High-strength non-evaporating brick and preparation method thereof

A steam-free brick, high-strength technology, applied in clay preparation devices, chemical instruments and methods, manufacturing tools, etc., can solve the problems of large batching and mixing workload, long hot water curing time, and lack of market competitiveness. Achieve the effect of low production cost, reduction of mining volume, and reduction of transshipment times

Inactive Publication Date: 2011-01-05

武汉钢铁有限公司

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The patent has a large amount of cementing material, and there are more than 10 kinds of raw materials in the whole formula. The actual production process is complicated, the workload of batching and mixing is large, and the hot water curing time is long, the production cost is high, and the market competitiveness is lacking.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Login to View More

Abstract

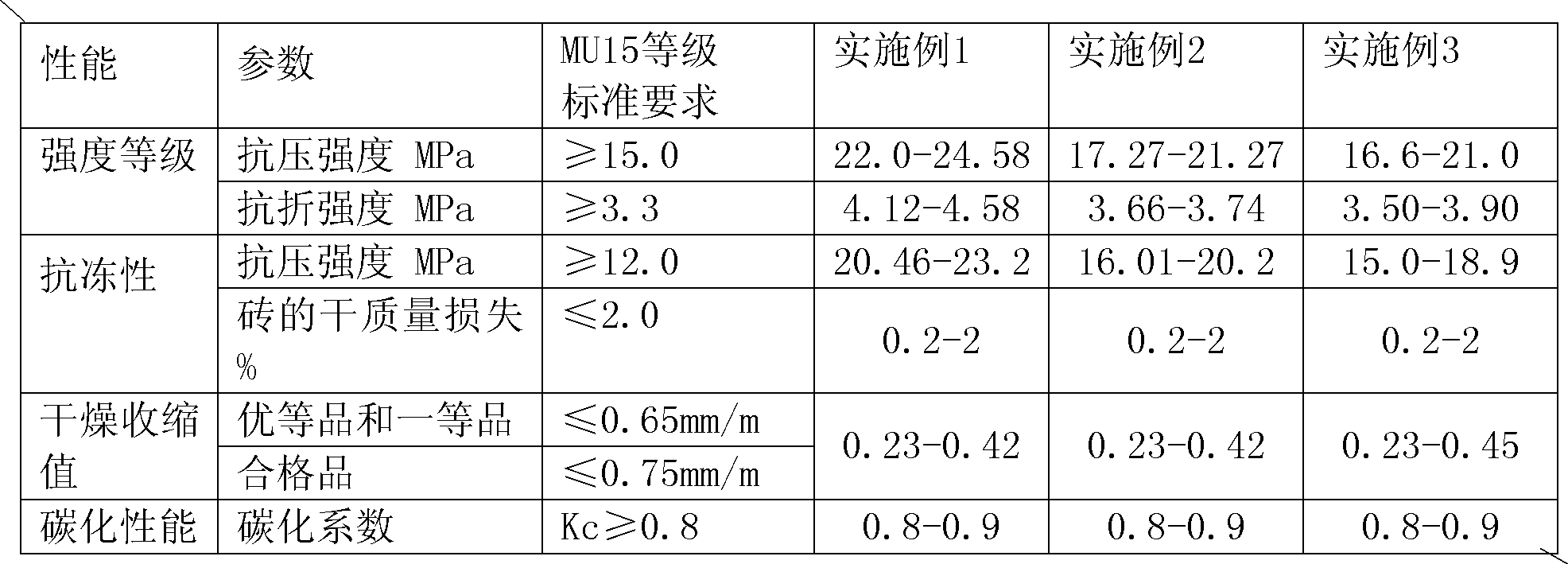

The invention discloses a high-strength non-evaporating brick and a preparation method thereof, belonging to the technical field of building materials. The non-evaporating brick comprises the following components in percentage by weight: 30-45 unground grain slag, 30-45 heavy slag, 10-20 fly ash, 2-5 industrial by-product gypsum, 1-5 activity excitant and 5-14 water. The preparation method of thehigh-strength non-evaporating brick is simple, has low production cost and produces non-evaporating bricks with strong frost-resistant performance, low drying shrinkage value and high strength over MU15.

Description

High-strength steam-free brick and preparation method thereof Technical field The invention belongs to the technical field of building materials. Background technique The new wall materials currently used in China are mainly concrete blocks, autoclaved fly ash bricks, autoclaved lime sand bricks, and aerated fly ash blocks. Non-burning bricks and non-steaming bricks have developed rapidly in recent years. Although their strength can reach MU10 or more, they have many problems with durability such as carbonization resistance, shrinkage resistance, and frost resistance. Questions from people in the Chinese brick and tile industry. In the current research reports and patented technologies of non-fired and non-steamed bricks, alkaline substances such as water glass, sodium hydroxide, and sodium sulfate are mainly added as activators to stimulate the hydration activity of slag and fly ash. For example, in the patent "Pure industrial waste residue-free and steam-free construction ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E04C1/00B28C5/00B28B3/00B28B11/24C04B28/14

Inventor 吴江红杨新亚李晖程刚甘万贵汪晖李灿华

Owner 武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com