Method for preparing rare earth aromatic carboxylic acids mesoporous red light material

An aromatic carboxylic acid and luminescent material technology, which is applied in luminescent materials, chemical instruments and methods, and optical devices to transmit sensing components, etc., to achieve the effects of regular and orderly microscopic morphology and simple and easy preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

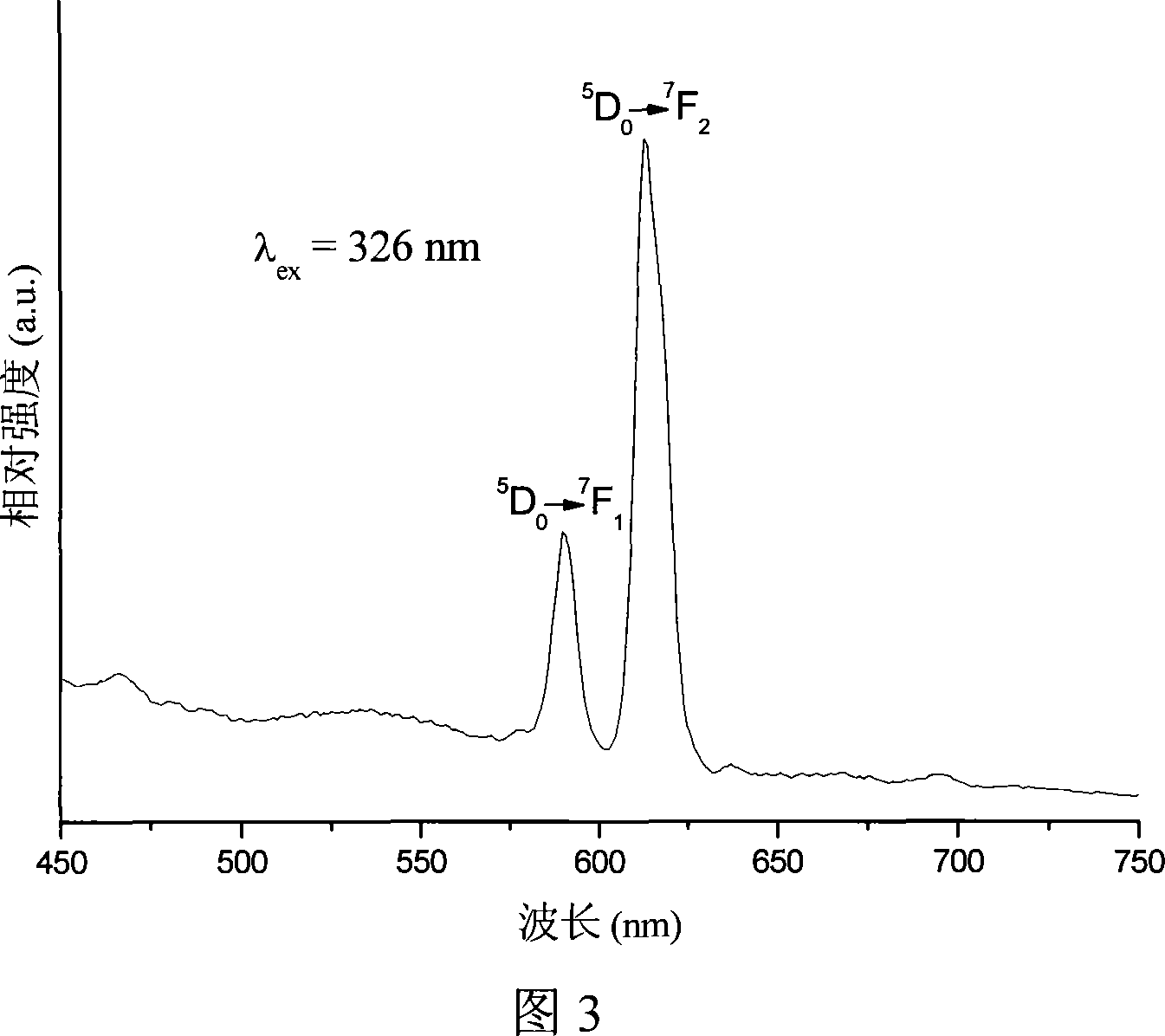

[0026] (1) Synthesis of europium-o-phenylacetic acid-o-phenanthroline complex

[0027] Add 0.20mmol Eu(NO 3 ) 3 ·6H 2 O, 0.30mmol o-formic acid phenylacetic acid and 0.20mmol o-phenanthroline, after stirring at room temperature for half an hour, pour it into a 15mL polytetrafluoroethylene-lined stainless steel reactor, and crystallize at 110°C for 72 hours, slowly Cool to room temperature. The obtained product was suction-filtered and washed several times with deionized water and absolute ethanol to obtain a white europium-o-formic acid phenylacetic acid-o-phenanthroline complex polycrystalline powder sample.

