Energy-saving window frame or window sash profile of polyurethane composite material and forming method

A technology of composite materials and molding methods, applied in the direction of wing sash frame, window/door frame, etc., can solve the problems of low speed and efficiency, and achieve the effect of energy saving, good dimensional stability and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

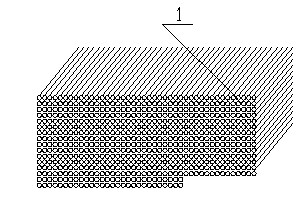

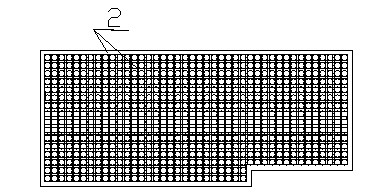

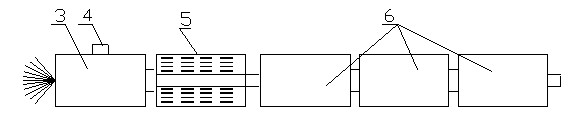

[0016] Embodiment 1: with reference to attached figure 1 and 2 . Polyurethane composite energy-saving window frame or sash frame profile, which includes glass fibers, and the multiple bundles of glass fibers are densely distributed to form the window frame or sash frame profile forming skeleton 1, and polyurethane resin 2 is composited with the inside and outside of the window frame or sash frame profile forming skeleton 1 And constitute a polyurethane window frame or sash frame profile, that is to say, the molding skeleton 1 of the window frame or sash frame profile is composed of multiple bundles of glass fibers, and the polyurethane resin 2 is completely composited with each glass fiber surface in the multiple bundles of glass fibers. And the glass fibers compounded with polyurethane resin 2 are bonded and solidified to form the required window frame or sash frame profile, that is, the inside and outside of the window frame or sash frame profile molding skeleton 1 refers t...

Embodiment 1-1

[0017] Example 1-1: On the basis of Example 1, 35%-40% polyurethane and 60%-75% glass fiber can be pultruded polyurethane profiles, which have better physical, mechanical and mechanical properties.

Embodiment 1-2

[0018] Example 1-2: On the basis of Example 1, 30%-35% polyurethane and 65%-70% glass fiber can be pultruded polyurethane profiles, which have good physical, mechanical and mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com