Water-system asymmetric super-capacitor based on NiCo2S4 and NiCo2S4 composite material

A technology of supercapacitors and composite materials, which is applied in the fields of hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, and double-layer capacitors, etc., can solve the problems of low energy density, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

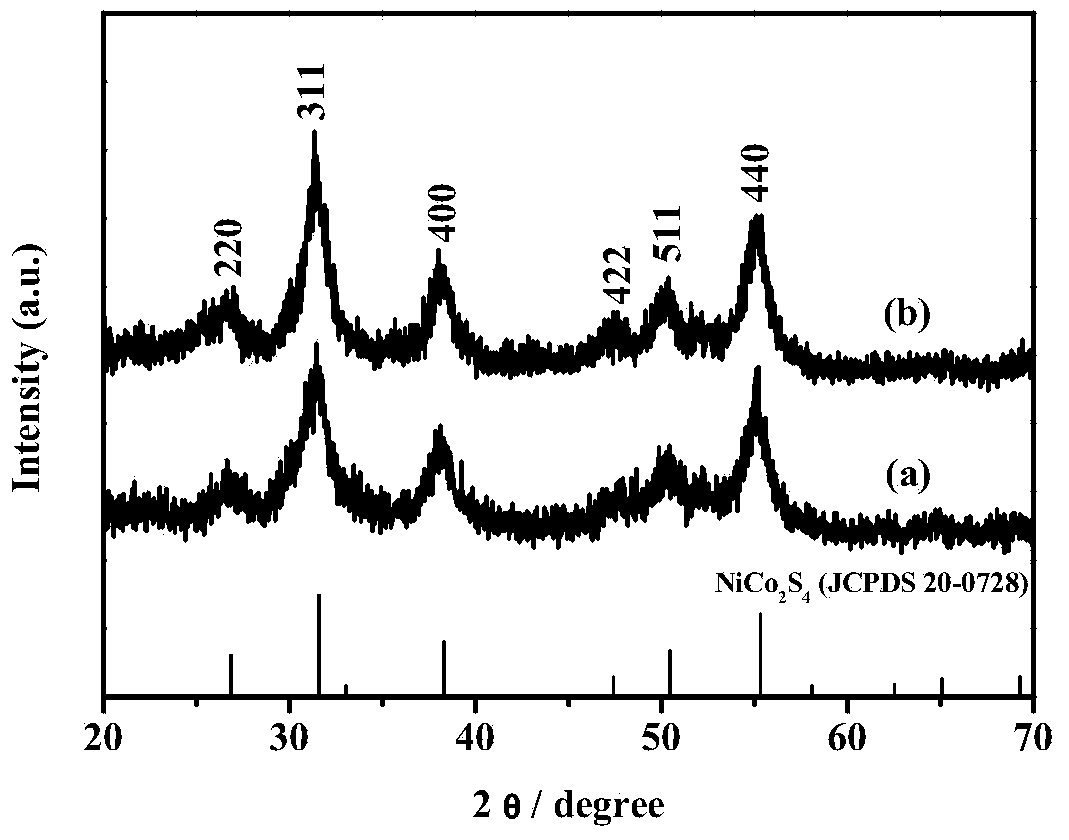

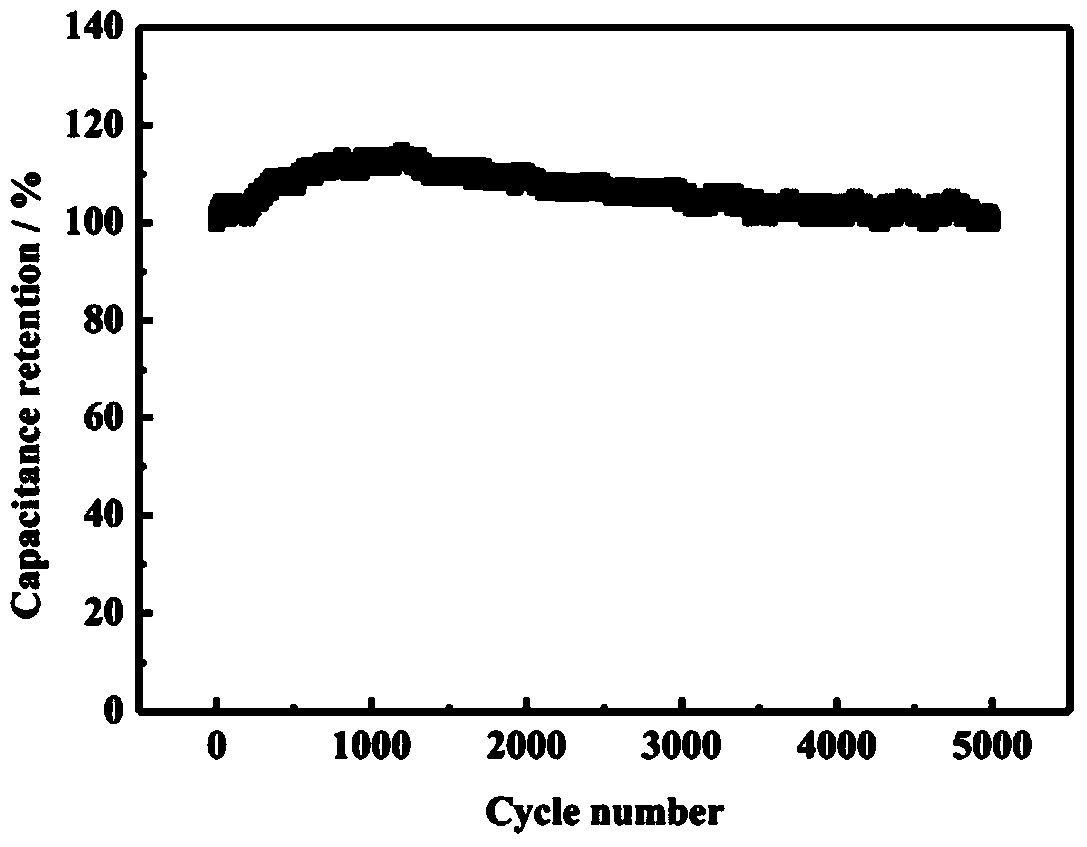

[0024] (1)NiCoS 4 Preparation of Nanomaterials

[0025] A Weigh the raw material Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O is dissolved in the mixed solvent of deionized water and ethylene glycol, and fully stirred, the Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 The mass ratio of O is 1:2. Then add 0.5mL CS with vigorous stirring 2 , continue stirring to dissolve to obtain a mixed solution.

[0026]B Transfer the mixed solution obtained above to a 100mL hydrothermal reaction kettle for hydrothermal reaction, the reaction temperature is 100-200°C, the reaction time is 6-48h, and naturally cool to room temperature after the reaction.

[0027] C. The product obtained above was separated with a centrifuge at a speed of 8000 rpm, washed several times with ethanol and deionized water respectively, and then dried at 60°C for 24 hours to obtain the product.

[0028] (2)NiCoS 4 Electrode preparation

[0029] The NiCoS obtained in step (1) 4 , acetylene black, and PVD...

Embodiment 2

[0035] (1)AC / NiCoS 4 Preparation of composite materials

[0036] A Weigh the raw material Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O is dissolved in the mixed solvent of deionized water and ethylene glycol, and fully stirred, the Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 The mass ratio of O is 1:2. Then add 0.02g AC to the above mixed solution, and then add 0.5mL CS under strong stirring 2 , continue stirring to dissolve to obtain a mixed solution.

