Preparation method of cathode material of germanium-mesoporous carbon fiber composite lithium battery

A negative electrode material and fiber composite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of waste of biomass resources, environmental pollution, lack of effective utilization technology, etc., achieve high specific capacity, unique structure, excellent The effect of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation of mesoporous carbon fiber (MCF):

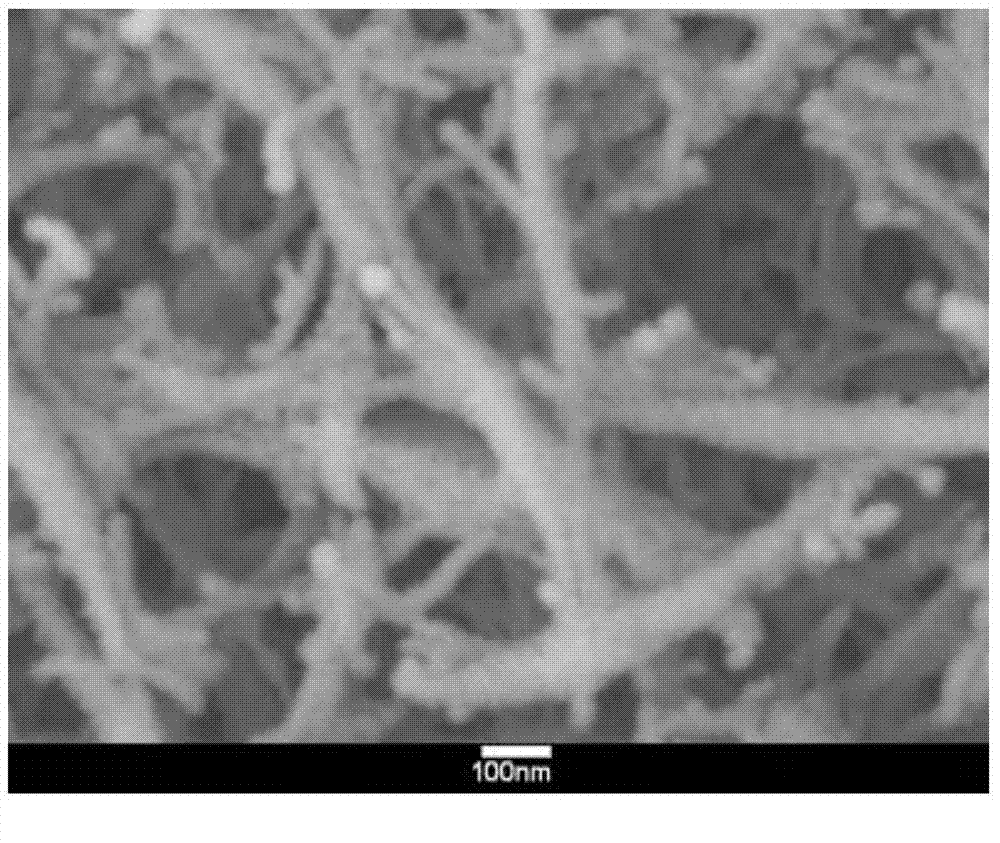

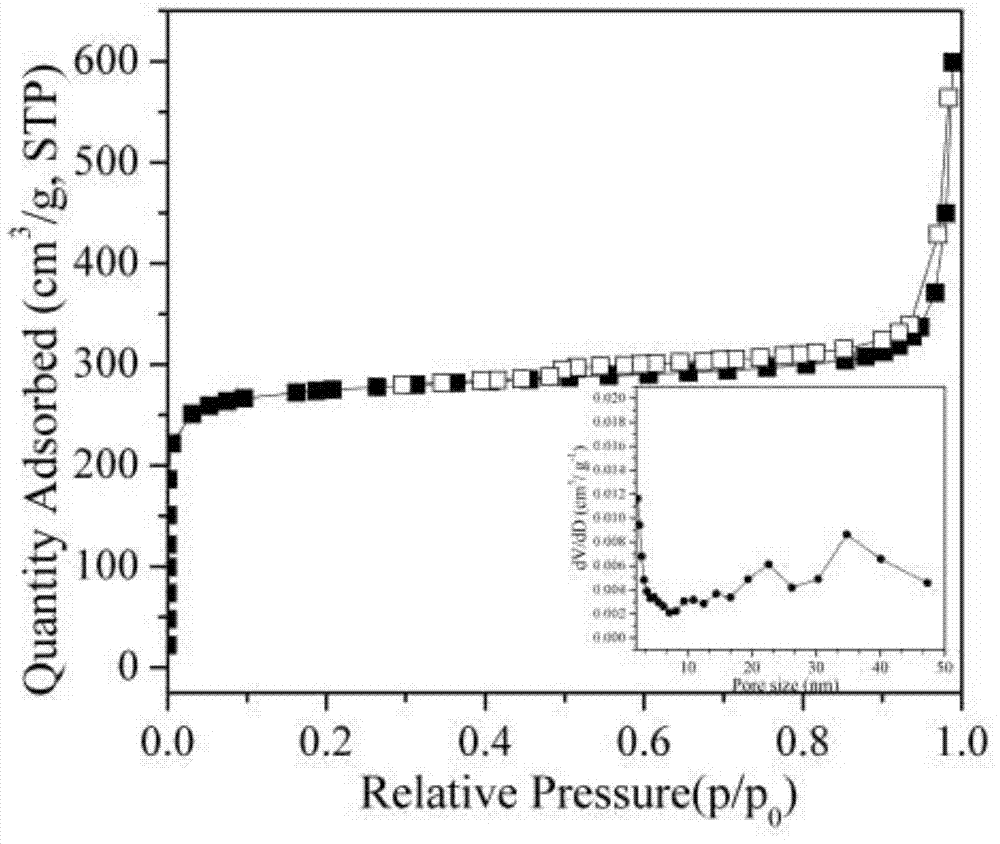

[0037] Take 0.994 g of LN, 0.426 g of PAN and 10 ml of DMF solvent, stir evenly and obtain LN / PAN composite fiber by electrospinning; place the obtained LN / PAN composite fiber in distilled water and etch for 48 h, Dry in a blast drying oven at 70 °C to obtain fibers with a special porous structure; place the porous structure fibers in a muffle furnace under an air atmosphere at 280 °C for 1 h, and in a tube furnace under a nitrogen atmosphere at 1.5 °C / min The heating rate was raised to 700 °C and kept at a constant temperature for 2 h; finally, heated to 850 °C with CO 2 After gas activation for 1 h, mesoporous carbon fibers (MCF) were obtained. The prepared MCF is a mesoporous fibrous structure with a specific surface area of 1070 m 2 g -1 , SEM such as figure 1 As shown, the nitrogen adsorption-desorption isotherm is shown as figure 2 shown.

[0038] 2. Preparation of Germanium-Mesoporous Carbon Fiber (GeMC...

Embodiment 2

[0043] 1. Preparation of Mesoporous Carbon Fibers (MCF)

