Method for preparing spinel ferrite film

A spinel ferrite and thin film technology is applied in the field of preparation of spinel ferrite thin films, can solve problems such as limiting wide application, increasing reaction cost, long sintering time, etc., and achieves simplified steps, reduced reaction time and Cost and effect of short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A cobalt ferrite CoFe 2 o 4 The preparation method of thin film, comprises the following steps:

[0022] Step 1: Prepare 50ml of electrolyte solution, in which CoSO 4 ·7H 2 The concentration of O is 0.025mol / L, FeSO 4 ·7H 2 The concentration of O is 0.05mol / L, then add H 2 SO 4 Adjust the pH to 4; use the Si-Pt sheet as the working electrode, the saturated calomel electrode as the reference electrode, and the platinum sheet as the counter electrode, and use the constant voltage method to electroplate at -2.1V for 3 minutes to obtain a cobalt-iron alloy film CoFe 2 ;

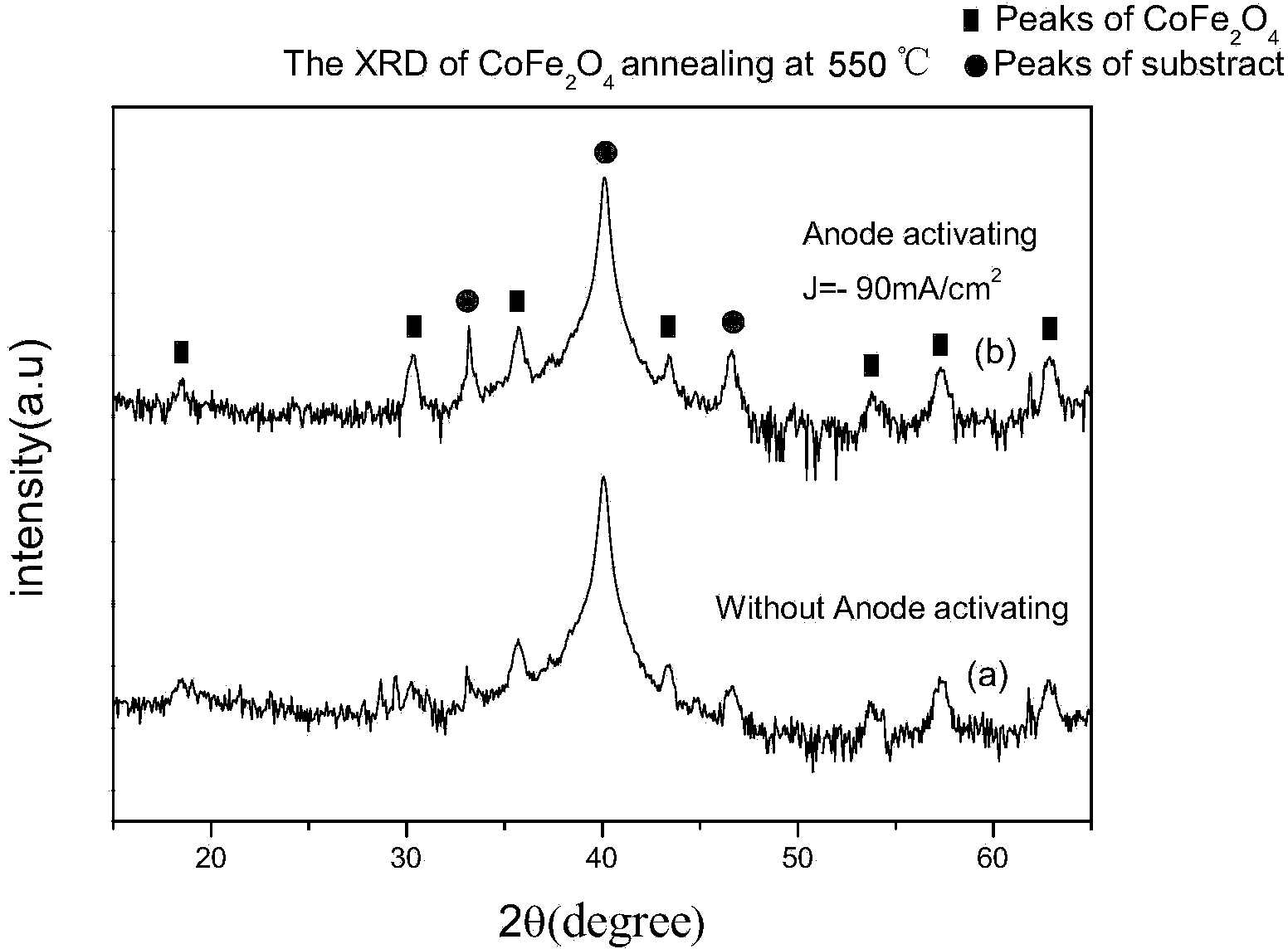

[0023] Step 2: Use the three-electrode method to carry out anodic activation treatment on the alloy film: prepare 50mL of 1.5mol / L NaOH solution as the electrolyte, use the cobalt-iron alloy film obtained in step 1 as the working electrode, and the saturated calomel electrode as the reference electrode, platinum The sheet is the counter electrode, at the current density J=-90mA / cm 2 Under constant...

