High temperature resistant, microwave transparent aluminum hydroxide/polyethersulfone conveyor belt and manufacturing method thereof

A technology of aluminum hydroxide and polyethersulfone is applied in the field of conveyor belts, which can solve the problems of difficulty in meeting the mechanical strength of conveyor belts, low dielectric constant, inability to withstand instantaneous high temperature, etc., and achieves excellent microwave transmission performance, low dielectric constant, Good toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of polyethersulfone support:

[0038] a. Drying of raw materials: Weigh 200g of polyethersulfone and dry in a plastic hopper dryer for 3 hours at a temperature of 160°C;

[0039] b. Plasticization: Put the dried polyethersulfone into the barrel of the screw injection molding machine to be plasticized to a molten state. is 100Mpa, the secondary pressure is 40Mpa, the injection speed is medium speed, the plasticizing back pressure is 5Mpa, and the screw speed is 40r / min;

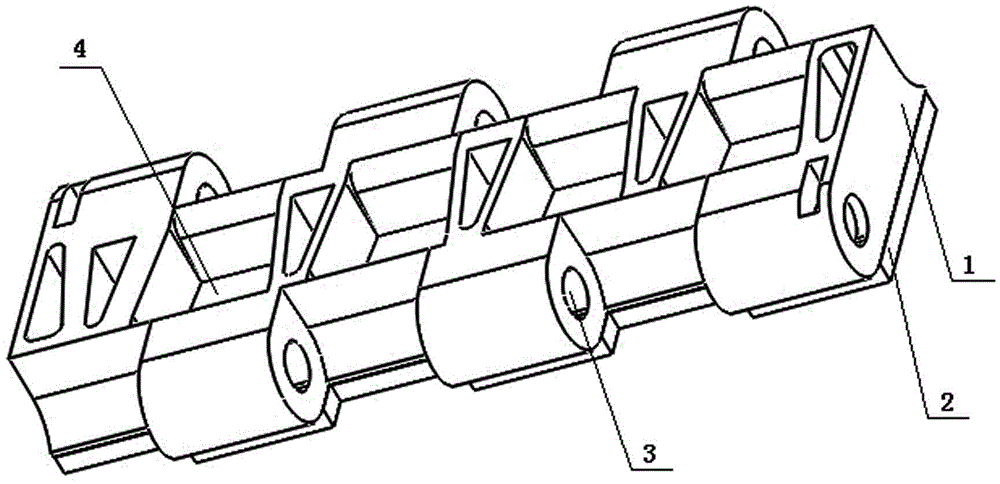

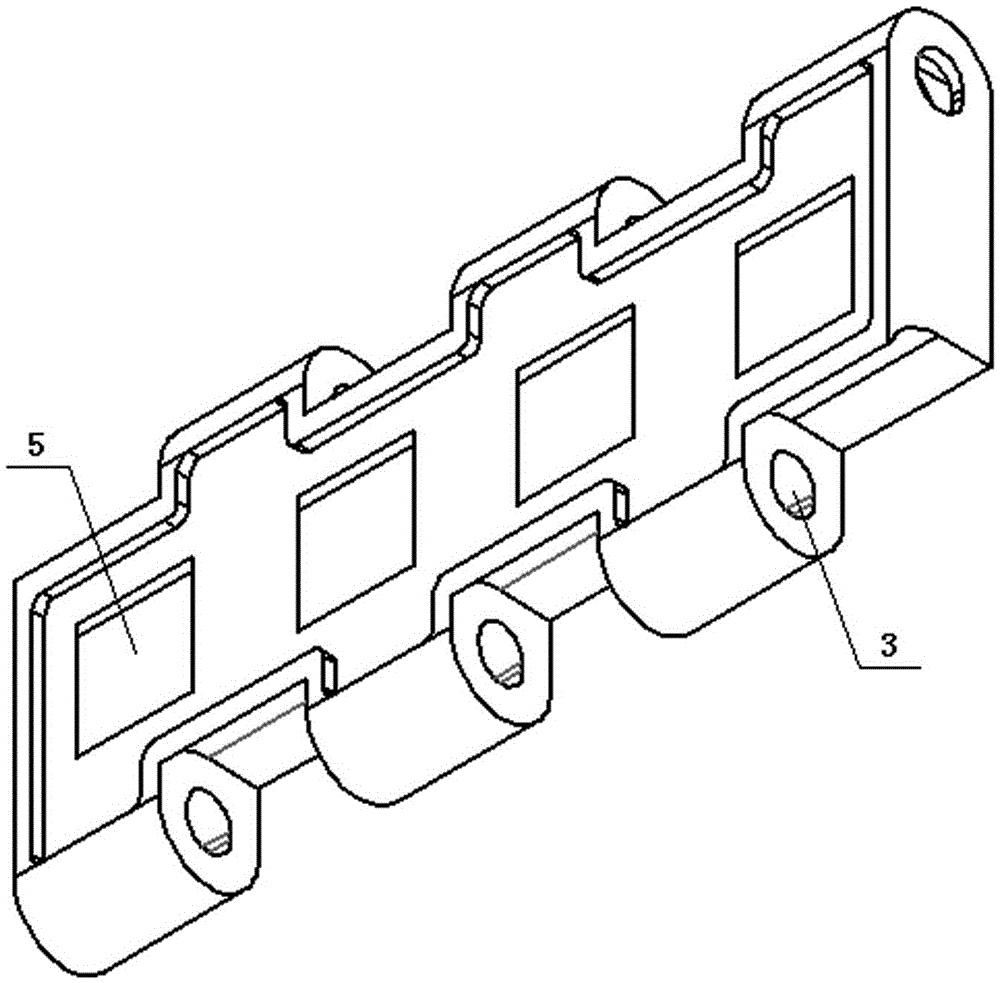

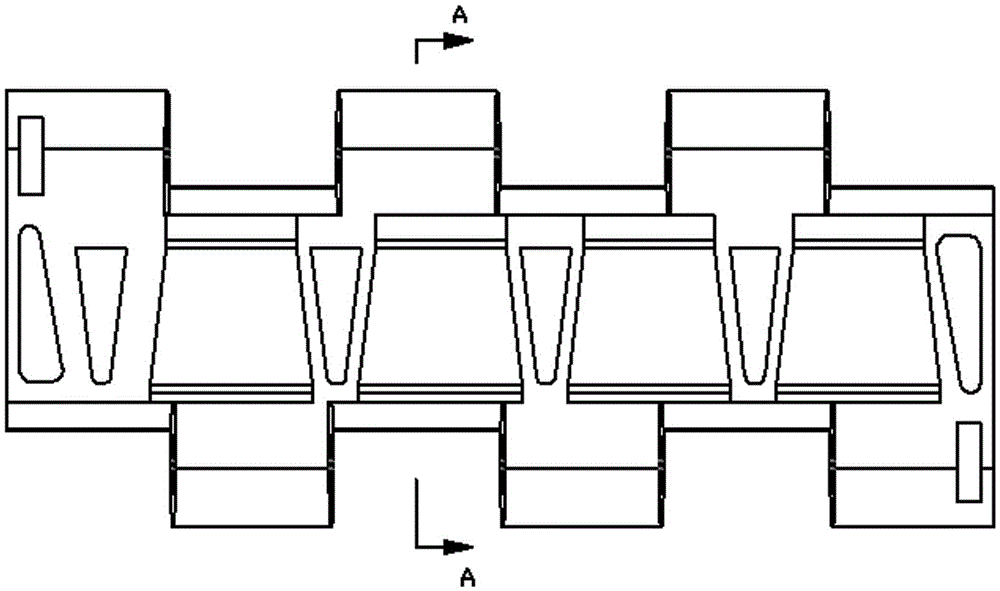

[0040] c. Injection mold filling: the temperature of the mold is 110°C. The polyethersulfone melt plasticized in step b is introduced into the mold, flow-filled and cooled to shape, and the injection mold filling process is completed. Among them, the polyethersulfone support The structure of the body is formed in the mold;

[0041] d. Cooling treatment: take out the polyethersulfone material injected and filled in step c from the closed mold, let it cool down to room temperature naturall...

Embodiment 2

[0051] (1) Preparation of polyethersulfone support:

[0052] a. Drying of raw materials: weigh 200g of polyethersulfone and dry in a plastic hopper dryer for 4 hours at a temperature of 170°C;

