Method for preparing dielectric adjustable three-dimensional graded nanocapsule wave absorbing material

A technology of nanocapsules and absorbing materials, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as performance limitation of single-shell layer, difficulty in preparation of double-shell layer, compatibility of composite materials, etc. , to achieve the effect of improving microwave magnetic loss, promoting anisotropic growth and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Dissolve 3 mmol of nickel acetate tetrahydrate and 1 g of polyethylene glycol 4000 in 20 mL of ethylene glycol, and stir magnetically at 80 ° C for 20 min until completely dissolved to obtain a clear solution 1;

[0050] 2. Add 0.045mol of sodium hydroxide to 10mL of ethylene glycol, and stir with magnetic force at 80°C for 20min until completely dissolved to obtain a clear solution 2;

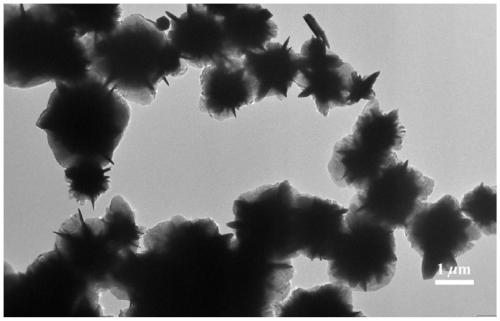

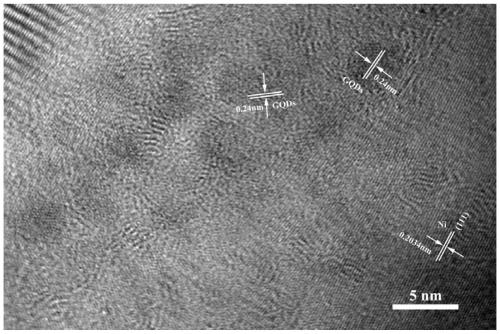

[0051] 3. Fully mix solution 1 and solution 2 and stir evenly, transfer to a 50ml polytetrafluoroethylene reactor lining, and put it into a stainless steel shell, react at 200°C for 8 hours, take it out after cooling to room temperature, and remove the product Use a magnetic field to separate out, and use distilled water and absolute ethanol to wash 3 times respectively, obtain the Ni hierarchical nano core;

[0052] 4. Redisperse the graded nano-Ni obtained in step 3 into deionized water, add 1g of polyvinylpyrrolidone (PVP) for ultrasonication and disperse evenly;

[0053] 5. Use ...

Embodiment 2

[0059] 1. Dissolve 3 mmol of nickel acetate tetrahydrate and 1 g of polyethylene glycol 4000 in 20 mL of ethylene glycol, and stir magnetically at 80 ° C for 20 min until completely dissolved to obtain a clear solution 1;

[0060] 2. Add 0.045mol flaky sodium hydroxide to 10mL ethylene glycol, and stir magnetically at 80°C for 20min until it is completely dissolved to obtain a clear solution 2;

[0061] 3. Fully mix solution 1 and solution 2 and stir evenly, transfer to a 50ml polytetrafluoroethylene reactor lining, and put it into a stainless steel shell, react at 200°C for 8 hours, take it out after cooling to room temperature, and remove the product Use a magnetic field to separate out, and use distilled water and absolute ethanol to wash 3 times respectively, obtain the Ni hierarchical nano core;

[0062] 4. Redisperse the graded nano-Ni obtained in step 3 into deionized water, add 1g of polyvinylpyrrolidone (PVP) for ultrasonication and disperse evenly;

[0063] 5. Use a...

Embodiment 3

[0069] 1. Dissolve 3 mmol of nickel acetate tetrahydrate and 1 g of polyethylene glycol 4000 in 20 mL of ethylene glycol, and stir magnetically at 80 ° C for 20 min until completely dissolved to obtain a clear solution 1;

[0070] 2. Add 0.045mol flaky sodium hydroxide to 10mL ethylene glycol, and stir magnetically at 80°C for 20min until it is completely dissolved to obtain a clear solution 2;

[0071] 3. Fully mix solution 1 and solution 2 and stir evenly, transfer to a 50ml polytetrafluoroethylene reactor lining, and put it into a stainless steel shell, react at 200°C for 8 hours, take it out after cooling to room temperature, and remove the product Use a magnetic field to separate out, and use distilled water and absolute ethanol to wash 3 times respectively, obtain the Ni hierarchical nano core;

[0072] 4. Redisperse the graded nano-Ni obtained in step 3 into deionized water, add 1g of polyvinylpyrrolidone (PVP) for ultrasonication and disperse evenly;

[0073] 5. Use a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com