Alloy micropowder electromagnetic wave absorbent and preparation method thereof

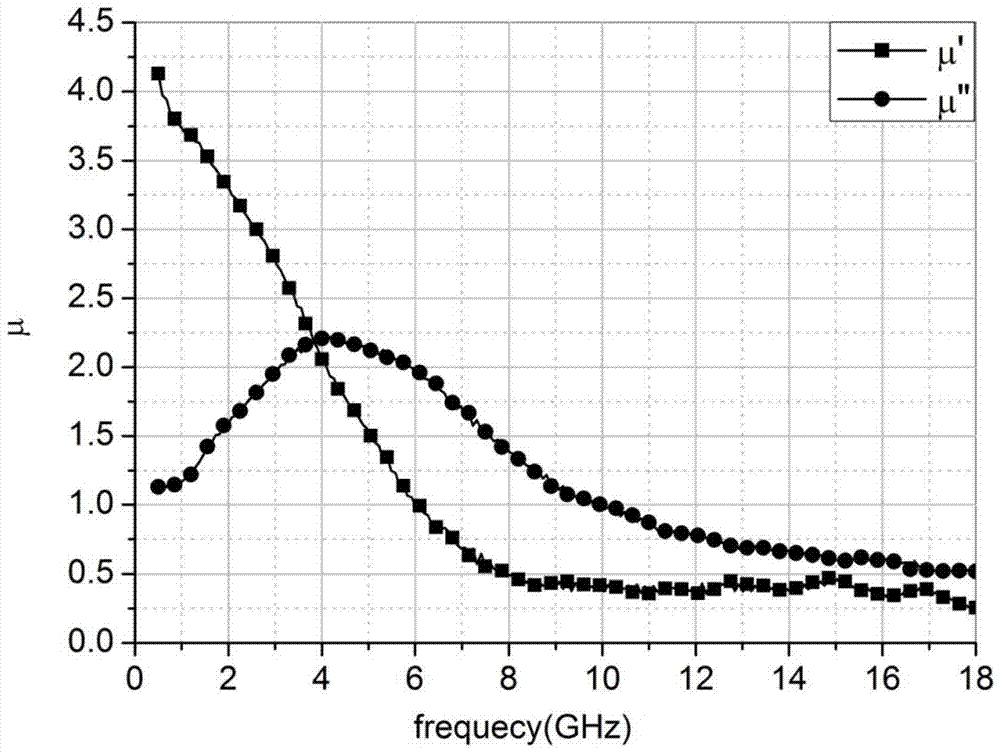

An electromagnetic wave and absorber technology, which is applied in the field of alloy micropowder electromagnetic wave absorber and its preparation, can solve the problem of high cost, achieve high flake degree, save cost, and improve microwave permeability and magnetic loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] S11. Weigh the pure iron block, polycrystalline silicon and pure chromium block according to the mole percentage of each component of the Fe-Si-Cr alloy being Fe:Si:Cr=77.3:21.5:1.2.

[0036] S12. Put the raw material weighed in S11 into the electric arc heating furnace with argon protection atmosphere, melt it to obtain molten metal liquid, and finally cast it into an ingot.

[0037] S13, mechanically crushing the ingot obtained in S12 to obtain fine particles with a particle size of 180 μm-220 μm.

