Nitrogen-doped carbon-clad manganese oxide lithium ion battery composite cathode material, and preparation method and application of composite cathode material

A manganese oxide lithium, ion battery technology, applied in the field of electrochemistry, can solve the problems of poor electrical conductivity and cycle stability, and achieve the effects of improving cycle performance and rate performance, good stability, and increasing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

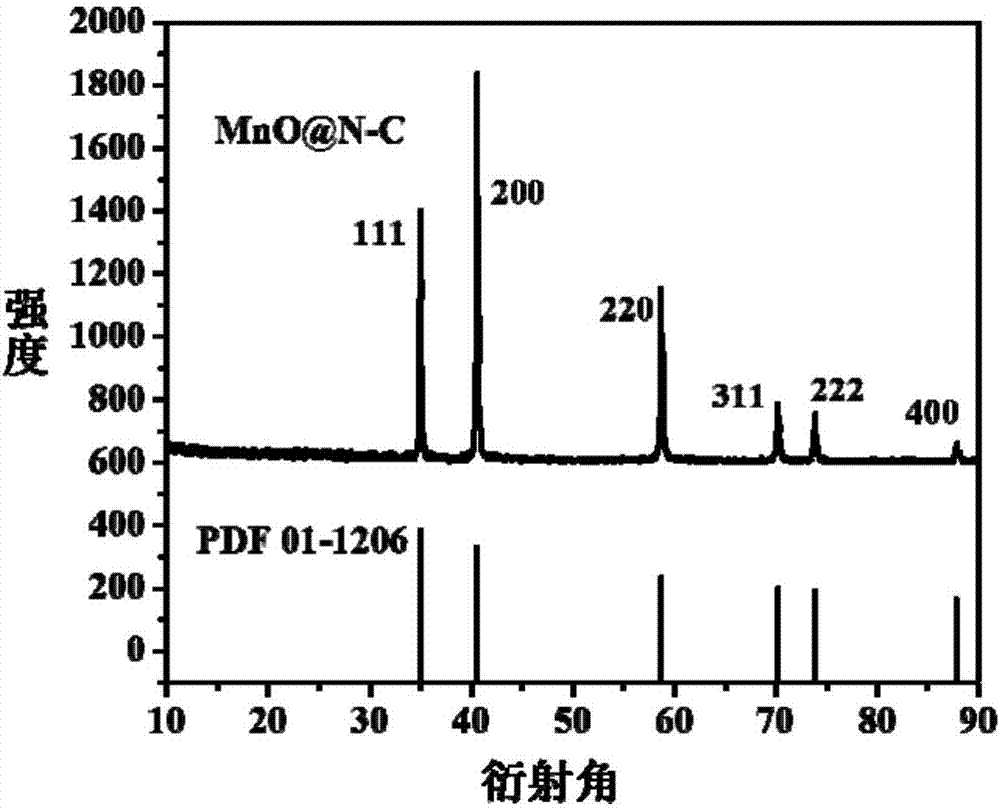

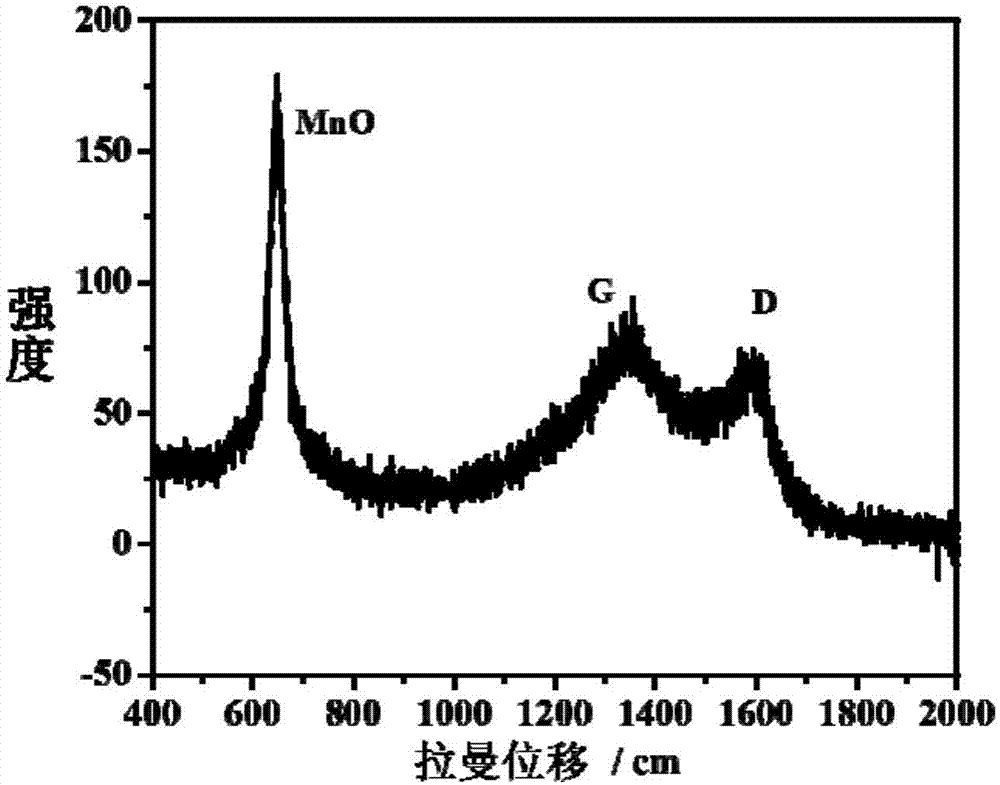

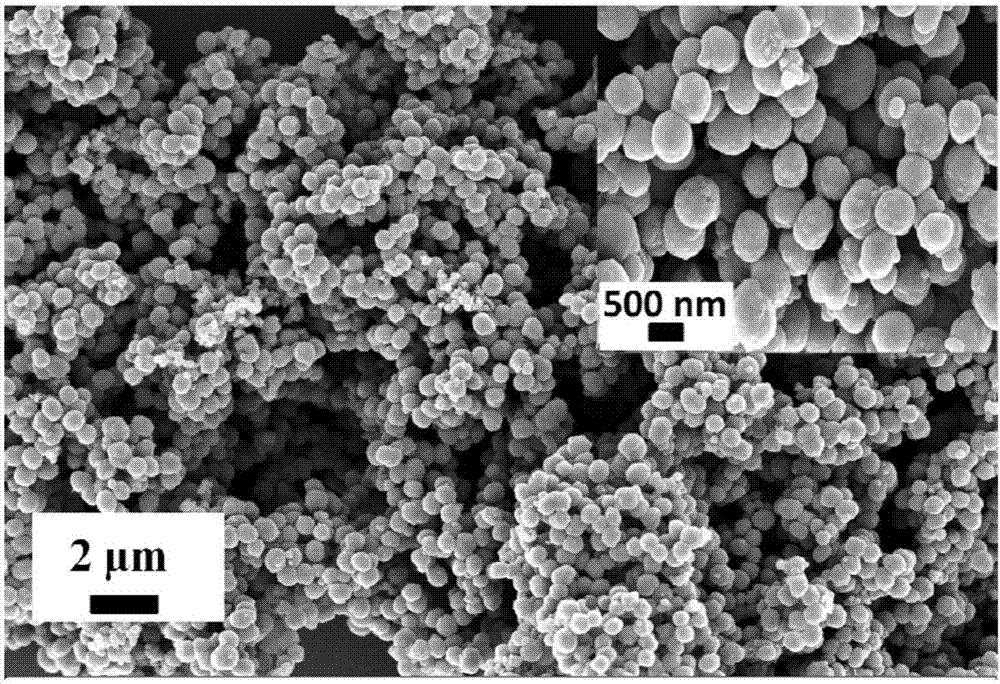

Embodiment 1

[0040] (1) Weigh 1mmol of manganese acetate and 10mmol of ammonium bicarbonate and dissolve them in 30mL of ethylene glycol, and stir at room temperature for 30min to obtain a uniformly mixed solution; transfer the solution obtained above to a 50mL reaction kettle, and The hydrothermal reaction was carried out at 180°C for 12 hours; the hydrothermal reaction product was centrifuged, washed 4 times with water and absolute ethanol, and then dried in a vacuum oven at 80°C to obtain the precursor nanosphere manganese carbonate particles; then , to coat dopamine, the process is as follows: Weigh 100 mg of nanosphere manganese carbonate and 100 mg of dopamine hydrochloride respectively, dissolve them in 50 mL of Tris buffer solution (pH=8.5), stir at room temperature for 24 hours, and centrifuge and wash with absolute ethanol 4 times and dried to obtain the manganese carbonate@polydopamine complex. Finally, the obtained manganese carbonate@polydopamine complex was placed in a porcel...

Embodiment 2

