Patents

Literature

179 results about "Coal stockpile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

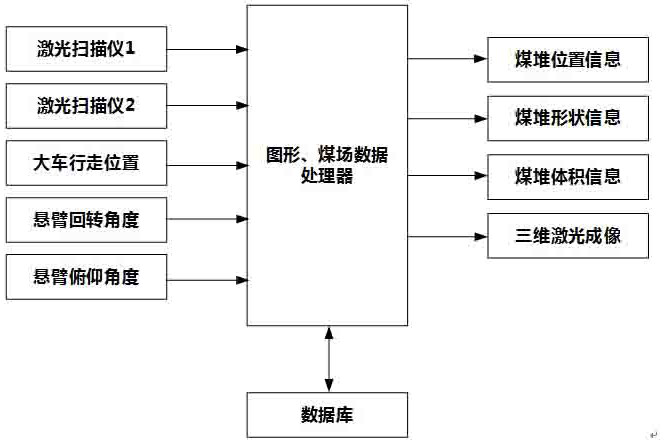

Coal-fired power plant coal yard refined management system and control method thereof

ActiveCN103455901AFast and accurate deliveryAccurate accessSystems intergating technologiesLogisticsInformatizationData acquisition

The invention relates to a coal-fired power plant coal yard refined management system and a control method of the coal-fired power plant coal yard refined management system. The coal-fired power plant coal yard refined management system is characterized by comprising a laser disc coal instrument, an intelligent temperature monitoring meter, a metering device, a stacker-reclaimer, a data acquisition unit, a controller, a data server, an application server and a computer client side. The application server comprises a coal database management module, a real-time stock management module, a coal storage management module and a heat loss evaluation and control module. The control method is characterized by including the following steps that coal pile outline data points and digital signs in a coal yard field are acquired according to the laser disc coal instrument, and three-dimensional reconstruction of coal piles is completed based on a VC++ and OpenGL platform; when coal is transported to a factory, information is input to the coal database management module through an input port in the computer client side. According to the coal-fired power plant coal yard refined management system and the control method, the informatization and intelligentization method is adopted, information is quickly and accurately transmitted, and coal heat loss is reduced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

A kind of environment-friendly degradable dust suppressant and preparation method thereof

InactiveCN102277135ANo toxicityNot corrosiveOther chemical processesChemistryEnvironmental resistance

The invention discloses an environmentally friendly biodegradable dust suppressant and a preparation method thereof. The preparation method comprises adding natural latex, natural plant fibers, glycerol and a surfactant into a mixer, stirring fully to mix them well, adding slowly the mixture into water, and stirring fully to obtain the environmentally friendly degradable dust suppressant. The environmentally friendly biodegradable dust suppressant has the functions of film forming, wetting and coagulation, and characteristics of no ash, no toxicity, no corrosivity, no secondary pollution, favorable biodegradability, simple preparation process, and low cost. After being sprayed on the surface of a material, the environmentally friendly biodegradable dust suppressant can form a continuous, intact, strong and ductile shell film to confine dust in a shell, and thus air pollution is avoided and material loss is reduced. The environmentally friendly biodegradable dust suppressant can resist the effects of wind power, rainwater and a general external force, is suitable for dust control of road surfaces, coal piles, ore piles, building sites, heat-engine plants, steel mills and coal transportation by trains, and has broad social and economic benefits.

