExcellent insulation materialSolution to short lifeWallsGlass fiberWeather resistance

Owner:OUCHUANG PLASTIC BUILDING MATERIAL ZHEJIANG

Polyurethane composite special-shaped profile for glass curtain wall and forming method

InactiveCN102102404AExcellent insulation materialSolution to short lifeWallsTemperature resistanceEnergy conservation

The invention relates to a polyurethane composite special-shaped profile consisting of polyurethane resin and glass fibers for a glass curtain wall and a forming method. The profile comprises the glass fibers, the multiple beams of glass fibers are densely covered to form a special-shaped profile skeleton, and the insides and the outsides of the polyurethane resin and the special-shaped profile skeleton are compounded to form the polyurethane special-shaped profile. The profile has the advantages that: 1, the profile has light weight and high strength; 2, the profile has energy conservation and heat insulation properties; 3, the profile is healthy and environmentally-friendly, and has remarkable energy-saving effect; 4, the profile has corrosion resistance, ageing resistance and long service life; 5, the profile has good dimensional stability; 6, the profile has good weather resistance, good high temperature resistance and better low temperature resistance; 7, the insulating performance is good; 8, the shock absorption performance is good; 9, the color is rich, and the polyurethane composite material has high hardness and can be used for coating various coatings and manufactured into profiles of various colors to adapt the purposes of different styles and grades; and 10, the profile has fatigue resistance, and the polyurethane composite material has high fatigue resistance so that safety and reliability of material usage are ensured.

