Water treatment method for removing arsenic by strengthening zero-valent iron

A zero-valent iron and water treatment technology, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of general removal effect, etc., to ensure the safety of water quality, simple operation and safe use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] This embodiment "a water treatment method for strengthening zero-valent iron to remove arsenic" is carried out according to the following method: add persulfate and zero-valent iron to the water containing arsenic, so that the molar ratio of zero-valent iron and persulfate in the water is 1:1~10:1, the molar ratio of persulfate to arsenic is 5:1~100:1, then the mixed solution is stirred and reacted at a speed of 50~300 rpm for 5-60 min, and the As is completed by filtration. remove.

[0027] The water containing arsenic in this embodiment refers to groundwater or surface water containing one or more of As(III), As(IV) and organic arsenic. Persulfates are potassium persulfate (sodium, ammonium, calcium, magnesium), potassium monopersulfate (sodium, ammonium, calcium, magnesium). Zero-valent iron can be commercially available zero-valent iron, nanometer zero-valent iron or iron waste from processing plants, such as filings, chips, shavings and iron powder.

specific Embodiment approach 2

[0028] The difference between this embodiment and specific embodiment one is that in addition to adding persulfate, the synergistic agent of persulfate is added at the same time, and the synergistic agent of persulfate is (chlorination, nitric acid, sulfuric acid) ferrous / iron one or several. Others are the same as the first embodiment.

[0029] In this embodiment, the molar equivalent ratio of the dosage of the persulfate synergistic agent to the dosage of the persulfate is 0.1:1˜1:1.

specific Embodiment approach 3

[0030] The specific embodiment one "a water treatment method for strengthening zero-valent iron to remove arsenic" is carried out according to the following method: add persulfate to the water containing arsenic, and fully mix, so that the molar ratio of persulfate to arsenic is 5 :1~100:1, and then pass the mixed solution through a filter column with zero-valent iron as the main component, and after filtration, the enhanced removal of As is completed.

[0031] The water containing arsenic in this embodiment refers to groundwater or surface water containing one or more of As(III), As(IV) and organic arsenic. Persulfates are potassium persulfate (sodium, ammonium, calcium, magnesium), potassium monopersulfate (sodium, ammonium, calcium, magnesium). Zero-valent iron can be commercially available zero-valent iron, iron waste from processing plants, such as filings, chips, shavings, and iron powder.

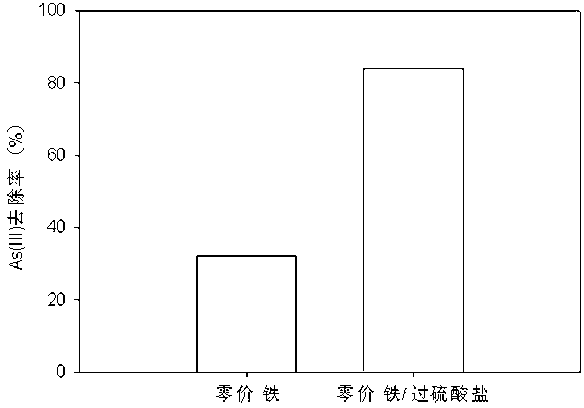

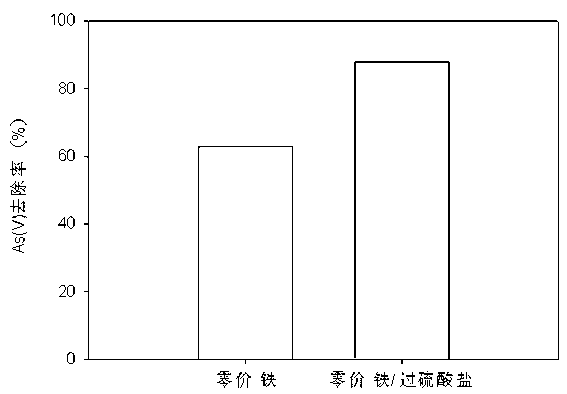

[0032] figure 1 It is the diagram of the removal effect of As(III) in this spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com