Application of spinel ferrite catalyst and method for urging persulfate to generate free radicals to catalytically degrade organic matters

A technology of spinel ferrite and persulfate, applied in chemical instruments and methods, solid waste removal, separation methods, etc., can solve problems such as easy to be oxidized and decomposed, harsh reaction conditions, complex reaction system, etc., to achieve High mechanical strength, complete catalysis, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific Embodiment 1: This embodiment is an application of a spinel ferrite catalyst, and the spinel ferrite catalyst is used as a catalyst to promote the generation of persulfate free radicals to promote the generation of persulfate or monopersulfate Application of free radicals.

[0015] The persulfate described in this embodiment is potassium persulfate, ammonium persulfate or sodium persulfate.

[0016] The monopersulfate described in this embodiment is potassium monopersulfate, ammonium monopersulfate or sodium monopersulfate.

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the spinel ferrite catalyst is spinel ferrite, metal-doped spinel ferrite, spinel Ferrite / carbonaceous material composite or spinel ferrite / metal oxide composite; wherein said spinel ferrite is NiFe 2 o 4 , MnFe 2 o 4 、CoFe 2 o 4 , ZnFe 2 o 4 , MgFe 2 o 4 、CuFe 2 o 4 , CrFe 2 o 4 , PbFe 2 o 4 , SrFe 2 o 4 、BaFe 2 o 4 and CaFe 2 o 4 One or a mixture of two of them, wherein the molecular formula of the metal-doped spinel ferrite is M 1-x N x Fe 2 o 4 , where 02 o 4 , MnFe 2 o 4 、CoFe 2 o 4 , ZnFe 2 o 4 , MgFe 2 o 4 、CuFe 2 o 4 , CrFe 2 o 4 , PbFe 2 o 4 , SrFe 2 o 4 、BaFe 2 o 4 or CaFe 2 o 4 , the carbonaceous material is one or a mixture of activated carbon, carbon nanotubes, graphene and bamboo carbon; wherein the spinel ferrite / metal oxide composite is made of spinel Made of ferrite and metal oxide, the mass ratio of the spinel ferrite to the metal ...

