Preparation method of spinel ferrite hollow sphere with core-shell structure

A technology of shell structure and spinel, which is applied in the field of preparation of spinel ferrite hollow spheres, can solve the problems of difficult surface modification, difficulty of hollow spheres, layer-by-layer coating, etc., and achieves convenient operation and simple preparation process , The effect of low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

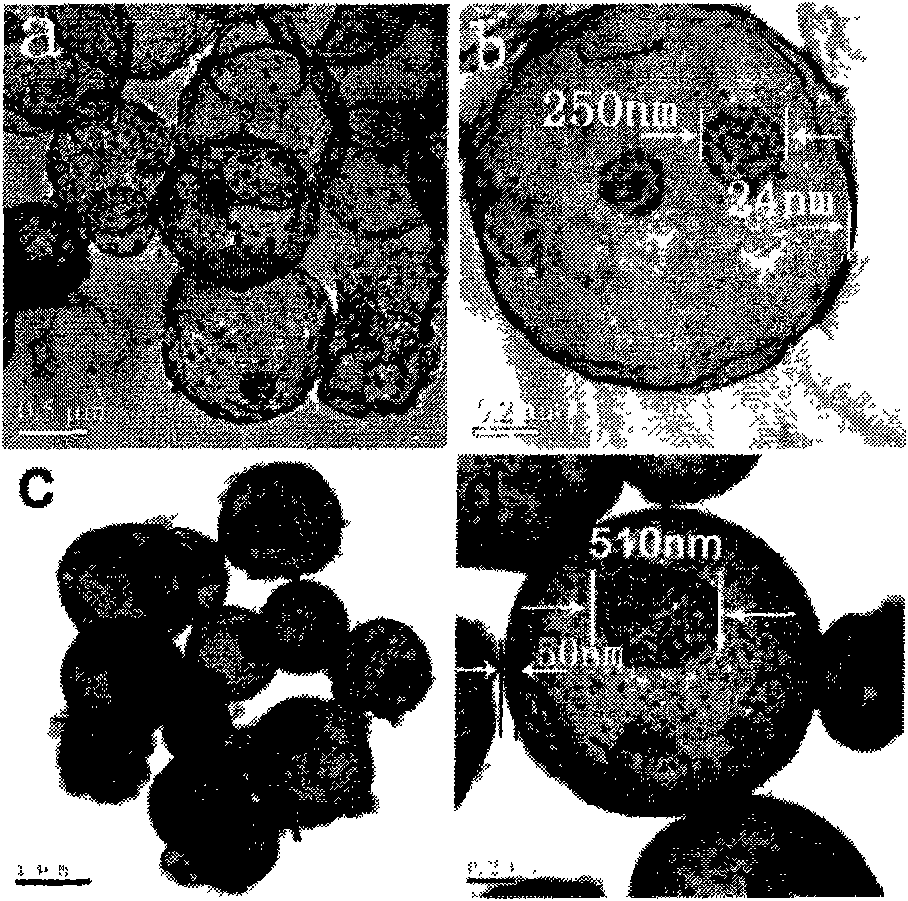

[0016] In a specific embodiment of the present invention, the preparation method of the spinel ferrite hollow sphere of the core-shell structure of the present invention comprises:

[0017] 1) Preparation of carbon spheres: according to the concentration of 2.5-10.3 grams of sucrose / 10ml of water, dissolve sucrose in water, then conduct hydrothermal treatment in an autoclave at 180°C-210°C for 70-150 minutes; filter out the solid product after natural cooling - carbon spheres, washed with deionized water, and then dispersed in deionized water to form a suspension of carbon spheres-water, wherein the weight ratio of carbon spheres / water is 1 / 100-1 / 10;

[0018] 2) Impregnation: Sonicate the carbon spheres obtained in step 1) in a mixed salt solution of divalent metal salt (M) and ferric salt (F) for 10-30 minutes, then soak for 4-20 hours under stirring, and filter Post-washing, drying at 100°C for 12 hours to obtain a powdery material;

[0019] Described divalent metal salt is...

