Magnetic fenton catalyst spinel ferrite employing fenton iron sludge as iron source and application of magnetic fenton catalyst spinel ferrite

A technology of spinel ferrite and catalyst, which is applied in the direction of physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, iron compound, etc., to achieve good effect, save iron slime treatment cost, iron slime produce less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: NiFe 2 o 4 The preparation and characterization process and its application

[0029] ((1), get a certain amount of Fenton's iron-containing sludge and nickel nitrate respectively, so that the mol ratio of nickel and iron is 1: 2;

[0030] (2), Fenton's iron-containing sludge and nickel nitrate solution are mixed and stirred evenly;

[0031] (3), slowly and evenly add sodium hydroxide solution in the resulting mixed solution, and adjust the pH to between 9.0-10.0;

[0032] (4), stirring the obtained mixed solution for more than 8 hours, centrifuging the stirred mixed solution, and washing the obtained solid with water for 2-3 times;

[0033] (5), drying the obtained solid at no higher than 110°C;

[0034] (6) Calcining the obtained solid in the temperature range of 700-900°C to obtain the magnetic Fenton catalyst NiFe 2 o 4 .

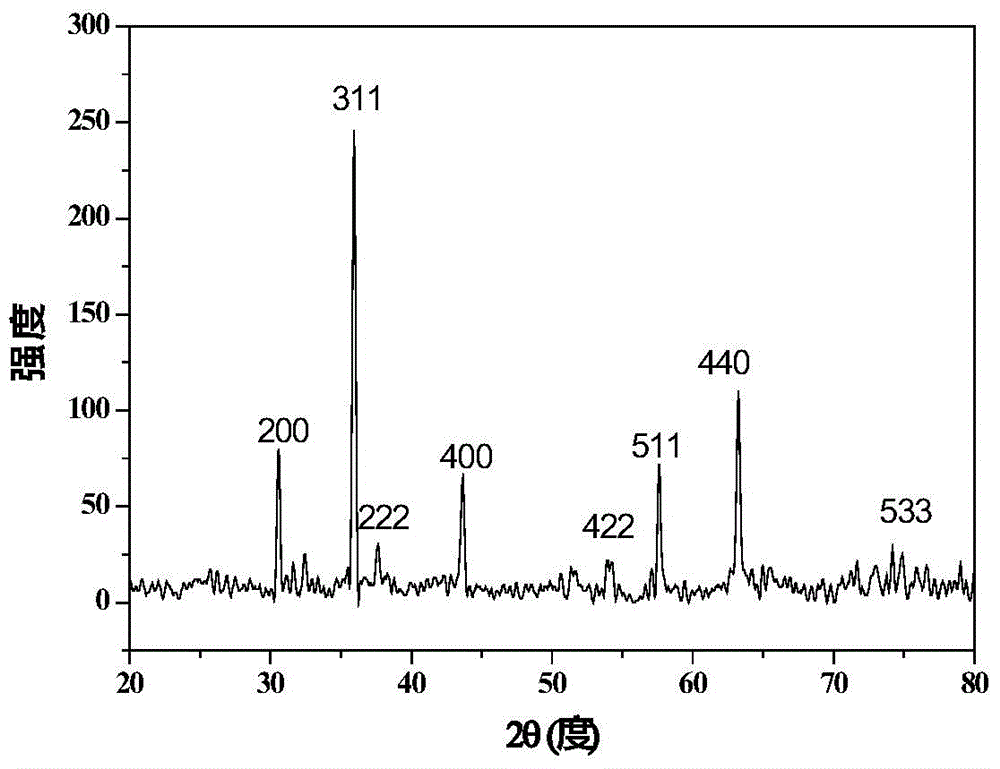

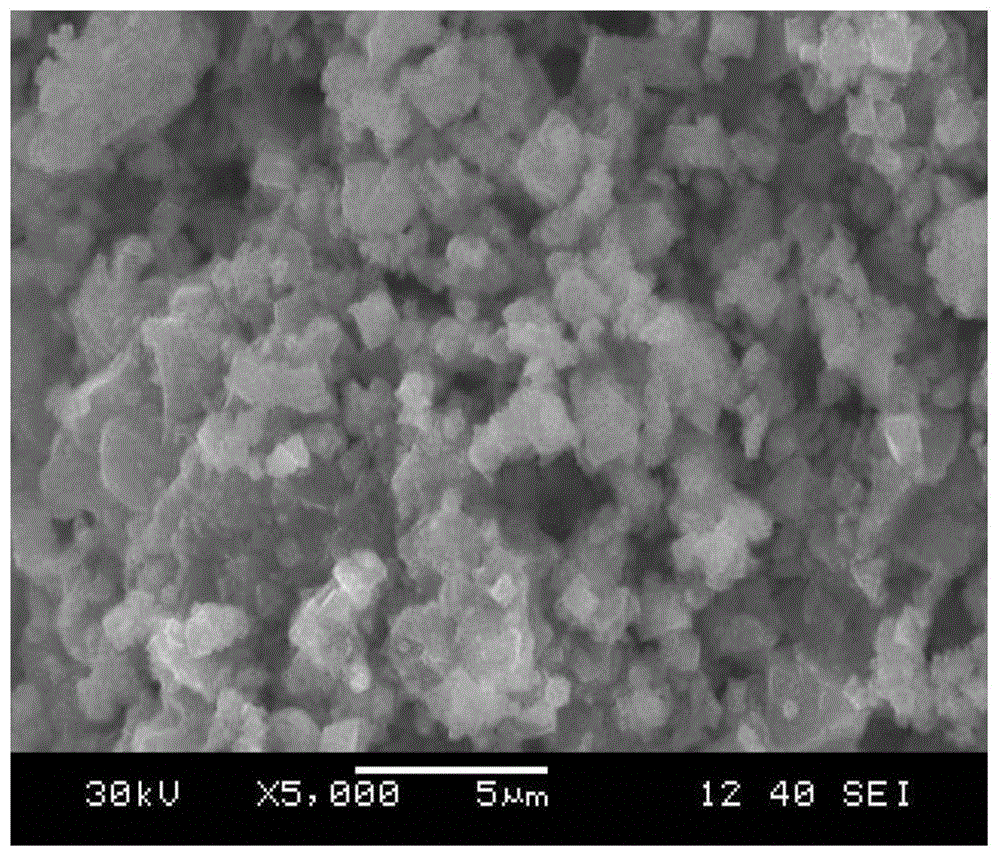

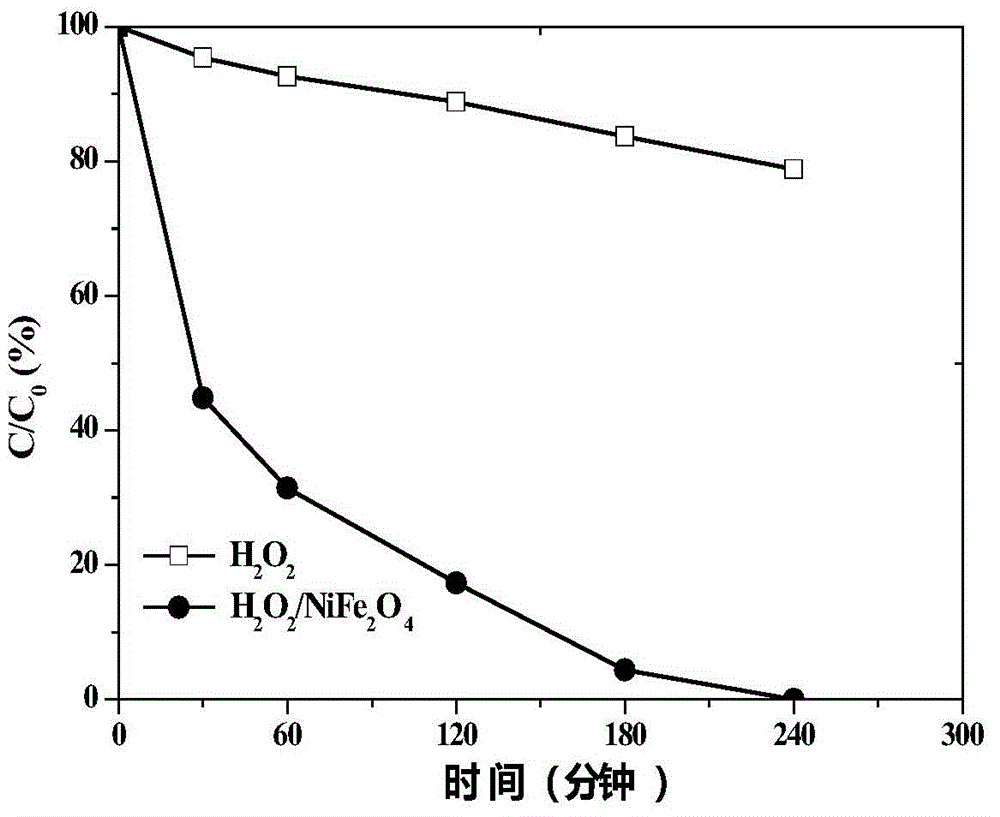

[0035] figure 1 Be the NiFe that the embodiment of the present invention makes 2 o 4 The X-ray diffraction (XRD) pattern, ...

Embodiment 2

[0038] Embodiment 2: with CuFe 2 o 4 Phenol Degradation Test for Fenton Catalyst