Owner:宁岱

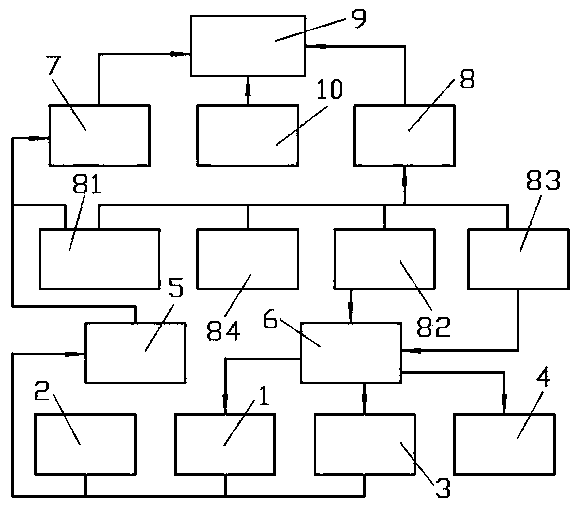

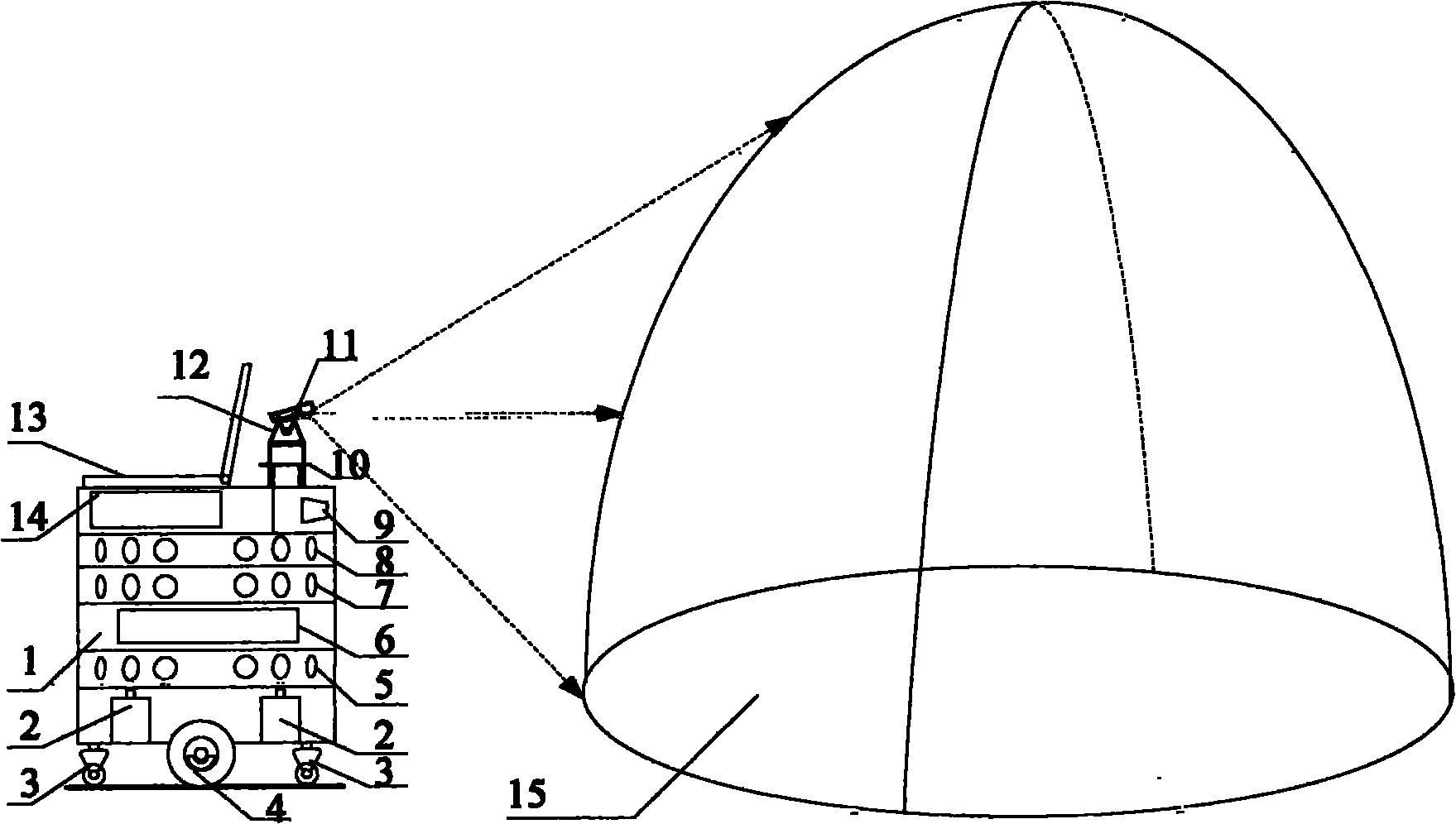

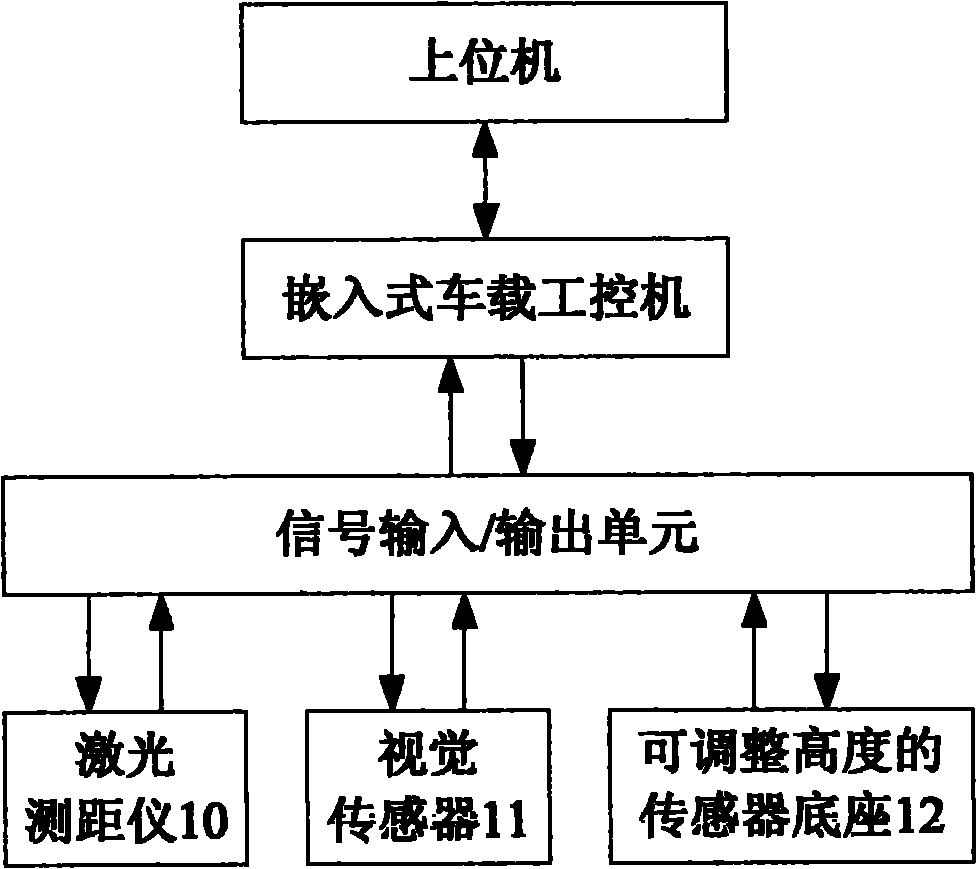

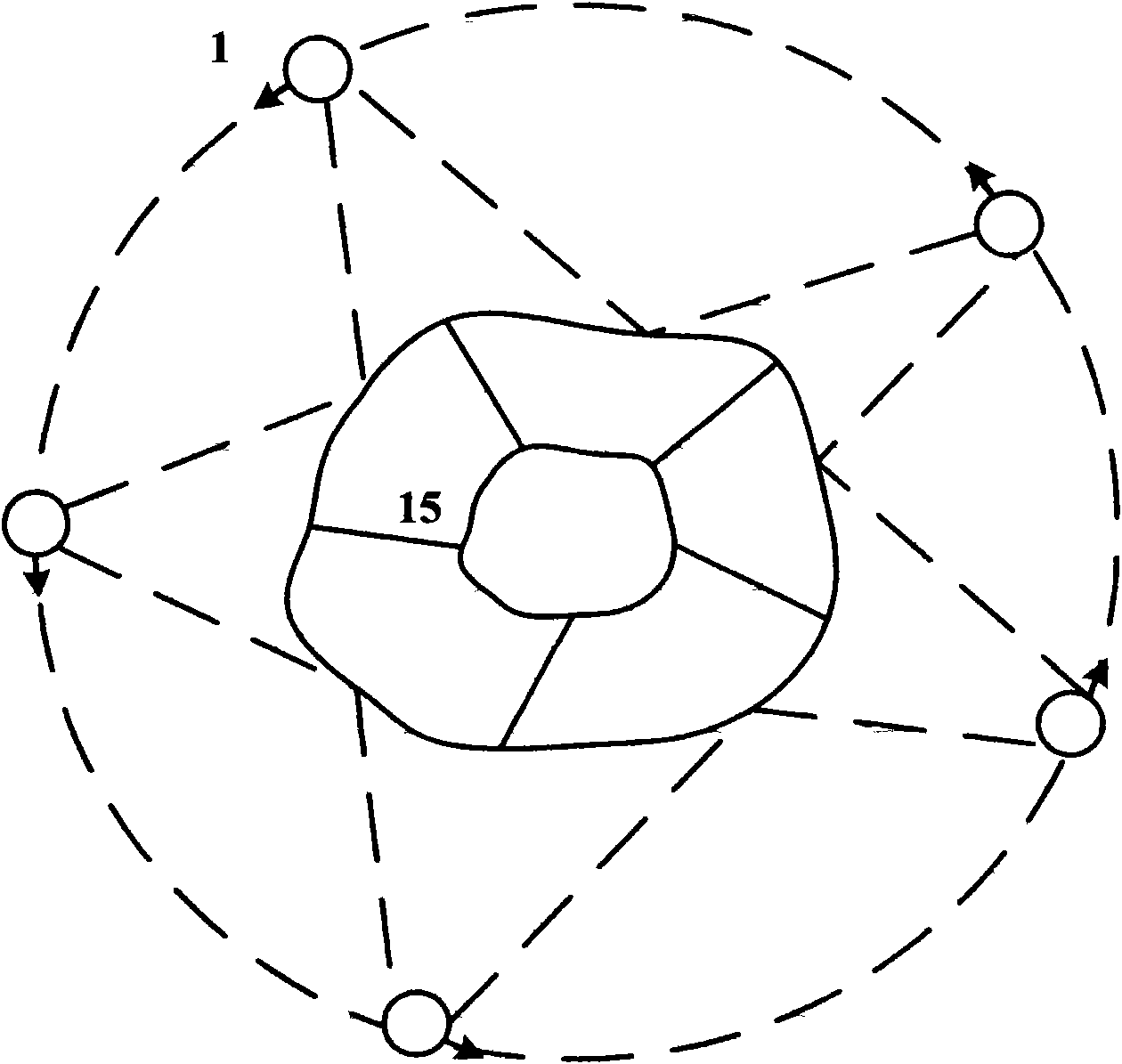

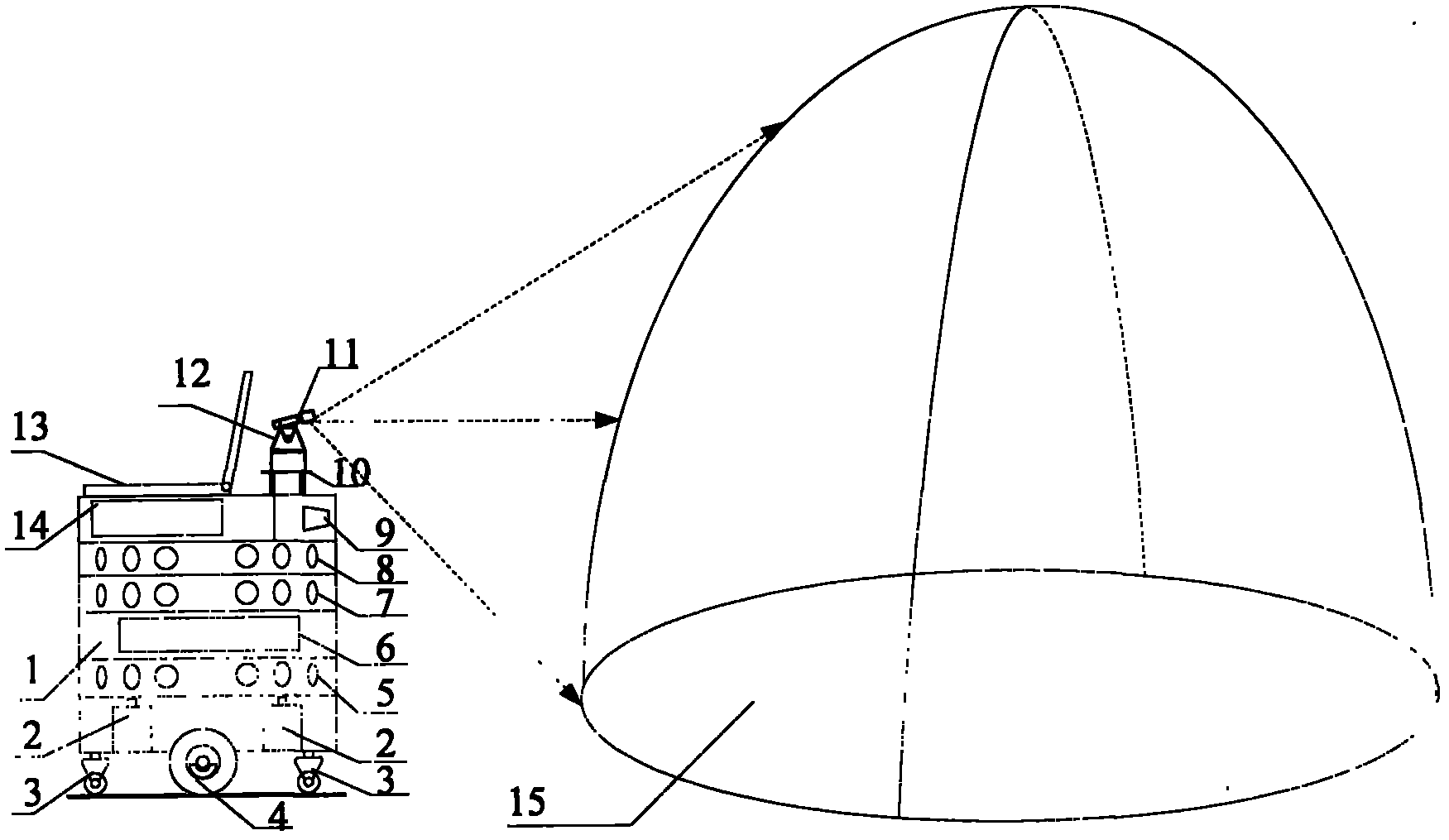

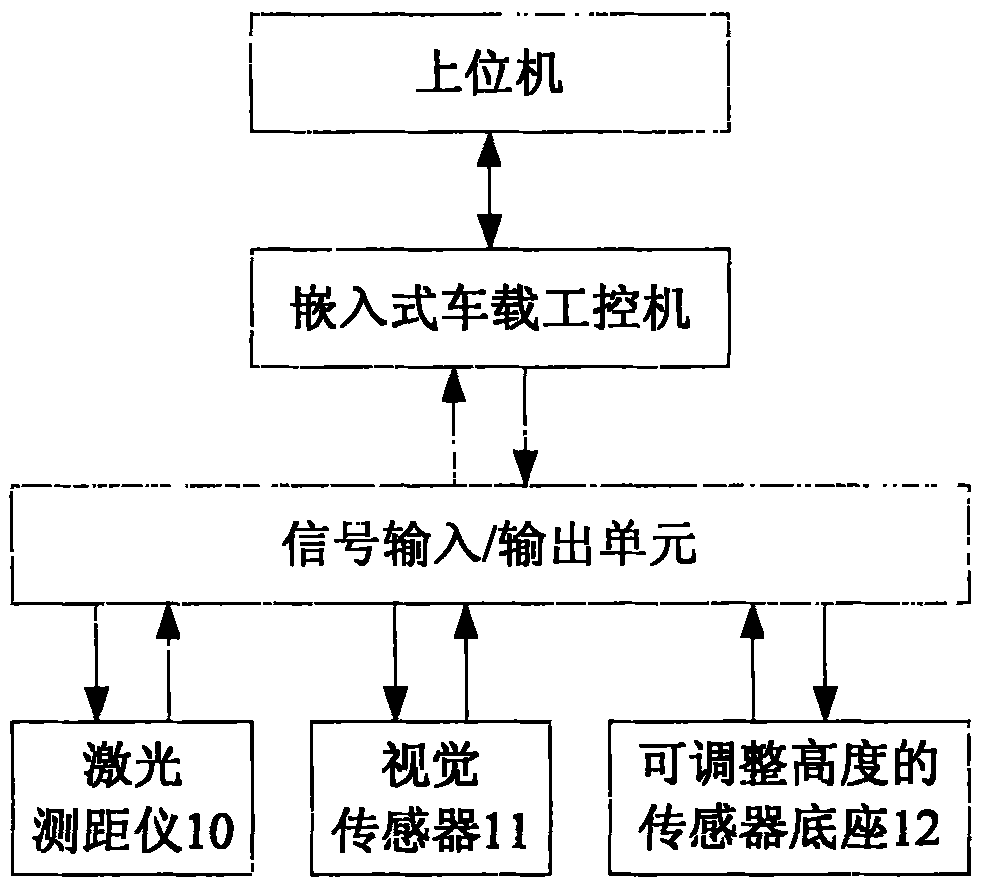

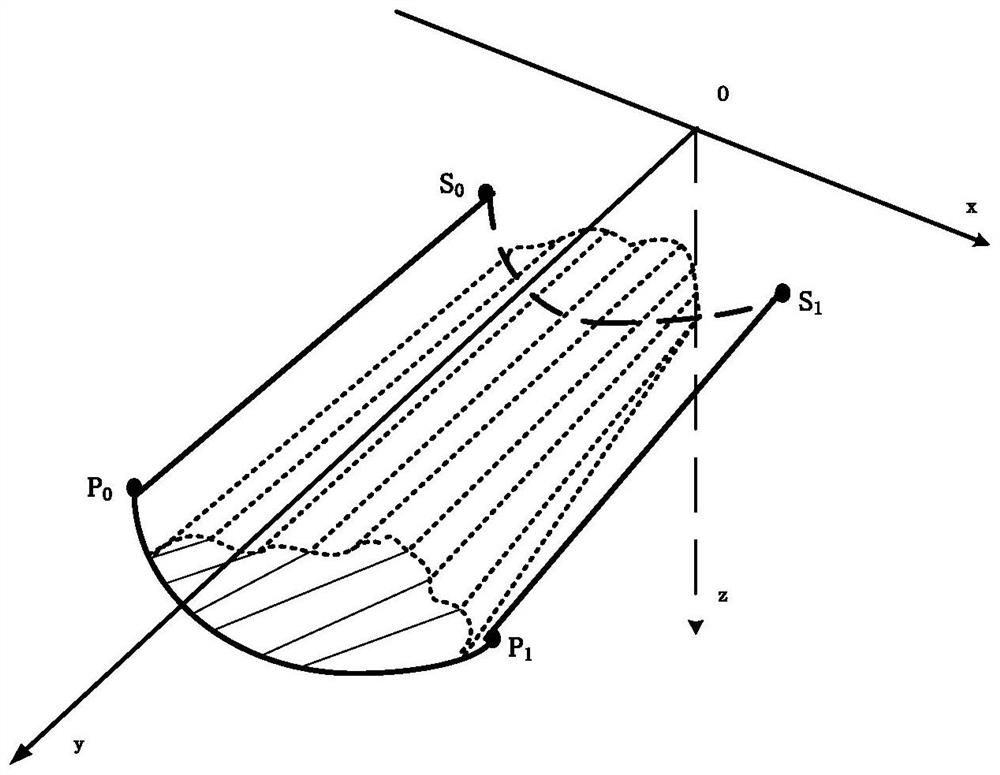

Automatic coal pile volume measurement method and special device

The invention provides an automatic coal pile volume measurement method and an automatic coal pile volume measurement device. The method comprises the following steps: 1, setting a plurality of markers on a coal pile; 2, cruising the coal pile by a cruising car, wherein while moving, the cruising car scans every marker, a laser range finder on the cruising car acquires the distances S from the cruising car to the markers and pitch rotation angles Phi, a GPS sensor arranged on the cruising car provides a current horizontal rotation angle beta, the distance from the laser range finder to the ground is H, and the spatial coordinate of each marker can be obtained; processing the acquired spatial coordinates of all markers to form a three-dimensional figure of the coal pile; and calculating the volume of the coal pile according to the three-dimensional figure of the coal pile. The method and the special device can accurately measure the volume of the coal pile and are easy to implement.

Owner:长沙友欣仪器制造有限公司

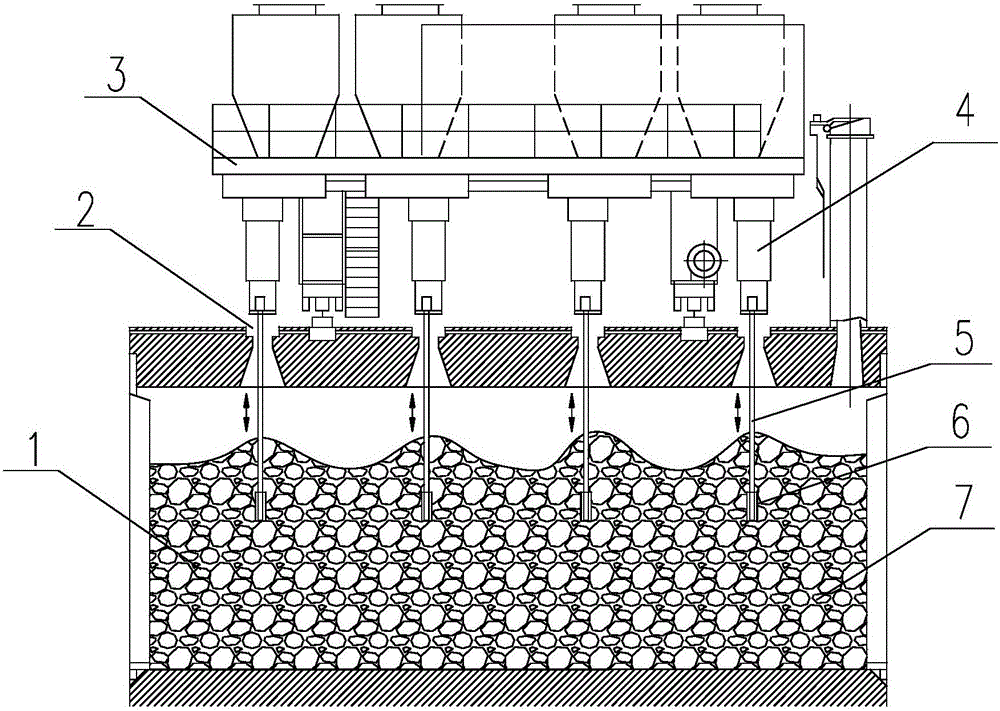

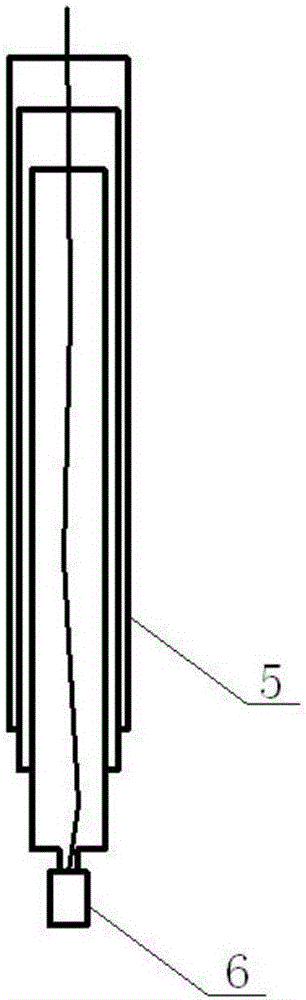

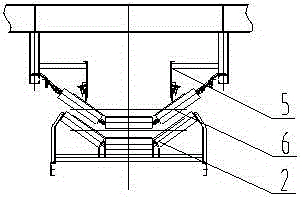

Method and device for increasing bulk density of coal charged into top-charging coke oven

InactiveCN105713623AIncrease the amount of coal loaded in a single holeHigh densityCoal charges mechanical treatmentCoke ovenHigh frequency vibration

The invention relates to a method and a device for increasing the coal charging bulk density of a top-loading coke oven. A plurality of coal charging ports are arranged on the top of the top-loading coke oven, and a coal charging car is used to simultaneously charge coal at the multiple coal charging ports; the coal charging car The coal lowering device is equipped with a telescopic vibration compacting device. When coal is loaded, the vibrating head at the bottom of the telescopic vibration compacting device extends into the position of 1 / 3~2 / 3 of the coal charging height of the coke oven carbonization chamber. Vibration compacts the surrounding coal material; while coal is being loaded, the vibrating head is lifted synchronously with the rise of the coal loading height. After the coal loading is completed, the vibrating head of the telescopic vibration compacting device continues to lift while vibrating, and reaches the top of the coal material Stop the vibration and retract until the stretchable vibrating compact device is withdrawn from the carbonization chamber as a whole. The invention can vibrate and compact the coal charged into the coking chamber of the coke oven, increase the bulk density of the coal charged into the furnace, increase the coal loading and coke output of the single-hole coke oven, and improve the quality of the coke.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Method and device for automatically measuring coal pile volume based on image and laser

InactiveCN102155913AAvoid errorsHigh measurement accuracyUsing optical meansLaser rangingThermodynamics

The invention provides a method and a special device for automatically measuring coal pile volume. The method comprises the steps of: firstly, disposing a plurality of markers on a coal pile; secondly, cruising the coal pile a circle by a cruising car, wherein while moving, the cruising car scans every marker, a laser range finder on the cruising car acquires the distances S from the cruising car to the markers and pitch rotation angles Phi, a GPS (global positioning system) sensor arranged on the cruising car provides a current horizontal rotation angle beta, the distance from the laser range finder to the ground is H, and the spatial coordinate of one marker can be obtained; processing the acquired spatial coordinates of all markers to form a three-dimensional figure of the coal pile; and calculating the volume of the coal pile according to the three-dimensional figure of the coal pile. The method and the special device can accurately measure the volume of the coal pile and are easy to implement.

Owner:湖南新航程智能测控技术有限公司

Modified gelatin dust suppressant and preparation method thereof

A modified gelatin dust suppressant and a preparation method thereof relate to a dust suppressant and a preparation method thereof; the dust suppressant comprises the following raw materials by weight percent: 2%-10% of industrial gelatin, 60-99% of water, 2%-10% of inorganic acid, 0-10% of surfactant, 0-10% of crosslinking agent, 0.01%-5% of sodium hydroxide and 0-5% of emulsifier. The preparation method comprises the following steps: adopting inorganic acid to degrade industrial gelatin at 20-80 DEG C for 2-15h, then using sodium hydroxide to neutralize the product and obtaining the finished product. According to different dust compositions and properties in different places, the degraded gelatin is used for wetting and penetrating tests and surfactant is added to increase the wetting and penetrating effect to different dusts. The dust suppressant of the invention is applicable to road surfaces, parks, construction site, scattered stock ground, mineral fields, coal dumps, ports and other operational areas which are easy to generate dust; after being dissolved in water and sprayed out, the dust suppressant can increase the coagulation of dust and inhibit the dispersion and movement of dust particles.

Owner:SHENYANG JIANZHU UNIVERSITY

Method for suppression and prevention of coal fires

The present invention relates to a method of inhibiting coal oxidation in a coal pile which includes coating all the surfaces of coal exposed to air with an oxidation inhibiting amount of a composition comprising (a) a water soluble cationic polymer and (b) a wetting agent selected from an anionic or nonionic surfactant, or mixtures thereof.

Owner:GENERAL ELECTRIC CO

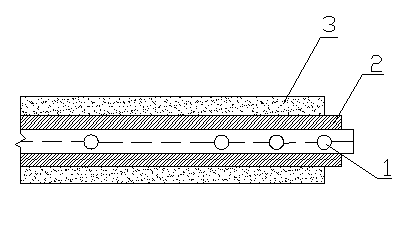

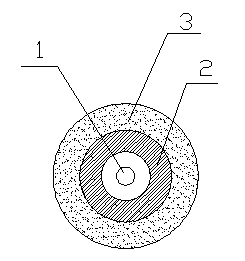

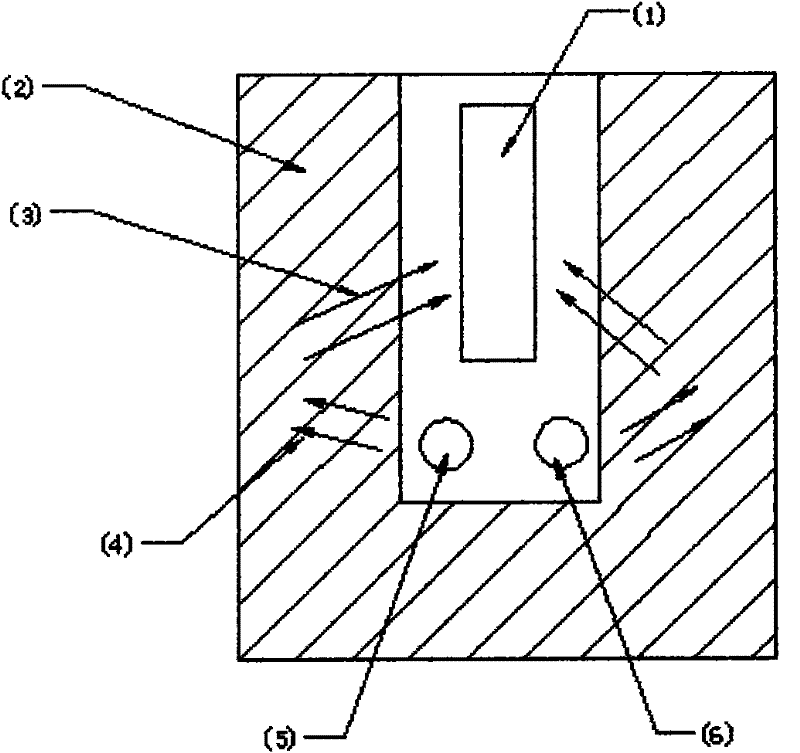

Coal bed multipoint temperature measuring cable-tray sensor

InactiveCN103105247AExtended service lifePracticalThermometer applicationsCarbon nanotubeEngineering

The invention relates to a coal bed multipoint temperature measuring cable-tray sensor which is used for coal pile temperature measuring. The coal bed multipoint temperature measuring cable-tray sensor comprises a temperature measurement component 1, an inner sheath 2 and an outer sheath 3. The inner sheath 2 is made of teflon materials and is coated on the periphery of the temperature measurement component 1. The outer sheath 3 is made of carbon nanotube composite materials and is coated on the periphery of the inner sheath 2. A temperature measurement range of the temperature measurement component 1 is selected according to needs, but the range is not limited to a bus type temperature measurement component and a digital temperature measurement component. When being applied, the coal bed multipoint temperature measuring cable-tray sensor is paved according to the shape and the characteristics of the coal pile, the sensor can be vertically inserted into the coal pile, or horizontally paved on the bottom of the coal pile, or surrounded around the coal pile, and thus the mode for paving is flexible and convenient. The coal bed multipoint temperature measuring cable-tray sensor has the advantages of being high temperature resistant, impact resistant, pulling resistant and high in abrasion resistance. The defects of being bad in abrasive resistance by being influenced by coal media in the prior art, and short in service life are overcome.