[0043] (1) Dissolve 1 mmol of manganese nitrate and 5 mmol of ammonium bicarbonate in 30 mL of absolute ethanol, and stir at room temperature for 30 minutes to obtain a uniformly mixed solution; transfer the above obtained solution to a 50 mL reaction kettle, Carry out hydrothermal reaction at 150°C for 10 hours; centrifuge the hydrothermal reaction product, wash it with water and absolute ethanol for 4 times, and dry it in a vacuum oven at 80°C to obtain the precursor nanosphere manganese carbonate particles; Subsequently, the coating of dopamine was carried out as follows: 100 mg of nanosphere manganese carbonate and 150 mg of dopamine hydrochloride were weighed, dissolved in 50 mL of Tris buffer solution (pH=8.5), stirred at room temperature for 24 hours, and centrifuged with absolute ethanol Washed 4 times and dried to obtain the product manganese carbonate@polydopamine complex. Finally, the obtained manganese carbonate@polydopamine complex was placed in a porcelain boat a...

Embodiment 3

[0046] (1) Weigh 1mmol of manganese sulfate and 15mmol of ammonium bicarbonate and dissolve them in 30mL of deionized water, stir at room temperature for 30min to obtain a uniformly mixed solution; The hydrothermal reaction was carried out at ℃ for 15 hours; the hydrothermal reaction product was centrifuged, washed 4 times with deionized water and absolute ethanol, and then dried in a vacuum oven at 80 ℃ to obtain the precursor nanosphere manganese carbonate Particles; then, dopamine coating, the process is as follows: Weigh 100mg of nanosphere manganese carbonate and 125mg of dopamine hydrochloride respectively, dissolve in 50 mL of Tris buffer solution (pH=8.5), stir at room temperature for 24h, wash with anhydrous Washed by ethanol centrifugation for 4 times and dried to obtain the product manganese carbonate@polydopamine complex. Finally, the obtained manganese carbonate@polydopamine complex was placed in a porcelain boat and placed in a tube furnace. Under the protection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com