Spinel type ferrite magnetic hollow microsphere and preparation thereof

A technology of spinel ferrite and microspheres is applied in the field of intercalation structure magnetic materials, which can solve the problems of less involvement of hollow magnetic materials and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

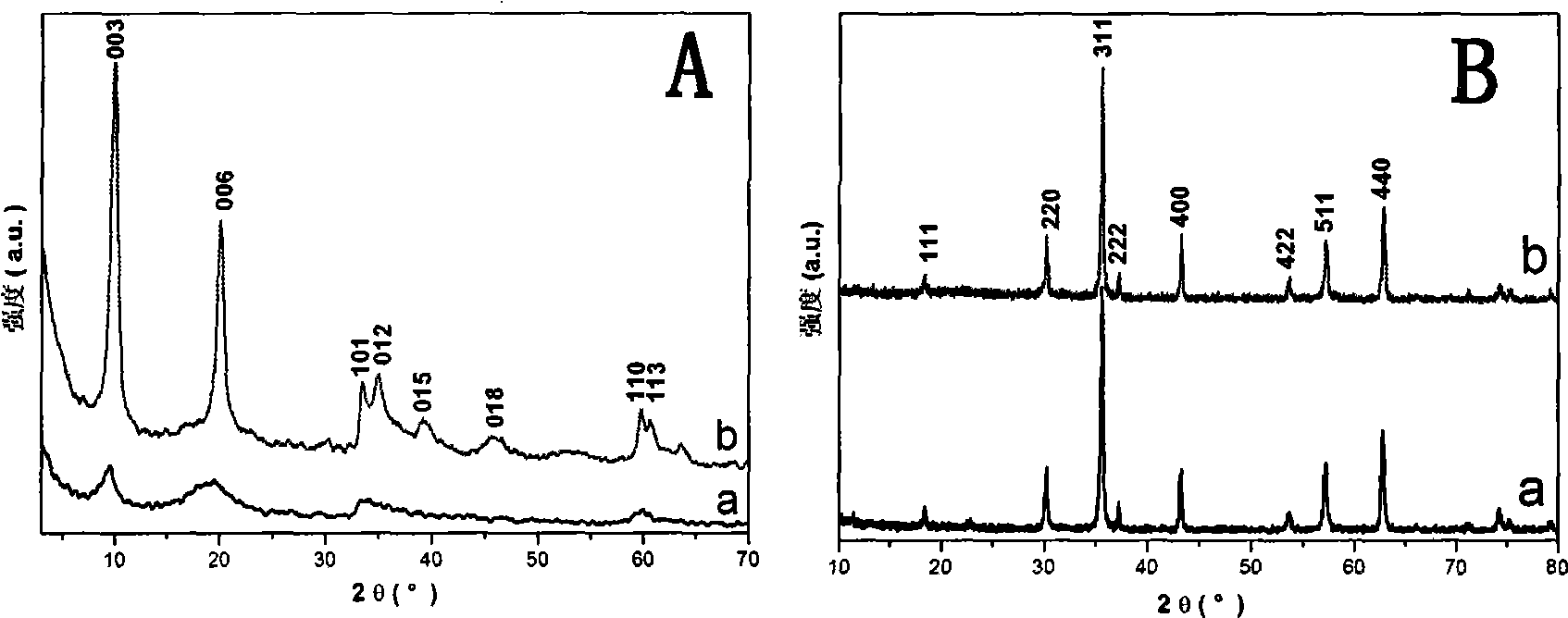

Method used

Image

Examples

Embodiment 1

[0040] A: Weigh 1.441g Co(NO 3 ) 2 ·6H 2 O, 0.688g FeSO 4 ·7H 2 O and 0.989g Fe 2 (SO 4 ) 3 ·xH 2 O dissolved in deionized water to make 100mL mixed salt solution, put the solution into a four-neck flask, blow nitrogen gas and stir to dissolve the salt; then weigh 6g NaOH and dissolve it in deionized water to make 100mL mixed alkali solution; weigh The moisture content is 4.0 g of sulfonated polystyrene dissolved in deionized water to make a 50 ml suspension.

[0041] B: Pour the sulfonated polystyrene suspension prepared in step A into the salt solution, and stir to make it evenly mixed;

[0042] C: Titrate the alkali solution prepared in step A to the mixed solution in step B, so that the pH of the solution is 7.0, and then crystallize at room temperature for 4 hours;

[0043] D: Put the colloidal slurry in step C into ice water at 0°C to cool, then wash three times with ice water passed through nitrogen, and finally wash twice with ethanol at 0°C, seal with ice eth...