[0039] Prepare CuFe with the catalyst preparation method described in embodiment 1 2 o 4 , to CuFe 2 o 4 It is a Fenton catalyst, which catalyzes and oxidizes phenol simulation wastewater with an initial concentration of 250mg / L, adjusts the pH of the wastewater to 3.0, and adds 2.0g / L of CuFe 2 o 4 Catalyst, add 4.0g / L concentration and be 30% hydrogen peroxide, record the removal rate of phenol under different time, the result is as follows Figure 4 shown.

[0040] Figure 4 for hydrogen peroxide alone and CuFe 2 o 4 The trend chart of the degradation effect of phenol under the catalytic oxidation of magnetic materials, comparing the removal effect of phenol in the above-mentioned control test, the result CuFe 2 o 4 The addition of magnetic materials significantly promotes the degradation of phenol and has a good catalytic effect.

Embodiment 3

[0041] Embodiment 3: with ZnFe 2 o 4 Phenol Degradation Test for Fenton Catalyst

[0042] Prepare ZnFe with the catalyst preparation method described in embodiment 1 2 o 4 , with ZnFe 2 o 4 It is a Fenton catalyst, which catalyzes and oxidizes phenol simulation wastewater with an initial concentration of 250mg / L, adjusts the pH of the wastewater to 3.0, and adds 2.0g / L of ZnFe 2 o 4Catalyst, add 4.0g / L concentration and be 30% hydrogen peroxide, record the removal rate of phenol under different time, the result is as follows Figure 5 shown.

[0043] Figure 5 For hydrogen peroxide alone and ZnFe 2 o 4 The trend chart of the degradation effect of phenol under the catalytic oxidation of magnetic materials, comparing the removal effect of phenol in the above-mentioned control test, the result ZnFe 2 o 4 The addition of the magnetic material significantly promotes the degradation of phenol and has a good catalytic effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com