Owner:OUCHUANG PLASTIC BUILDING MATERIAL ZHEJIANG

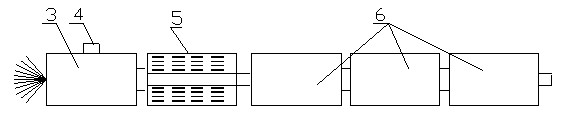

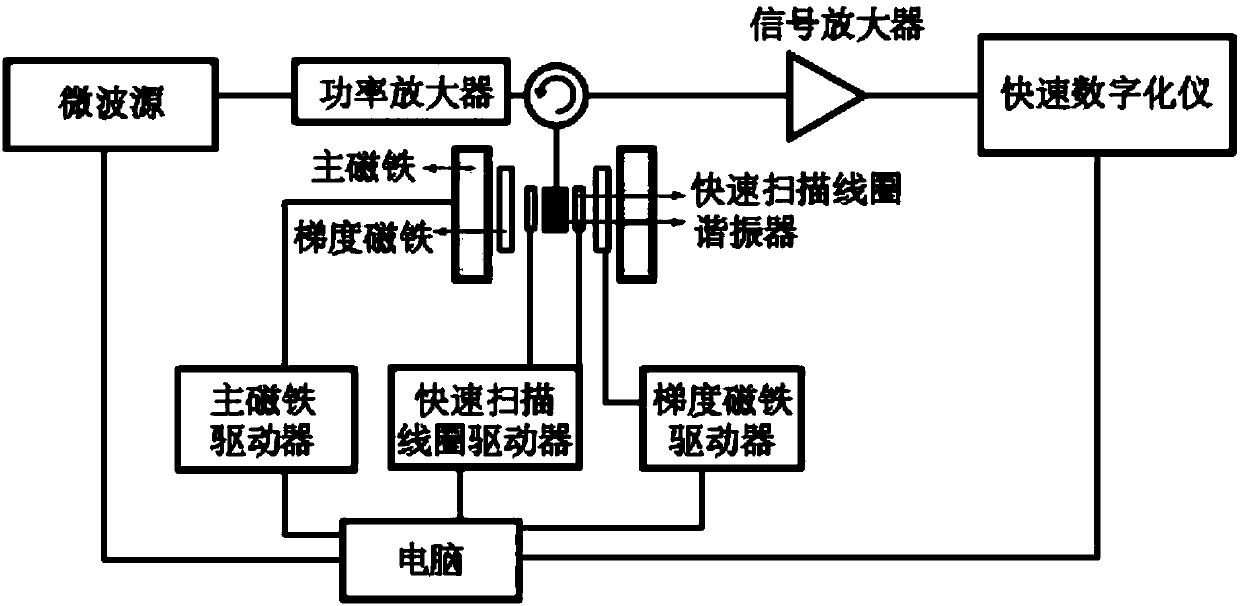

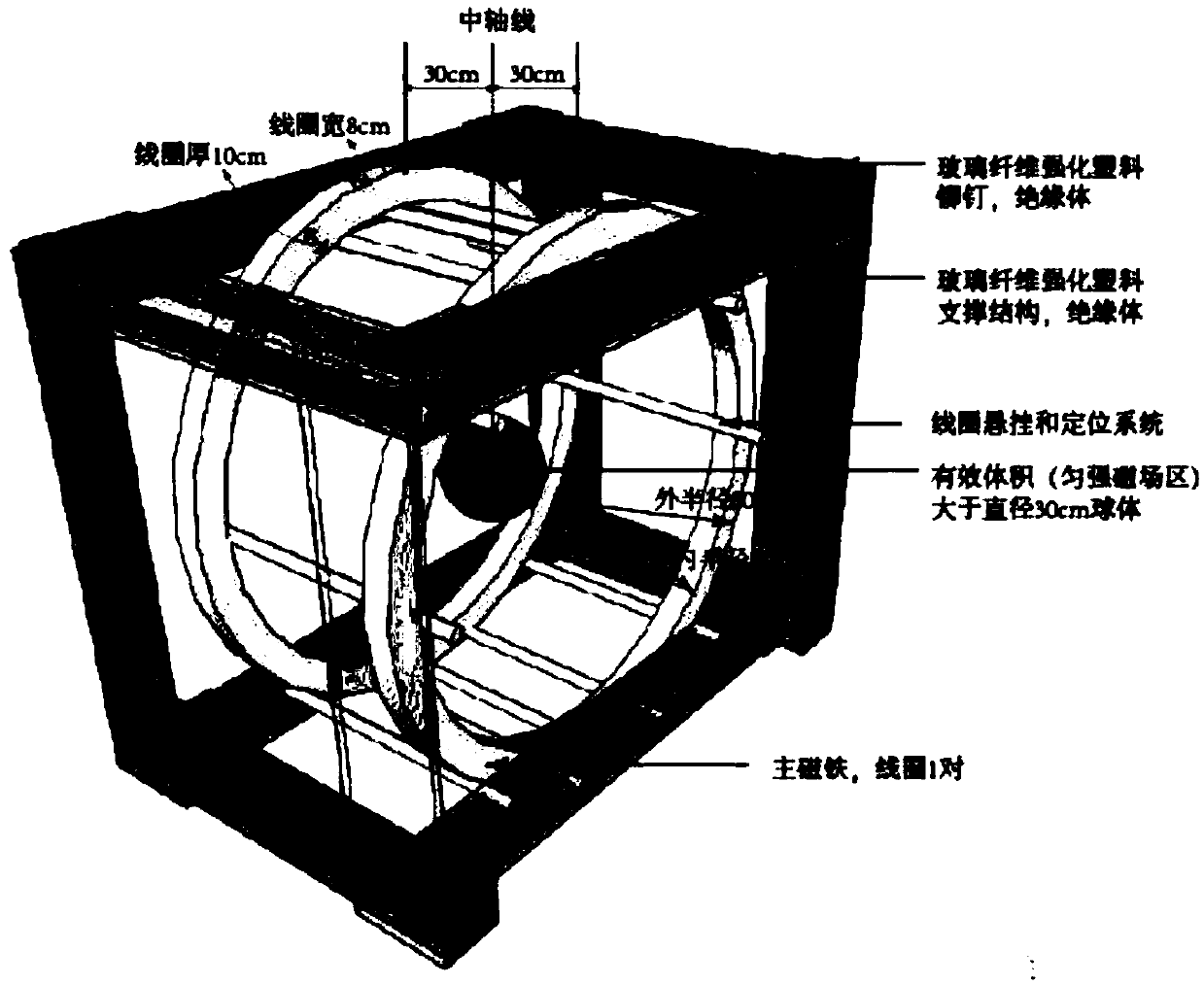

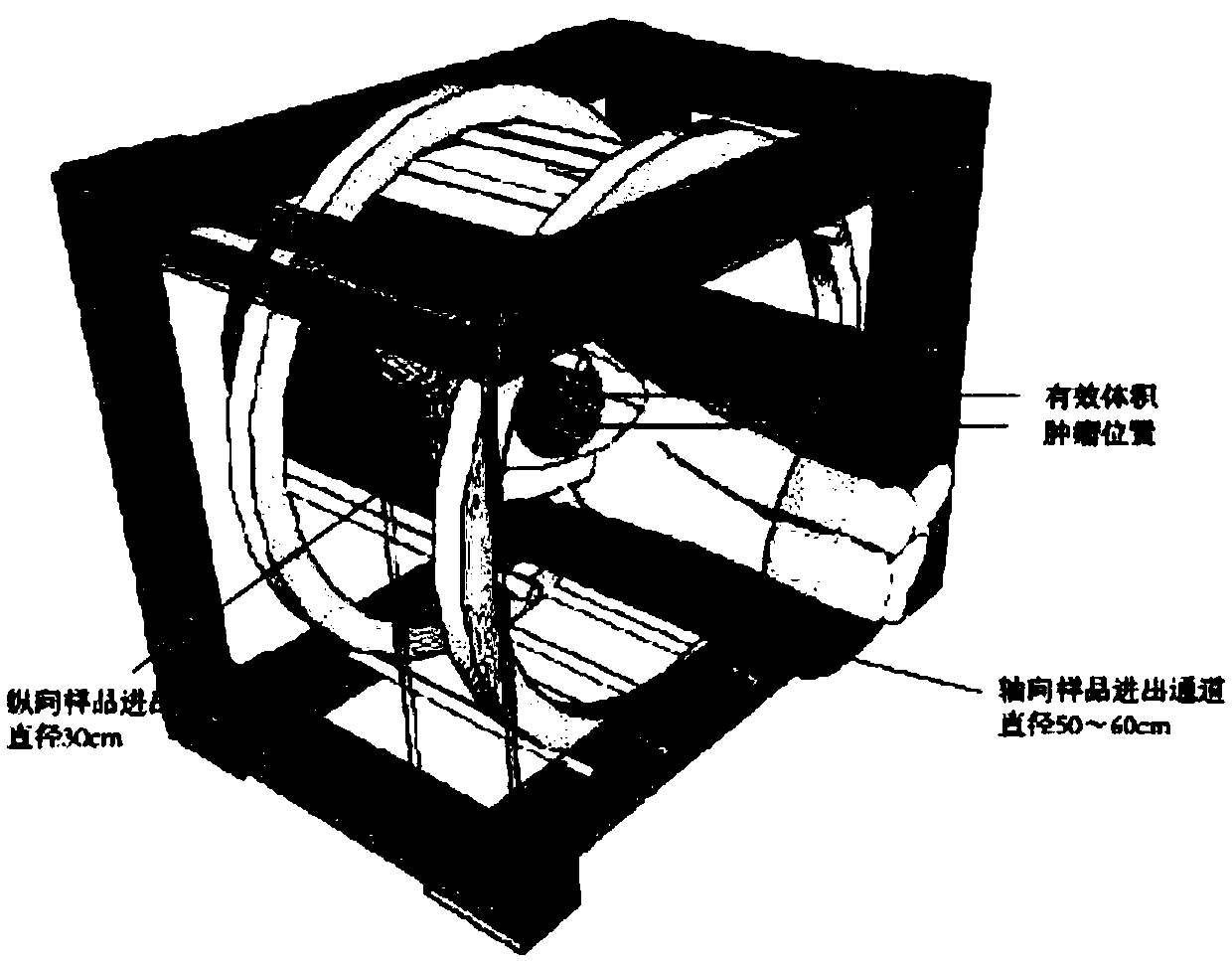

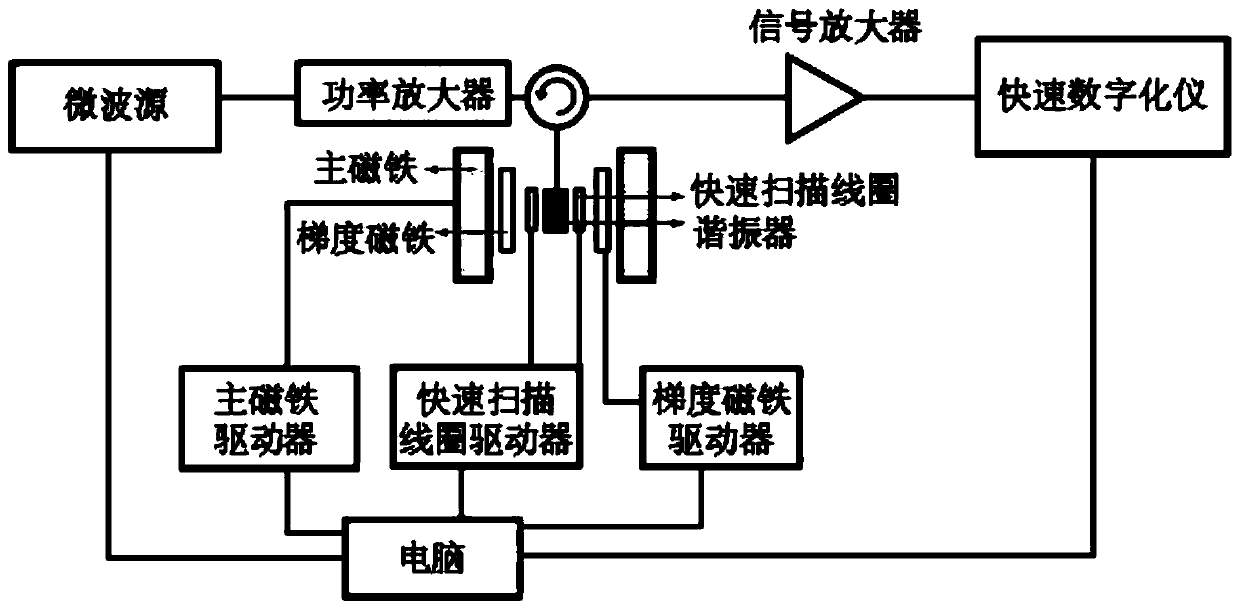

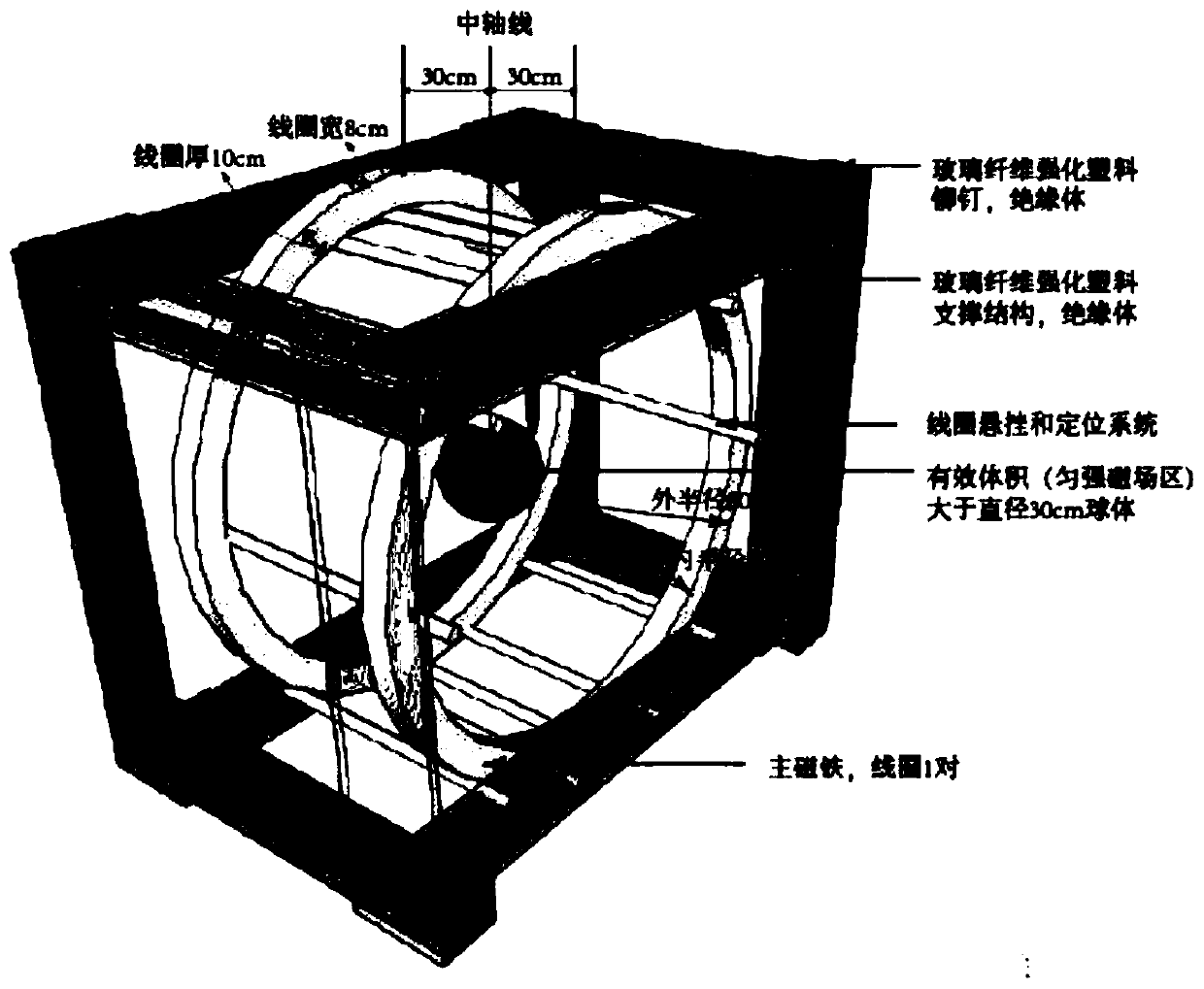

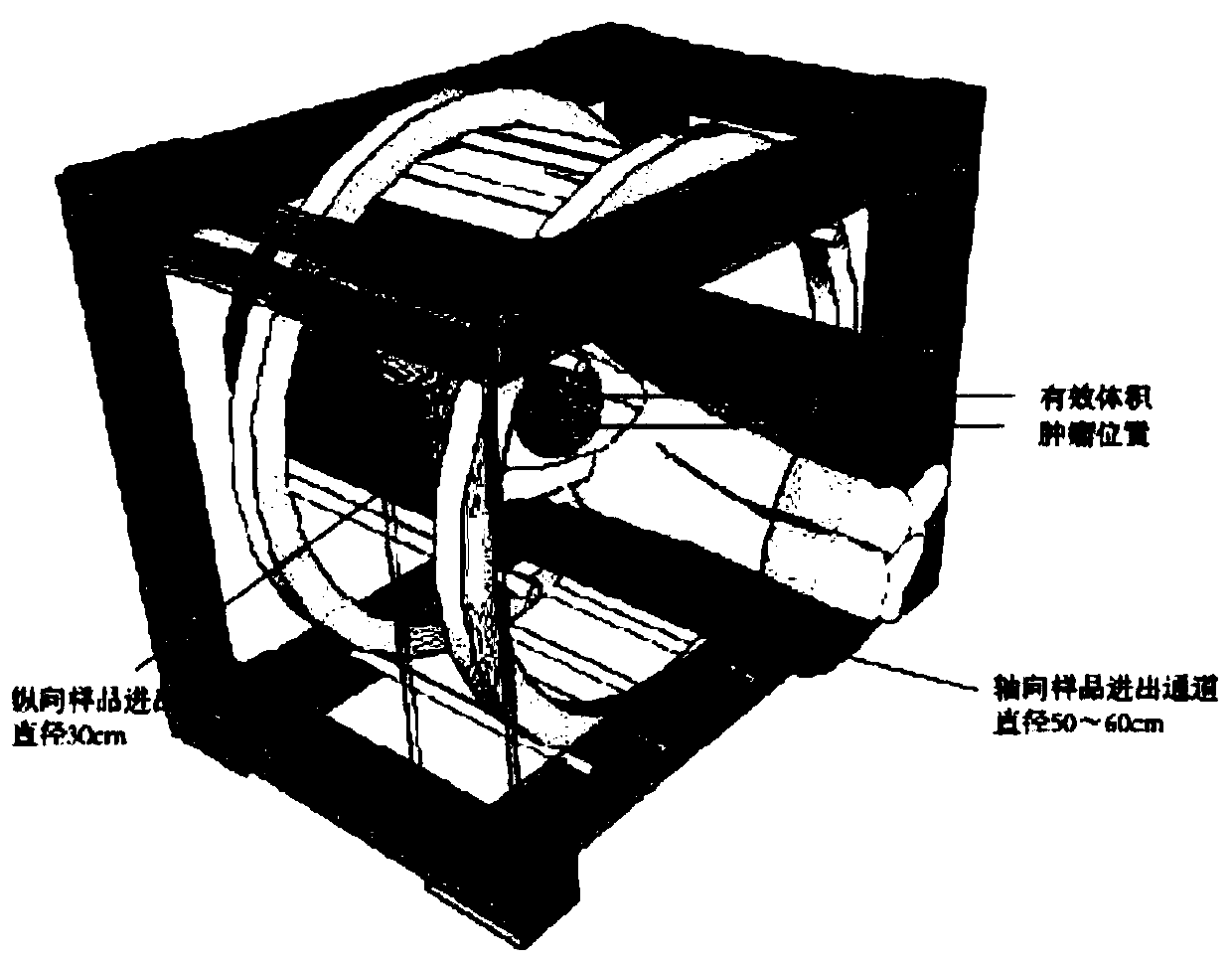

Electronic paramagnetic imager

ActiveCN109620224AImprove signal-to-noise ratioData collection time is shortDiagnostic recording/measuringSensorsData acquisitionElectron

The invention discloses an electronic paramagnetic imager. The electronic paramagnetic imager comprises a sample container, a quick-scanning resonator, a pair of quick-scanning coils, a pair of main magnets, a pair of gradient magnets, a main magnet driver, a gradient magnet driver, a quick-scanning coil driver, a microwave source, a power amplifier, a signal amplifier, a quick digitalizerand a computer. A signal is directly recorded by the quick digitalizer, and the electronic paramagnetic imager has the advantages that the ratio of signal to noise is extremely high, the data collecting timeis short, and big-power input is achieved, and the frequency can be adjusted. Theelectronic paramagnetic imager reconstructs a two-dimensional image of a tumor according to space distribution of a sample signal. The work frequency of the imager is low frequency about 250 MHz, the electronic paramagnetic imager can measure a tumor model of a mouse and the human body, the microwave permeability is better, the measuring range is larger relatively, and an operation does not need to be performed.

Owner:常州特征信息科技有限公司

A kind of magnetic nanochip absorber and preparation method thereof

ActiveCN111424235BFlat surfaceReduce internal defectsMagnetic/electric field screeningVacuum evaporation coatingMaterials scienceVacuum coating

The invention relates to the technical field of wave-absorbing materials, in particular to a magnetic wave-absorbing agent and a preparation method thereof. The preparation method is to use the vacuum coating method to alternately deposit a certain thickness of magnetic material and dielectric material on a substrate uniformly coated with a sacrificial layer to obtain a multilayer film, then remove the sacrificial layer to obtain a multilayer magnetic film, and then crush the multilayer magnetic film to obtain a magnetic film. Nanosheet-like absorbent. The preparation process is simple and easy to adjust, and the prepared magnetic nanochip absorbent has smooth surface, few internal defects, small stress, controllable magnetic composition, multilayer structure, large aspect ratio and good surface insulation. It can break through the magnetic permeability bottleneck of the magnetic nanocrystalline absorbent prepared by the existing ball milling method due to rough surface, large internal defects and stress, poor microstructure control ability, and limited width-to-thickness ratio. The microwave permeability of magnetic absorbers and suppresses their permittivity.

