A kind of magnetic nanochip absorber and preparation method thereof

A magnetic nano-absorbent technology, applied in the field of microwave-absorbing materials, can solve the problems of increasing internal demagnetization field, reducing initial magnetic permeability, and deteriorating wave-absorbing performance of sheet-shaped absorbing composite materials, achieving fewer internal defects and improving microwave absorption. The effect of strong controllability of magnetic permeability and microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

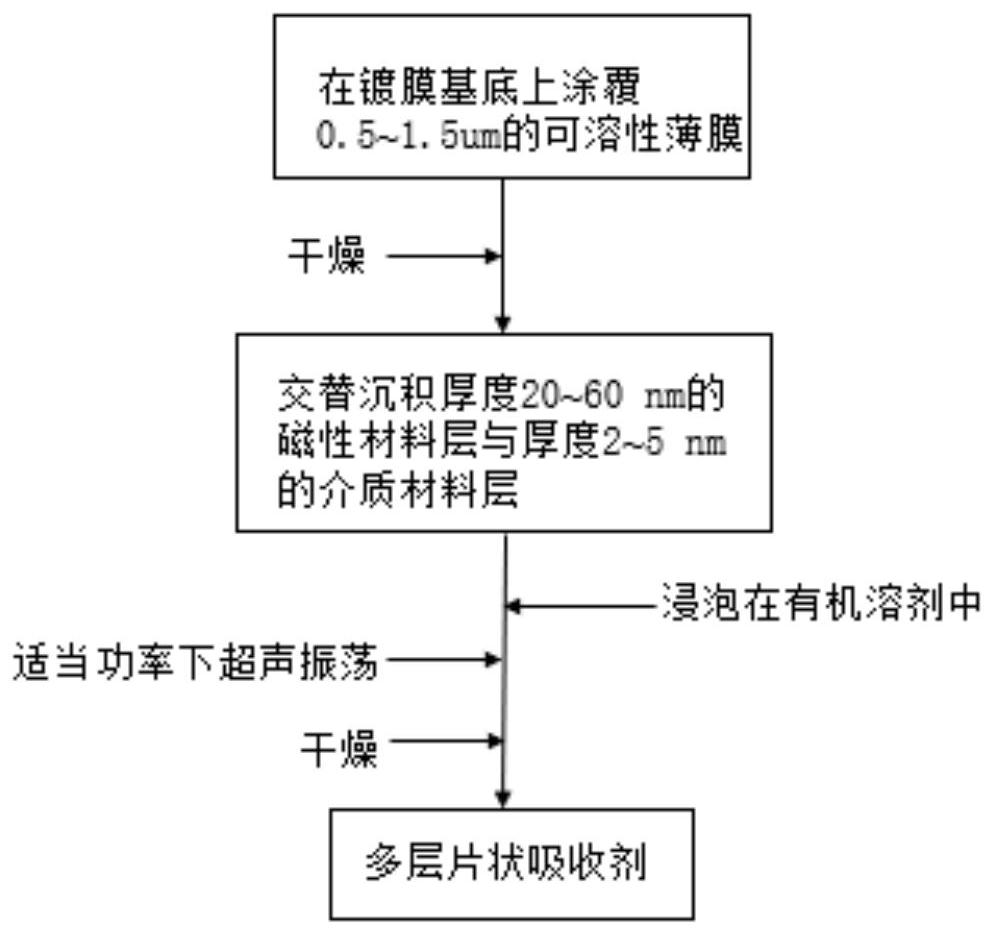

Method used

Image

Examples

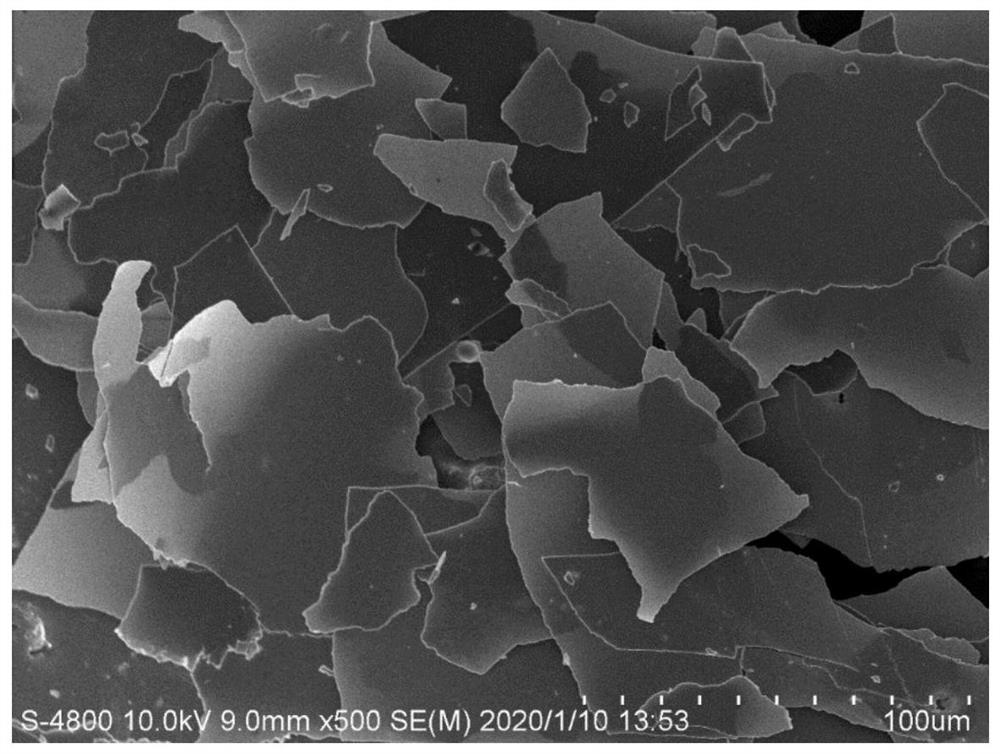

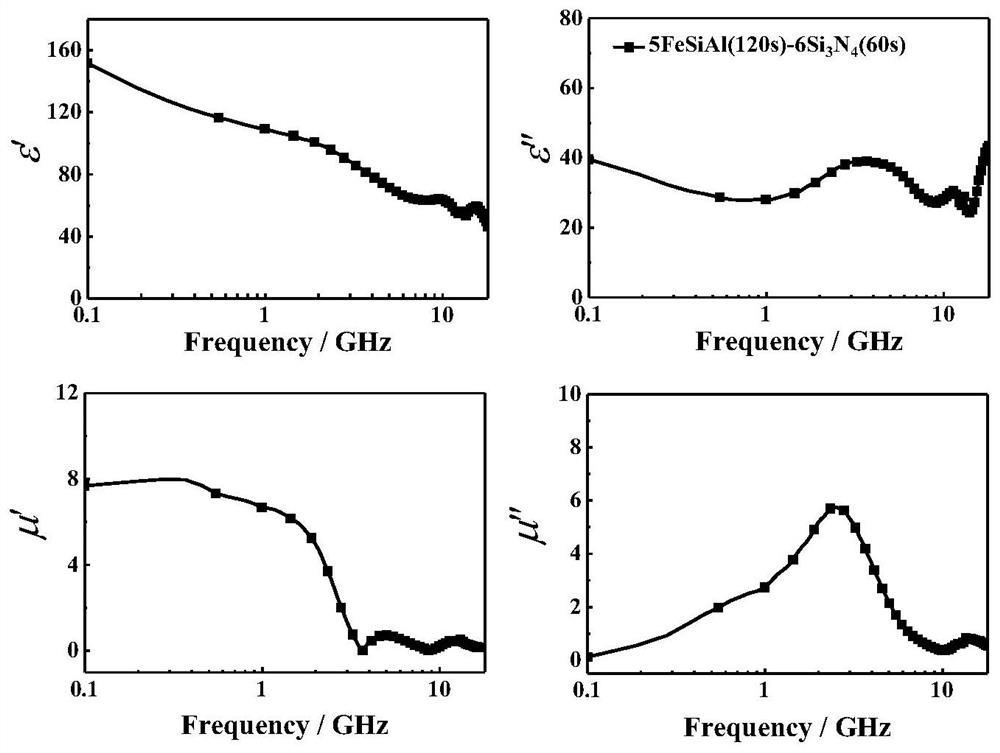

Embodiment 1

[0039] A solution with a mass ratio of PVP to absolute ethanol of 15% was prepared, and the solution was spin-coated on a glass fiber plate by a spin coater, and the thickness of the coating film was controlled to be 1 μm after drying. Magnetron sputtering was used to alternately sputter FeSiAl magnetic material layers and Si on the glass fiber plate coated with PVP film. 3 N 4 Dielectric material layer, a total of 5 magnetic layers sputtered, 6 dielectric layers, the bottom layer and the top layer are Si 3 N 4 . The sputtering current of FeSiAl target is 0.8A, the sputtering time of each layer is 120s, Si 3 N 4 The target adopts radio frequency sputtering, the sputtering power is 250W, and the sputtering time of each layer is 60s. The sputtering pressure is 0.25Pa, the flow rate of argon gas is 40 sccm, and the rotational speed of the sample stage is 20 r / min. After the sputtering is completed, place the obtained film in absolute ethanol, and set the ultrasonic power de...

Embodiment 2

