Anticorrosion support structure of hatching machine

A support structure and corrosion-resistant technology, applied in the field of corrosion-resistant support structures of incubators, can solve problems such as inability to resist corrosion, incubators easy to rust, and inconvenience for normal use of incubators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

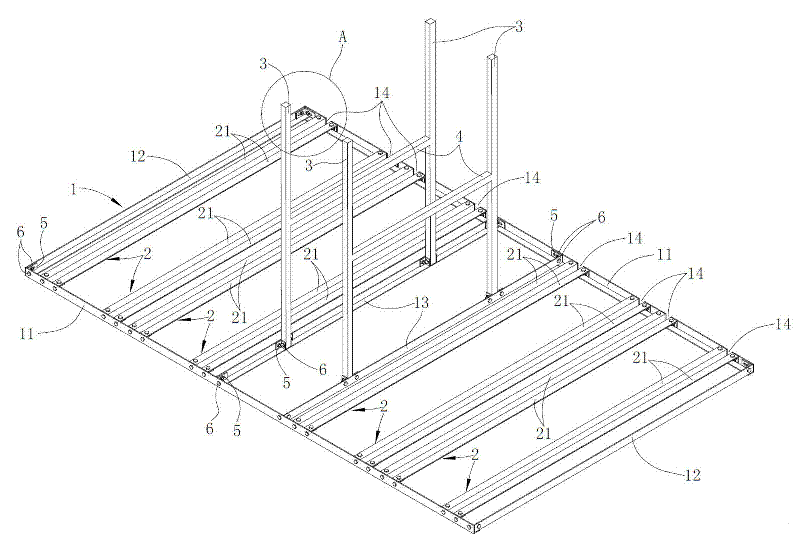

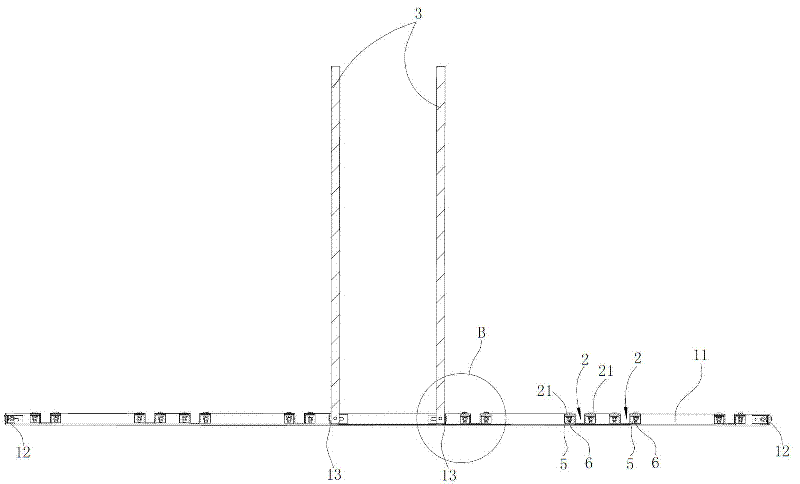

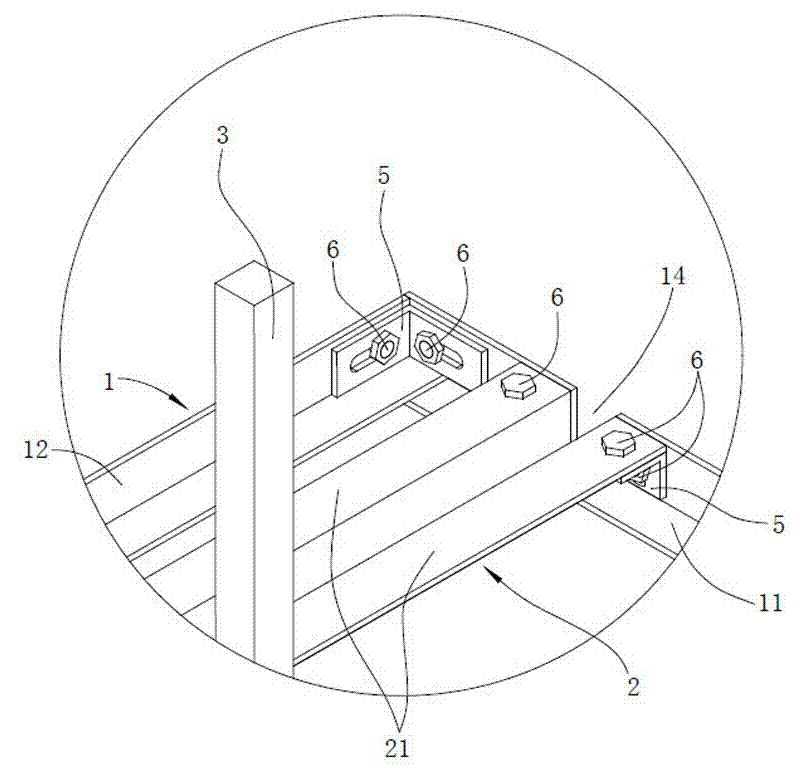

[0031] see figure 1 — Figure 4 :

[0032] The rectangular horizontal bottom frame 1 is composed of two lateral support rods 11 spaced from front to back and two longitudinal support rods 12 spaced from left to right. A longitudinal support rod 12 is connected between the same ends of the two lateral support rods 11 in the length direction. Two longitudinal connecting rods 13 spaced apart from each other are arranged in the middle section of the bottom frame 1 in the longitudinal direction, and the front and rear ends of each connecting rod 13 are connected with the corresponding lateral support rods 11 .

[0033] Four vertical upright columns 3 arranged in a rectangular manner are arranged in the middle section of the bottom frame 1 in the length direction. The lower ends of every two columns 3 arranged in the longitudinal direction are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com