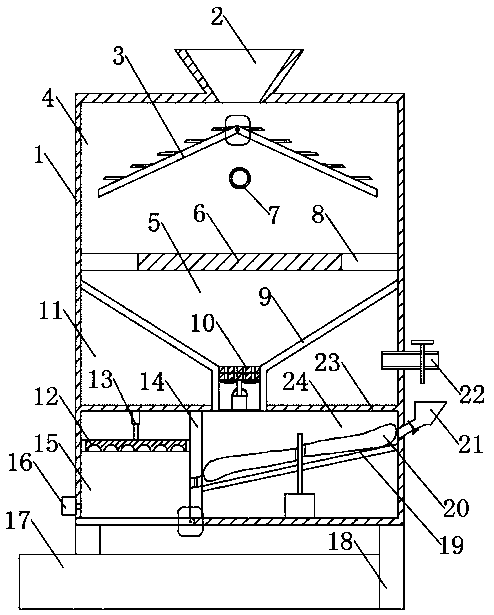

Red mud solid waste comprehensive treatment reduction duplex furnace and process

A comprehensive treatment and red mud technology, applied in furnaces, rotary drum furnaces, furnace types, etc., can solve problems such as unstable product quality, increased treatment costs, and large energy consumption, and achieve reduced transshipment times, strong functionality, and energy saving The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

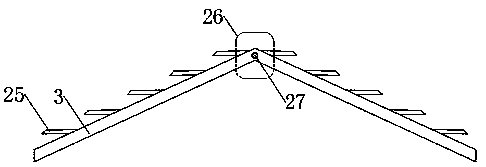

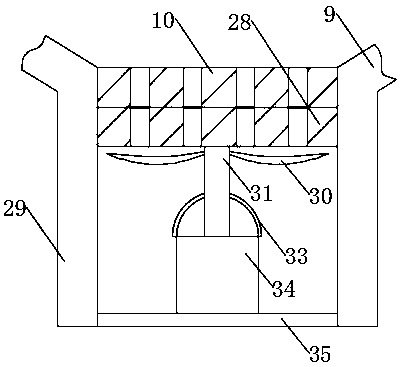

Method used

Image

Examples

Embodiment 1

[0047] The process of red mud solid waste comprehensive treatment and reduction dual furnace, the processing flow of this product includes the following steps:

[0048] Step 1: To prepare the red mud composite material, first add lime powder and granules to the red mud raw material for stirring to dilute the water in the red mud material, and then mix the red mud raw material, limestone and reducing agent according to the ratio of 10:1: 0.5 for mixing and mixing. The model of the reducing agent is HSCY / 100. The mixed charge is transported to the pre-reduction rotary kiln by a belt conveyor, heated to about 1100°C in the rotary kiln, and the mixed charge is pre-reduced to obtain red mud. Composite raw materials;

[0049] Step 2: Dry the red mud composite material, take the red mud, discharge the red mud composite material from the hopper into the upper surface of the drying plate, and dry it at a temperature of 180°C for 10 minutes;

[0050] Step 3: calcining the red mud compo...

Embodiment 2

[0059] The process of red mud solid waste comprehensive treatment and reduction dual furnace, the processing flow of this product includes the following steps:

[0060] Step 1: To prepare the red mud composite material, first add lime powder and granules to the red mud raw material for stirring to dilute the water in the red mud material, and then mix the red mud raw material, limestone and reducing agent according to the ratio of 10:1: 0.5 for mixing and mixing. The model of the reducing agent is HSCY / 100. The mixed charge is transported to the pre-reduction rotary kiln by a belt conveyor, heated to about 1100°C in the rotary kiln, and the mixed charge is pre-reduced to obtain red mud. Composite raw materials;

[0061] Step 2: Dry the red mud composite material, discharge the red mud composite material from the hopper into the upper surface of the drying plate, and dry it at a temperature of 182°C for 12 minutes;

[0062] Step 3: calcining the red mud composite material at a...

Embodiment 3

[0071] The process of red mud solid waste comprehensive treatment and reduction dual furnace, the processing flow of this product includes the following steps:

[0072]Step 1: To prepare the red mud composite material, first add lime powder and granules to the red mud raw material for stirring to dilute the water in the red mud material, and then mix the red mud raw material, limestone and reducing agent according to the ratio of 10:1: 0.5 for mixing and mixing. The model of the reducing agent is HSCY / 100. The mixed charge is transported to the pre-reduction rotary kiln by a belt conveyor, heated to about 1100°C in the rotary kiln, and the mixed charge is pre-reduced to obtain red mud. Composite raw materials;

[0073] Step 2: Dry the red mud composite material, take the red mud, discharge the red mud composite material from the hopper into the upper surface of the drying plate, and dry it at a temperature of 187°C for 18 minutes;

[0074] Step 3: calcining the red mud compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com