Method for preparing magnetic spinel ferrite hollow ball in one-step method

A spinel ferrite, hollow sphere technology, applied in the fields of inorganic material magnetism, nanostructure manufacturing, nanotechnology, etc., can solve problems such as affecting production efficiency, cumbersome steps, consumption of production raw materials, etc., and achieves uniform size distribution and operation. Simple, high saturation magnetization and coercivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 20mmol of ferric chloride and 10mmol of cobalt dichloride and mix them into 100ml of ethylene glycol, then add 8g of urea and 0.1g of polyvinylpyrrolidone, stir to form a brown transparent mixed solution; The solution is placed in a high-pressure stainless steel reaction kettle lined with polytetrafluoroethylene, the filling degree is 80%, the sealing bolt is tightened, and the reaction is carried out at 180°C for 20 hours. The product is separated by washing with deionized water and absolute ethanol with a magnet. Dry at 60°C for 4 hours to obtain magnetic CoFe 2 o 4 hollow ball.

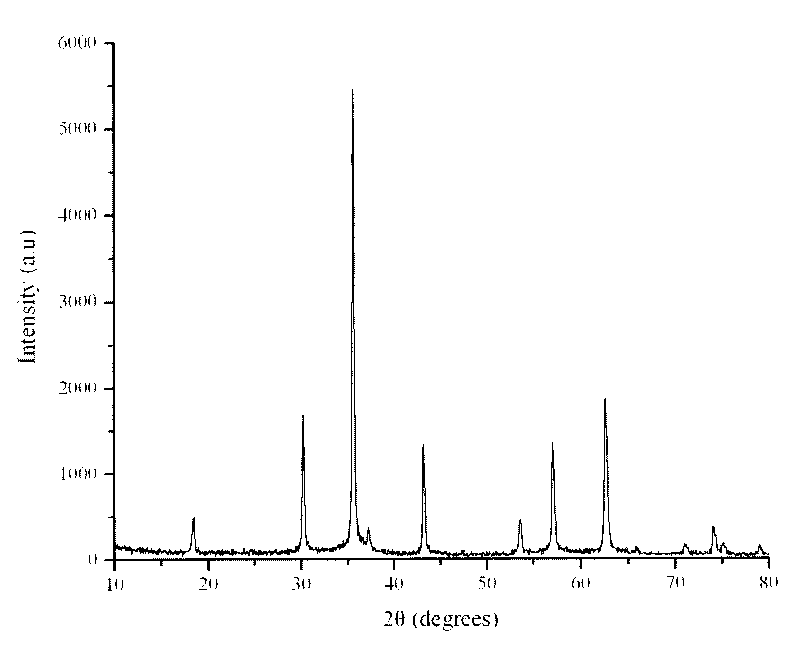

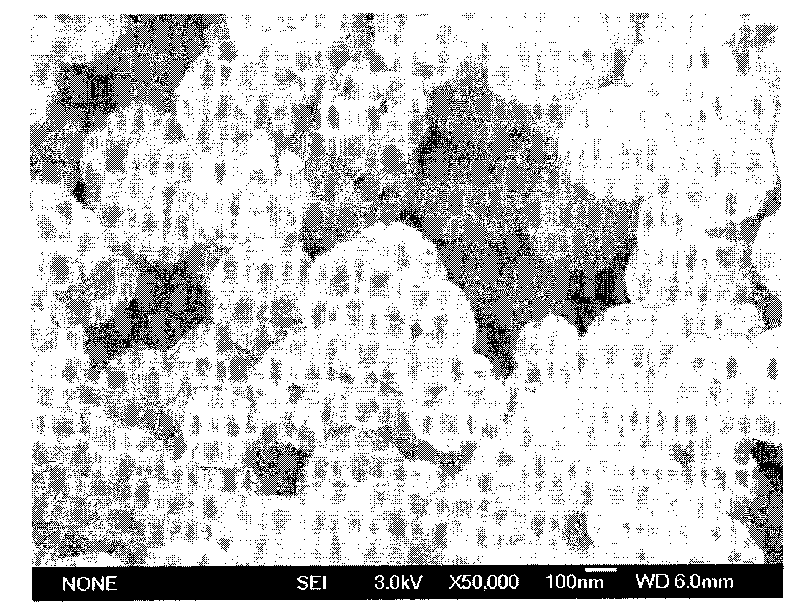

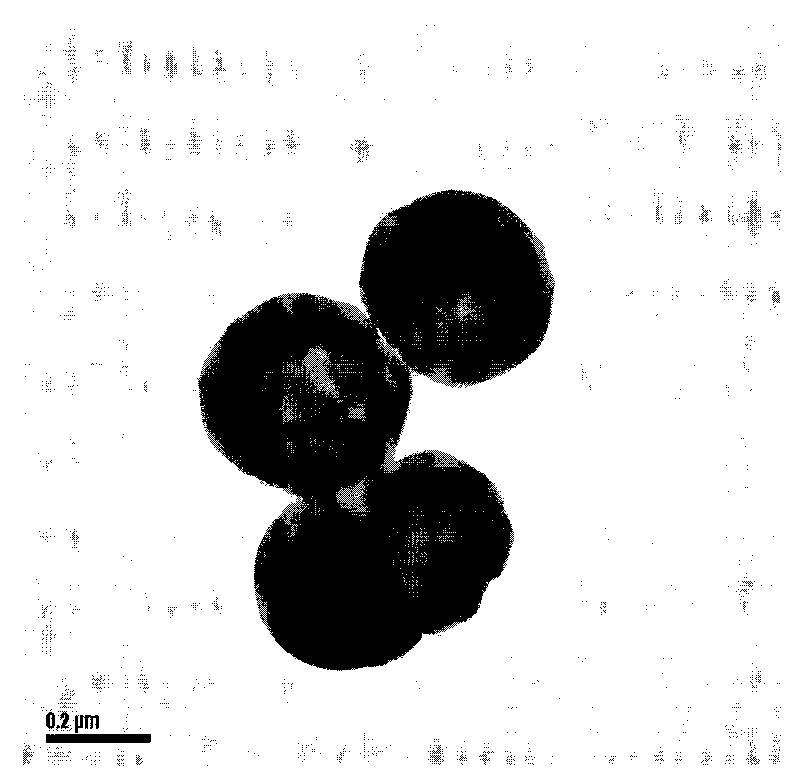

[0027] The purity of the obtained sample is very high, and its XRD diffraction peak is the same as that of standard CoFe 2 o 4 The spectrum (JCPDS 22-1086) corresponds completely, without any impurity peaks. The size of the hollow sphere is about 350nm, the wall thickness of the hollow sphere is about 80nm, the typical saturation magnetization of the product is 75emu / g, the residua...

Embodiment 2

[0029] Experimental method is the same as embodiment 1, just changes cobalt dichloride into nickel sulfate, promptly obtains magnetic NiFe 2 o 4 Hollow sphere, the average particle size is about 300nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com