Method for preparing quantum point with hyperbranched polymer supermolecule nano-reactor

A technology of hyperbranched polymers and nanoreactors, applied in chemical instruments and methods, luminescent materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Add 197 mg of palmitic acid to a 100 ml reaction bottle, add 40 ml of chloroform to dissolve it, then add 117 mg of hyperbranched amidoamine polymer, and stir for 12 hours at room temperature.

[0021] The second step: add 8 mg of Cd(AC) to the chloroform solution obtained above 2 5 ml of aqueous solution, sealed with a glass stopper, and stirred at room temperature for 48 hours.

[0022] Step 3: Store in a separatory funnel, and separate the chloroform solution in the lower layer into a reaction bottle. Nitrogen for 10-15 minutes, then add 2 ml, the concentration is 0.39mg / ml, and the Na after deoxygenation 2 Put the aqueous solution of S into the reaction bottle, continue to pass nitrogen gas for 10 minutes, and continue stirring at normal temperature for about 1 hour. Static separation can give clear light yellow CdS chloroform solution.

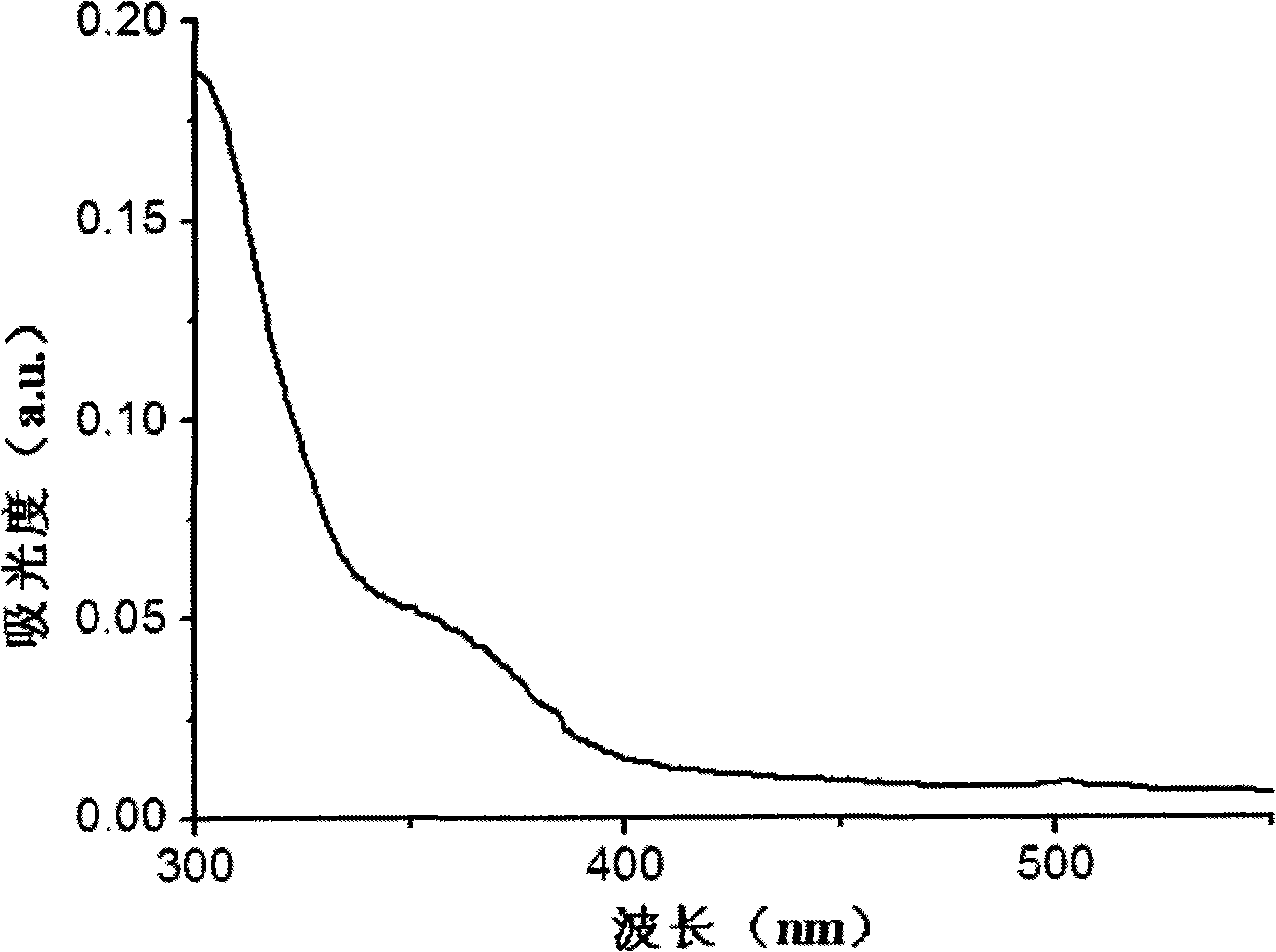

[0023] Such as figure 1 As shown, the ultraviolet-visible spectrum of the CdS quantum dots prepared in this example s...

