Green-ball concentrated screening equipment and process thereof

A technology for screening equipment and green balls, which is used in sieves, solids separation, grids, etc., can solve the problems of high operation and maintenance costs, increased drop of green balls, low green ball strength, etc., so as to improve equipment utilization, improve The effect of fabric uniformity and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

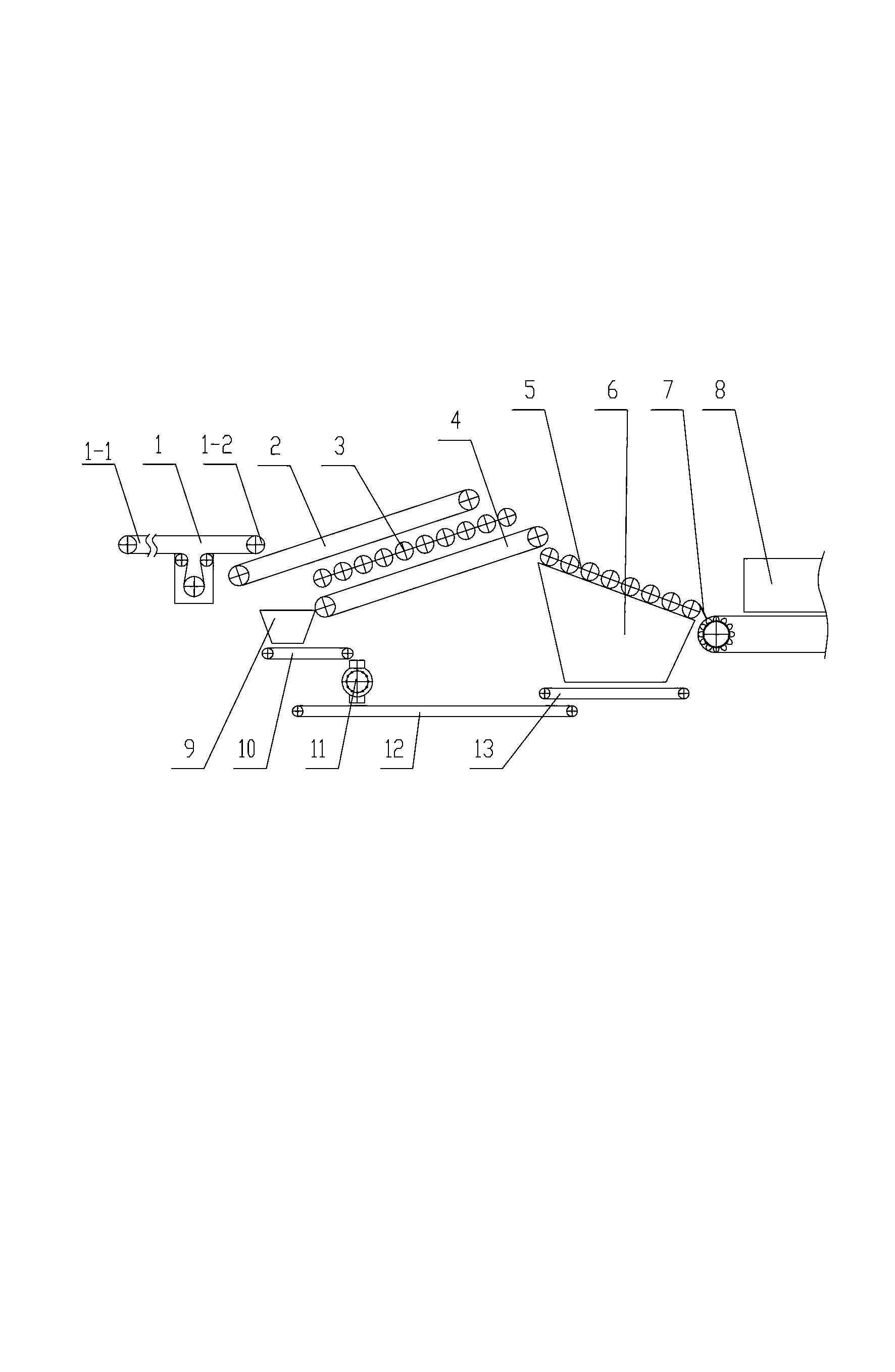

[0022] like figure 1 As shown, the green ball centralized screening equipment of the present invention is characterized in that it includes a green ball aggregate belt conveyor 1 with a feeding end 1-1 arranged in the pelletizing room and a discharging end 1-2 arranged in the chain grate machine room , the swing belt conveyor 2 connected with the discharge end 1-2 of the raw ball aggregate belt conveyor 1, the large ball roller screening machine 3 located below the swing belt conveyor 2, and the large ball roller The large ball chute 9 at the tail of the type screening machine 3, the large ball receiving belt conveyor 10 located below the large ball chute 9, the raw ball crusher located below the discharge end of the large ball receiving belt conveyor 10 11. The bulk material collection belt conveyor 12 located under the raw ball crusher,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com