[0037] B Transfer the mixed solution obtained above to a 100mL hydrothermal reaction kettle for hydrothermal reaction, the reaction temperature is 100-200°C, the reaction time is 6-48h, and naturally cool to room temperature after the reaction.

[0038] C. The product obtained above was separated with a centrifuge at a speed of 8000 rpm, washed several times with ethanol and deionized water respectively, and then dried at 60°C for 24 hours to obtain the product.

[0039] (2)AC / NiCoS 4 Electrode preparation

[004...

Embodiment 3

[0046] (1)CQDs / NiCoS 4 Preparation of composite materials

[0047] A Weigh the raw material Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O is dissolved in the mixed solvent of deionized water and ethylene glycol, and fully stirred, the Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 The mass ratio of O is 1:2. Then add 0.02g CQDs to the above mixed solution, and then add 0.5mL CS 2 , continue stirring to dissolve to obtain a mixed solution.

[0048] B Transfer the mixed solution obtained above to a 100mL hydrothermal reaction kettle for hydrothermal reaction, the reaction temperature is 100-200°C, the reaction time is 6-48h, and naturally cool to room temperature after the reaction.

[0049] C. The product obtained above was separated with a centrifuge at a speed of 8000 rpm, washed several times with ethanol and deionized water respectively, and then dried at 60°C for 24 hours to obtain the product.

[0050] (2)CQDs / NiCoS 4 Electrode preparation

[0051] The CQDs / NiCo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com