Owner:WUHAN UNIV OF TECH

Reinforcing rib section for polyurethane composite material energy-saving door and door sash frame or window and window sash frame

InactiveCN102031914BSolution to short lifeExcellent corrosion-resistant materialWindow/door framesWing framesFiberEngineering

The invention relates to a reinforcing rib section for a polyurethane composite material energy-saving door frame or door sash frame or window frame or window sash frame, which is made from polyurethane resin and glass fiber, and a molding method. The reinforcing rib section comprises glass fibers, wherein a reinforcing rib section molding framework for a door frame / sash or a window frame / sash consists of a plurality of bundles of densely covered glass fibers; and polyurethane resin is compounded with the inner and outer surfaces of the reinforcing rib section molding framework for the door frame / sash or the window frame / sash. The reinforcing rib section has the advantages of light weight, high intensity, energy conservation, heat preservation, heat insulation, health, environmental friendliness, remarkable energy-saving effect, corrosion resistance, ageing resistance, long service life, high size stability, high weather resistance, high high-temperature resistance, higher low-temperature resistance, good insulating property, high damping performance and rich color; a polyurethane composite material has high hardness; and the reinforcing rib section can be painted with various paints to obtain sections of various colors so as to adapt to different styles and grades.

Owner:OUCHUANG PLASTIC BUILDING MATERIAL ZHEJIANG

Electron Paramagnetic Imager

ActiveCN109620224BImprove signal-to-noise ratioData collection time is shortDiagnostic recording/measuringSensorsData acquisitionSignal-to-quantization-noise ratio

Owner:常州特征信息科技有限公司

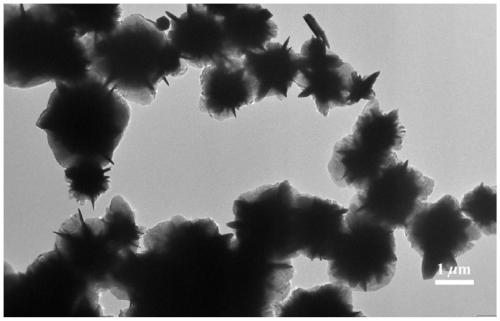

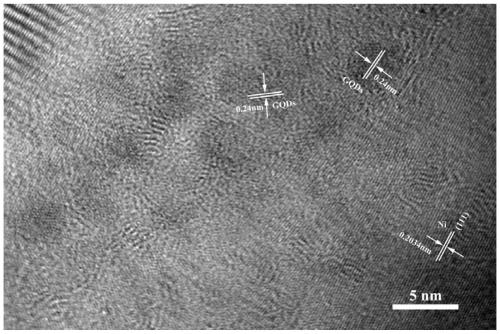

Method for preparing dielectric adjustable three-dimensional graded nanocapsule wave absorbing material

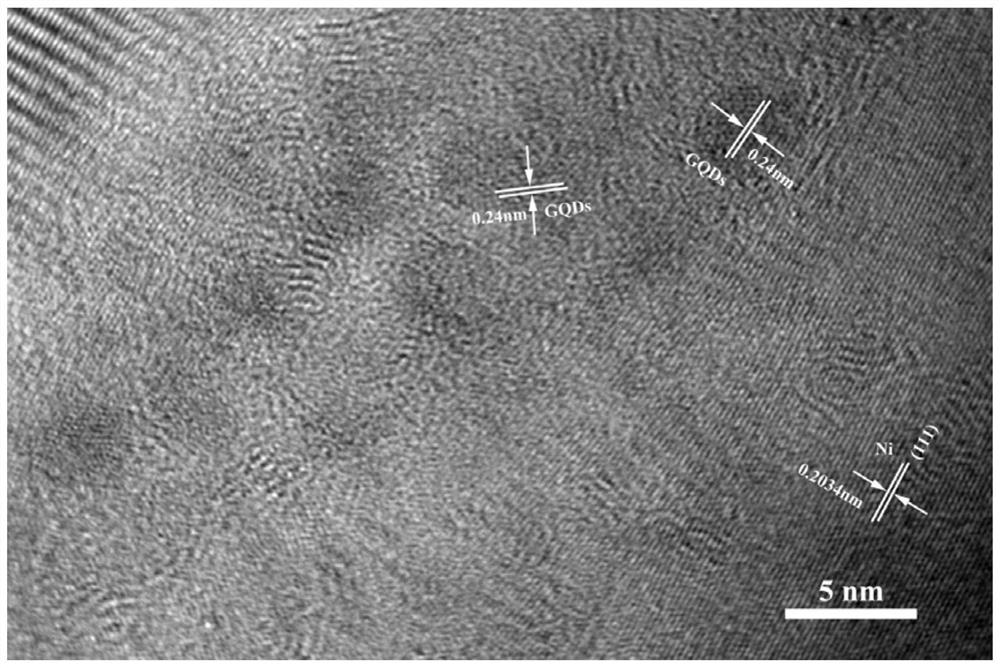

ActiveCN111230140AEnhanced Multiple ScatteringImprove microwave magnetic lossMaterial nanotechnologyTransportation and packagingNickel saltPolystyrene

The invention discloses a method for preparing a dielectric adjustable three-dimensional graded nanocapsule wave absorbing material. Nickel salt is reduced through a one-step polyhydric alcohol solvothermal method, a three-dimensional graded nano structure formed by nickel (Ni) nanosheets through random crossing is prepared, then the surface of a magnetic graded Ni core is covered with a polystyrene (PS) shell layer embedded and decorated by graphene quantum dots (GQDs) through in-situ polymerization, and therefore the Ni / GQDs / PS three-dimensional graded nanocapsule wave absorbing material isobtained. According to the method, the multiple scattering and microwave magnetic conductivity of a face easy to magnetize is improved through the geometric effect and anisotropism of a Ni graded structure, and three-dimensional magnetic loss enhancement is achieved. The graded Ni core-coated GQDs / PS shell layer is compounded through polar and nonpolar materials, the microwave dielectric constantcan be adjusted, and dielectric loss, impedance matching and the absorption frequency band are modulated accordingly; and meanwhile, Ni core oxidization is effectively avoided, and the adjustable waveabsorption performance of the material is achieved.

