Rare-earth doped spinel ferrite/aluminum-doped zinc oxide composite fiber and preparation method thereof

A technology of spinel ferrite and aluminum-doped zinc oxide, which is applied in the direction of inorganic raw material rayon, etc., can solve the problems such as no public report of rare earth-doped spinel ferrite/ZAO composite fiber, and achieve the process of Controllable parameters and microstructure, less pollution and high preparation purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

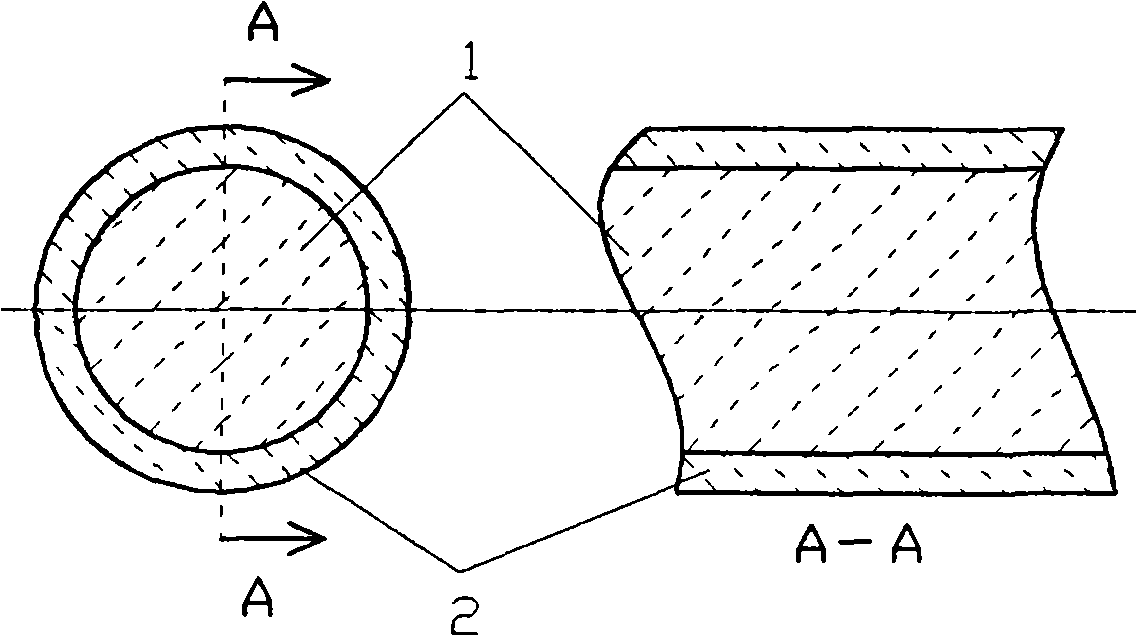

Image

Examples

Embodiment 1

[0026] (1) Preparation of the gel precursor: first dissolve basic nickel carbonate, cobalt nitrate, iron nitrate, samarium oxide, and citric acid in deionized water, Ni 2+ :Co 2+ :Fe 3+ :Sm: The molar ratio of organic acid is 0.6:0.4:1.9:0.1:8, stir evenly, stir at room temperature for 15-20 hours, and form a gel precursor after dehydration under reduced pressure;

[0027] (2) The organogel precursor is spun into gel cellulose filaments by spinning, spinning or spinning, and the cellulose filaments are kept in the temperature range of 700-800 °C, and then naturally cooled to room temperature after 5-6 hours of heat preservation. Rare earth doped spinel ferrite Ni 0.6 co 0.4 Fe 1.9 SM 0.1 o 4 The fiber is the core of the composite fiber;

[0028] (3) Put zinc acetate dihydrate and aluminum trichloride hexahydrate into the mixed solvent of ethanolamine and glycol methyl ether, wherein the molar ratio of Al:Zn:solvent is 1:0.1:12, and keep warm at 30°C for 2 After dissolv...

Embodiment 2

[0032] (1) Preparation of gel precursor: first, nickel acetate, cobalt acetate, iron nitrate, samarium oxide and lactic acid were dissolved in deionized water, and Ni 2+ :Co 2+ :Fe 3+ :Sm: The molar ratio of organic acid is 0.7:0.3:1.8:0.2:7, stir evenly, stir at room temperature for 12-15 hours, and form a gel precursor after dehydration under reduced pressure;

[0033] (2) The organogel precursor is spun into gel cellulose filaments by spinning, spinning or spinning. The cellulose filaments are kept in the temperature range of 600-700 ° C, and naturally cooled to room temperature after 7 hours of heat preservation to obtain rare earth Doped spinel ferrite Ni 0.7 co 0.3 Fe 1.8 SM 0.2 o 4 The fiber is the core of the composite fiber;

[0034] (3) Put zinc acetate dihydrate and aluminum trichloride hexahydrate into the mixed solvent of ethanolamine and glycol methyl ether, the molar ratio of Al:Zn:organic solvent is 1:0.2:13, and keep warm at 40°C for 2 hours After diss...

Embodiment 3

[0038] The rare earth element was replaced by Ce, and the others were the same as in Example 1. The obtained composite fiber had a core diameter of 8-12 μm, a length of 400 μm-1 m, and a coating thickness of 80-90 nm. The composite fiber has an attenuation of about 8dB in the 1-30GHz band, and a bending strength of 1300-1700kg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com