[0042] A solution with a mass ratio of PVP to absolute ethanol of 15% was prepared, and the solution was spin-coated on a glass fiber plate by a spin coater, and the thickness of the coating film was controlled to be 1 μm after drying. Alternately sputtering Fe magnetic material layer and SiO on glass fiber board by magnetron sputtering 2 Dielectric material layer, a total of 6 magnetic layers sputtered, 7 dielectric layers, the bottom layer and the top layer are SiO 2 . The sputtering current of Fe target is 0.8A, the sputtering time of each layer is 60s, SiO 2 The target is radio frequency sputtering, the sputtering power is 150W, the sputtering time for each layer is 60s, the sputtering pressure is 0.25Pa, the flow rate of argon gas is 40sccm, and the rotation speed of the chassis is 20r / min. After the sputtering is completed, the obtained film is placed in absolute ethanol, and the power density is 1500W / cm 2 . After the shaking was completed, the obtained particles we...

Embodiment 3

[0045] A solution with a mass ratio of PVP to absolute ethanol of 15% was prepared, and the solution was spin-coated on a glass fiber plate by a spin coater, and the thickness of the coating film after drying was controlled to be 1.5 μm. Alternately sputtering Fe magnetic material layer and SiO on glass fiber board by magnetron sputtering 2 Dielectric material layer, the bottom layer and the top layer are SiO 2 . The sputtering current of Fe target is 0.8A, the sputtering time of each layer is 60s, SiO 2 The target adopts radio frequency sputtering, the sputtering power is 150W, and the sputtering time of each layer is 60s. A total of 20 magnetic layers and 21 dielectric layers are sputtered. The sputtering pressure is 0.25 Pa, the argon gas flow rate is 40 sccm, and the rotation speed of the chassis is 20 r / min. After the sputtering is completed, the obtained film is placed in absolute ethanol, and the power density is 500W / cm 2 . After the shaking was completed, the obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com