Spinel ferrite/CNx nanocomposite and preparation method thereof

A technology of spinel ferrite and nanocomposite materials, which is applied in the direction of nanocarbon, carbon nanotubes, nanotechnology, etc., and can solve problems affecting performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

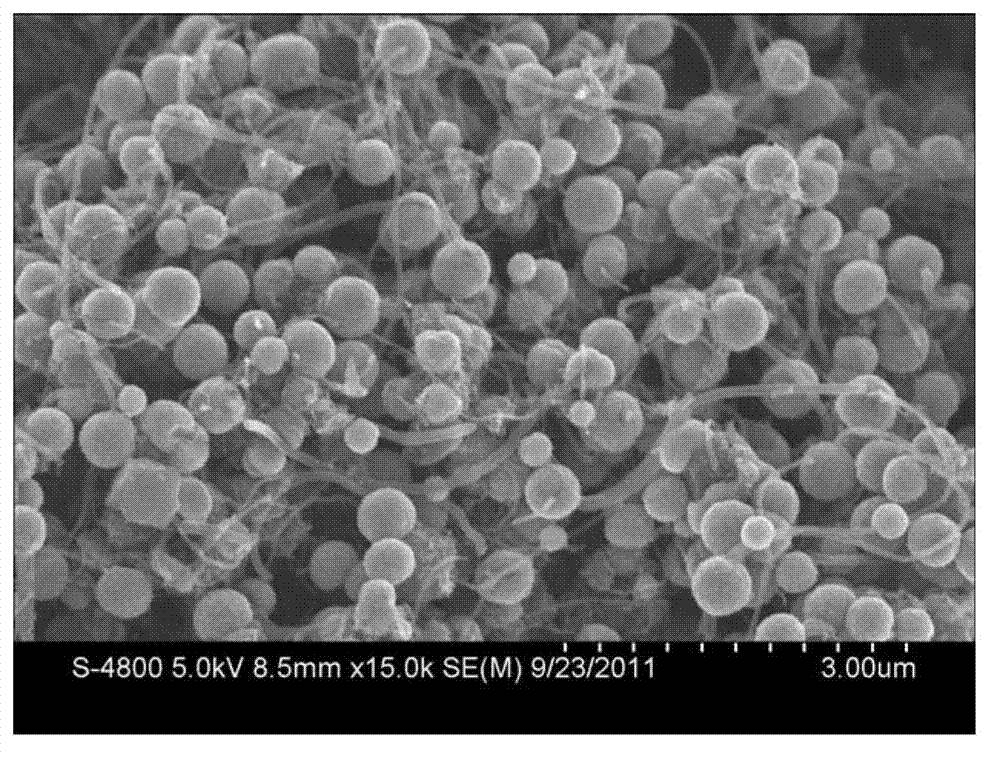

[0026] Preparation of ferroferric oxide / CNx nanocomposites

[0027] 1) Preparation of nitrogen-doped carbon nanotubes (CNx);

[0028] Using diethylamine and sec-butylamine as carbon source and nitrogen source, Fe / SBA-15 molecular sieve as catalyst, nitrogen-doped carbon nanotube material (CN X );

[0029] 2) Preparation of Fe3O4 / CNx nanocomposites;

[0030] A) Weigh 0.1g of newly prepared CNx in 40ml of ethylene glycol, and ultrasonically disperse it for 30 minutes to obtain the first solution;

[0031] B) FeCl 3 Dissolved in the first solution to form a second solution; wherein, the concentration of ferric ions in the second solution is 0.05mol / l;

[0032] C) At normal temperature and pressure, add ethylenediamine to the second solution prepared in step B), and stir thoroughly to obtain the third solution, wherein the amount of ethylenediamine added is the same as the amount of ethylene glycol added in step A) The volume ratio is 0.05:1;

[0033] D) Place the third solu...

Embodiment 2

[0036] Preparation of spinel manganese ferrite / CNx nanocomposites

[0037] 1) Preparation of nitrogen-doped carbon nanotubes (CNx);

[0038] Using diethylamine and sec-butylamine as carbon source and nitrogen source, Fe / SBA-15 molecular sieve as catalyst, nitrogen-doped carbon nanotube material (CN X );

[0039] 2) Preparation of spinel manganese ferrite / CNx nanocomposite;

[0040] A) Weigh 0.1g of newly prepared CNx in 40ml of ethylene glycol, and ultrasonically disperse it for 30 minutes to obtain the first solution;

[0041] B) According to MFe 2 o 4 The stoichiometric ratio of metal ions in the medium was weighed MnCl 2 and FeCl 3 , and dissolved in the first solution to form a second solution; wherein, the concentration of ferric ions in the second solution is 0.4mol / l;

[0042] C) At normal temperature and pressure, add ethylenediamine to the second solution prepared in step B), and stir thoroughly to obtain the third solution, wherein the amount of ethylenediamin...

Embodiment 3、4、5

[0046] Except step B) in step 2) in embodiment 3,4,5 according to MFe 2 o 4The stoichiometric ratio of metal ions in ZnSO was weighed separately 4 and FeCl 3 , CoSO 4 and FeCl 3 , Ni(NO3) 2 and FeCl 3 , other steps and conditions are the same as in Example 2, and spinel zinc ferrite / CNx nanocomposites, cobalt ferrite / CNx nanocomposites, nickel ferrite / CNx nanocomposites can also be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com