Owner:徐州中矿奥特麦科技有限公司

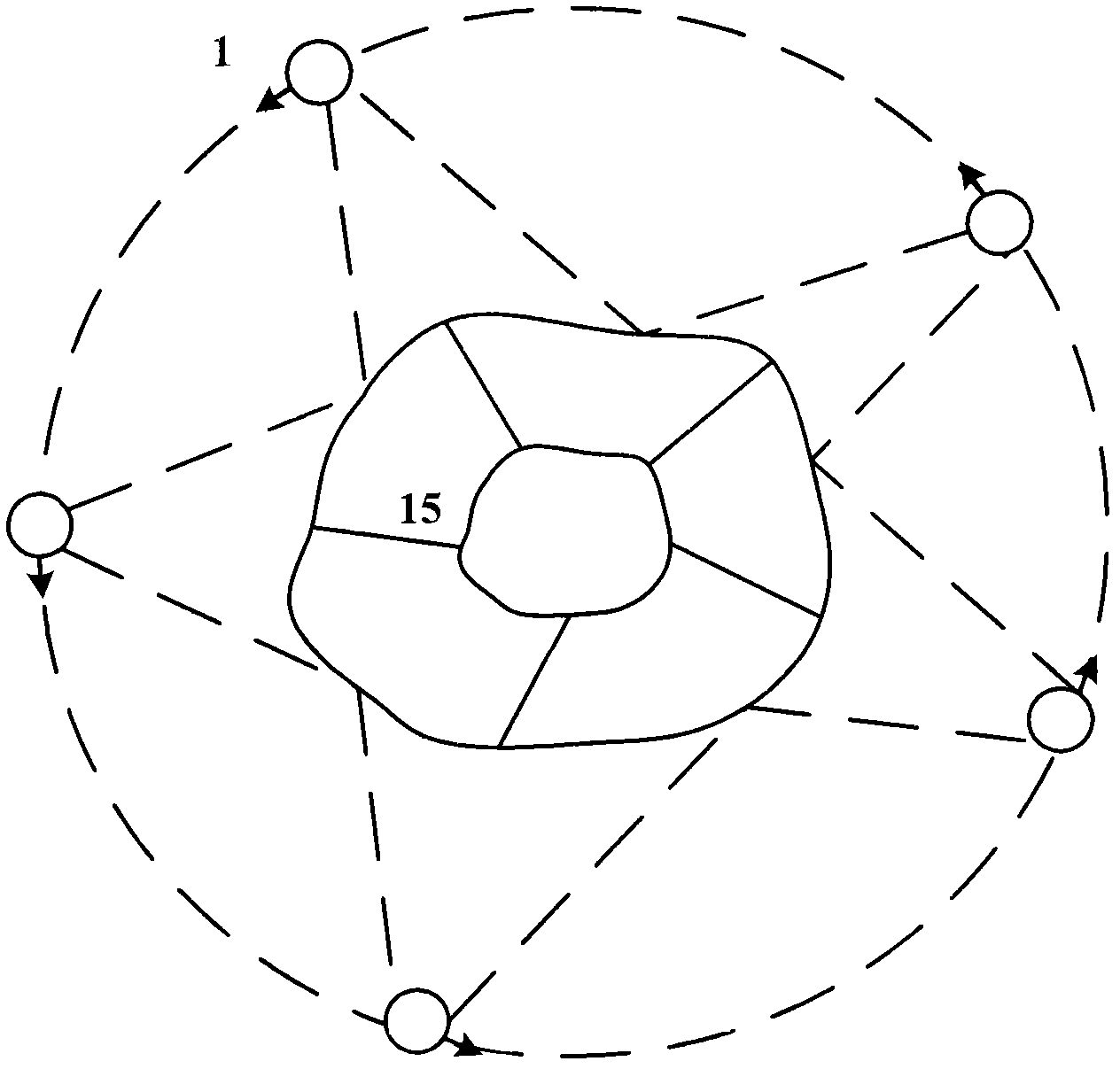

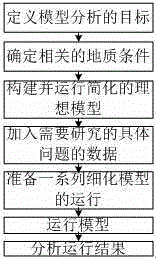

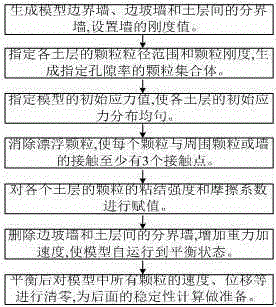

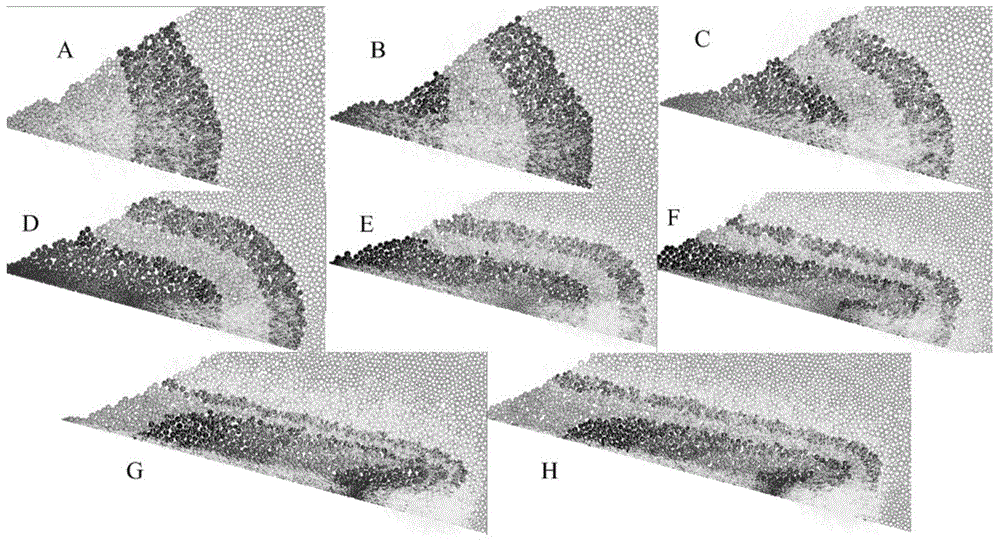

Method for simulating spontaneous combustion of coal stacks

InactiveCN104634815AResolve continuityIncrease computational costMaterial heat developmentThermodynamicsPetroleum engineering

The invention discloses a method for simulating the spontaneous combustion of coal stacks. The method is characterized by comprising the following steps: based on the particle characteristics of the coal stacks, establishing a coal stack spontaneous combustion model by using PFC3D as a simulation, and simulating the spontaneous combustion oxidiation of the coal stacks and the temperature field change and energy migration during the process by using a thermal coupling model; simulating the flowing of oxygen and reaction of the oxygen and coal by using small particles, and achieving the process through FISH. The method comprises the following steps: establishing a coal stack model and an oxygen flowing model, and analyzing a temperature field and a flow field. The method can be used for analyzing the spontaneous combustion process of the certain scale coal stacks.

Owner:LIAONING TECHNICAL UNIVERSITY

Experimental device for testing effect of foam collosol on inhibiting dust

InactiveCN104198377ASuppress critical wind speed valueSuppression of dust suppression effectUsing mechanical meansMaterial analysisBulk cargoThermodynamics

An experimental device for testing an effect of foam collosol on inhibiting dust mainly comprises an air supply part, a sample experiment pipe part and a test part. The air supply part comprises a stepless speed change fan and a reducing right-angle elbow pipe. The sample experiment pipe part comprises an experiment pipe, a quick connection valve, a slot and a sampling plate. The test part comprises an anemograph, a test pipe, a DS-FC handheld intelligent dust tester and a dust concentration measuring port. The device can be used for quantitatively testing a critical wind speed value of the foam collosol for inhibiting the dust, so that a quantitative evaluation actual measurement instrument is provided for further researching and developing a new formula of the higher-efficiency foam collosol. The device can be further applied to quantitative test of the dust inhibition effect of a surface cohesive material for inhibiting bulk cargos. With the application of the device, a novel quantitative test and analysis method is provided for researching and developing technologies for inhibiting raised dust of coal piles and port bulk cargos, and the device has very wide application prospects in the research and development field.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

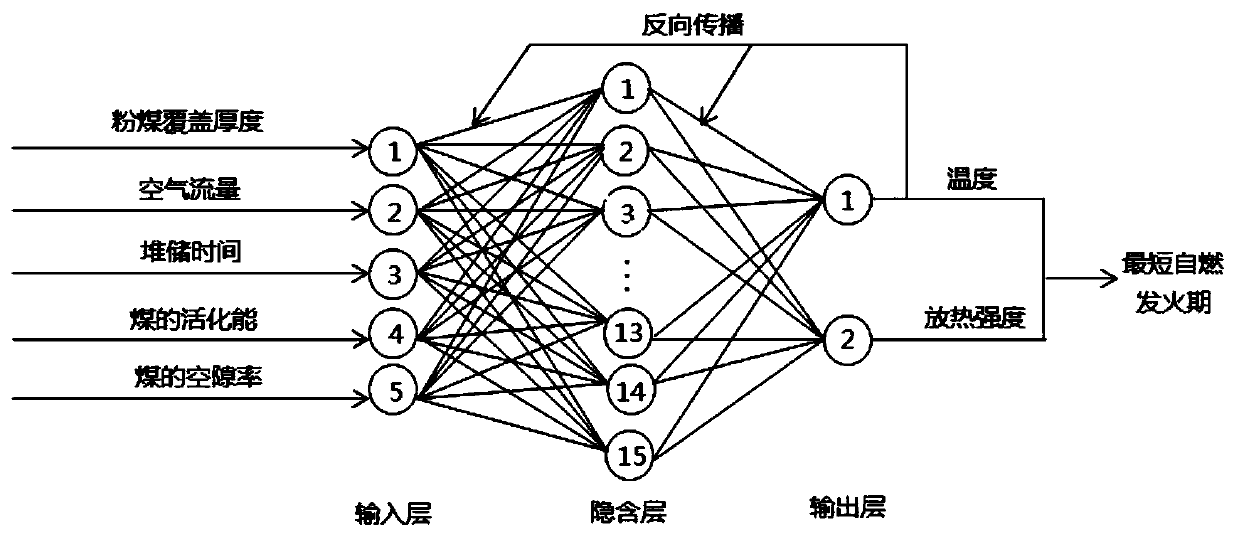

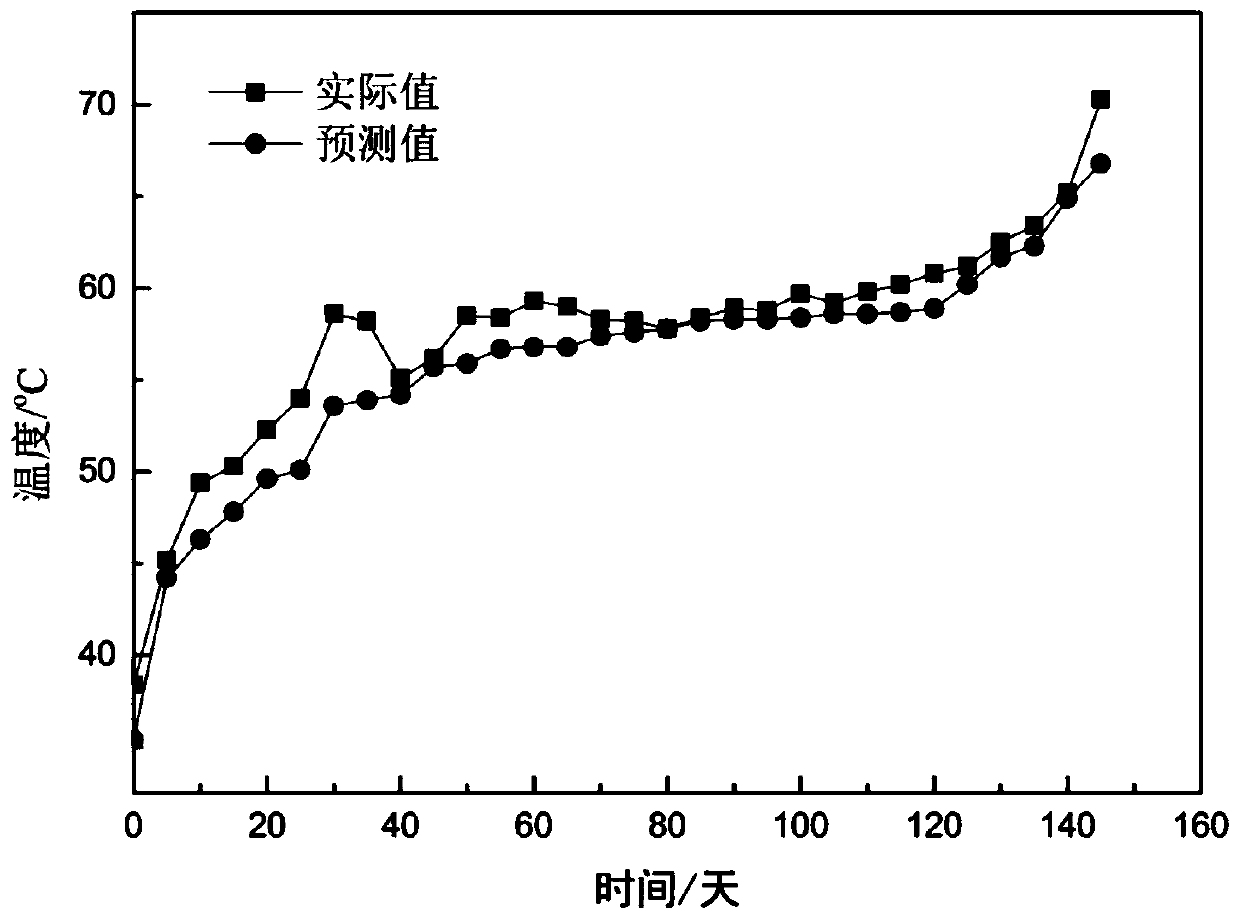

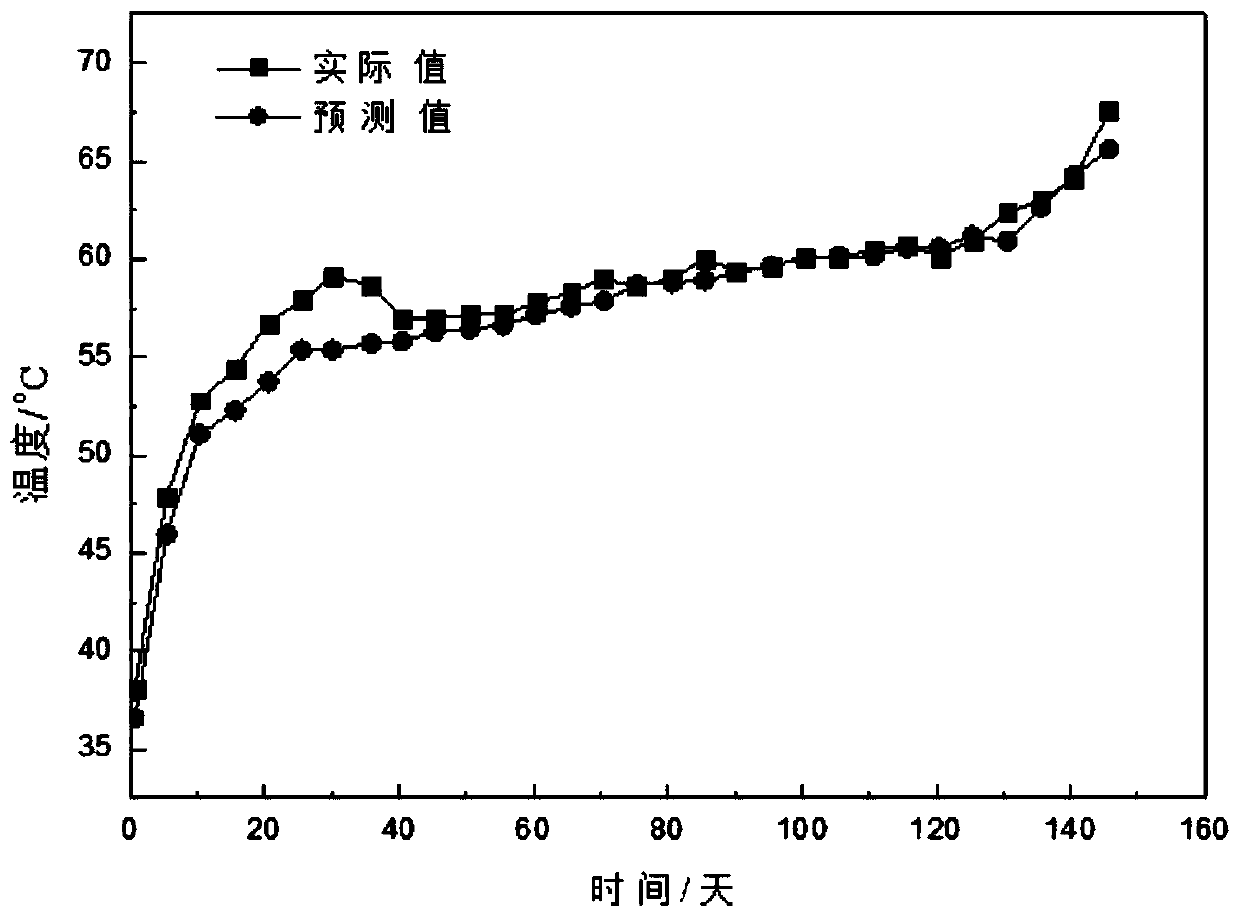

Method for predicting pulverized coal covered coal pile safe stacking and storing time by using neural network

ActiveCN111027257ASpontaneous combustion in advanceRespond in advance to the spontaneous combustion periodMaterial heat developmentFuel testingSimulationNetwork model

The invention discloses a method for predicting pulverized coal covered coal pile safe stacking and storing time by using a neural network. The method comprises the steps of firstly, obtaining factorsrelated to the safety dump time through investigation, analysis and identification; setting the pulverized coal covering thickness, the air flow, the stacking and storing time, the coal activation energy and the coal pile void ratio as influence factors of the coal pile safe stacking and storing time; taking the heat release intensity and the temperature as indexes for judging the spontaneous combustion tendency of the coal pile, constructing a neural network model, setting a minimum mean square error for training to obtain a BP neural network model for predicting the temperature and the heatrelease intensity through influence factors such as stacking time, and calculating the shortest spontaneous combustion period of the coal pile according to the BP neural network model. The method hasthe advantages of being simple, accurate, wide in application range and the like.