Owner:HEFEI UNIV OF TECH

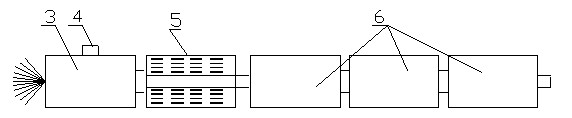

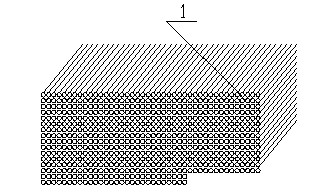

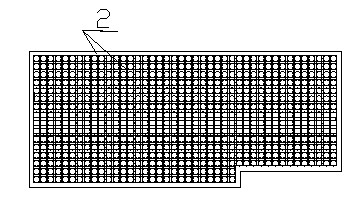

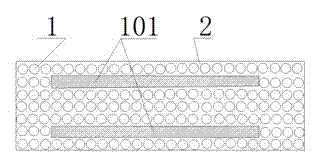

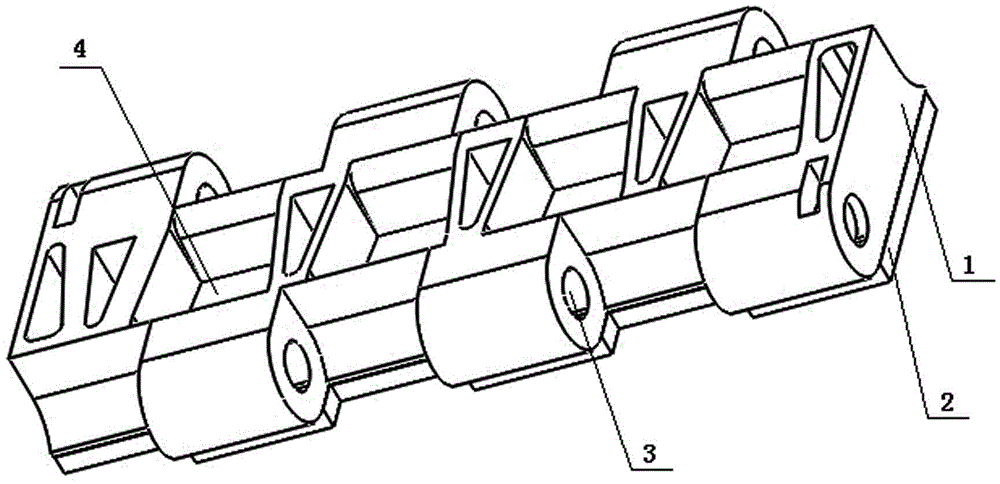

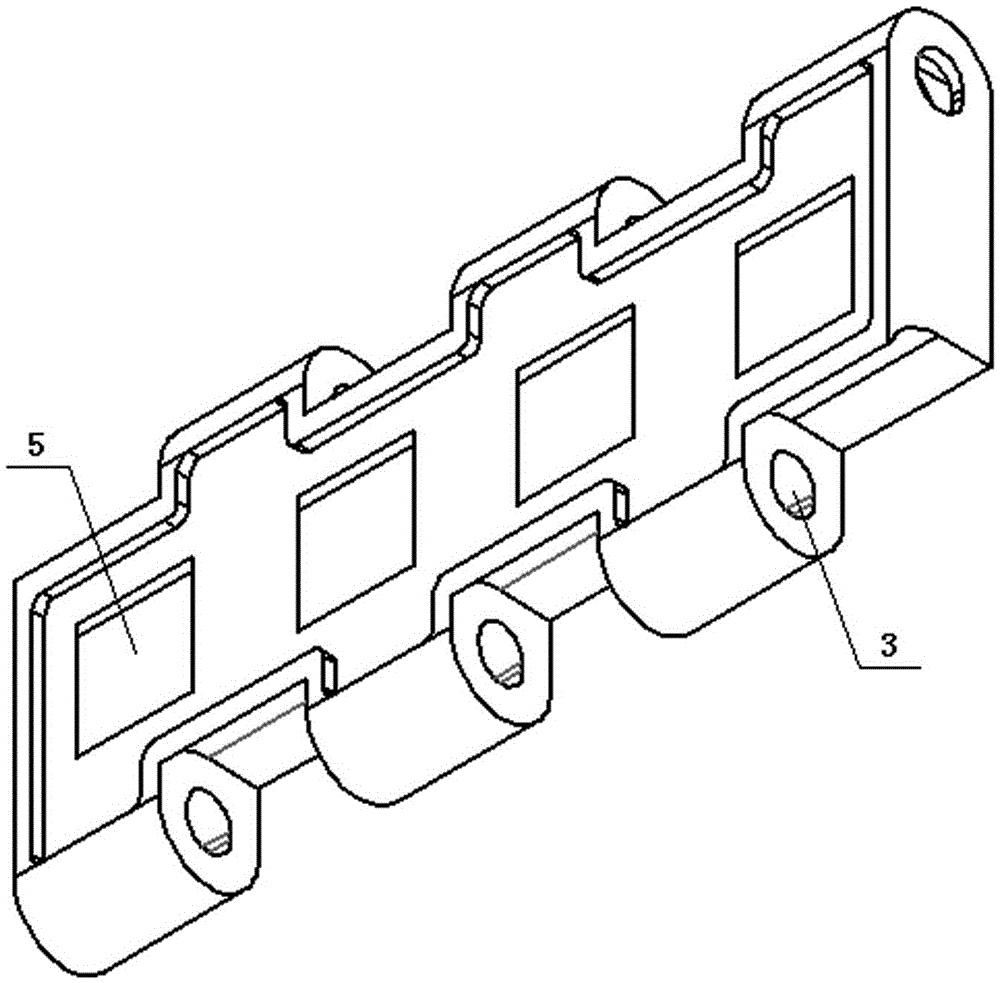

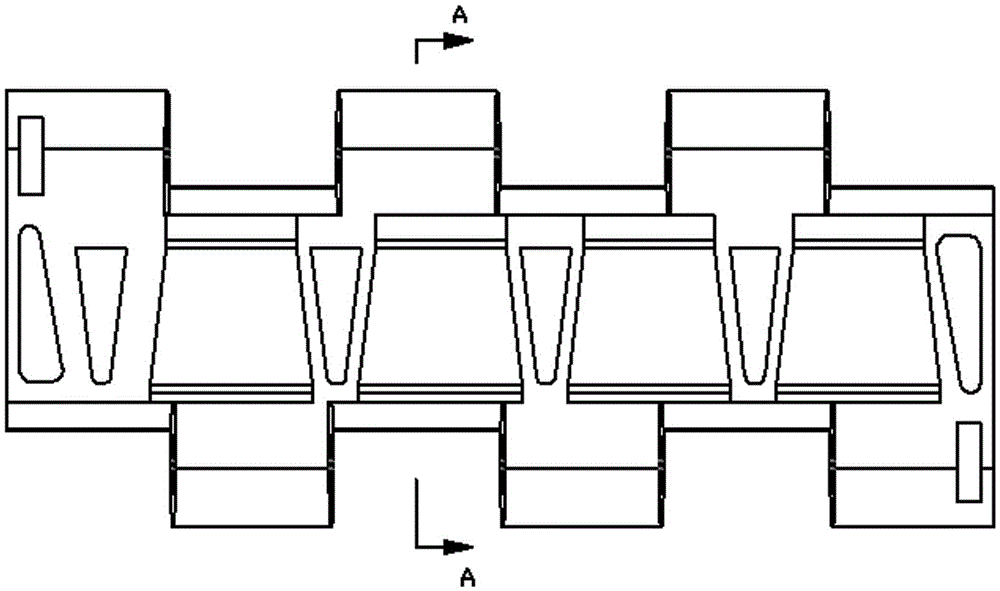

High temperature resistant, microwave transparent aluminum hydroxide/polyethersulfone conveyor belt and manufacturing method thereof

InactiveCN103552803BImprove microwave permeabilityLow dielectric constantConveyorsPhosphoric acidOil spill

The invention discloses a high-temperature-resistant and microwave-permeable aluminum hydroxide / polyether sulfone conveyor belt and a method for manufacturing the same. The method includes manufacturing a polyether sulfone support by an injection molding technology; uniformly dispersing aluminum hydroxide powder in N,N-dimethylacetamide and phosphoric acid mixed solution to manufacture aluminum hydroxide emulsion; coating the aluminum hydroxide emulsion on the upper surface of the polyether sulfone support and performing heat treatment on the polyether sulfone support to manufacture a plurality of conveyor belt units; connecting the aluminum hydroxide / polyether sulfone conveyor belt units with one another by a polyether sulfone hinge pin (6) to form the aluminum hydroxide / polyether sulfone conveyor belt. The high-temperature-resistant and microwave-permeable aluminum hydroxide / polyether sulfone conveyor belt and the method have the advantages that polyether sulfone is processed by an injection process, the high-temperature-resistant and microwave-permeable aluminum hydroxide / polyether sulfone conveyor belt is suitable for industrial large-scale production and is high in mechanical strength and excellent in microwave-permeable performance, and the surfaces of the conveyor belt can resist instant high temperatures ranging from 900 DEG C to 1000 DEG C, so that industrial continuous production of expanded graphite can be guaranteed, and development on offshore oil spilling emergency efficient cleaning equipment can be promoted.