[0053] b. Plasticization: Put the dried polyethersulfone into the cylinder of the screw injection molding machine to be plasticized to a molten state. 110Mpa, the secondary pressure is 50Mpa, the injection speed is medium speed, the plasticizing back pressure is 6Mpa, and the screw speed is 50r / min;

[0054] c. Injection mold filling: the temperature of the mold is 120°C. The polyethersulfone melt plasticized in step b is introduced into the mold, flow-filled and cooled to shape, and the injection mold filling process is completed. Among them, the polyethersulfone support The structure of the body is formed in the mold;

[0055] d. Cooling treatment: take out the polyethersulfone material injected and filled in step c from the closed mold, let it cool down to room temperature natural...

Embodiment 3

[0065] (1) Preparation of polyethersulfone support:

[0066] a. Drying of raw materials: weigh 200g of polyethersulfone and dry in a plastic hopper dryer for 4 hours at a temperature of 170°C;

[0067] b. Plasticization: Put the dried polyethersulfone into the barrel of the screw injection molding machine to be plasticized to a molten state. is 130Mpa, the secondary pressure is 50Mpa, the injection speed is high speed, the plasticizing back pressure is 8Mpa, and the screw speed is 50r / min;

[0068] c. Injection mold filling: the temperature of the mold is 140°C. The polyethersulfone melt plasticized in step b is introduced into the mold, flow-filled and cooled to shape, and the injection mold filling process is completed. Among them, the polyethersulfone support The structure of the body is formed in the mold;

[0069] d. Cooling treatment: take out the polyethersulfone material injected and filled in step c from the closed mold, let it cool down to room temperature naturall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com