Owner:CHINA UNIV OF MINING & TECH

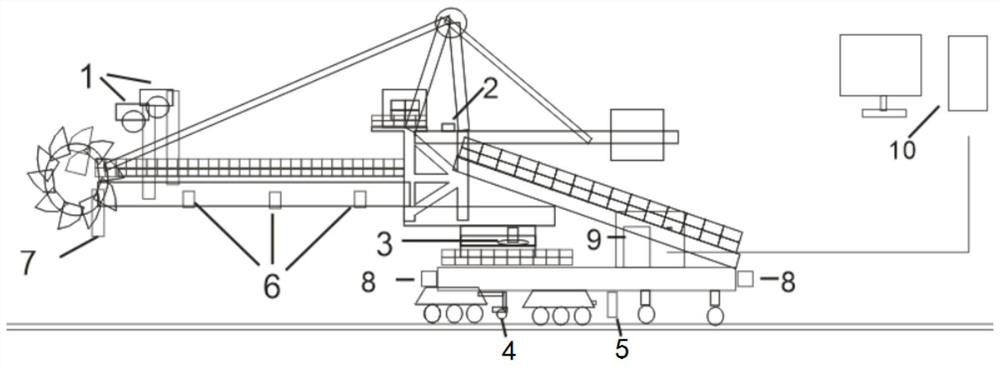

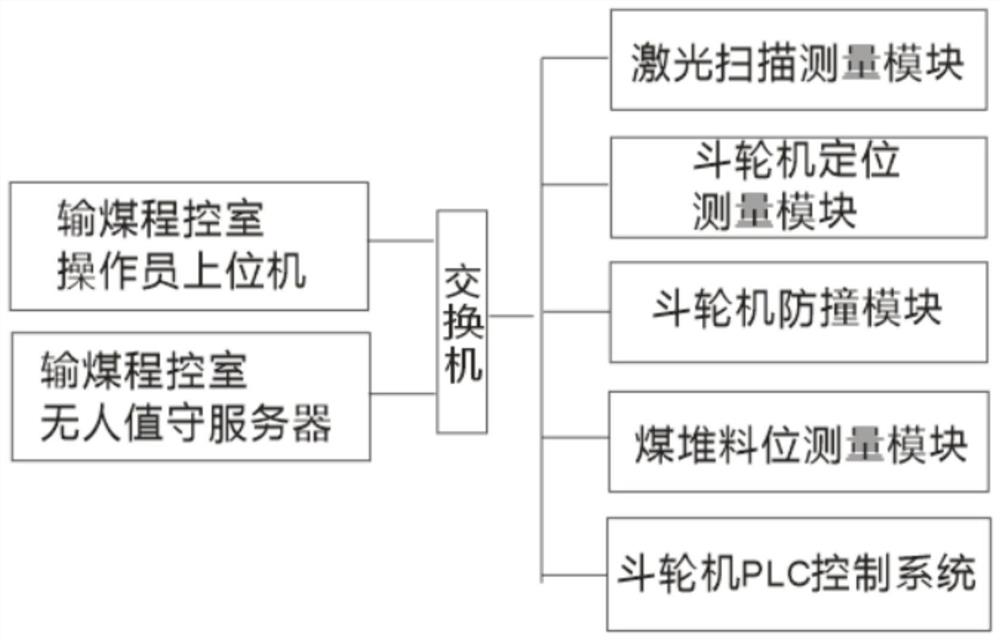

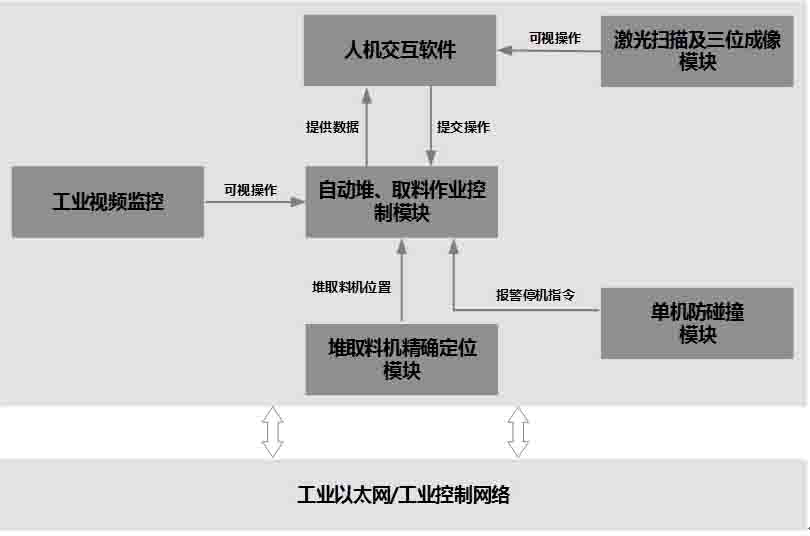

Unmanned operation system for material stacking and taking of bucket wheel machine

InactiveCN112110220AImprove efficiencyRealize unattendedConveyorsMachines/enginesAutomatic controlControl engineering

The invention provides an unmanned operation system for material stacking and taking of a bucket wheel machine. The unmanned operation system comprises a bucket wheel machine positioning mechanism with a correction function, a coal pile contour laser scanning and measuring mechanism and a bucket wheel machine safety anti-collision mechanism; the bucket wheel machine positioning mechanism with thecorrection function is connected with a bucket wheel machine pitching mechanism and a bucket wheel machine vehicle body; the coal pile contour laser scanning and measuring mechanism is connected witha bucket wheel machine cantilever; and the bucket wheel machine safety anti-collision mechanism is arranged on the bucket wheel machine cantilever and the bucket wheel machine vehicle body. Accordingto the unmanned operation system, the coal pile contour can be scanned in real time to realize real-time updating of a coal pile model, interference data can be effectively screened out, interferenceof field interference factors on a material taking strategy is eliminated, and thus real unmanned operation and free switching between manual control and automatic control are realized.

Owner:CHINA DATANG TECH & ENG

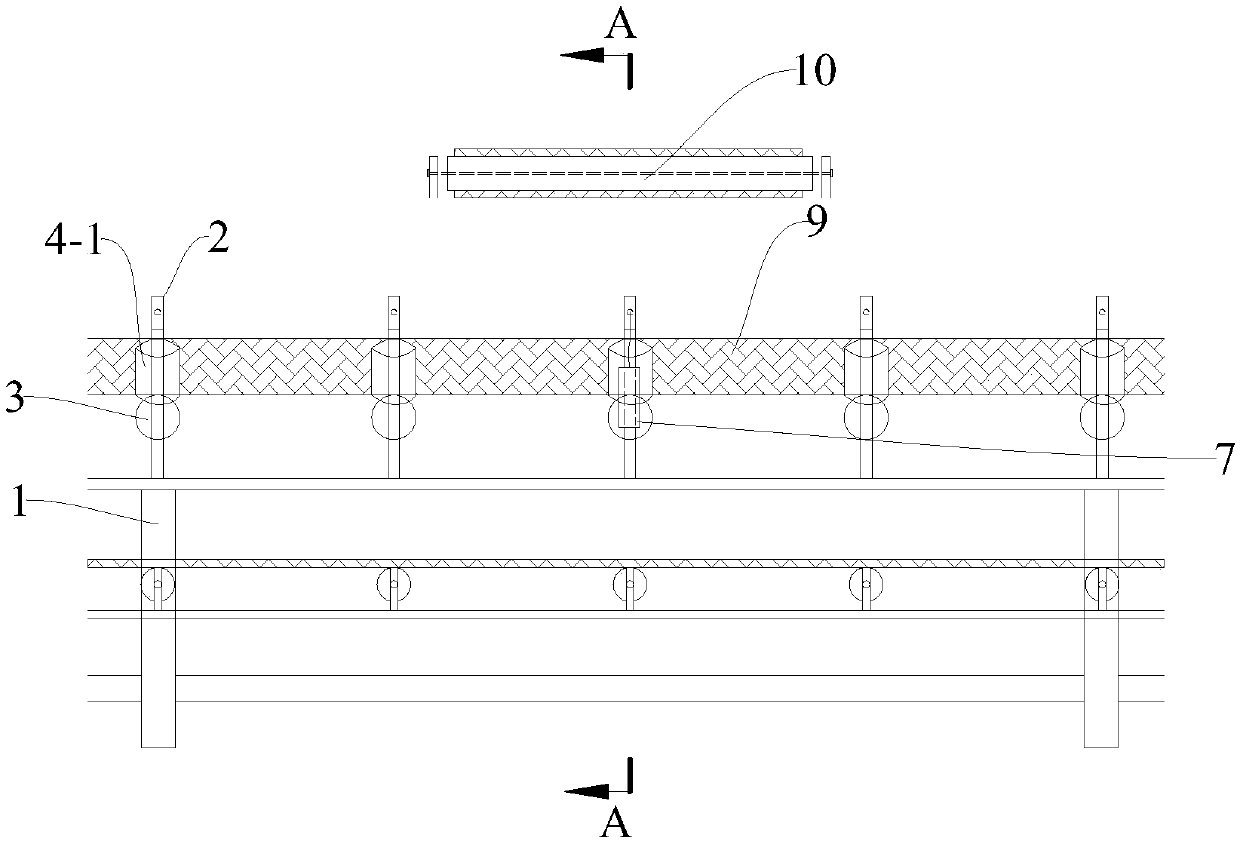

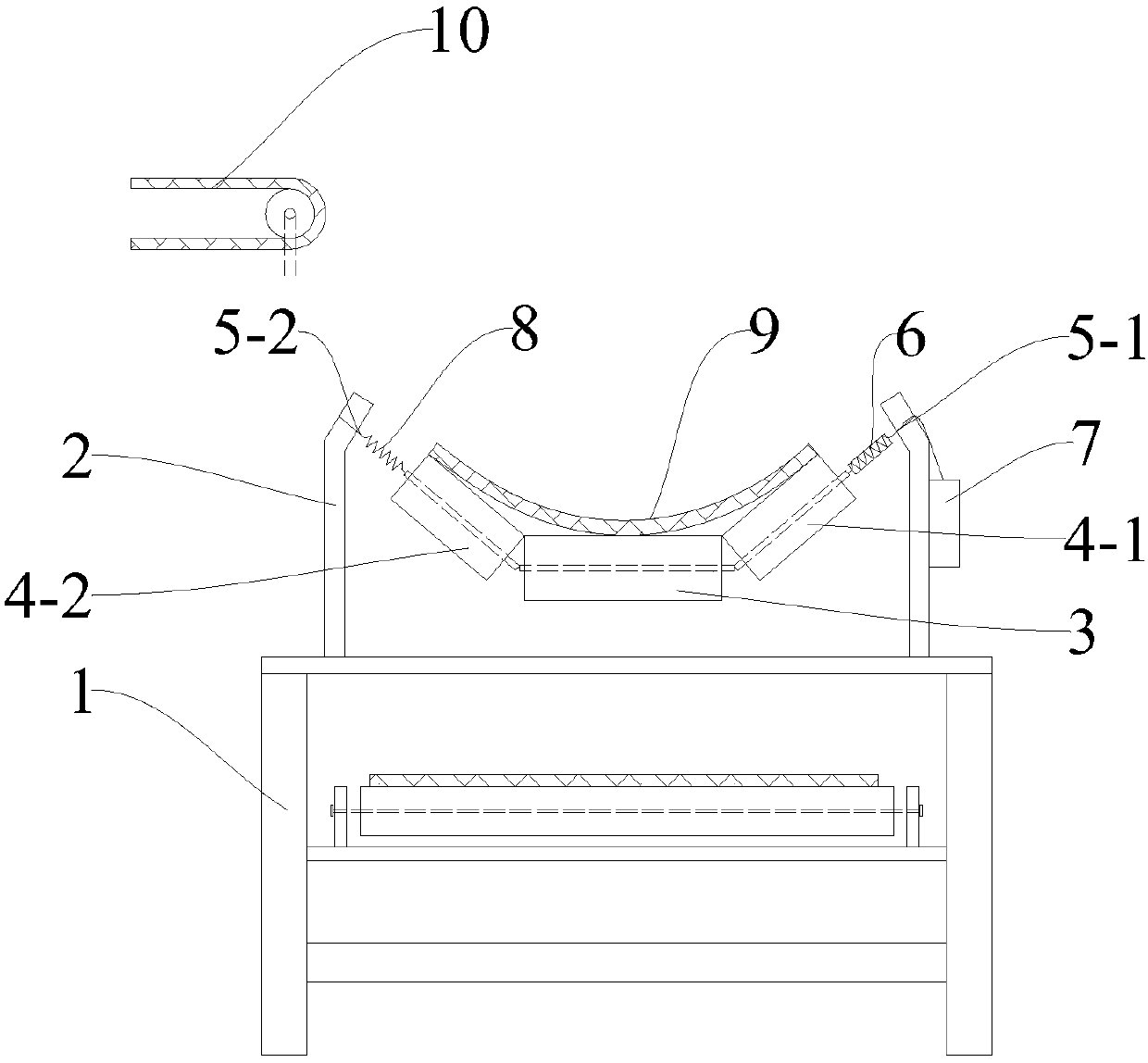

Coal piling preventing early warning protection device for belt conveyor

PendingCN107555120AAvoid bendingPrevent deviationConveyorsControl devices for conveyorsMining engineeringStructural engineering

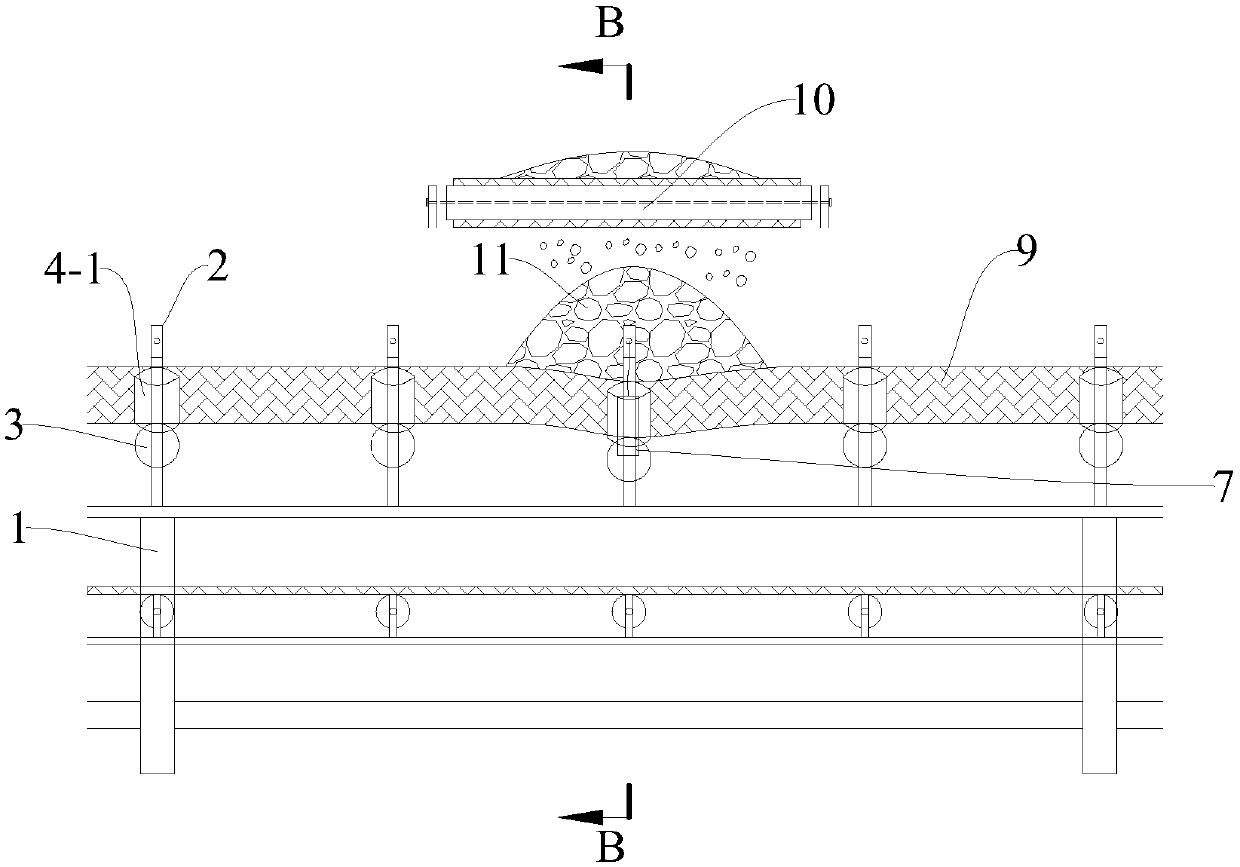

The invention discloses a coal piling preventing early warning protection device for a belt conveyor. The coal piling preventing early warning protection device for the belt conveyor comprises a rack(1), a carrier roller support (2), a middle carrier roller (3), a right carrier roller (4-1), a left carrier roller (4-2) and a suspending device; the right side of the middle carrier roller (3) is connected with the right carrier roller (4-1), and the left side of the middle carrier roller (3) is connected with the left carrier roller (4-2); the left side of the left carrier roller (4-2) is connected with the suspending device suspended on the carrier roller support (2); the right side of the right carrier roller (4-1) is connected with a tension gauge which is connected with a hook (5-1) connected to the carrier roller support (2) in a hanging manner, and the right carrier roller (4-1) is hung up in a suspended manner; the tension gauge is electrically connected with a controller (7); and the weight of a coal pile (11) accumulated on a belt (9) can be judged according to the tension borne by the tension gauge, and the controller (7) sends out an early warning signal when coal is ceaselessly increased, an alarming signal is sent out when the accumulated coal amount exceeds a certain range, and therefore the coal piling amount can be monitored in real time, and early warning is performed in advance and alarming is performed in time during coal piling.

