Core-shell structure magnetic microsphere aluminum oxide and method for preparing the same

A spherical alumina, core-shell structure technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, catalyst carriers, etc., can solve the problems of poor magnetic properties and low content of magnetic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step A: Weigh 3.49g Ni(NO) at a molar ratio of 3:5:2 3 ) 2 ·6H 2 O, 3.98g FeCl 2 ·4H 2 O and 3.23gFe(NO 3 ) 3 ·9H 2 Dissolve O in 40ml and remove O 2 Mixed salt solution in deionized water; weigh 2.40g NaOH and 2.97g anhydrous Na 2 CO 3 Dissolve in 40ml de O 2 Prepare mixed alkali solution in deionized water; in N 2 Under the protection, slowly drip the mixed alkaline solution into the mixed salt solution. When the pH value in the system reaches 7, stop the dripping. 2 Stir and crystallize in a water bath at 40°C for 17 hours under protection; wash the filtrate with deionized water until the pH value of the washing water is 7, then wash twice with ethanol, and vacuum dry at 40°C for 24 hours to obtain Ni 2+ -Fe 2+ -Fe 3+ -CO 3 2- -LDHs layered precursors. The above samples were fired at 960°C for 5 hours to obtain spinel ferrite NiFe 2 O 4 .

[0035] Step B: Use a high-speed grinder to combine the obtained spinel ferrite NiFe 2 O 4 Grind into particles about 1-5μm; press N...

Embodiment 2

[0041] Keep other preparation conditions unchanged in Example 1. After step D is completed, press NiFe 2 O 4 The mass accounts for 25% of the final magnetic micro spherical alumina, weigh 2g NiFe 2 O 4 -SiO 2 -γ-Al 2 O 3 The microspheres were ultrasonically dispersed in 160ml of deionized water and then transferred to a stirred and heated reactor containing 1.93g of aluminum n-butoxide, hydrolyzed in a water bath at 85°C for 30 minutes, and concentrated HNO was added dropwise 3 When the pH value of the system reached 1, the temperature was raised to 95°C and refluxed and stirred for 24 hours. The resulting NiFe 2 O 4 -SiO 2 -γ-Al 2 O 3 The microsphere sol was dried at 70℃ for 24h to obtain NiFe 2 O 4 -SiO 2 -Al(OH) 3 Dry gel particles.

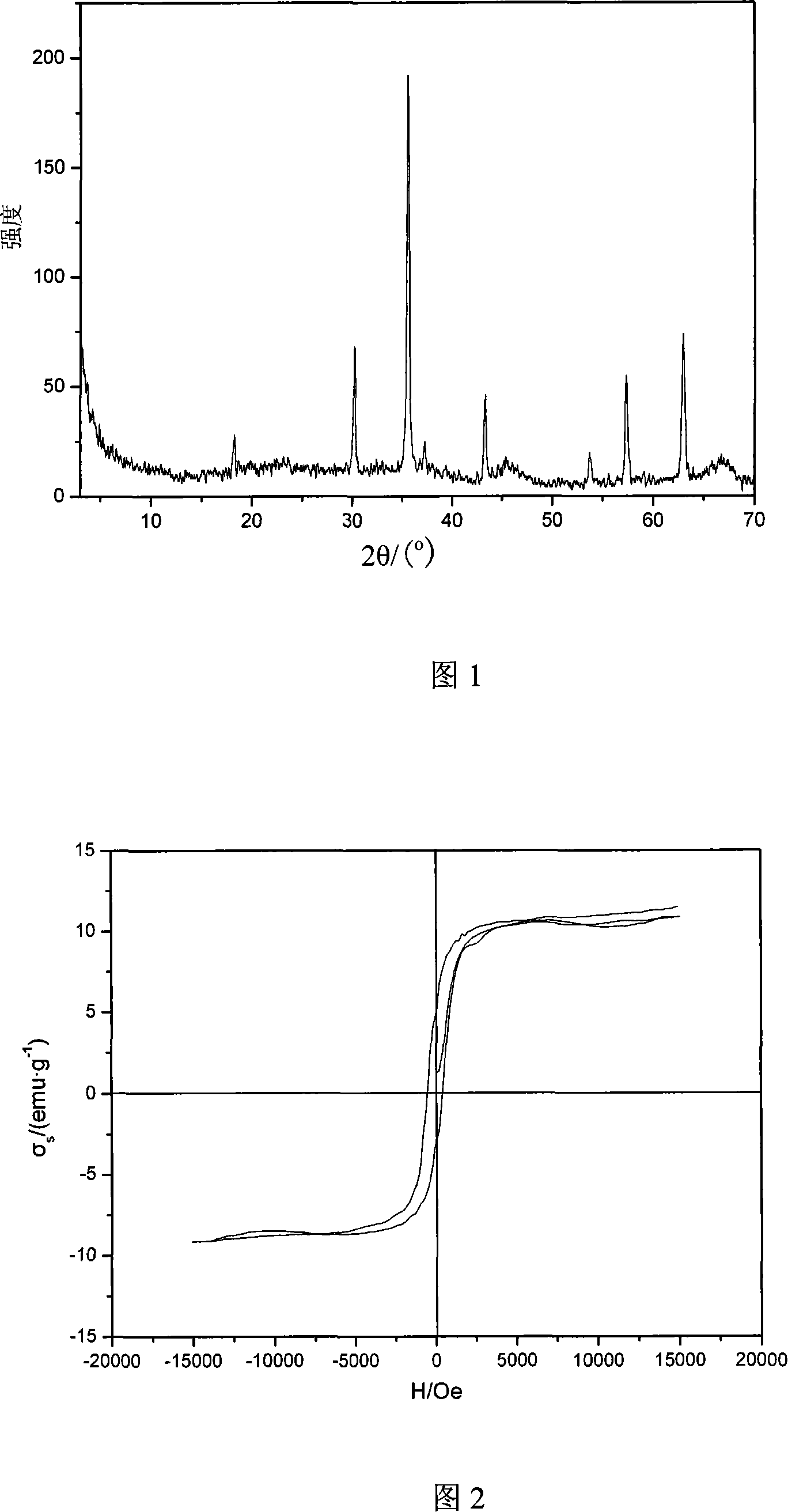

[0042] Put the product in the muffle furnace at 10℃·min -1 The temperature is increased to 600℃ and kept for 4h, and finally cooled to room temperature with the furnace to obtain magnetic micro spherical NiFe 2 O 4 -SiO 2 -γ-Al 2 O 3 . Determined ...

Embodiment 3

[0044] Step A: Weigh 3.49g Co(NO) in a molar ratio of 3:5:2 3 ) 2 ·6H 2 O, 3.98g FeCl 2 ·4H 2 O and 3.23gFe(NO 3 ) 3 ·9H 2 Dissolve O in 40ml and remove O 2 Prepared into a mixed salt solution in deionized water.

[0045] Others are the same as in Example 1. The magnetic microspherical CoFe is finally prepared 2 O 4 -SiO 2 -γ-Al 2 O 3 .

[0046] Determined CoFe 2 O 4 -SiO 2 -γ-Al 2 O 3 CoFe in microspheres 2 O 4 , SiO 2 And Al 2 O 3 The mass fractions are 27.6%, 30.2% and 42.2%, respectively. CoFe 2 O 4 -SiO 2 -γ-Al 2 O 3 The specific saturation magnetization is 24.46emu·g -1 , The coercivity is 1203Oe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com