Owner:YANSHAN UNIV

Preparation method of modified aluminium silicate ceramic fiber blanket for microwave expansion

ActiveCN103321051BImprove microwave permeabilityDoes not affect puffing efficiencyFibre treatmentFiberFlexural strength

The invention discloses a preparation method of a modified aluminium silicate ceramic fiber blanket for microwave expansion. The preparation method comprises the following steps of: firstly, dissolving polyether sulfone and polyvinylpyrrolidone into N,N-dimethylacetamide solvent to prepare polyether sulfone solution; then conducting ultrasonic oscillation on aluminium oxide powder with average particle size of 1.5 mu m so that the aluminium oxide powder can be dispersed in the polyether sulfone solution to prepare mixed aluminium oxide-polyether sulfone solution; then dip-coating the mixed aluminium oxide-polyether sulfone solution into the aluminium silicate ceramic fiber blanket sold in the market; and naturally airing at atmospheric temperature. The prepared modified aluminium silicate ceramic fiber blanket is high in tensile strength and bending strength, excellent in microwave permeation property, and capable of meeting the high-temperature-resistant requirement of the expansion procedure. In addition, the preparation method has the advantages of being simple and convenient to operate, and low in cost.

Owner:YANSHAN UNIV

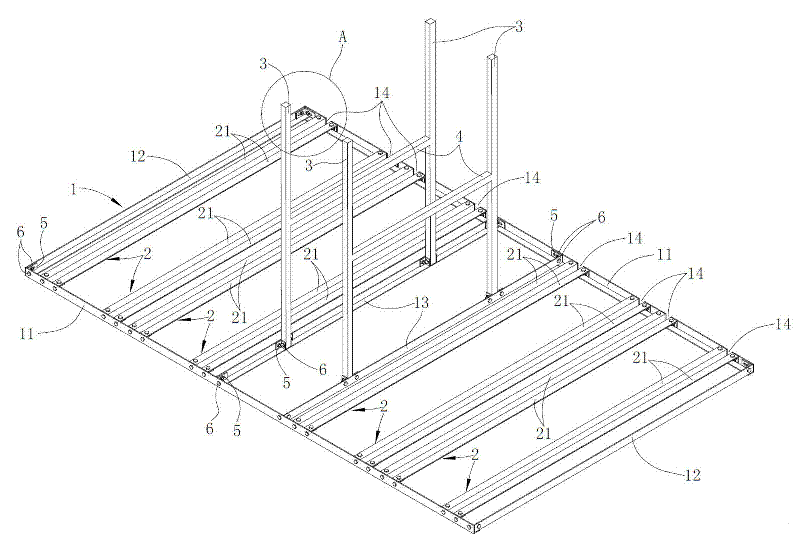

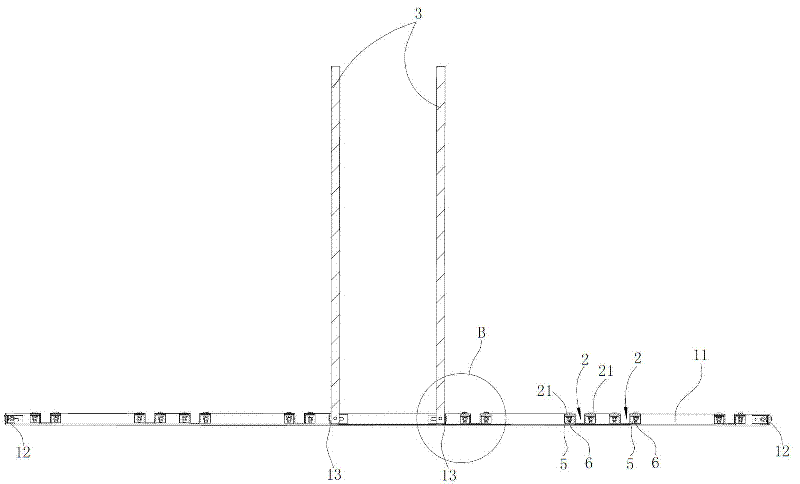

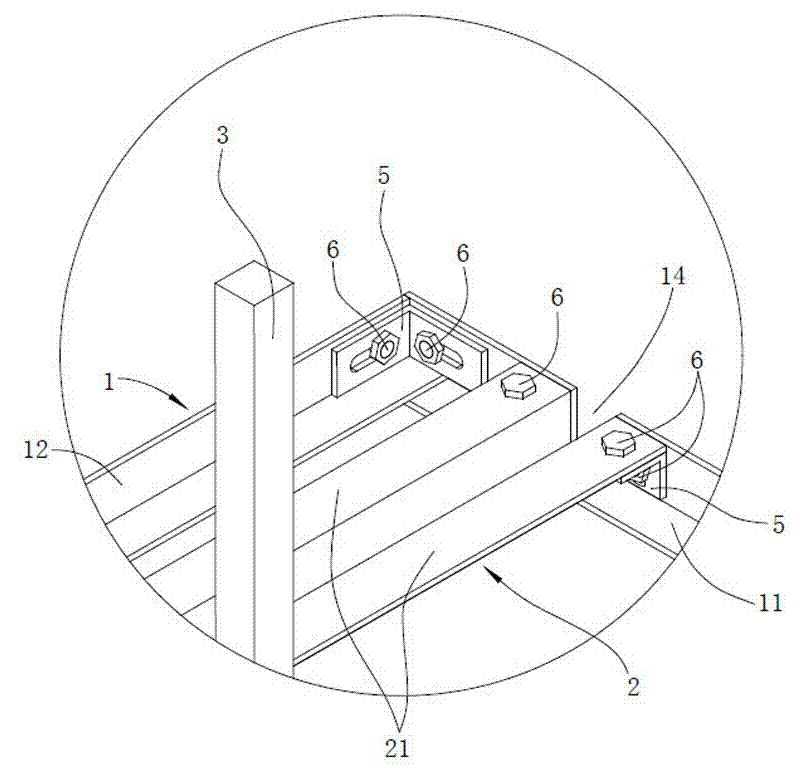

Anticorrosion support structure of hatching machine

InactiveCN102379253AGood corrosion resistant materialImprove the immunityPoultry incubationEngineeringHatching

The invention relates to an anticorrosion structure of a hatching machine, which comprises a rectangular horizontal bottom frame, a plurality of horizontal longitudinal guide rails, four vertical columns, and longitudinal connecting beams. The horizontal longitudinal guide rails are arranged on each side of the bottom frame in the length direction, the four vertical columns arranged in a rectangular form are disposed in the middle of the bottom frame in the length direction, each longitudinal connecting beam is disposed between the middles of the corresponding two vertical columns arranged longitudinally, and all of the bottom frame, the guide rails, the vertical columns and the connecting beams are made of glass fiber reinforced plastics. By adopting the technical scheme that all of the bottom frame, the guide rails, the vertical columns and the connecting beams are made of the glass fiber reinforced plastics, the support structure is insulating and thermal-insulating. The hatching machine with the support structure is not easy to rust and is anticorrosion, and normal service of the hatching machine is more facilitated.

Owner:吴二乔

Preparation method of a dielectrically adjustable three-dimensional hierarchical nanocapsule absorbing material

ActiveCN111230140BEnhanced Multiple ScatteringImprove microwave magnetic lossMaterial nanotechnologyTransportation and packagingNickel saltIn situ polymerization

The invention discloses a preparation method of a dielectrically adjustable three-dimensional hierarchical nanocapsule wave-absorbing material. A three-dimensional hierarchical nanostructure formed by randomly intersecting nickel (Ni) nanosheets is prepared by reducing a nickel salt through a one-step polyol solvothermal method. Then, in situ polymerization is used to coat a polystyrene (PS) shell layer modified by graphene quantum dots (GQDs) on the surface of the magnetically graded Ni core, thereby obtaining a Ni / GQDs / PS three-dimensional hierarchical nanocapsule absorbing material. . The invention improves the multiple scattering and microwave permeability of the easily magnetized surface through the geometric effect and anisotropy of the Ni hierarchical structure, and realizes three-dimensional magnetic loss enhancement; the graded Ni core is coated with the GQDs / PS shell, and the polarity Combined with non-polar materials, the microwave dielectric constant can be adjusted, and the dielectric loss, impedance matching, and absorption frequency band can be modulated. At the same time, it can effectively prevent the oxidation of the Ni core and realize the adjustable microwave absorption performance of the material.