Embodiment 2

[0027] The difference between this embodiment and embodiment 1 is that when the anode activation treatment is carried out in step 2, the current density J=-110mA / cm 2 .

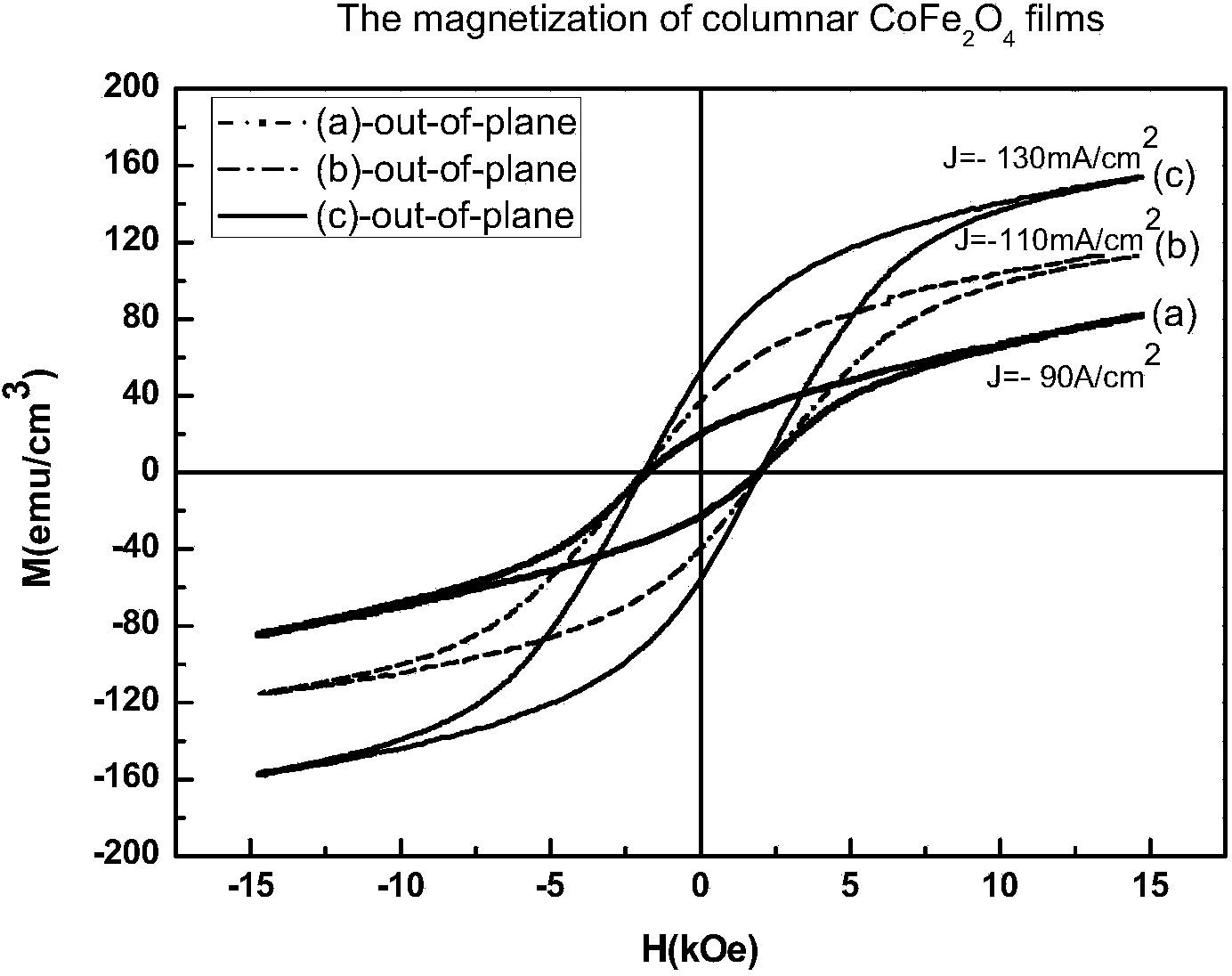

[0028] image 3 (b) is the CoFe that embodiment 2 obtains 2 o 4 The hysteresis loop of the film, given by image 3 (b) It can be seen that the coercive force of the film is about 2.5kOe, and the saturation magnetization perpendicular to the film surface is 110emu / cm 3 .

Embodiment 3

[0030] The difference between this embodiment and embodiment 1 is that when the anodic activation treatment is carried out in step 2, the current density J= - 130mA / cm 2 .

[0031] image 3 (c) is the CoFe that embodiment 3 obtains 2 o 4 The hysteresis loop of the film, given by image 3(c) It can be seen that the coercive force of the film is about 2.5kOe, and the saturation magnetization perpendicular to the film surface is 150emu / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com