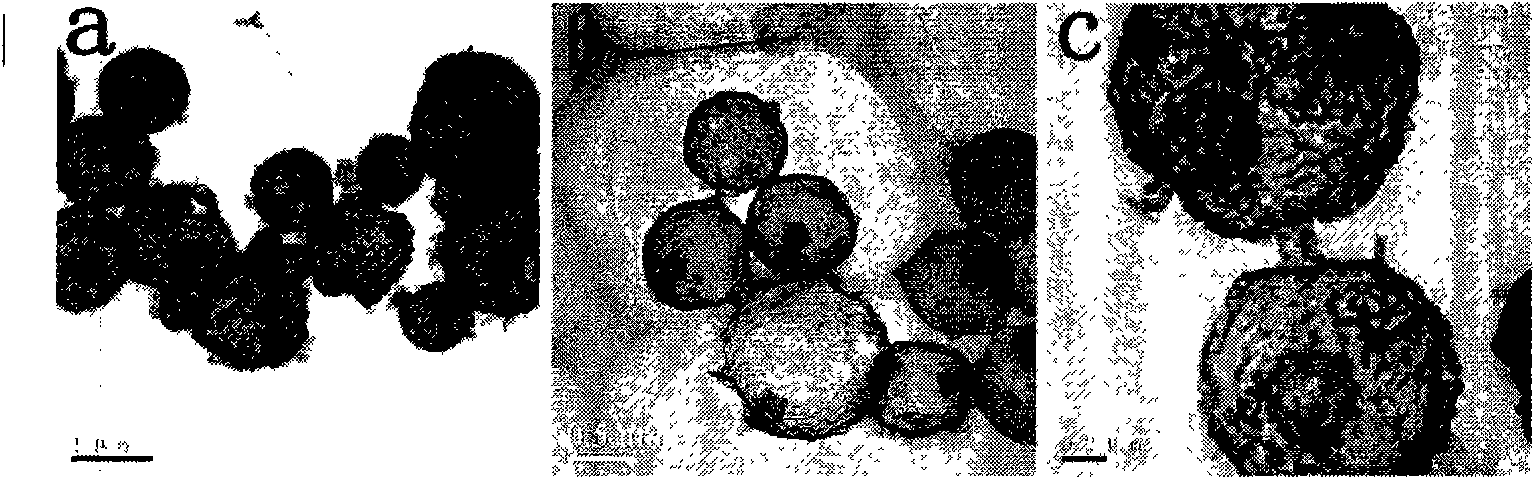

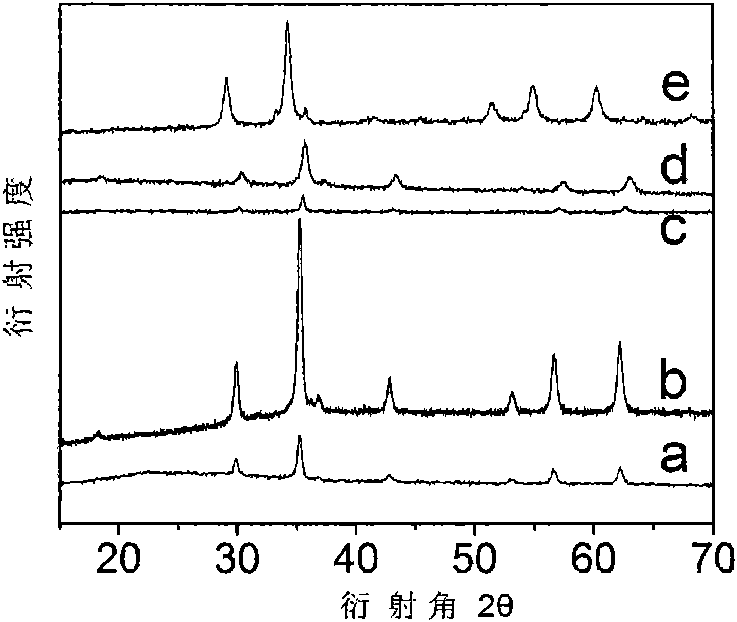

Embodiment 1

[0026] Firstly, the carbon sphere template was prepared with sucrose by hydrothermal method: 5.134 grams of sucrose was dissolved in 10ml of water to form a uniform transparent solution. After washing with ion water for 3 times and drying at 100°C, carbon spheres with a diameter of 3.2 μm can be obtained. Then about 0.4 g of the obtained carbon spheres was put into 10 ml of deionized water, and ultrasonicated for 5 minutes to obtain a carbon sphere-water suspension.

[0027] Impregnation: 5.95 g of Zn(NO 3 ) 2 ·6H 2 O and 16.16 g Fe(NO 3 ) 3 9H 2 O is dissolved in 10ml of water (that is, the concentration of zinc nitrate is 1.07M, the concentration of ferric nitrate is 2.14M, and the molar ratio of the two is 1:2) to form a uniform salt solution; the carbon sphere-water suspension and the metal salt The solution was stirred and mixed for 3-5 minutes, then sonicated for 15 minutes, and then stirred for an additional 5 hours. The suspension was filtered and washed, and th...

Embodiment 2

[0032] Firstly, the carbon sphere template was prepared with sucrose by hydrothermal method: 5.134 grams of sucrose was dissolved in 10ml of water to form a uniform transparent solution. After washing with ion water for 3 times and drying at 100°C, carbon spheres with a diameter of 3.2 μm can be obtained. Then about 0.4 g of the obtained carbon spheres was put into 10 ml of deionized water, and ultrasonicated for 5 minutes to obtain a carbon sphere-water suspension.

[0033] Impregnation: 8.94 g of Zn(NO 3 ) 2 ·6H 2 O and 24.24 g Fe(NO 3 ) 3 9H 2 O is dissolved in 10ml of water (that is, the concentration of zinc nitrate is 1.3M, the concentration of ferric nitrate is 2.6M, and the molar ratio of the two is 1:2) to form a uniform salt solution; carbon sphere-water suspension and metal salt solution Stir to mix for 3-5 minutes, then sonicate for 15 minutes, then continue stirring for 5 hours. The suspension was filtered and washed, and then dried at 100° C. for 12 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com