[0044] Take 0.710 g of LN, 0.710 g of PAN and 10 ml of DMF solvent, stir evenly and obtain LN / PAN composite fiber by electrospinning; place the obtained LN / PAN composite fiber in distilled water and etch for 48 h, Dry in a blast oven at 70 °C; place the dried fibers in a muffle furnace under an air atmosphere at 280 °C for 1 h, then raise the temperature to 700 °C at a rate of 1.5 °C / min in a tube furnace under a nitrogen atmosphere. ℃ and keep the temperature for 2 h; finally, heated to 850 ℃ with CO 2 After gas activation for 1 h, mesoporous carbon fibers (MCF) were obtained.

[0045] 2. Preparation of Germanium-Mesoporous Carbon Fiber (GeMCF) Composites

[0046] Take 50 mg of MCF, 5 ml of concentrated nitric acid, and 5 ml of distilled water, put them into a polytetrafluoroethylene liner, conduct a hydrothermal reaction at 60 °C for 60 min, then centrifuge and wash; wash the obtained MCF and 3 ml of GeCl 4 , 10 ml...

Embodiment 3

[0050] 1. Preparation of Mesoporous Carbon Fibers (MCF)

[0051] Take 0.994 g of LN, 0.426 g of PAN and 10 ml of DMF solvent, stir evenly and obtain LN / PAN composite fiber by electrospinning; place the obtained LN / PAN composite fiber in distilled water and etch for 48 h, Dry in a blast oven at 70 °C; place the dried fibers in a muffle furnace under an air atmosphere at 280 °C for 1 h, then raise the temperature to 700 °C at a rate of 1.5 °C / min in a tube furnace under a nitrogen atmosphere. ℃ and keep the temperature for 2 h; finally, heated to 850 ℃ with CO 2 After gas activation for 1 h, mesoporous carbon fibers (MCF) were obtained.

[0052] 2. Preparation of Germanium-Mesoporous Carbon Fiber (GeMCF) Composites

[0053] Take 50 mg of MCF, 5 ml of concentrated nitric acid, and 5 ml of distilled water, put them into a polytetrafluoroethylene liner, conduct a hydrothermal reaction at 60 °C for 60 min, then centrifuge and wash; wash the obtained MCF and 4.6 ml of GeCl 4 , 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com