Embodiment 2

[0025] Step 1: Add 235 mg of palmitic acid to a 100 ml reaction bottle, then add 40 ml of chloroform to dissolve it, then add 120 mg of hyperbranched polyethyleneimine, and stir for 12 hours at room temperature.

[0026] The second step: add 8 mg of Cd(ClO) to the chloroform solution obtained above 4 ) 2 5 ml of aqueous solution, sealed with a glass stopper, and stirred at room temperature for 48 hours.

[0027] Step 3: Store in a separatory funnel, and separate the chloroform solution in the lower layer into a reaction bottle. Nitrogen gas for 10-15 minutes, then add 2 ml, the concentration is 0.98 mg / ml, and the Na after deoxygenation 2 Put the aqueous solution of S into the reaction bottle, continue to pass nitrogen gas for 10 minutes, and continue stirring at normal temperature for about 1 hour. Static separation can give clear light yellow CdS chloroform solution.

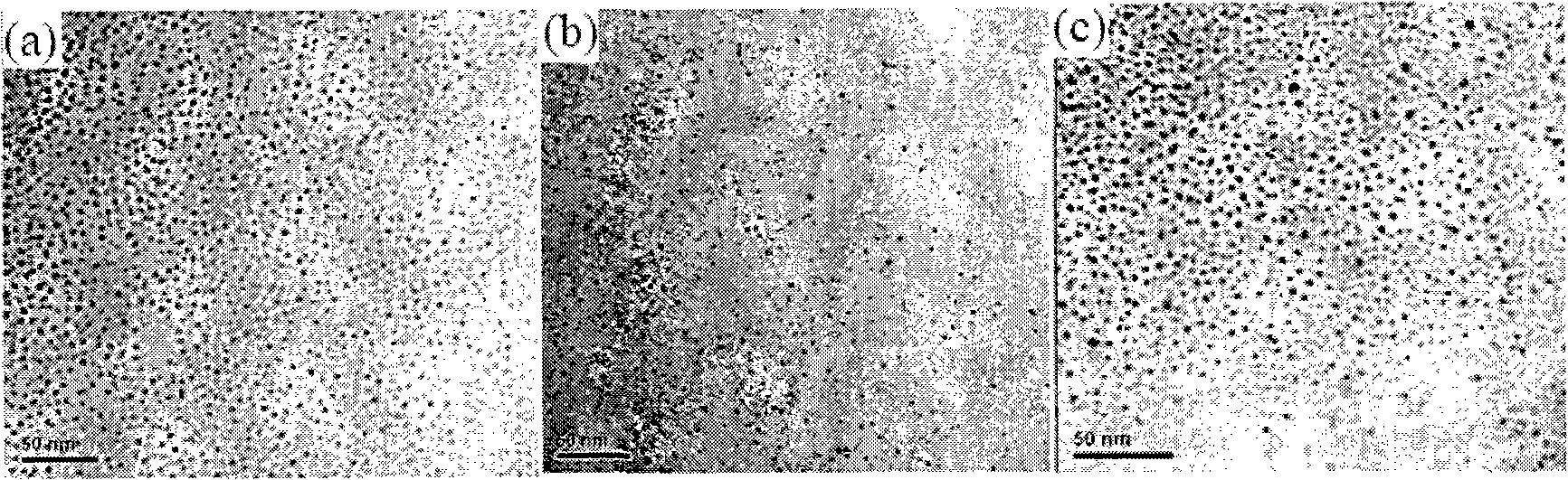

[0028] The transmission electron microscope image of the prepared CdS quantum dots is as follows figu...

Embodiment 3

[0030] Step 1: Add 142 mg of palmitic acid to a 100 ml reaction bottle, then add 40 ml of chloroform to dissolve it, then add 124 mg of hyperbranched sulfone-amine polymer, and stir at room temperature for 12 hours.

[0031] The second step: add 8 mg of Cd(NO) to the chloroform solution obtained above 3 ) 2 5 ml of aqueous solution, sealed with a glass stopper, and stirred at room temperature for 48 hours.

[0032] Step 3: Store in a separatory funnel, and separate the chloroform solution in the lower layer into a reaction bottle. Nitrogen for 10-15 minutes, then add 2 ml, the concentration is 1.17 mg / ml, and the Na after deoxygenation 2 Put the aqueous solution of S into the reaction bottle, continue to pass nitrogen gas for 10 minutes, and continue stirring at normal temperature for about 1 hour. The light yellow chloroform solution of CdS quantum dots can be obtained by static separation.

[0033] The properties of the product obtained in this example were tested by ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com