Owner:江苏徐钢钢铁集团有限公司

Dispersing and flattening apparatus for uniform drying of transportation coals in coal dryer using reheat steam

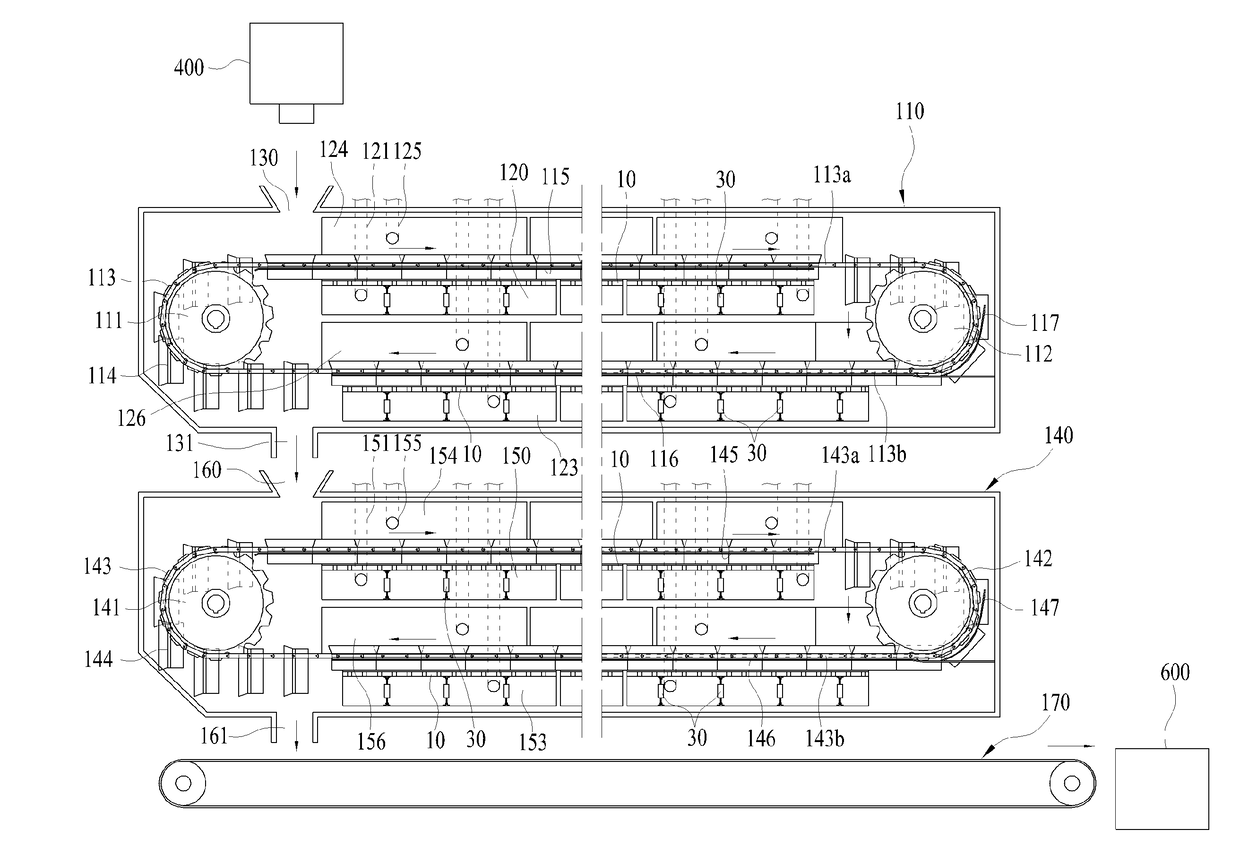

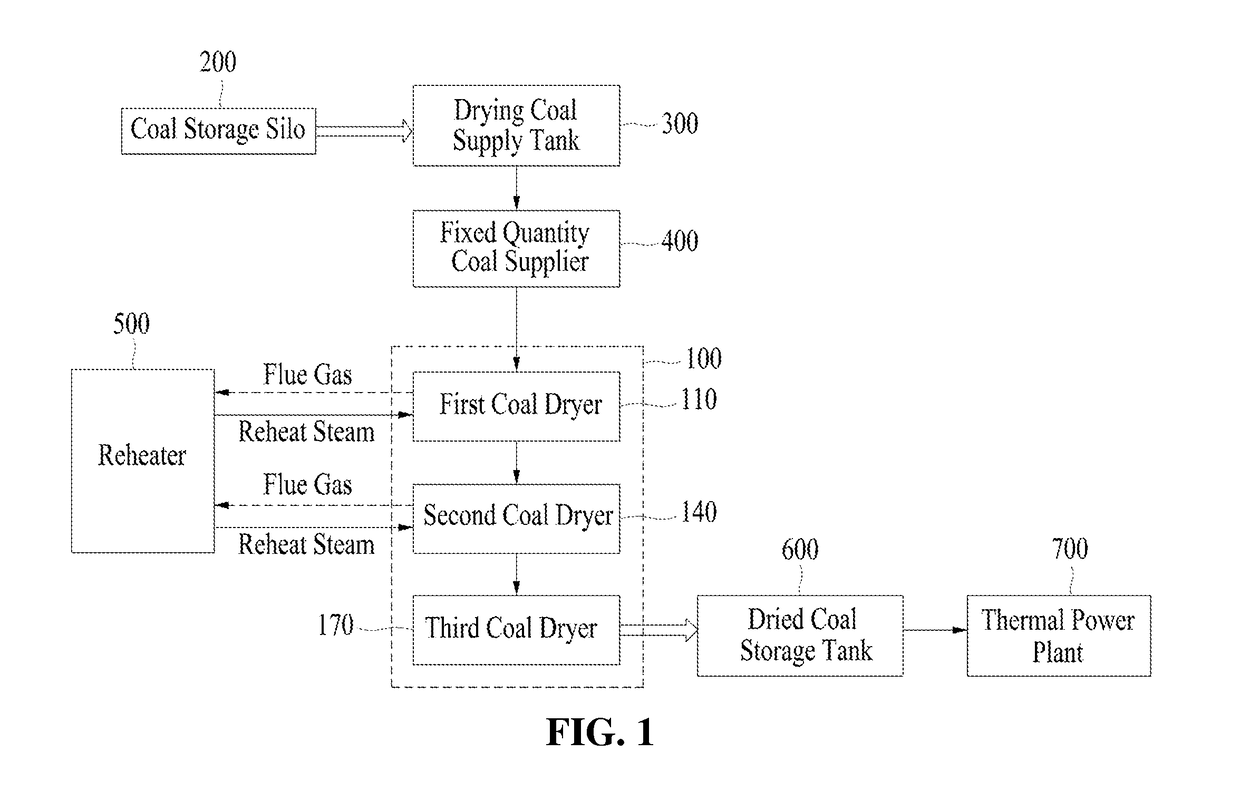

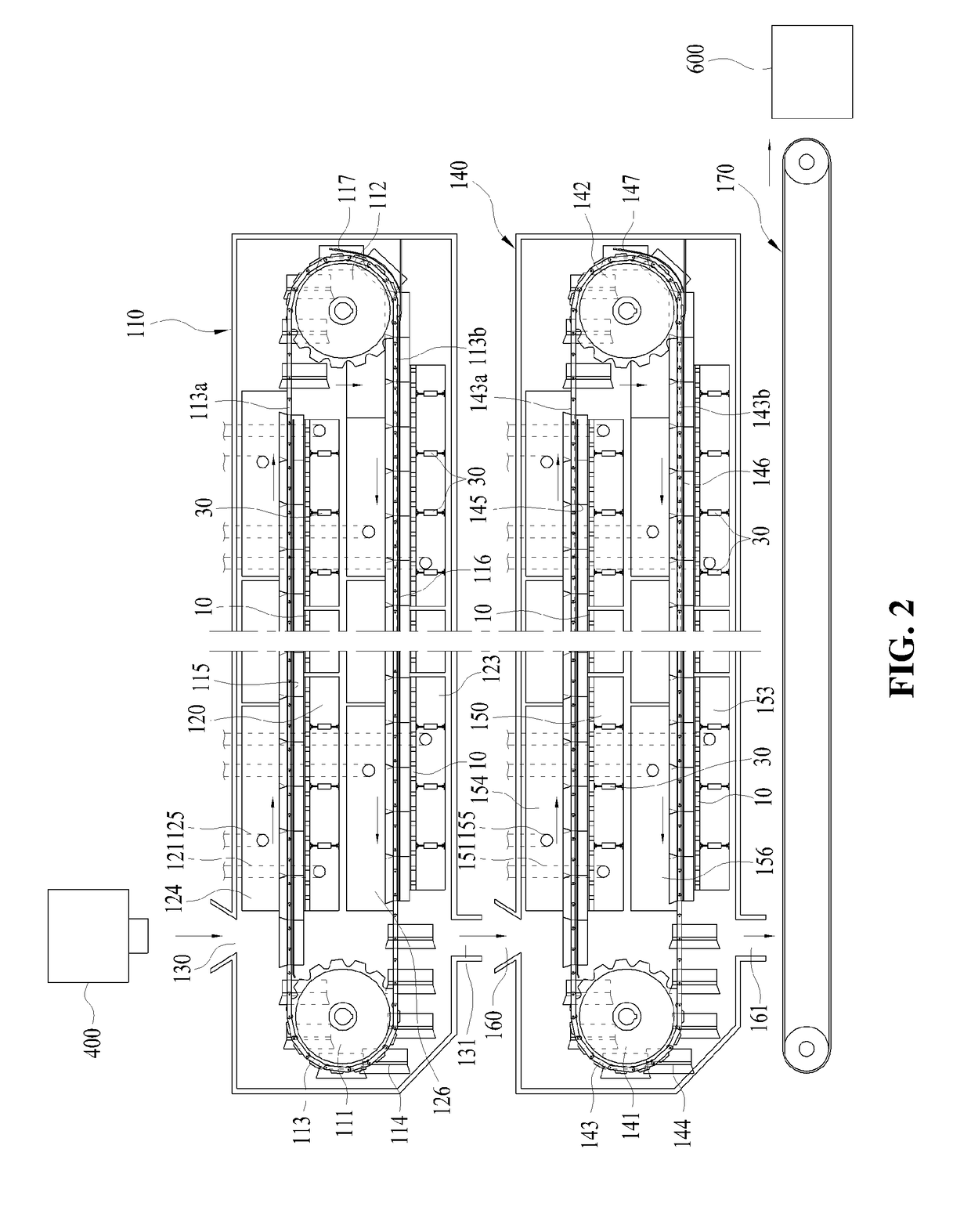

InactiveUS20170145316A1Efficient dryingIncrease calorie valueDrying solid materials with heatCoke ovensProcess engineeringCoal particle

The present invention relates to an apparatus that reduces loads of piles of coals that are input from a fixed quantity coal supplier via a pulverizer to a multi-stage dryer and are transferred, and uniformly disperses and flattens the piles of the coals, thereby improving drying efficiency, in the multi-stage dryer that dries coals using reheat steam, wherein coals that are primarily dried by the first coal dryer are input into the second coal dryer to be secondarily dried, the apparatus including: a column-shaped body that is installed on surfaces of the plurality of first transfer plates and second transfer plates, which faces an upper side, at a specific interval; a division boss that protrudes from a central portion of a front surface of the body to divide and disperse a central portion of piles of coals input from a fixed quantity coal supplier onto the surfaces of the first transfer plates and the second transfer plates, which face an upper side, into left and right parts; and a pair of fixing members that are fixed at upper ends of the first guide rails and the second guide rails that horizontally support the first transfer plates and at upper ends of the third guide rails and the fourth guide rails that horizontally support the second transfer plates to fixedly support opposite ends of the body, wherein the piles of the coals that are transferred on the surfaces of the first transfer plates and the second transfer plates, which face an upper side, are flattened at a specific height so that reheat steam sprayed while passing through the first transfer plates and the second transfer plates uniformly comes into contact with surfaces of coal particles.

Owner:HANKOOK TECH

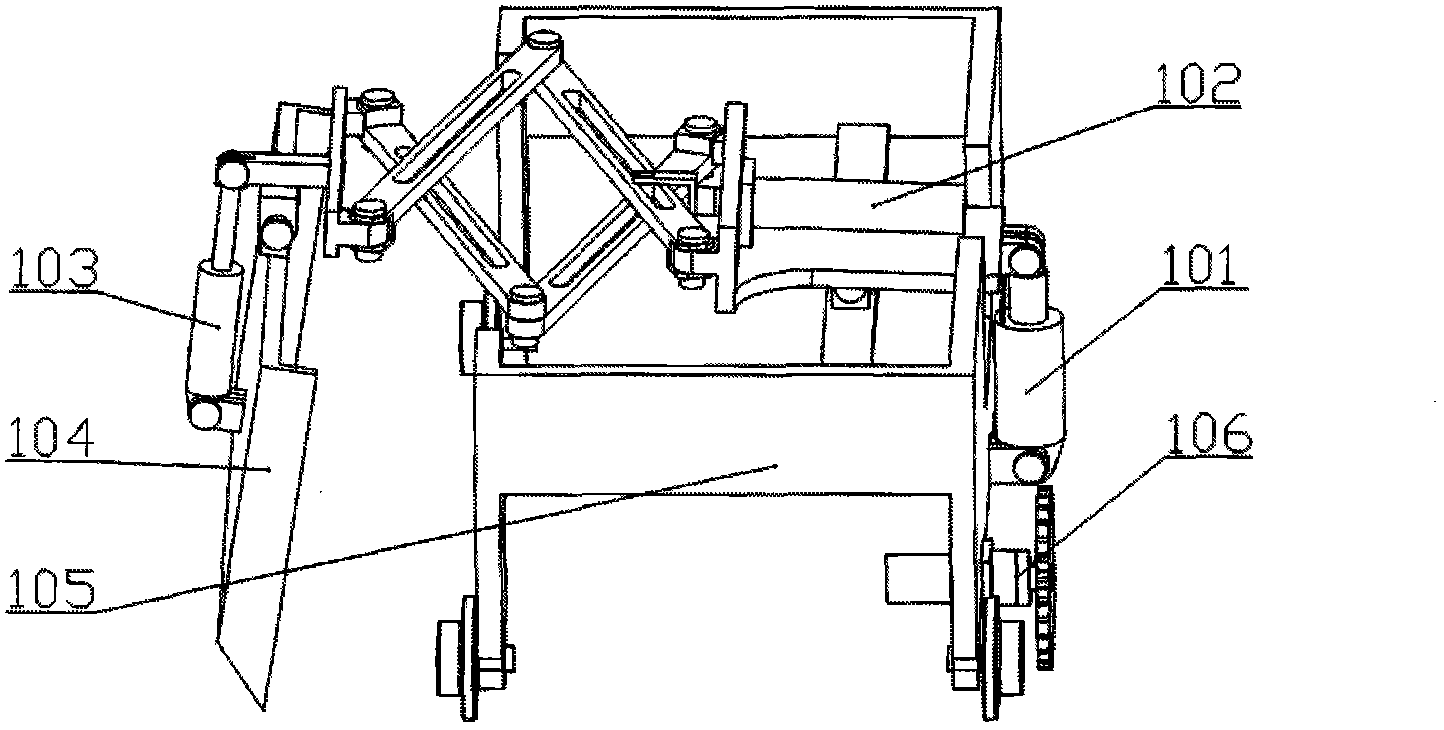

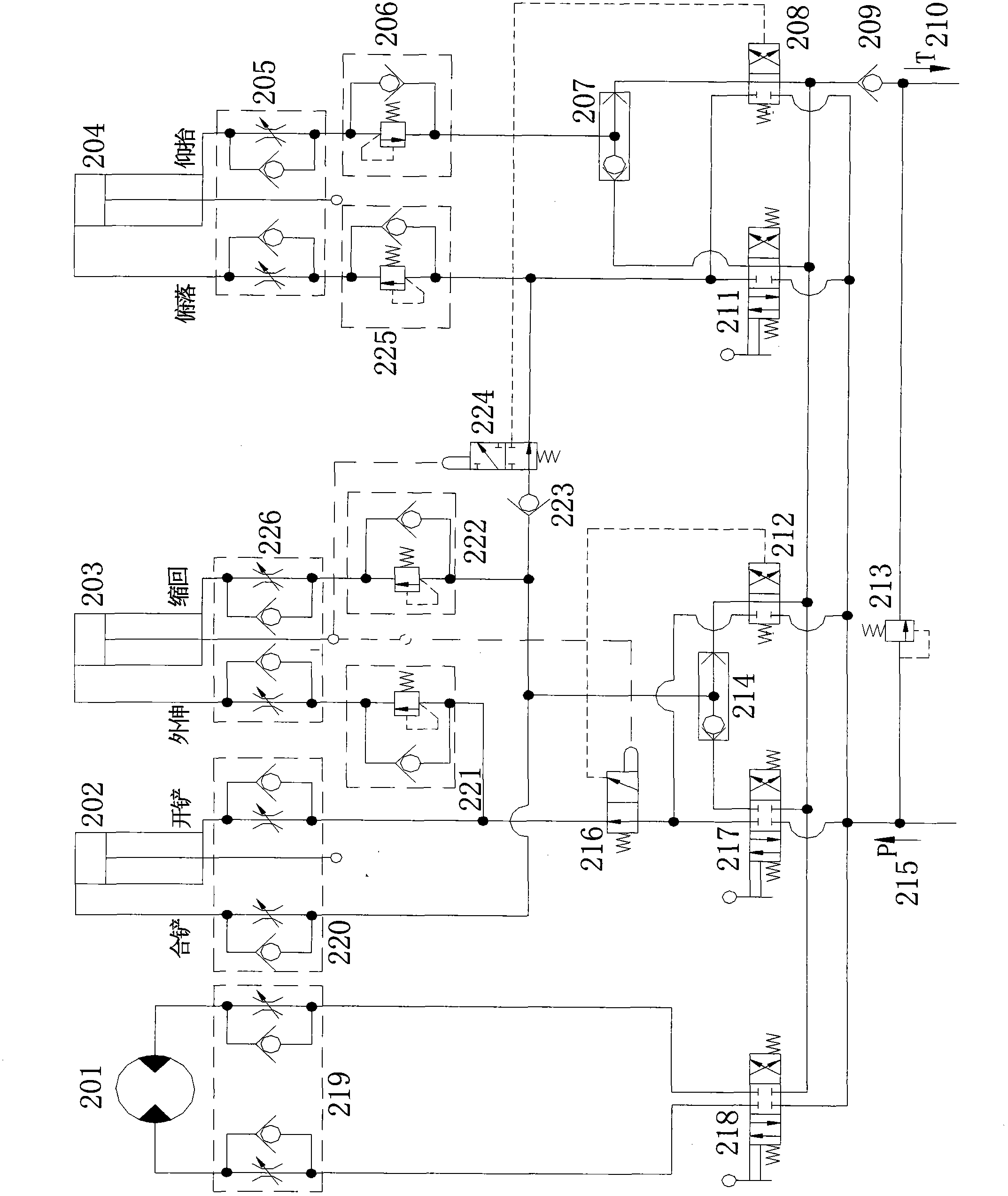

Hydraulic control system for coal pickup manipulator and working method

InactiveCN102705000AReduce labor intensityImprove work efficiencyServomotorsEarth drilling and miningControl systemHydraulic circuit

The invention discloses a hydraulic control system for a coal pickup manipulator and a working method. The hydraulic control system for the coal pickup manipulator mainly consists of a main oil circuit, a travelling hydraulic loop, a hydraulic loop for opening and closing a pickup shovel, a hydraulic loop for stretching a scissors fork, a branch line oil circuit, a hydraulic loop for pickup shovel pitching and an oil return circuit, wherein all components are used for controlling the travelling of the coal pickup manipulator and the coal pickup work. According to the hydraulic control system for the coal pickup manipulator, which is disclosed by the invention, an operator always can use any comfortable gesture no matter what relative position is formed between a coal pile and the manipulator within the working range of the coal pickup manipulator, scattered coal can be picked up to a scraper conveyer by a small quantity of simple operation action via the operation handle of each manual reversing valve of a hydraulic system, so that the labor intensity of workers can be greatly lightened, and the working efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

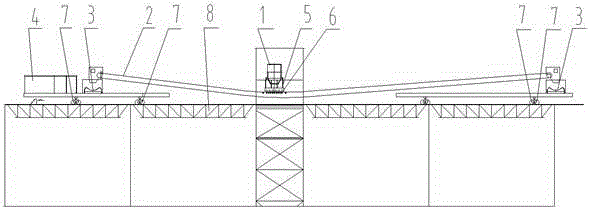

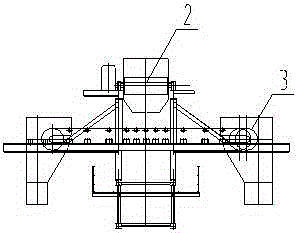

Reversible mobile crown block stockpiling device for coal storage yard

ActiveCN105197616AOvercome the weakness of too large stroke and low efficiencyReduce the overall heightLoading/unloadingMachine partsElectrical control

A reversible mobile crown block stockpiling device for a coal storage yard comprises a belt conveyor, a mobile reversible belt conveyor, suspended reversible belt feeders, an electrical control chamber, a suspended guide chute, a suspended roller unit, walking driving devices, discharging car steel structures and a crown block anchoring device, wherein the belt conveyor is an incoming material adhesive tape machine, is supported in the air by steel structures and is perpendicular to the mobile reversible belt conveyor, a steel-structure transfer tower is arranged in the transition point, the suspended guide chute and the suspended roller unit are fixed on the transfer tower, the suspended reversible belt feeders and the electrical control chamber are fixed on the steel structures at two ends of the mobile reversible belt conveyor, the adhesive tape machine part of the mobile reversible belt conveyor is supported by the steel structures, and driven walking wheels are arranged below the structures. The reversible mobile crown block stockpiling device is simple in structure, has multiple functions, is low in economic cost and easy to implement and is applied to wharfs, metallurgy, coal, ports, electric power, building materials and other industrial fields.