specific Embodiment approach 3

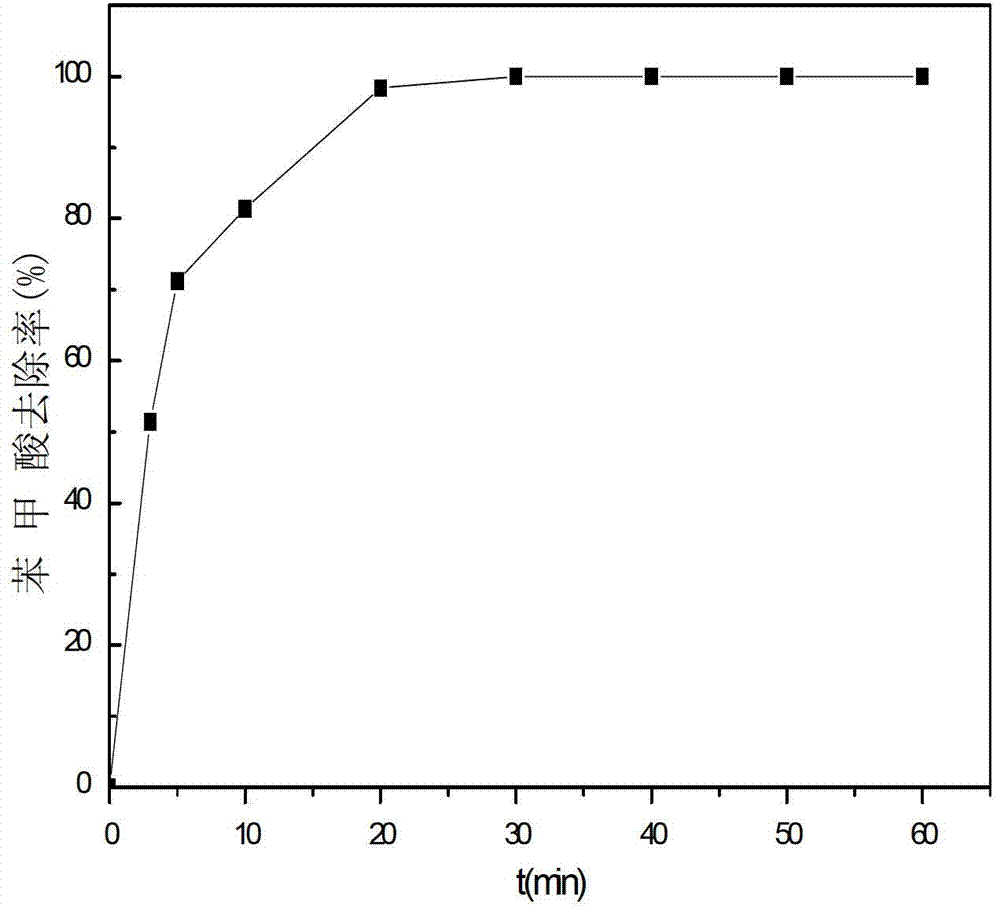

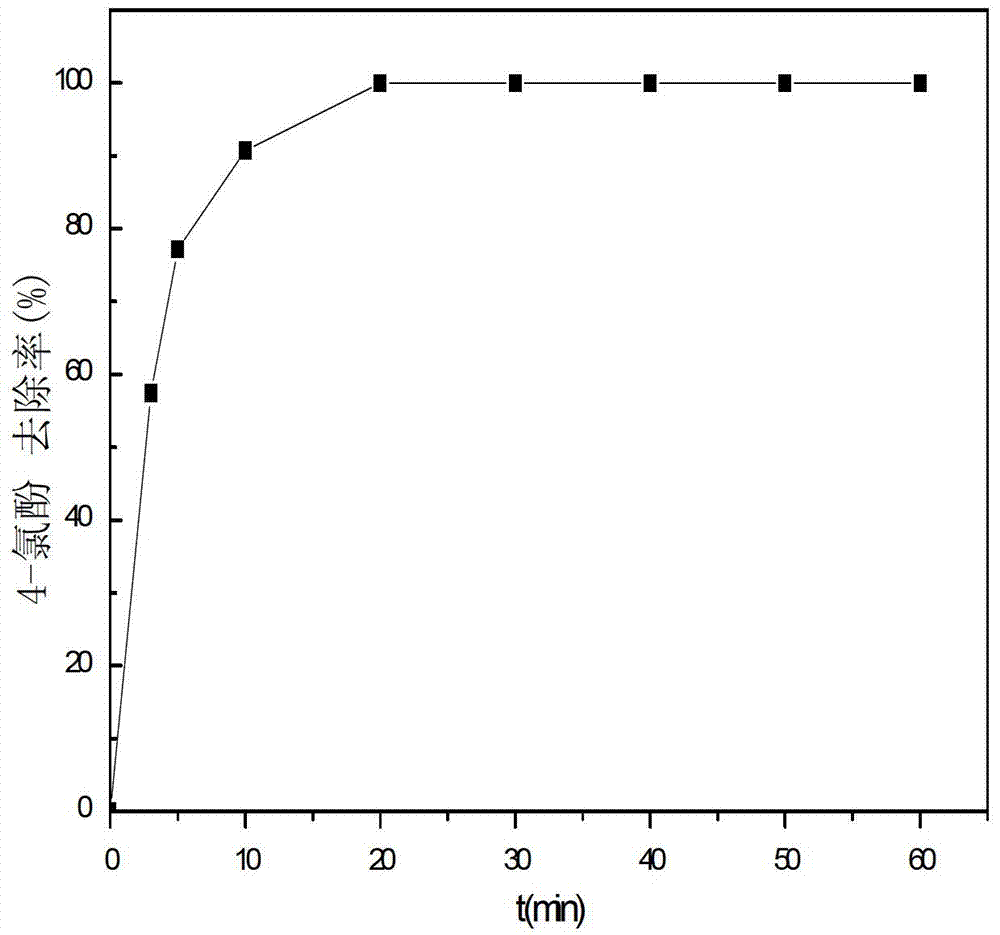

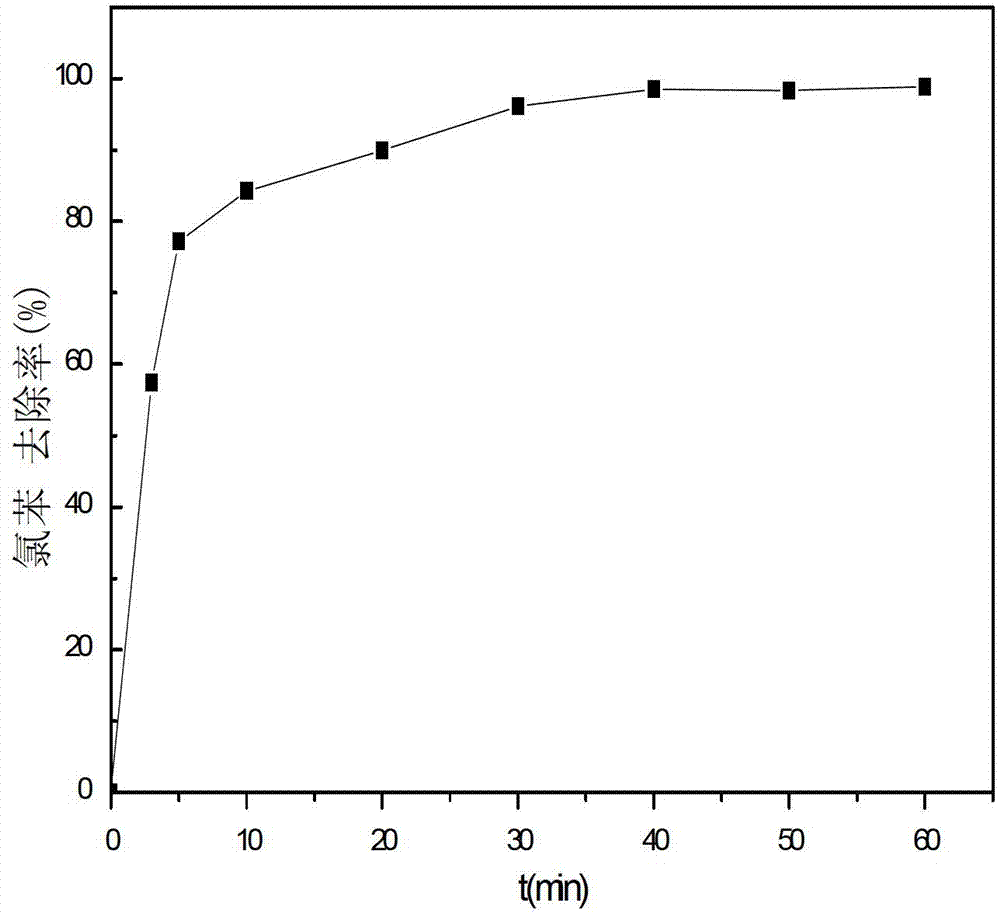

[0022] Specific embodiment three: This embodiment is a method for utilizing spinel ferrite catalysts to promote persulfate to produce free radicals to catalyze and degrade organic matter, specifically as follows: 1. Pretreatment: first, the water to be treated The pH value of the solution is adjusted to 4~8, and the temperature is controlled at 15°C~30°C to obtain pretreated water; 2. Degradation: first add persulfate or monopersulfate to deionized water to form an aqueous solution, and then add step 1 The obtained pretreated water is then added with a spinel ferrite catalyst, and treated at a stirring speed of 100r / min~4000r / min for 1min~200min to complete the degradation of organic matter in the water to be treated; The volume ratio of aqueous solution and the pretreatment water that step 1 obtains is (0.01~0.9): 1; If what add in step 2 is persulfate: S in the aqueous solution that obtains in step 2 2 o 8 2- The concentration is 0.5μmol / L~100μmol / L, and the spinel ferrite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com