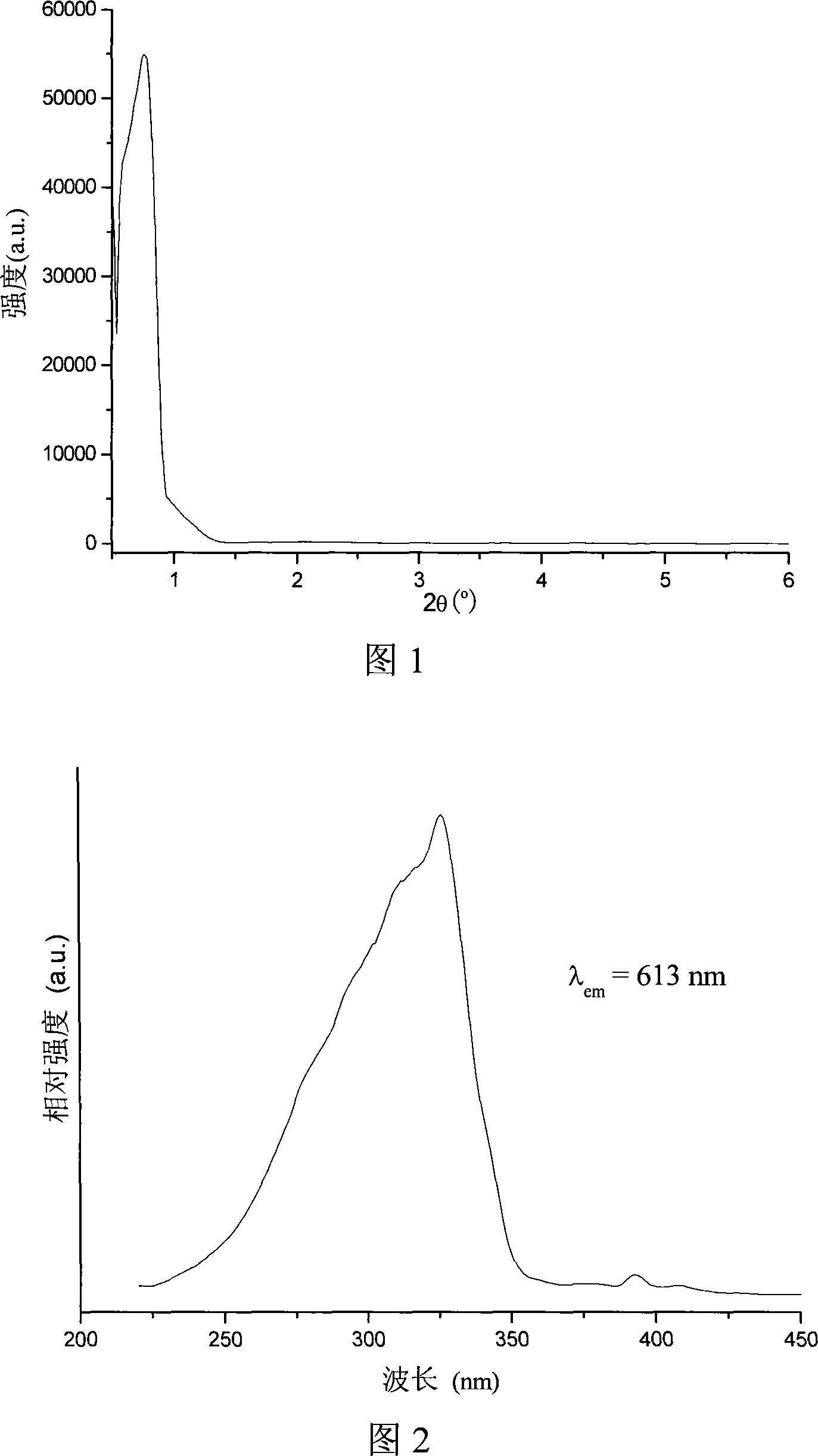

[0028] (2) Synthesis reaction of mesoporous MCM-41

[0029] Add 20mL of deionized water to 0.80g of cetyltrimethylammonium bromide (CTAB) surfactant, stir at 40°C for 30 minutes to dissolve it, then add 10mL of concentrated ammonia water, and add 2mL of Orthoethyl silicate (TEOS), continue to stir for 24 hours, put the obtained colloidal liquid into a stainless ste...

Embodiment 2

[0034] (1) Synthesis of europium-o-formic acid phenylacetic acid-2,2'-bipyridine complex

[0035] Add 0.40mmol Eu(NO 3 ) 3 ·6H 2 O, 0.60mmol o-formic acid phenylacetic acid and 0.40mmol 2,2'-bipyridine, stirred at room temperature for half an hour, poured into a 15mL stainless steel reaction kettle lined with polytetrafluoroethylene, and crystallized at 110°C for 72 Hours, slowly cooled to room temperature. The resulting product was suction-filtered and washed five times with deionized water and absolute ethanol to obtain a white polycrystalline powder sample of europium-o-formic acid phenylacetic acid-2,2'-bipyridine complex.

[0036] (2) Synthesis reaction of mesoporous MCM-41

[0037]Add 20mL of deionized water to 0.80g of cetyltrimethylammonium bromide (CTAB) surfactant, stir at 60°C for 15 minutes to dissolve it, then add 10mL of concentrated ammonia water, and then stir vigorously Add 2 mL of tetraethyl orthosilicate (TEOS), continue to stir for 24 hours, put the ob...

Embodiment 3

[0041] (1) Synthesis of europium-5-hydroxyisophthalic acid-phenanthroline complex

[0042] Add 0.30mmol Eu(NO 3 ) 3 ·6H 2 O, 0.45mmol 5-hydroxyisophthalic acid and 0.30mmol o-phenanthroline were stirred at room temperature for half an hour and then poured into a 15mL polytetrafluoroethylene-lined stainless steel reactor, and crystallized at 130°C for 80 Hours, slowly cooled to room temperature. The obtained product was suction-filtered and washed 6 times with deionized water and absolute ethanol to obtain a white polycrystalline powder sample of europium-5-hydroxyisophthalic acid-o-phenanthroline complex.

[0043] (2) Synthesis reaction of mesoporous MCM-41

[0044] Add 25mL of deionized water to 1.16g of cetyltrimethylammonium bromide (CTAB) surfactant, heat and stir to dissolve it, then add 12mL of concentrated ammonia water, and then add 4mL of tetraethyl orthosilicate under vigorous stirring (TEOS), continue to stir for 32 hours, put the obtained colloidal liquid into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com