Embodiment 2

[0046] A: Weigh 0.721.g Co(NO 3 ) 2 ·6H 2 O, 0.344g FeSO 4 ·7H 2 O and 0.495g Fe 2 (SO 4 ) 3 ·xH 2 O was dissolved in deionized water to make 100mL mixed salt solution, put the solution into a four-neck flask, blow nitrogen gas and stir to dissolve the salt; then weigh 4g NaOH and dissolve it in deionized water to make 100mL mixed alkali solution; weigh The moisture content is 7.0 g of sulfonated polystyrene dissolved in deionized water to make a 50 ml suspension.

[0047] B: Pour the sulfonated polystyrene suspension prepared in step A into the salt solution, and stir to make it evenly mixed;

[0048] C: Titrate the alkali solution prepared in step A to the mixed solution in step B to make the pH of the solution 7.0, and then crystallize in a 40°C water bath for 0.5h;

[0049] D: Put the colloidal slurry in step C into ice water at 0°C to cool, and then wash the three-stone ferrite with ice water passed through nitrogen.

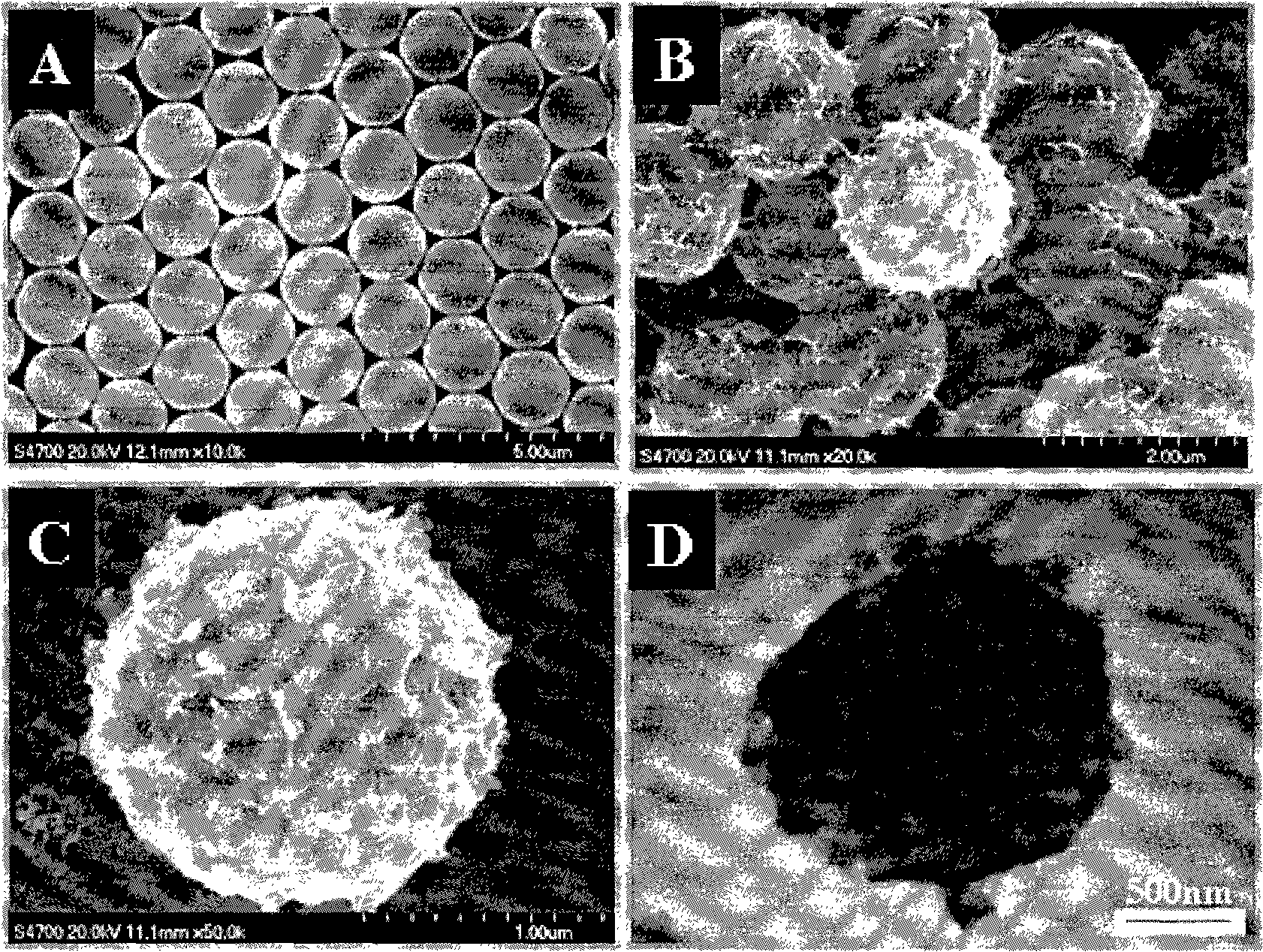

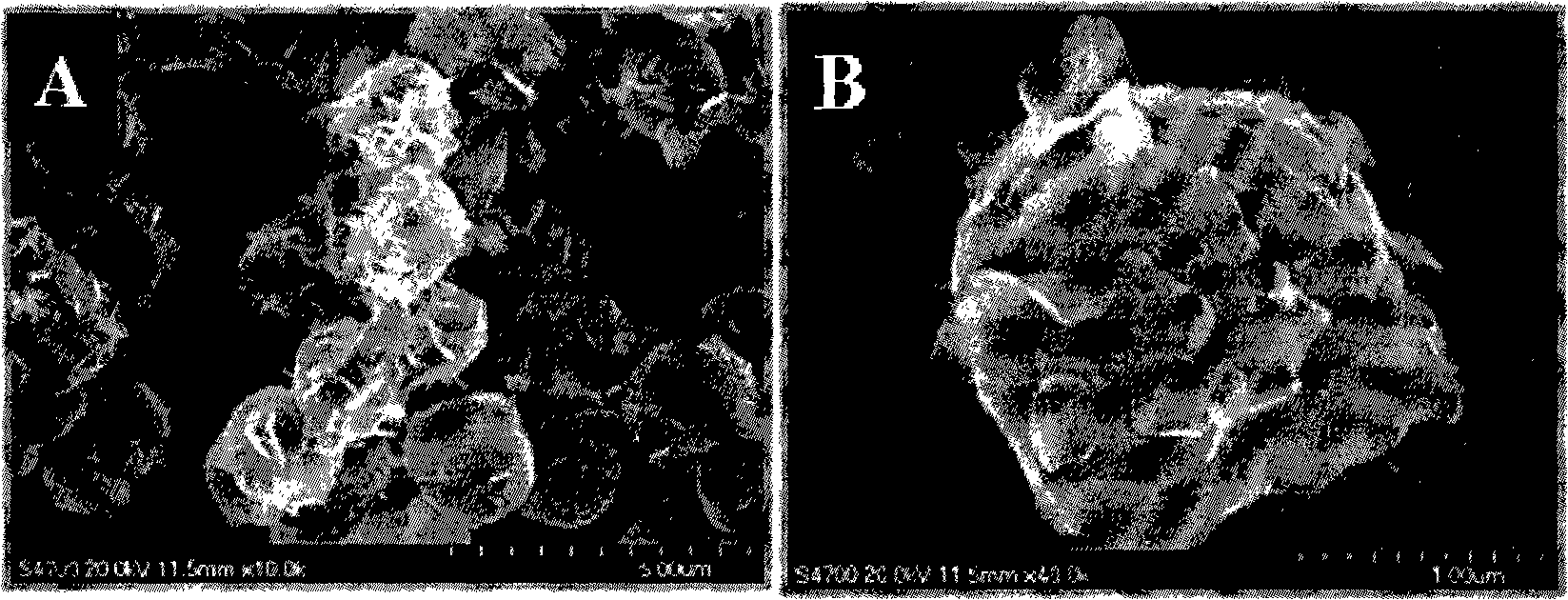

[0050] Hitachi-S4700N SEM was used to analy...

Embodiment 3

[0059] A: Weigh 0.721.g Co(NO 3 ) 2 ·6H 2 O, 0.344g FeSO 4 ·7H 2 O and 0.495g Fe 2 (SO4 ) 3 ·xH 2 O was dissolved in deionized water to make 100mL mixed salt solution, put the solution into a four-neck flask, blow nitrogen gas and stir to dissolve the salt; then weigh 4g NaOH and dissolve it in deionized water to make 100mL mixed alkali solution; weigh The moisture content is 7.0 g of sulfonated polystyrene dissolved in deionized water to make a 50 ml suspension.

[0060] B: Pour the sulfonated polystyrene suspension prepared in step A into the salt solution, and stir to make it evenly mixed;

[0061] C: Titrate the alkaline solution prepared in step A to the mixed solution in step B to make the pH of the solution 7.0, and then crystallize in a water bath at 40°C for 1.5h;

[0062] D: Put the colloidal slurry in step C into ice water at 0°C to cool, then wash three times with ice water passed through nitrogen, and finally wash twice with ethanol at 0°C, seal with ice e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com