Coal blending weighing screening and breaking system in gas film coal storage yard

A crushing system and gas-film coal pile technology, applied in membrane technology, gas treatment, separation methods, etc., can solve the problem of large dust in coal blending, achieve the effects of reducing dust, fast construction, and reducing the number of transfers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

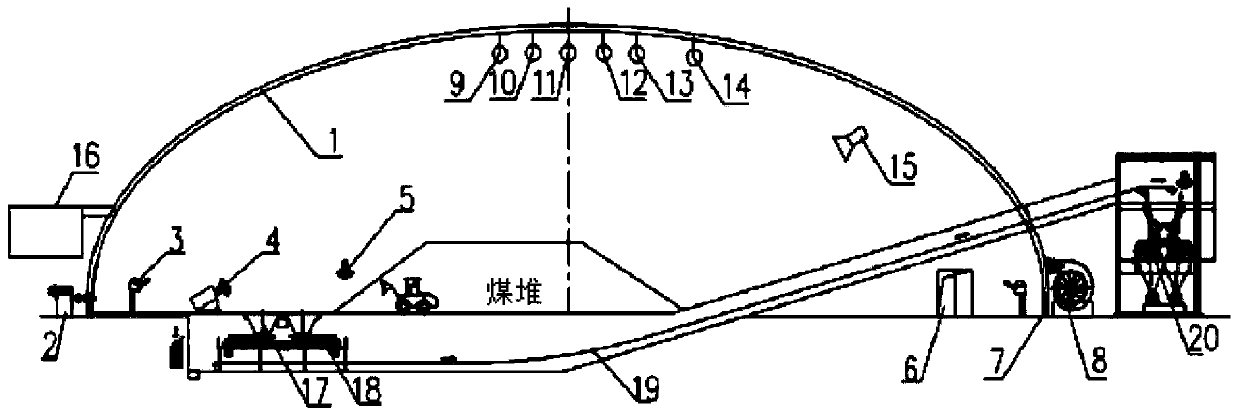

[0025] A coal blending weighing, screening and crushing system in a gas film coal storage yard includes a coal blending weighing, screening and crushing system and a gas film storage yard system surrounding the coal storage yard.

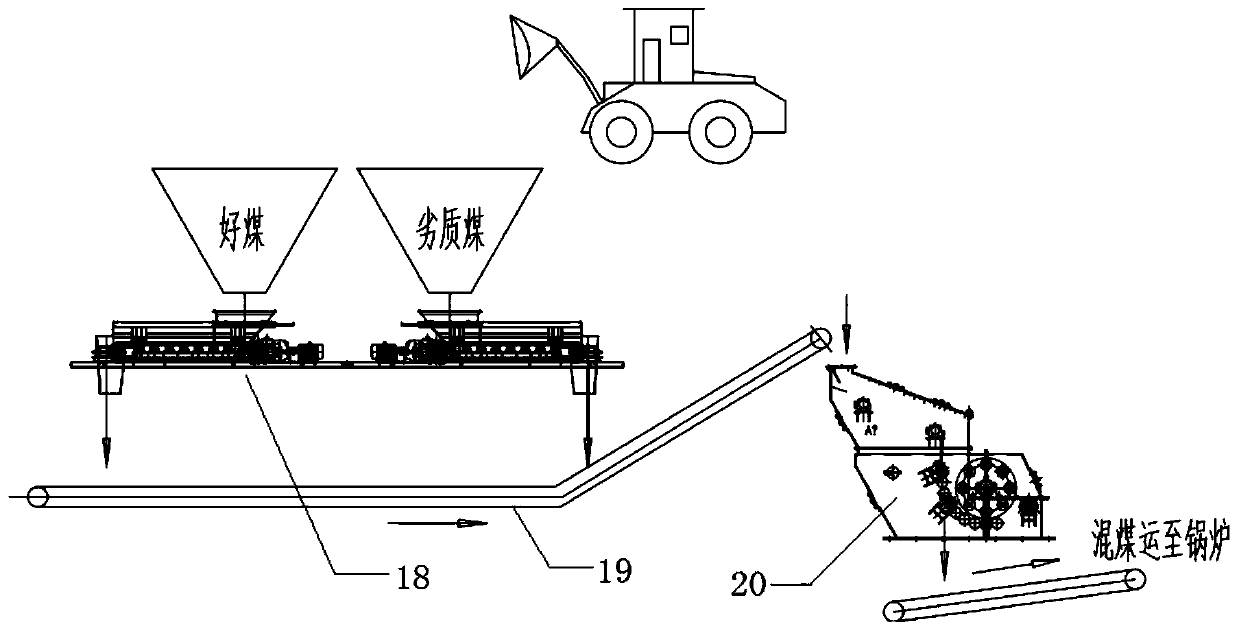

[0026] Such as Figure 1 ~ Figure 2 As shown, the coal blending weighing, screening and crushing system includes two weighing coal feeders 18 and one screening and crushing integrated machine 20. The screening and crushing integrated machine 20 is located outside the gas film yard system, and the weighing coal feeder 18 and the integrated screening and crushing machine 20 are connected by a belt conveyor 19. Specifically, the weighing coal feeder 18 has a coal drop hopper 17, and the weighing coal feeder 18 is grouped for weighing good coal and poor quality coal. As an existing technology, the weighing coal feeder 18 can transmit weighing data to the central control room in real time, and on the other hand, the coal feed rate of the weighing coal feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com