Owner:BEIJING FANGDA CARBON TECH CO LTD

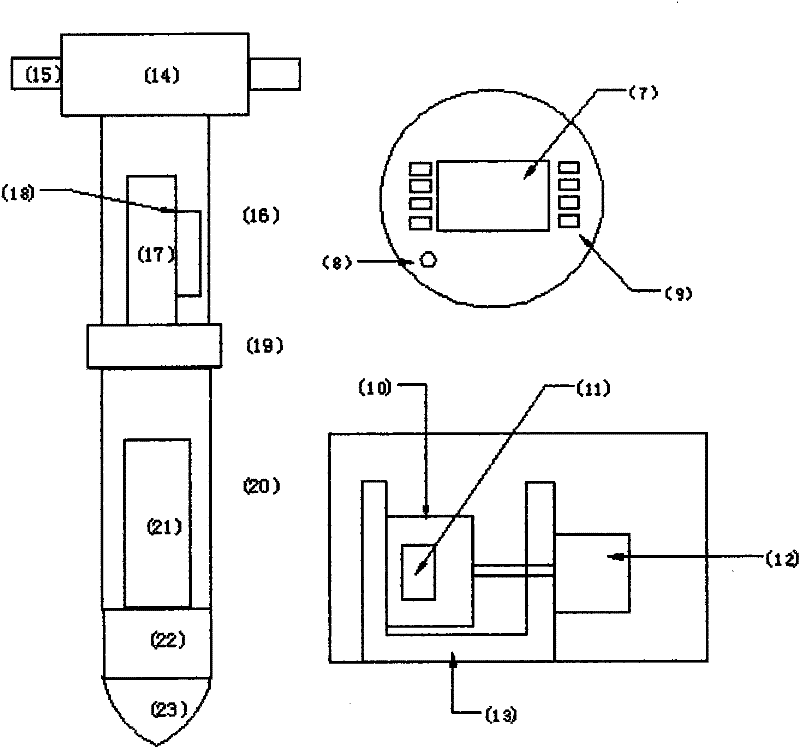

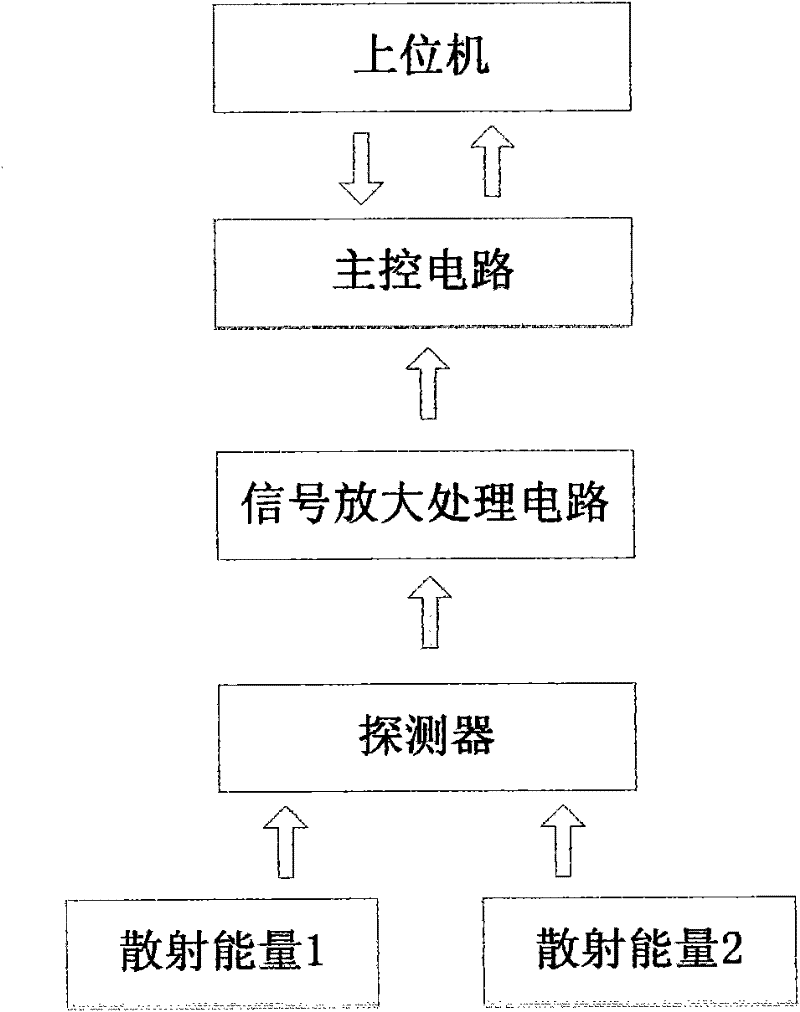

Method and device for automatically recognizing coal types

InactiveCN102128840AAccurate measurementAvoid measurement errorsMaterial analysis by transmitting radiationGamma photonMeasuring instrument

The invention provides a method and special device for rapidly determining coal ash content. The method comprises the following steps of: 1, inserting a quick ash measuring instrument into a coal pile and scanning the coal pile by using gamma photons; and 2, counting and analyzing energy scattered by surrounding coal piles by using a detector, finding the proportional relation between combustible components and incombustible components in coal, selectively analyzing the contents of metal elements with high orders in the incombustible components to determine a quantization model between scattered energy and coal ash, calculating the ash content of the coal by using energy according to a mathematical relation established by using the model, storing the quantization model in the form of parameter and automatically removing or modifying unreasonable or highly-deviated data, wherein the parameter can be automatically extracted for measuring when the same type of coal is detected for the next time. By adopting the method and device, the coal types can be correctly recognized and coal type parameter can be calculated and stored. The method and the device are easy to implement.

Owner:HUNAN UNIV

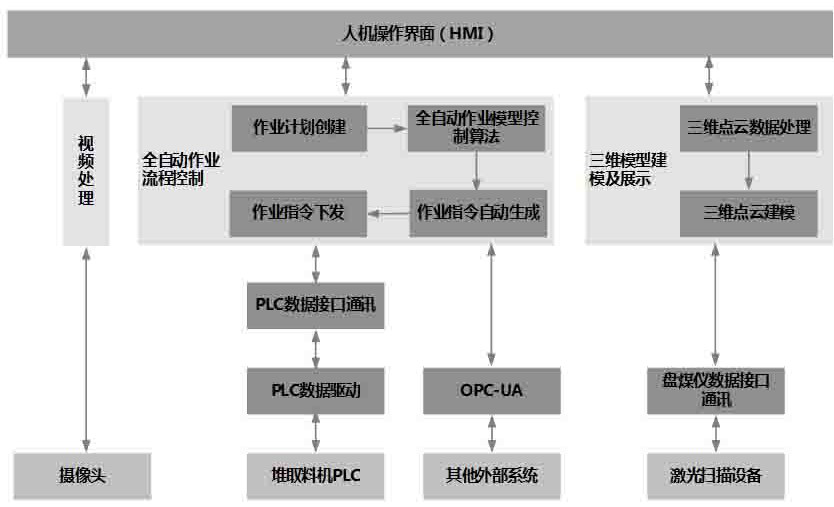

Power plant coal conveying remote intelligent stacking and reclaiming control method

ActiveCN112596455AGuaranteed uptimeEasy to operateLoading/unloadingProgramme control in sequence/logic controllers3d imageLaser scanning

The invention discloses a power plant coal conveying remote intelligent stacking and reclaiming control method. A three-dimensional dynamic laser scanner is used as a detection device, a target material pile of a storage yard is scanned in real time, a three-dimensional image imaging modeling technology is used to carry out three-dimensional modeling on real-time data obtained through scanning, and the real-time data is displayed on a monitoring picture; meanwhile, through operation plan and operation task management, an operation plan is created according to the real-time data of the coal pile of the coal yard, and a background program analyzes the operation plan content and automatically converts the operation plan content into a task instruction which can be executed by a PLC; and through an accurate positioning system and multiple safety protection measures, the walking, pitching and rotating actions of a single machine are adjusted in time, and therefore a stacker-reclaimer is controlled to conduct automatic stacking and reclaiming operation. Through an accurate positioning system and multiple safety protection measures, on the premise that safety is determined, the walking, pitching and rotating actions of the single machine are adjusted in time, and therefore the stacker-reclaimer is controlled to conduct automatic stacking and reclaiming operation.

Owner:HUANENG POWER INT ENERGY DEV CO LTD

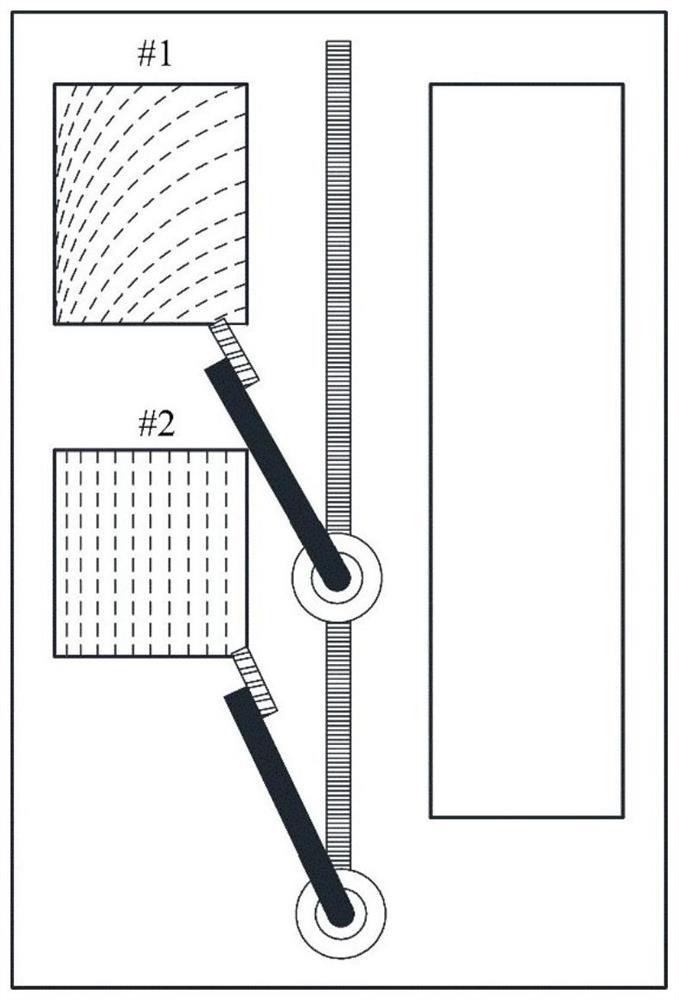

Straight-going material taking method and device of bucket-wheel stacker-reclaimer

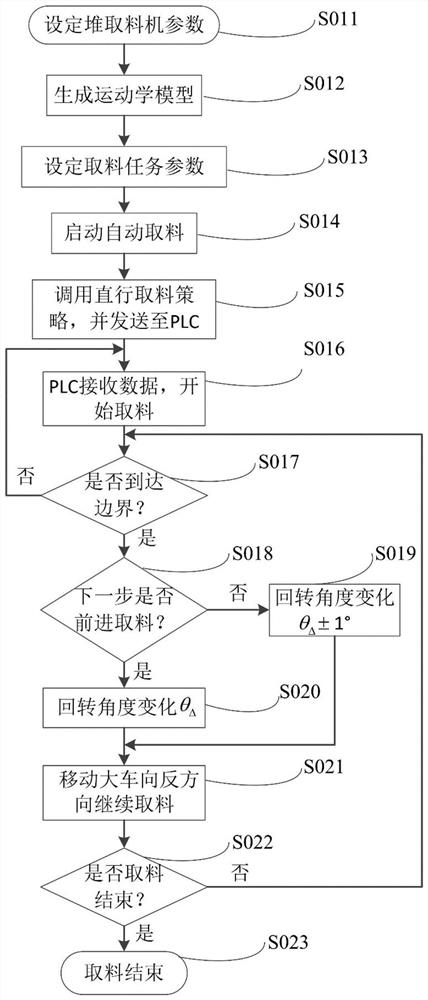

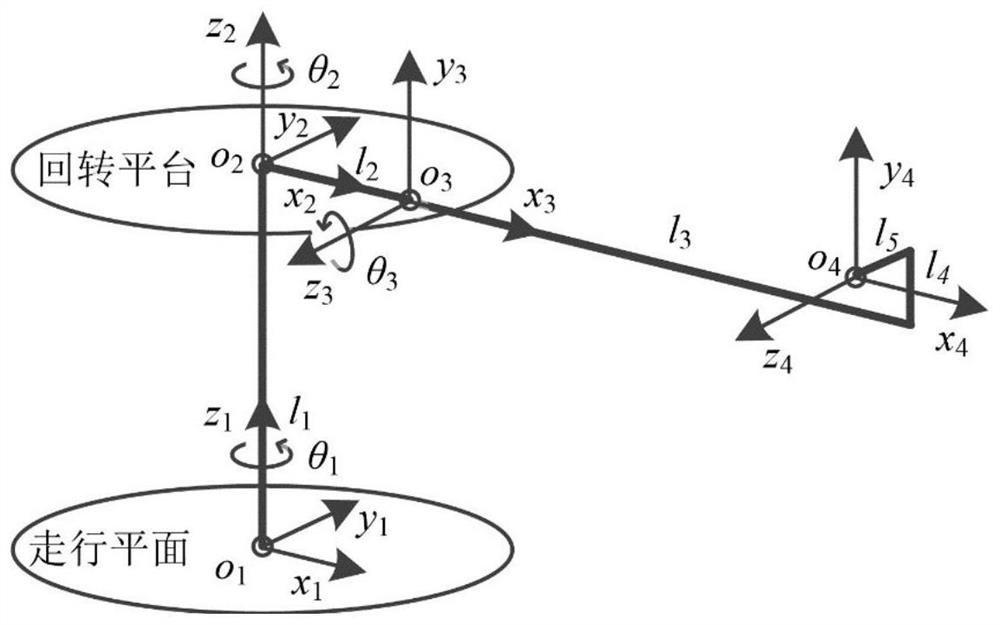

PendingCN114084585AMeet production needsImprove applicabilityGeometric CADConveyorsPoint cloudLaser scanning

The invention provides a straight-going material taking method and device of a bucket-wheel stacker-reclaimer. The method comprises the following steps of acquiring equipment mechanical parameters and basic operation data of the bucket-wheel stacker-reclaimer, establishing a kinematics model of the bucket-wheel stacker-reclaimer based on a robot kinematics theory, wherein the kinematic model is used for representing the relation between the angle and the position of the bucket-wheel stacker-reclaimer, obtaining point cloud data of a laser scanner, generating a three-dimensional model of a target material pile, and obtaining boundary position information of the target material pile according to the kinematic model, setting straight-going material taking parameters, based on a preset straight-going material taking strategy and the boundary position information of the target material pile, acquiring a straight-going material taking task of the target material pile, and controlling the bucket-wheel stacker-reclaimer to execute a material taking action according to the straight-going material taking task. The problem that the coal pile cutting widths of a forward feeding material taking hopper wheel and a backward material taking hopper wheel are different is solved, and the material taking flow is guaranteed.