Owner:HEFEI UNIV OF TECH

Composite energy-saving door window frame or door window sash frame and forming method

InactiveCN102518357BSolution to short lifeExcellent corrosion-resistant materialWindow/door framesGlass/slag layered productsEnvironmental resistanceGlass fiber

Owner:OUCHUANG PLASTIC BUILDING MATERIAL ZHEJIANG

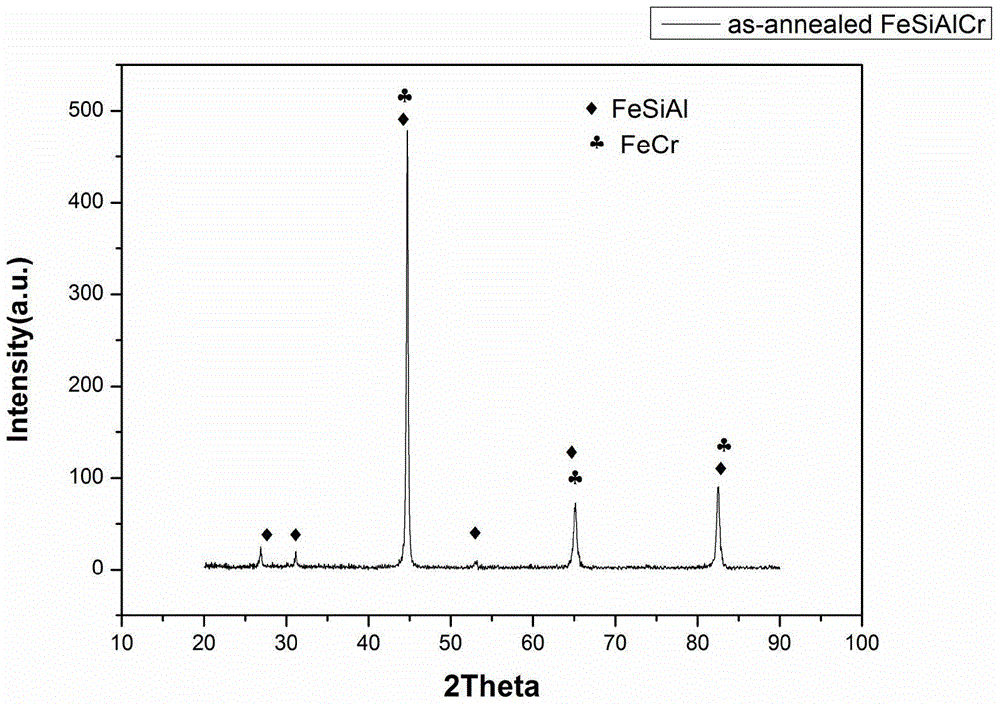

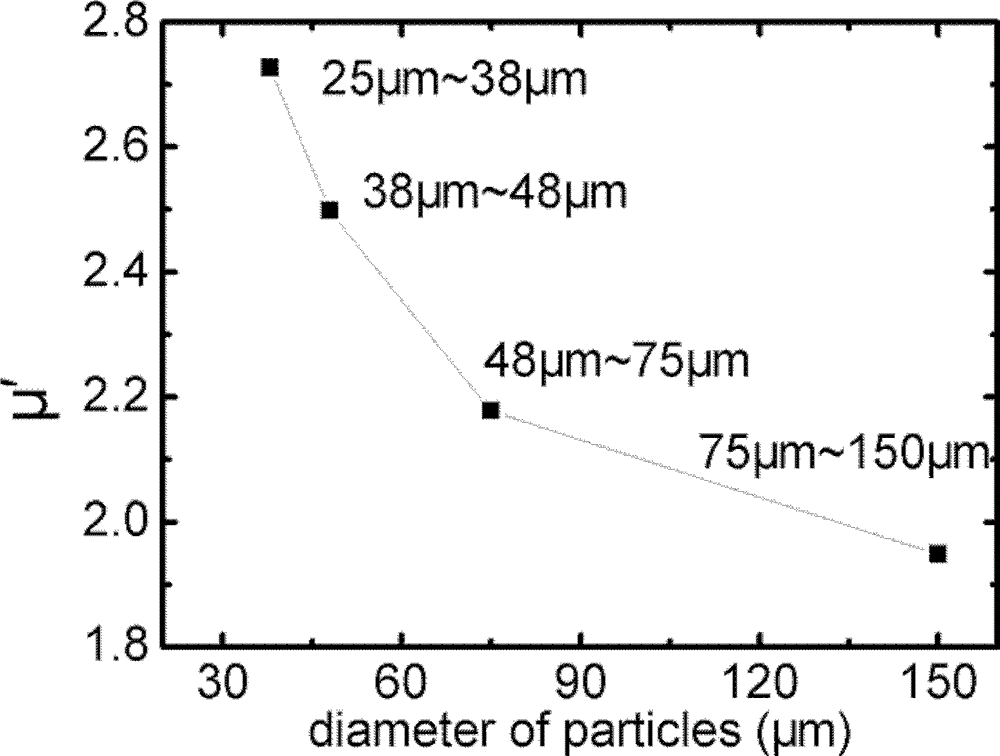

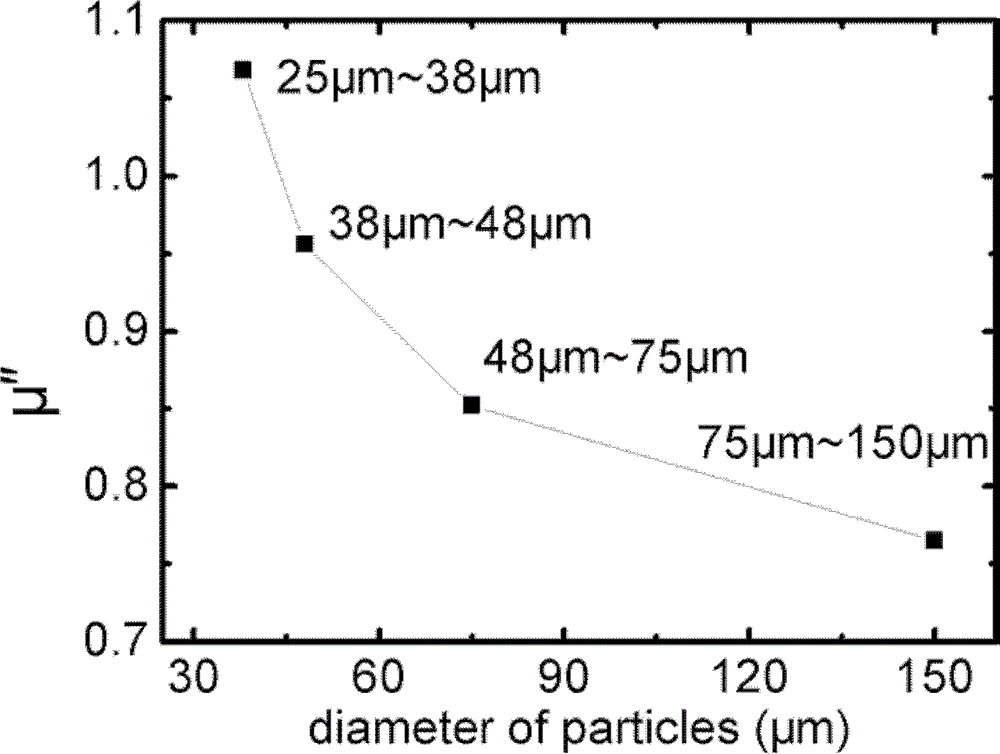

A kind of preparation method of fe-si-al soft magnetic material with high microwave magnetic permeability

