Garbage transfer station with automatic compression function

A technology of garbage transfer station and function, which can be used in trash cans, garbage conveying, garbage collection, etc. It can solve the problems of reducing the volumetric efficiency of equipment, increasing the number of garbage transfers, and not having compressing garbage devices, so as to solve the problems of secondary pollution and volumetric efficiency. Low cost, lower waste transportation cost, and the effect of important promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

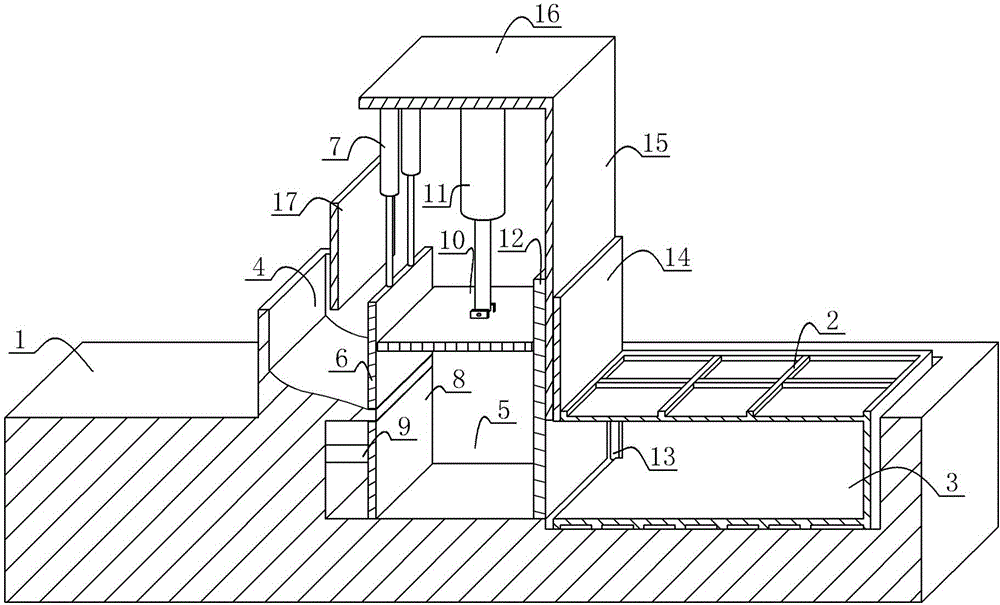

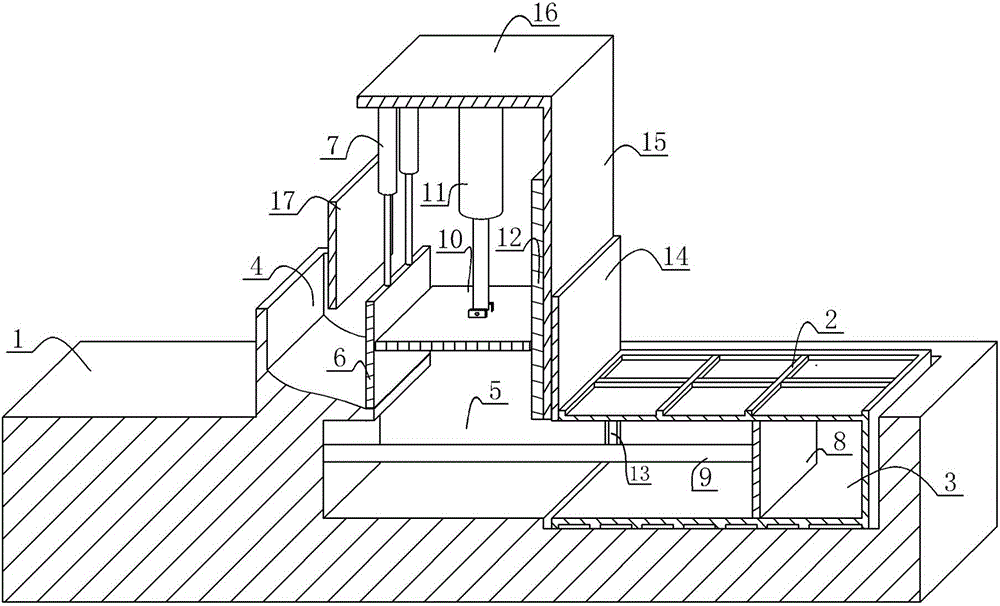

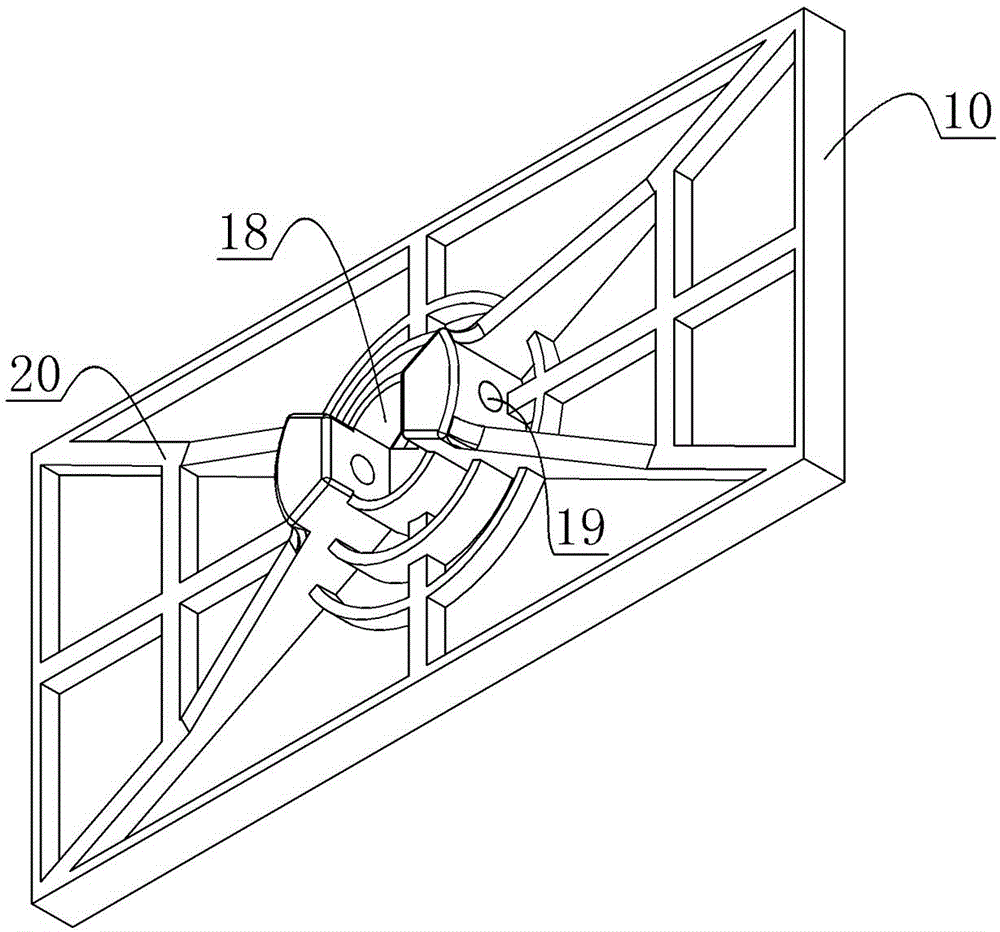

[0021] like figure 1 As shown, a schematic structural diagram of a garbage transfer station with automatic compression function is given, which includes a foundation 1, a garbage bin 2, a garbage dump trough 4, a compression chamber 5, an isolation plate 6, an isolation hydraulic cylinder 7, a horizontal push plate 8, Push in the hydraulic cylinder 9, compression plate 10, compression hydraulic cylinder 11, compression chamber cover 12, lift hydraulic cylinder 13, dustbin cover 14, vertical plate 15, horizontal plate 16 and shielding plate 17; Supporting function, carrying the entire garbage transfer station. The shown dustbin 2 is located below the upper plane of the foundation 1, and the interior is a garbage storage cavity 3. The left end of the dustbin 2 is open, and a dustbin cover 14 is arranged at the opening. The compression chamber 5 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com