Owner:BEIJING HUANENG XINRUI CONTROL TECH

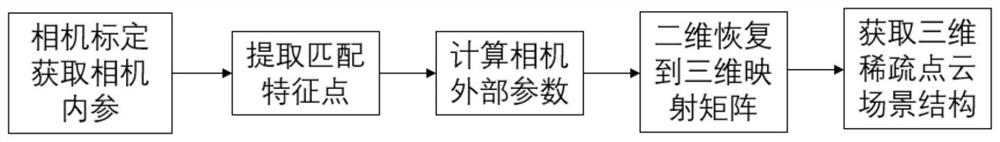

Coal inventory system and method based on vision

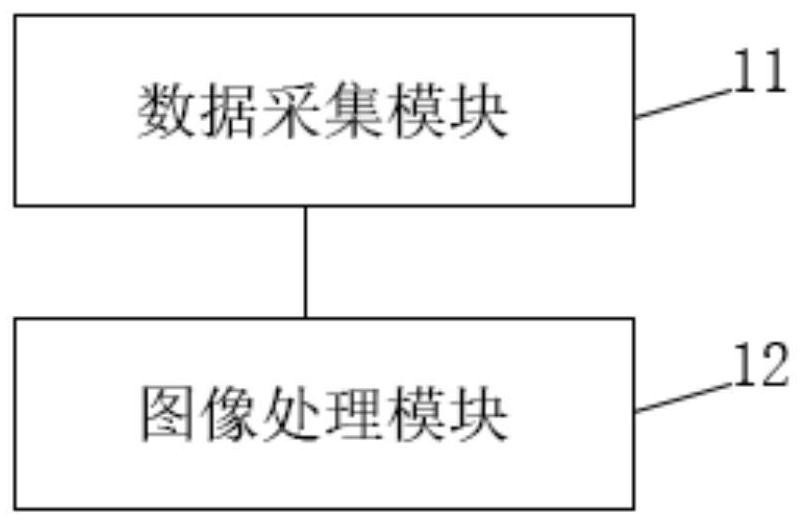

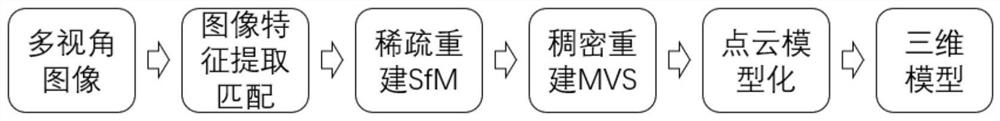

PendingCN112150629AThe data collection process is fully automatedEasy to countImage enhancementImage analysisData informationData acquisition

The invention discloses a coal inventory system based on vision, which comprises a data acquisition module and an image processing module, and is characterized in that the data acquisition module is connected with the image processing module; the data acquisition module is used for receiving image information of a coal storage yard and POS data information of an unmanned aerial vehicle acquired bythe unmanned aerial vehicle, and sending image information and POS data information of the unmanned aerial vehicle to the image processing module; the image processing module is used for calculatingparameters of a camera based on a motion recovery structure algorithm according to the image information and POS data information of the unmanned aerial vehicle, constructing a three-dimensional sparse point cloud model according to the parameters, and reconstructing a dense point cloud model according to the three-dimensional sparse point cloud model;constructing a three-dimensional model of thecoal yard based on a three-dimensional reconstruction algorithm and texture mapping according to the dense point cloud model and carrying out integration on a selected area in the three-dimensional model to calculate the volume of the coal pile, and calculating the weight of the coal pile according to the coal type of the selected area and the corresponding density.

Owner:福建华电可门发电有限公司 +1

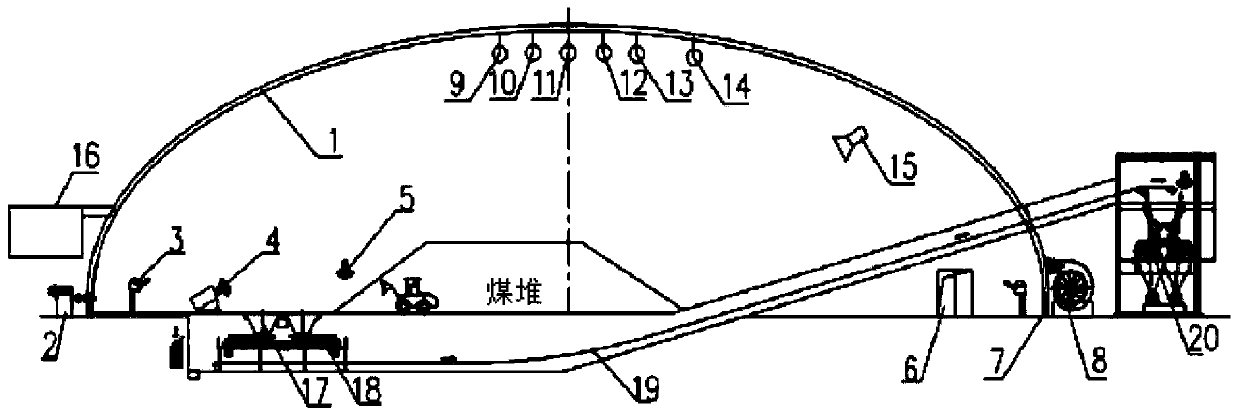

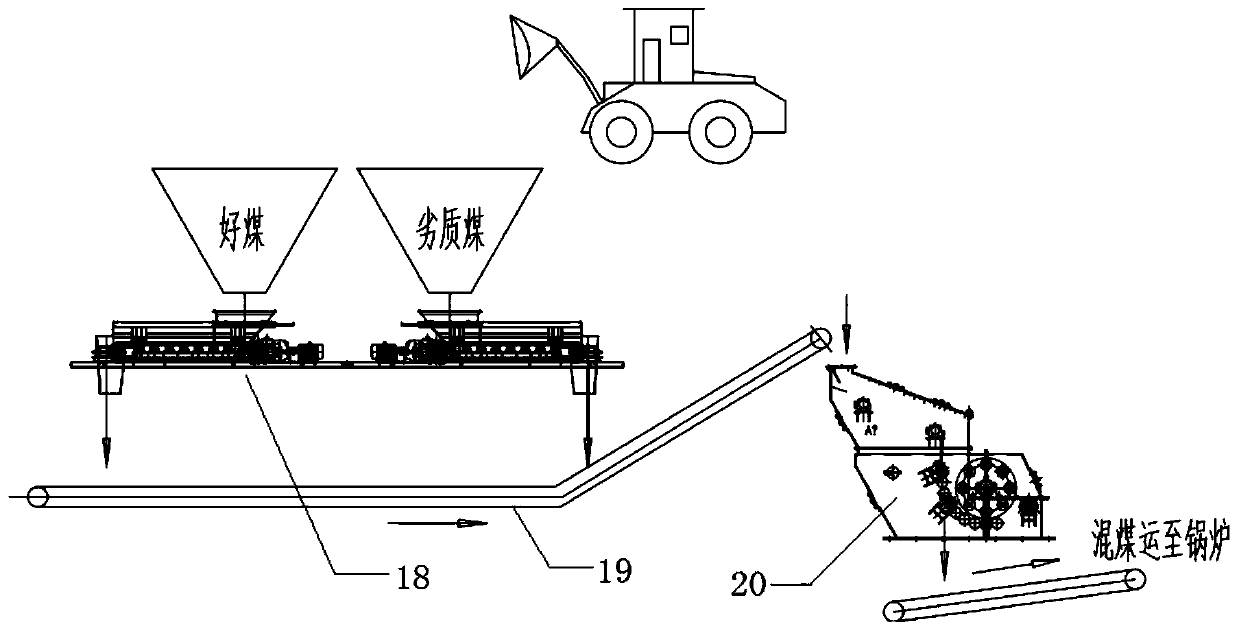

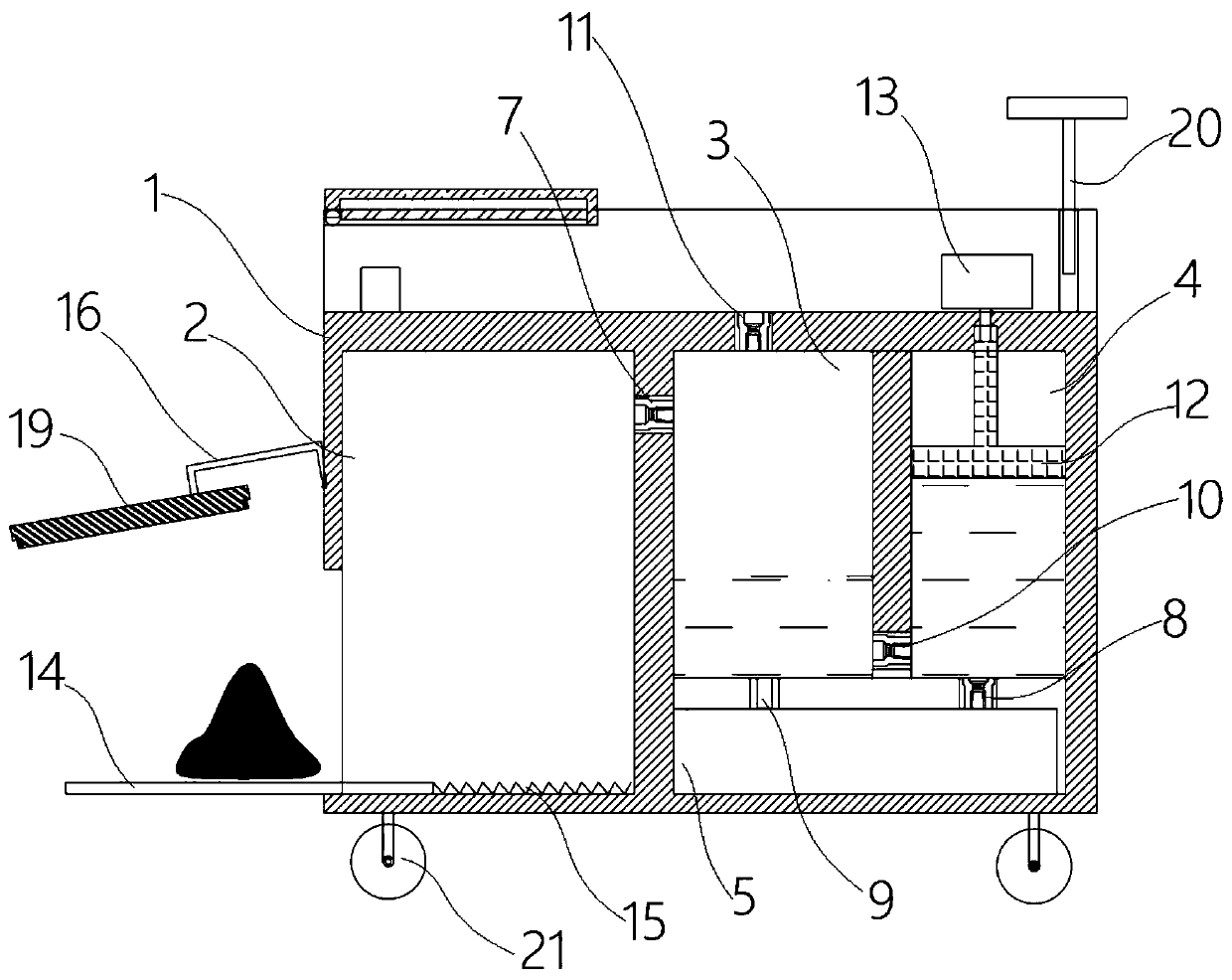

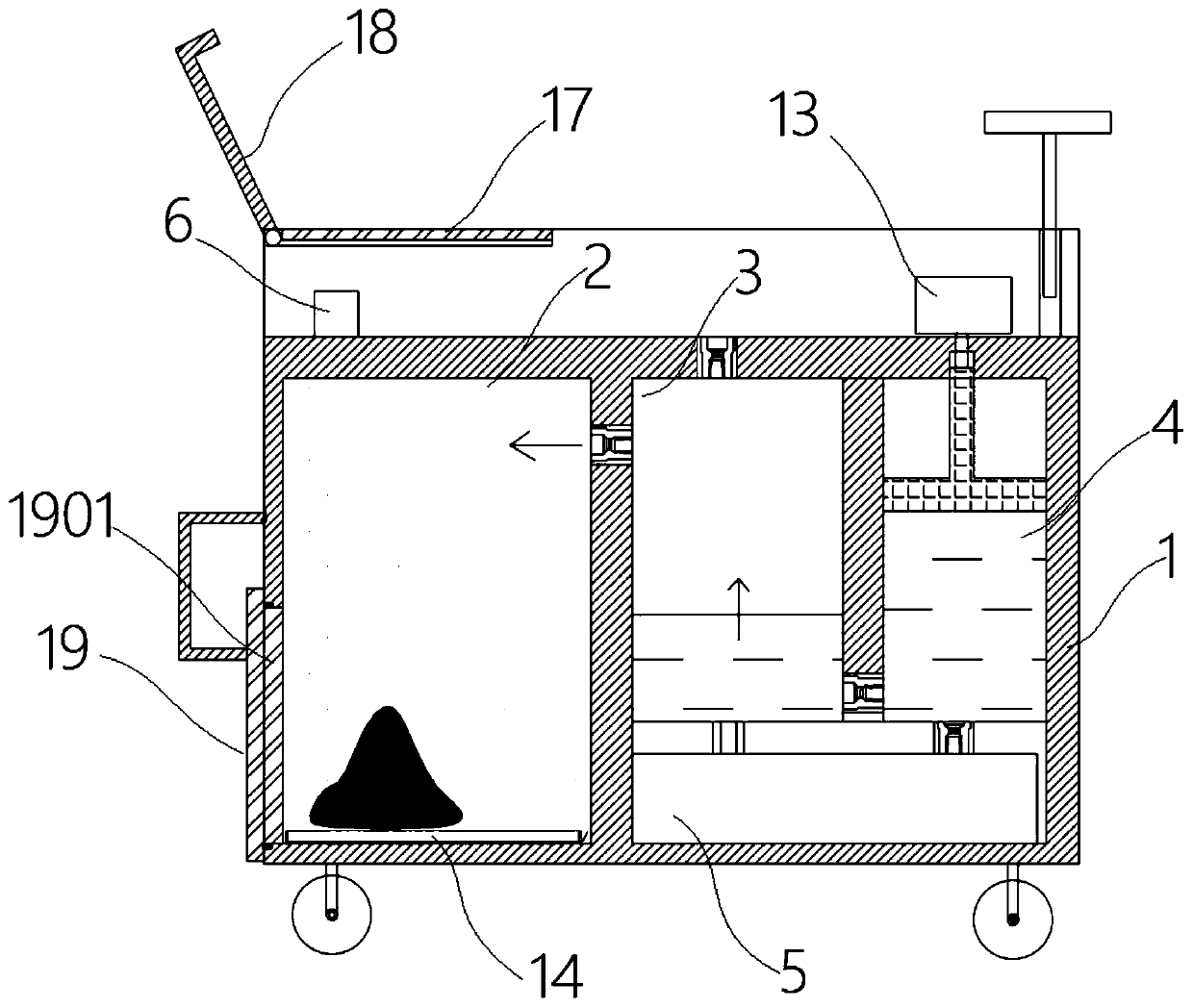

Coal blending weighing screening and breaking system in gas film coal storage yard

PendingCN111468265AMeet the qualified coal burning requirementsReduce maintenanceGas treatmentUsing liquid separation agentAutomatic controlThermodynamics

The invention discloses a coal blending weighing screening breaking system in a gas film coal storage yard. The system comprises a gas film yard system surrounding the coal storage yard and a coal blending weighing screening and breaking system body mounted in the gas film yard system, the coal blending weighing screening breaking system body comprises two weighing coal feeders and a screening andbreaking integrated machine, the weighing coal feeders and the screening and breaking integrated machine are connected through a belt transport machine, a coal blocking wall, a gas film, a monitoringunit, an air blowing system, an atomizing dust suppression device and an automatic control system are mounted in the gas film yard system, coal blending is achieved in the gas film yard system, mixedcoal is subjected to screening and breaking integration, dust and equipment investment are reduced, compositions and mounting positions of the monitoring unit, the air blowing system and the atomizing dust suppression device are optimized in the gas film yard system, coal yard full-closed environment-friendly technical needs can be met, dust conditions in the coal yard can be subjected to real-time and automatic monitoring, and the coal dust zero emissions can be achieved.