InactiveCN102623122BIncrease the complex permeability μIncrease the value of the complex permeability μInorganic material magnetismMicrowaveMass ratio

The invention discloses a preparation method of Fe-Si-Al soft magnetic material with high microwave magnetic permeability, which belongs to the field of high-frequency magnetic performance magnetic materials. The present invention includes the following steps: 1) 100-mesh Fe-Si-Al raw powder is sieved through 100-mesh, 200-mesh, and 300-mesh sieves in turn, and the 75 μm-150 μm powder is called A type powder, and the 48 μm-75 μm powder is called B type. Powder; the mass percent of the Fe-Si-Al raw powder component is: Fe: (82.6-x-y)%, Si: (10.3+x)%, Al: (7.1+y)%, |x|≤ 0.7, |y|≤1.7; 2) Flake treatment, control the average particle size / thickness ratio of the powder between 14 and 26; 3) Remix according to the mass ratio of Class A: Class B = 0.5 to 2 to obtain high Microwave permeability soft magnetic alloy powder. The invention has simple process and convenient operation, and the Fe-Si-Al alloy powder is sieved before mechanical ball milling, which can improve its microwave magnetic permeability, and can greatly increase its microwave magnetic permeability if it is further processed into flakes.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A microwave frequency band electromagnetic wave absorber and preparation method thereof

ActiveCN105088109BReduce effective anisotropyImprove microwave permeabilityElectromagnetic absorptionElectronic materials

The invention belongs to the technical field of electronic materials, and particularly relates to a microwave frequency band (0.5GHz-18GHz) electromagnetic wave absorbent and a preparing method thereof. The absorbent is made of pure ferrum, pure aluminum, pure chromium and polycrystalline silicon. By mass, larger than or equal to 65% but smaller than or equal to 78% of pure Fe, larger than or equal to 5% but smaller than or equal to 12% of pure aluminum, larger than or equal to 2% but smaller than or equal to 12% of pure chromium and larger than or equal to 8% but smaller than or equal to 16% of polycrystalline silicon are molten, and nanocrystalline / amorphous biphase particles with the grain size of 10-50 nm are formed. According to the prepared absorbent, when an electromagnetic absorption material is prepared with the 30-40% of absorbent and paraffin as an auxiliary material, on the frequency band of 0.5 GHz-18 GHz, magnetic conductivity [mu]'max is larger than or equal to 7 but smaller than or equal to 8, and [mu]''max is larger than or equal to 4 but smaller than or equal to 5. The technology is simple, operability is high, and cost is low. The absorbent is suitable for batched production.

Owner:成都佳驰电子科技股份有限公司

Preparation method for high temperature-resistant microwave-permeable aluminum hydroxide/polyethersulfone composite material

ActiveCN103554539BImprove microwave permeabilityImprove high temperature resistanceCoatingsEmulsionPhosphoric acid

The invention discloses a preparation method for a high temperature-resistant microwave-permeable aluminum hydroxide / polyethersulfone composite material. The method comprises the following steps: dissolving polyethersulfone powder in an N,N-dimethylacetamide solvent and carrying out drying to prepare a polyethersulfone support; uniformly dispersing aluminum hydroxide powder in a mixed solution of N,N-dimethylacetamide and phosphoric acid to prepare an aluminum hydroxide emulsion; and dumping the aluminum hydroxide emulsion into a culture dish filled with the polyethersulfone support and carrying out a series of heat treatment at a temperature of 80 to 200 DEG C so as to prepare the aluminum hydroxide / polyethersulfone composite material with excellent high temperature resistance and microwave permeability. The aluminum hydroxide / polyethersulfone composite material prepared in the invention has high mechanical strength and excellent microwave permeability and can meet requirements for the working condition of an instant high temperature of 900 to 1000 DEG C. The preparation method provided by the invention has the advantages of simple procedures, easy operation and low cost.

Owner:YANSHAN UNIV

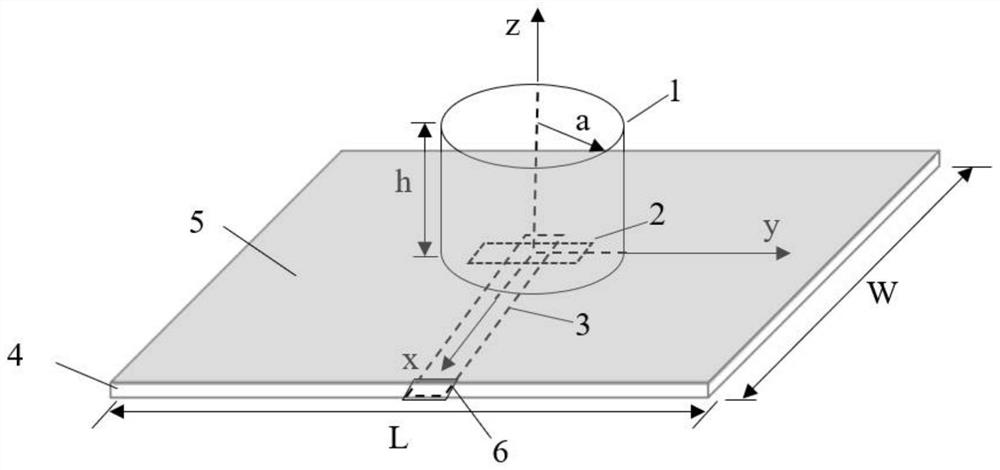

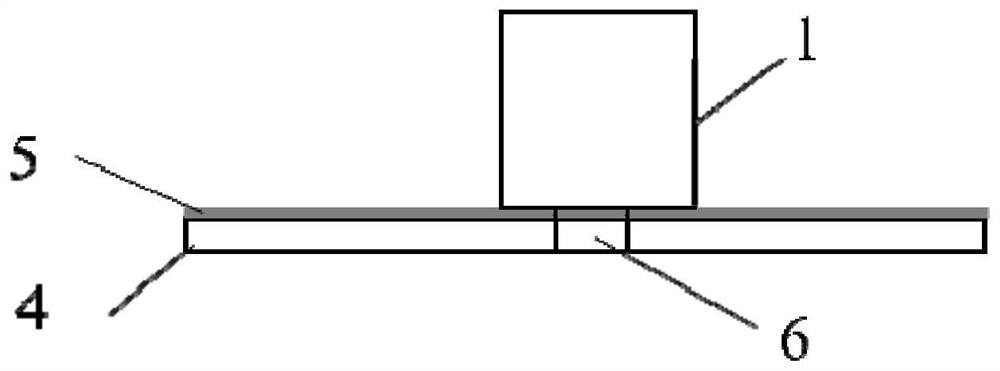

Preparation method of magnetic dielectric composite material dielectric resonator and miniaturized antenna

ActiveCN114094301AImprove performanceImprove microwave permeabilityRadiating elements structural formsAntennas earthing switches associationDielectric substrateMiniaturization

The invention discloses a preparation method of a magnetic dielectric composite material dielectric resonator and a miniaturized antenna, the dielectric resonator is formed by mixing spinel ferrite and hexagonal ferrite materials, the mass fraction of the spinel ferrite is 10-40%, the mass fraction of the hexagonal ferrite is 60-90%, and the sum of the mass percentages of the components is 100%. The dielectric resonator prepared by the method can be applied to a miniaturized antenna, the structure of the antenna comprises an antenna dielectric substrate, the surface of the antenna dielectric substrate is covered with a metal copper sheet, the center of the surface, connected with the metal copper sheet, of the antenna dielectric substrate is provided with a gap feed structure, and the dielectric resonator is adhered to the center of the metal copper sheet;' the miniaturized antenna is smaller in size and larger in bandwidth, and the performance of the antenna is improved.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com