Flexible quantum dot random laser based on PDMS polymer

A random laser and quantum dot technology, applied in the field of lasers, can solve the problems of high threshold, lack of feedback mechanism, and increased pump light loss, etc., to achieve the effect of lowering the threshold and enhancing the effect of multiple scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

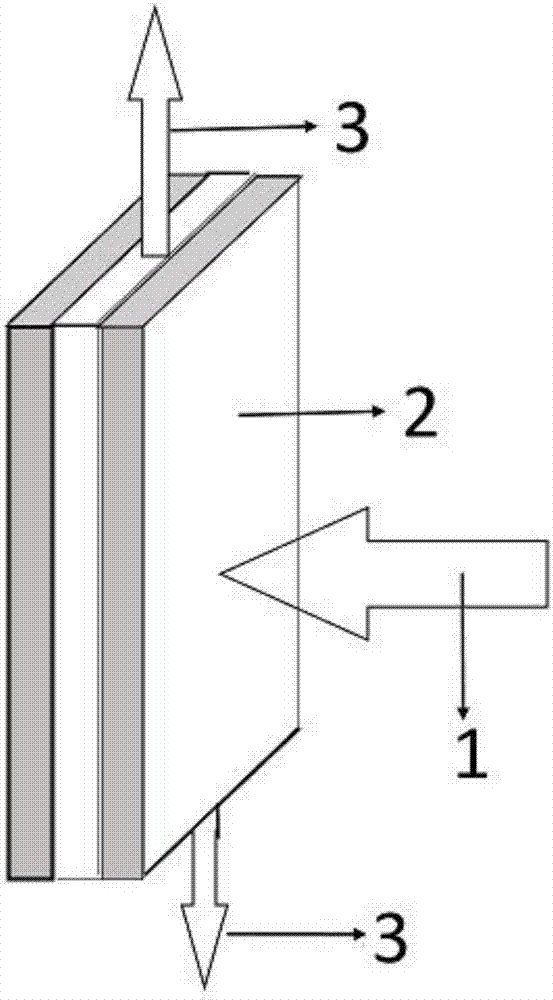

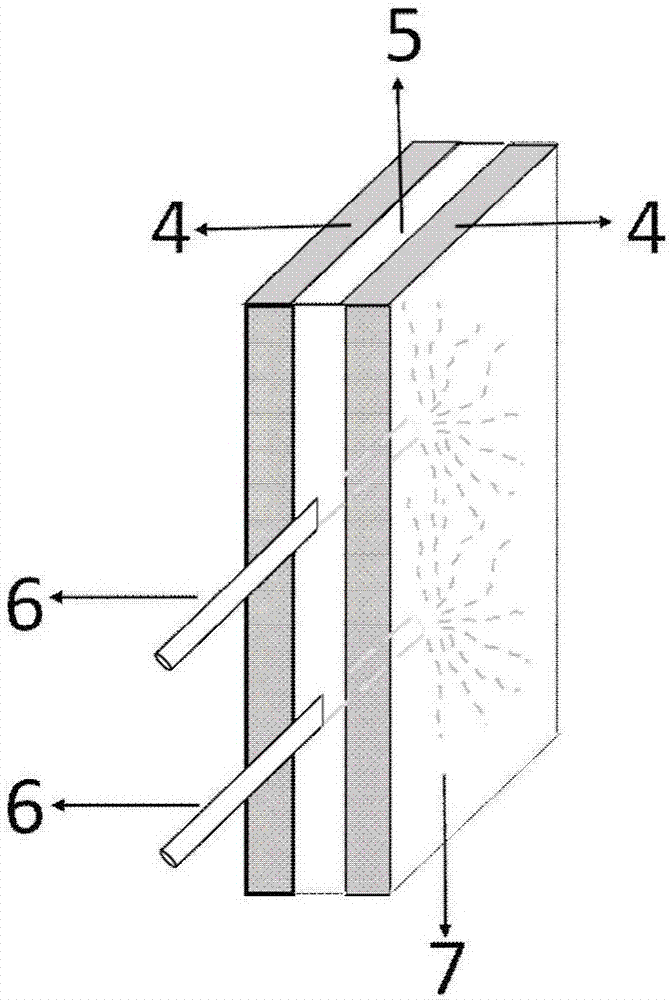

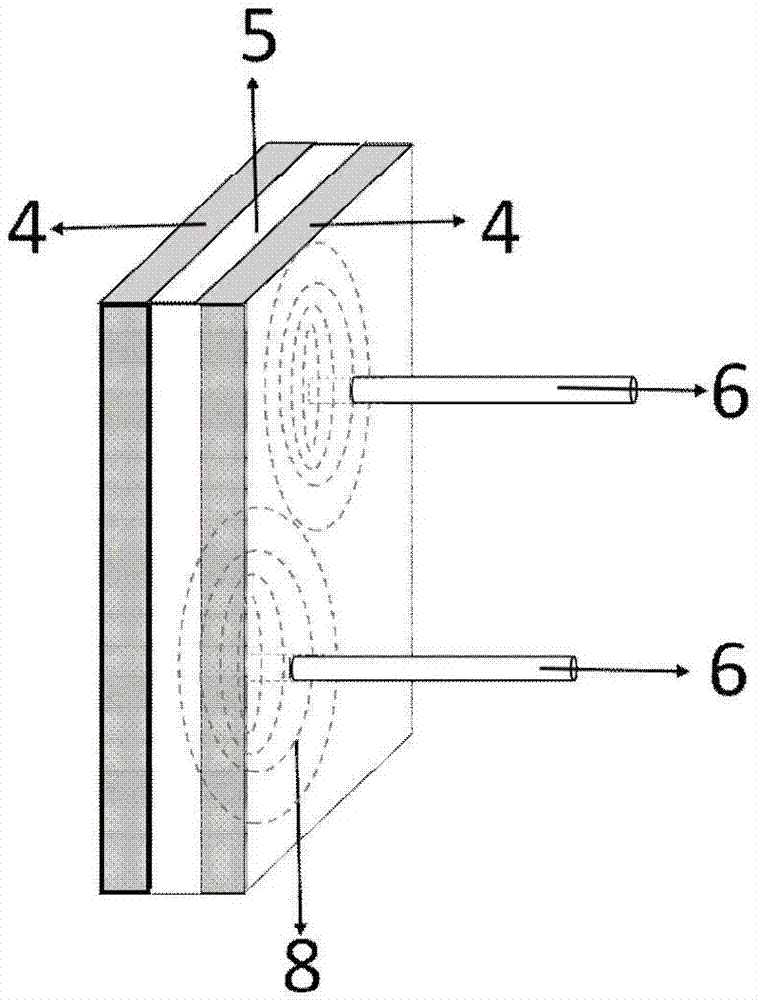

[0019] Such as Figure 1~3 As shown, a random laser based on PDMS polymer flexible quantum dots includes an external pump light 1 and a structural sample 2; the structural sample includes the first and second PDMS thin film layers 4 and between the first and second PDMS thin film layers Sandwiched permeable layer 5. The concentration of the cross-linking agent in the first and second PDMS film layers 4 is 5%, and the concentration of the cross-linking agent in the permeation layer 5 is 2.2%. The permeation layer 5 is a PDMS film layer with uneven internal stress distribution, which is permeated by quantum dots, and the quantum dot material acts as a gain medium in the process of random laser emission. The permeable layer 5 is provided with a number of linear grooves 7 diverging from the center point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com