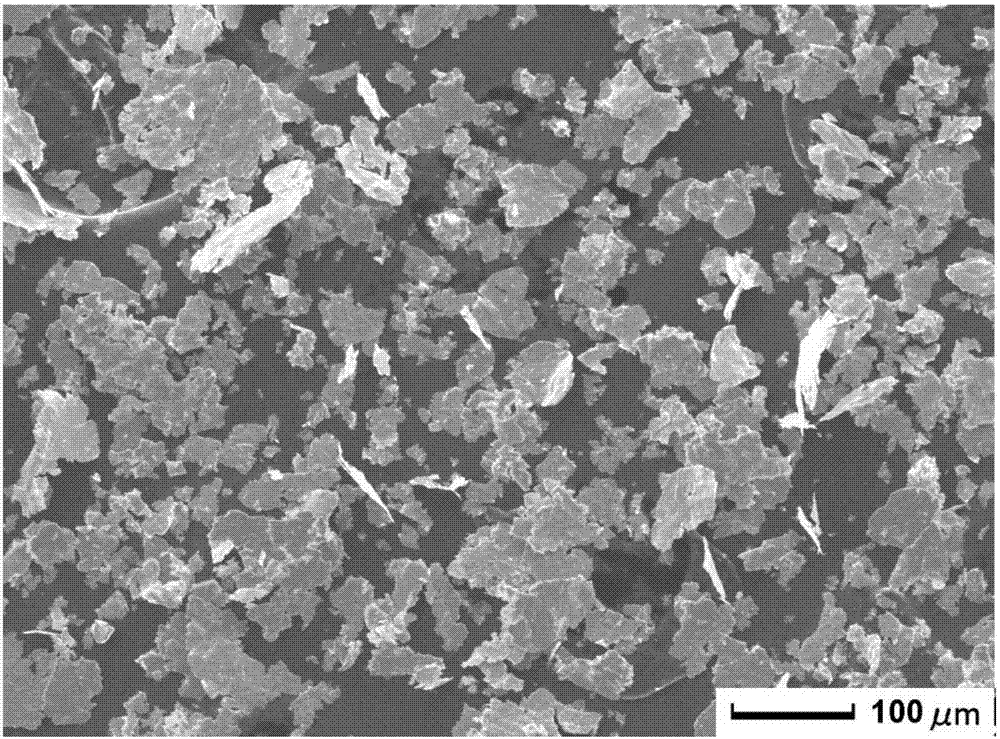

[0038] S14, putting the microfine particles after S13 mechanically crushing into a planetary ball mill for wet ball milling, the balls, material and absolute ethanol are formulated into a mixture according to a weight ratio of 250:1:25 and put into a ball mill tank for ball milling, Zirconium balls with a diameter of 15mm were selected as the grinding balls, the milling speed was 200r / min, and the milling time was 48 hours.

[0039] S15 , drying the material taken out aft...

Embodiment 2

[0042] S21. According to the mole percentage of each component of the Fe-Si-Cr alloy is Fe:Si:Cr=76.5:21.5:2, weigh the pure iron block, polysilicon and pure chromium block.

[0043] S22. Put the raw material weighed in S21 into the electric arc heating furnace with argon protection atmosphere, melt it to obtain molten metal liquid, and finally cast it into an ingot.

[0044] S23. Mechanically crushing the ingot obtained in S22 to obtain fine particles with a particle size of 180 μm-220 μm.

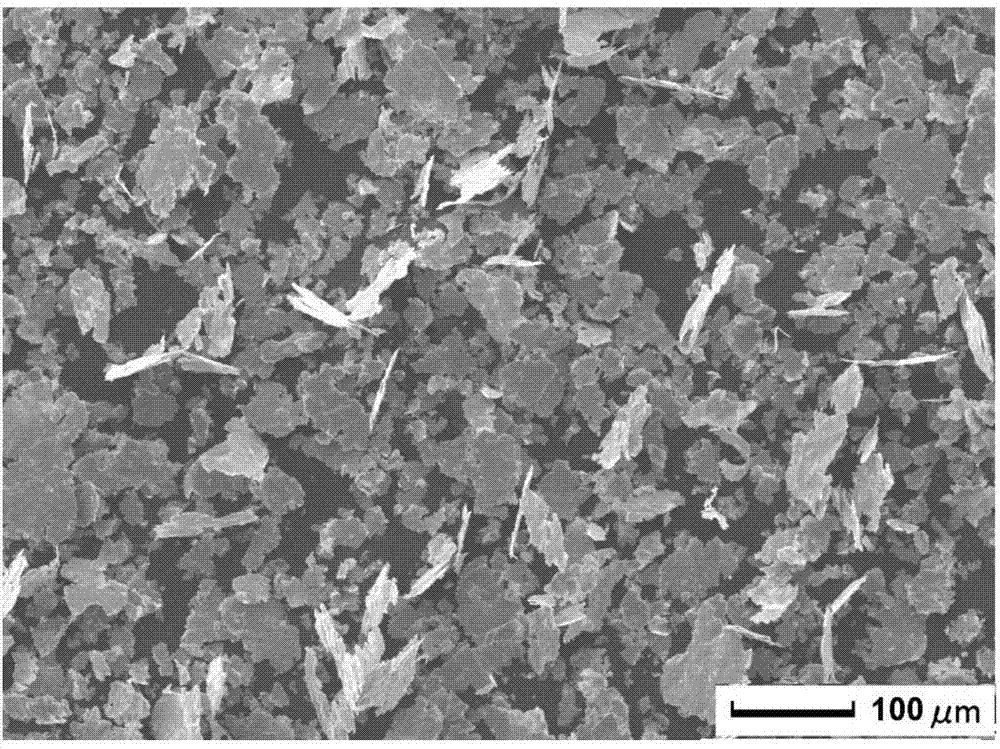

[0045] S24, putting the microfine particles after S23 mechanical crushing into a planetary ball mill for wet ball milling, the balls, material and absolute ethanol are formulated into a mixture according to a weight ratio of 250:1:25 and put into a ball mill tank for ball milling, Zirconium balls with a diameter of 15mm were selected as the grinding balls, the milling speed was 200r / min, and the milling time was 48 hours.

[0046]S25 , drying the material taken out after the ball milling...

Embodiment 3

[0049] S31. According to the mole percentage of each component of the Fe-Si-Cr alloy is Fe:Si:Cr=75.5:21.5:3, weigh the pure iron block, polysilicon and pure chromium block.

[0050] S32. Put the raw material weighed in S31 into the electric arc heating furnace with argon protection atmosphere, melt it to obtain molten metal liquid, and finally cast it into an ingot.

[0051] S33. Mechanically crushing the ingot obtained in S32 to obtain fine particles with a particle size of 180 μm-220 μm.

[0052] S34, putting the microfine particles after S33 mechanical crushing into a planetary ball mill for wet ball milling, the balls, material and absolute ethanol are formulated into a mixture according to a weight ratio of 250:1:25 and put into a ball mill tank for ball milling, Zirconium balls with a diameter of 15mm were selected as the grinding balls, the milling speed was 200r / min, and the milling time was 48 hours.

[0053] S35 , drying the material taken out after the ball millin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com