Owner:CHINA CHENGDA ENG

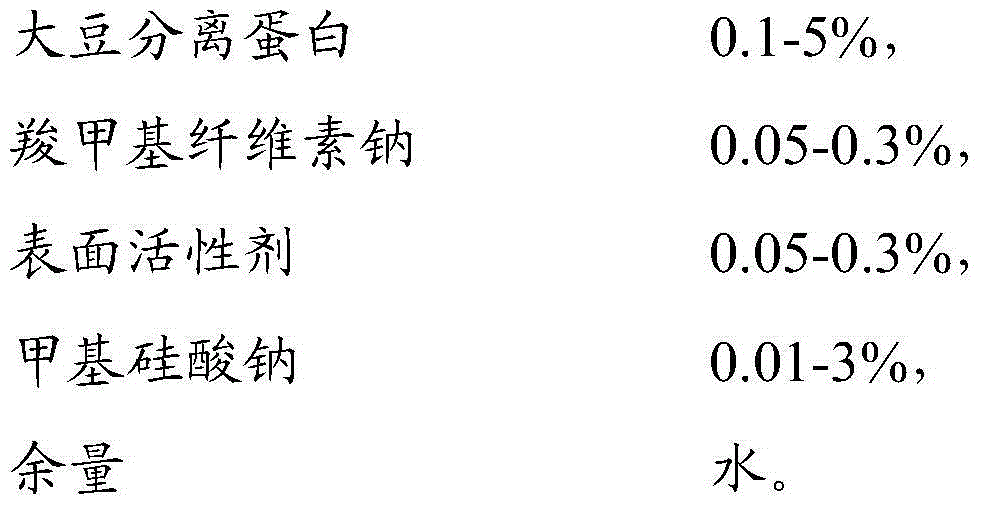

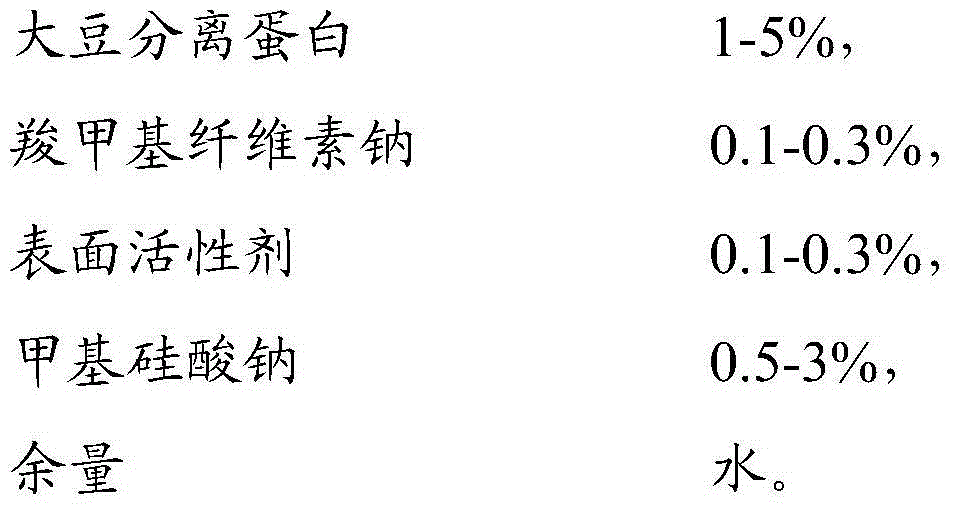

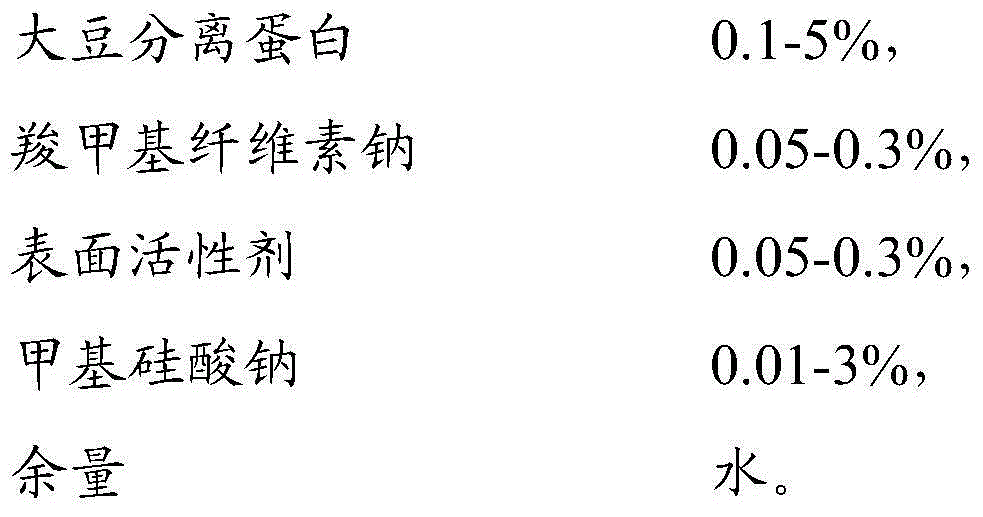

Coal pile surface waterproof covering agent and preparation method thereof

ActiveCN104629687AGood dust suppression performanceEasy to degradeOther chemical processesChemistrySodium carboxymethylcellulose

The invention discloses a coal pile surface waterproof covering agent and a preparation method thereof. The coal pile surface waterproof covering agent is mainly prepared from the following raw materials in percentage by weight: 0.1-5% of soy isolate protein, 0.05-0.3% of sodium carboxymethylcellulose, 0.05-0.3% of a surfactant, 0.01-3% of methyl sodium silicate and the balance of water. The preparation method comprises the following steps: mixing the soy isolate protein, sodium carboxymethylcellulose, surfactant and water for reaction; and adding the methyl sodium silicate and mixing uniformly to obtain the coal pile surface waterproof covering agent. The coal pile surface waterproof covering agent disclosed by the invention has good dustproof, windproof and rainproof properties and relatively high bonding strength and resists sun exposure and thus is suitable for an outdoor coal pile and can effectively meet the dust suppression requirement on the outdoor coal pile in a power plant; the preparation method is simple to operate and has relatively low requirements on the reaction equipment; and moreover, the temperature required in the reaction process is not high, the heating time is not long, the energy consumption is low, and thus the preparation method is suitable for industrial production.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

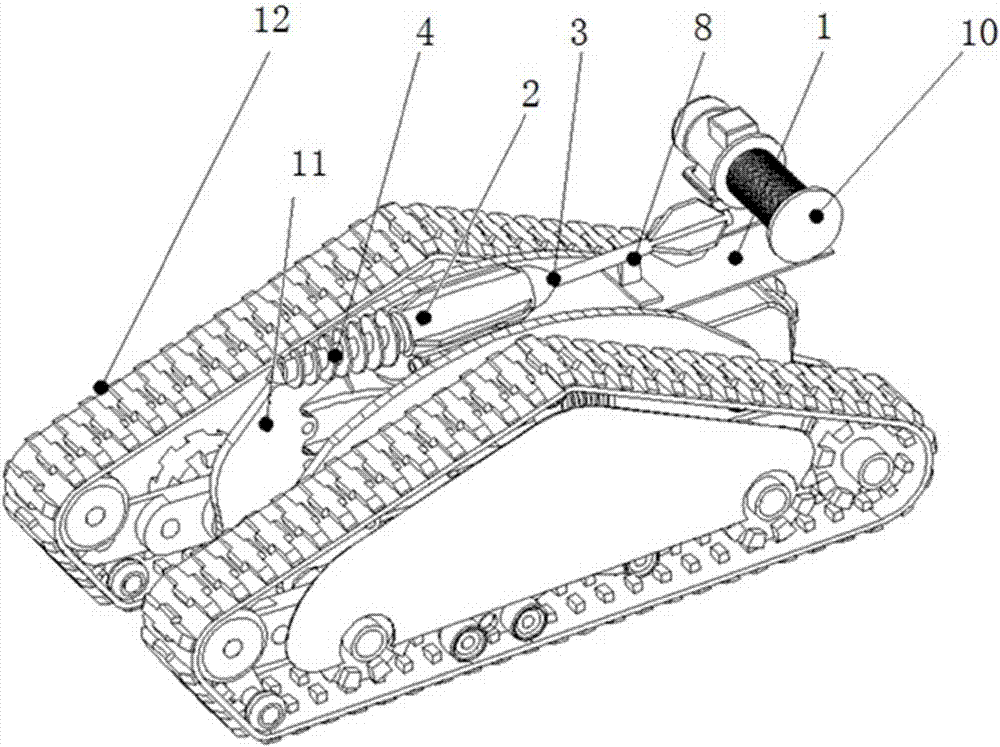

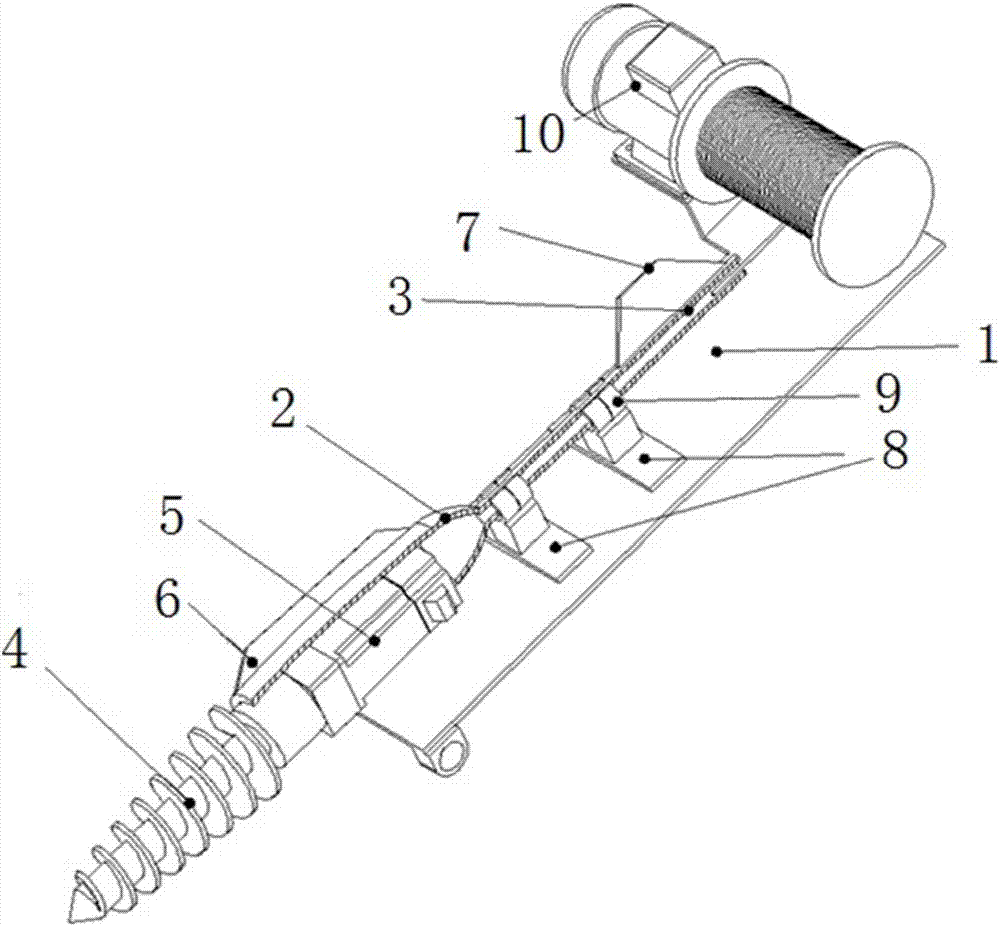

Coal pile temperature measurement crawling robot

PendingCN106949992AImprove monitoring accuracyHigh precisionThermometer applicationsManipulatorMining engineeringElectric machinery

The invention provides a coal pile temperature measurement crawling robot comprising a chassis of which the two sides are provided with crawler belts; and a drill bit component which is arranged on the chassis. The drill bit component comprises a supporting plate which is arranged on the chassis, a working cabin which is arranged on the supporting plate, a self-tapping drill bit of which the tail end is arranged in the working cabin and the front end stretches out of the front end of the working cabin, a temperature measurement probe which is arranged on the self-tapping drill bit, a motor which is arranged in the working cabin and connected with the tail end of the self-tapping drill bit, and a temperature measurement instrument which is arranged in the working cabin and connected with the temperature measurement probe. The coal temperature detection drill bit has the following advantages that 1) the monitoring accuracy is high and the accuracy is at least enhanced for 15 times in comparison with that of the present mode; 2) the equipment cost is low and the equipment input is reduced to 20% in comparison with that of the present mode; and 3) the market gap can be broken through, the bar type coal bunker has no detection means in comparison with the garden type coal bunker, and the equipment provides the detection means.

Owner:江西查湃智能科技有限公司 +1

Coal yard coal dump density measuring device

ActiveCN109827868AHigh measurement accuracyAccurate inventory resultsSpecific gravity measurementYardGas pressure transducer

The invention discloses a coal yard coal dump density measuring device. The coal yard coal dump density measuring device comprises a base and is characterized in that a measuring box and a standard gas distribution box which are communicated with each other are arranged on the base; a first one-way valve is arranged between the measuring box and the standard gas distribution box, and the measuringbox is provided with a gas pressure sensor for detecting the pressure of the measuring box; the standard gas distribution box is connected with a liquid standard box; a second one-way valve is arranged between the standard gas distribution box and the liquid standard box, and the standard gas distribution box is provided with a third one-way valve; a piston plate capable of pushing liquid into the standard gas distribution box is arranged in the liquid standard box and connected with an air cylinder push rod arranged on a measuring rack; the liquid standard box is further connected with a liquid supply box. The coal yard coal dump density measuring device has the advantages that coal dump density can be accurately and fast measured, the coal yard checking result is accurate, the workloadof density measuring is reduced greatly, manpower is saved greatly, density measuring efficiency is increased, accurate reference is provided for enterprise production and operation management, and the device is high in practical value and popularization value.

Owner:国能常州发电有限公司

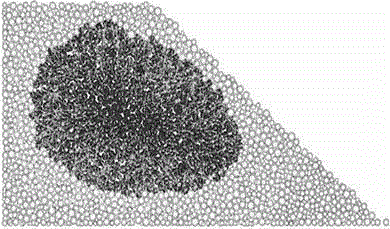

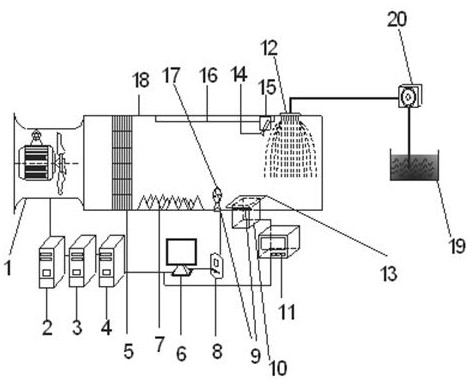

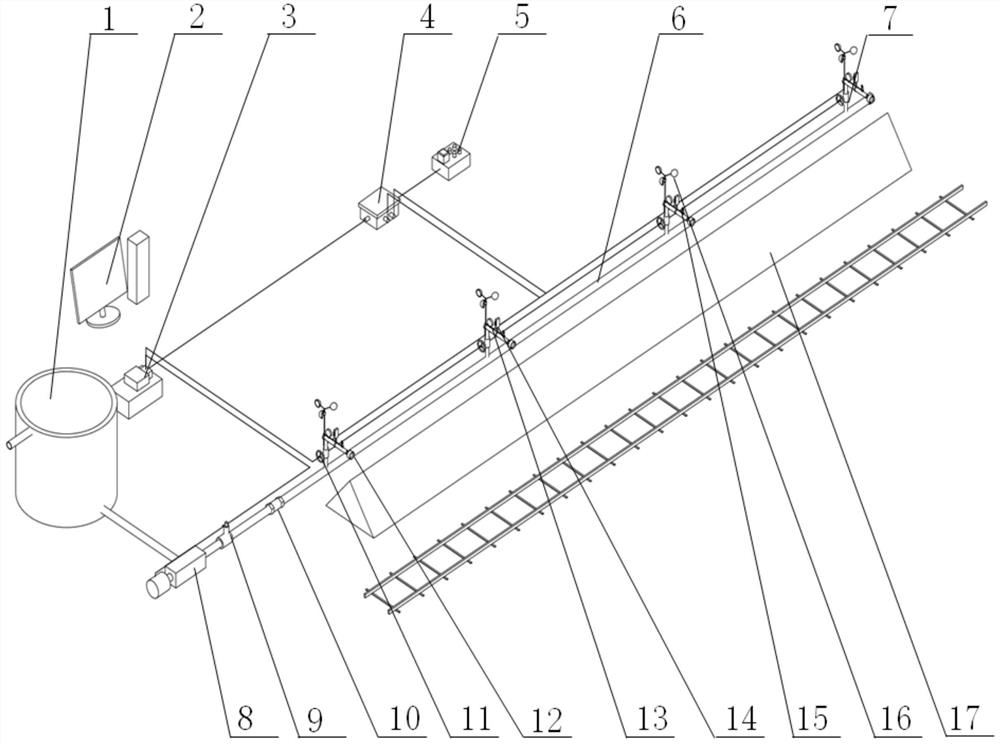

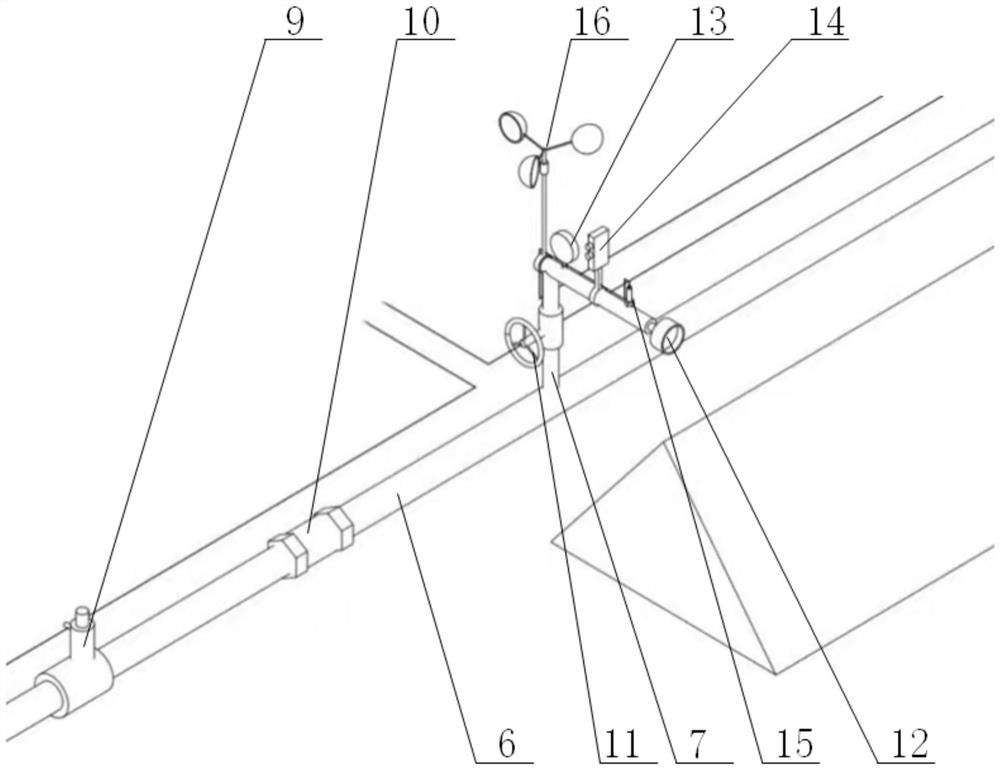

Open-air coal pile dusting amount test similarity experiment system and measurement method

The invention relates to an open-air coal pile dusting amount test similarity experiment system and a measurement method. The system comprises a fan and a wind tunnel frame. A flow equalizing plate used for adjusting the airflow direction is arranged right in front of the draught fan in the frame. A rough element for increasing turbulence intensity is arranged behind the flow equalizing plate, a wind speed sensor is arranged behind the rough element and connected with a wind speed displayer outside the frame, the wind speed displayer is connected with a computer, a rigid tray for containing dust samples is arranged next to the wind speed sensor, a mass sensor is fixed below the tray, and the sensor is connected with the computer. A sliding rod is arranged above the tray, a slidable fixingclamp is arranged on the sliding rod and fixes the high-speed camera, and a spray head is arranged at the tail end of the system and connected with a water pump and a water tank through a guide pipe.The system can be used for measuring the dusting amount of different coal piles under the multi-factor coupling effect, and provides support for researching and developing an economical, applicable, reasonable and efficient open-air coal pile dust comprehensive treatment technology.

Owner:TAIYUAN UNIV OF TECH

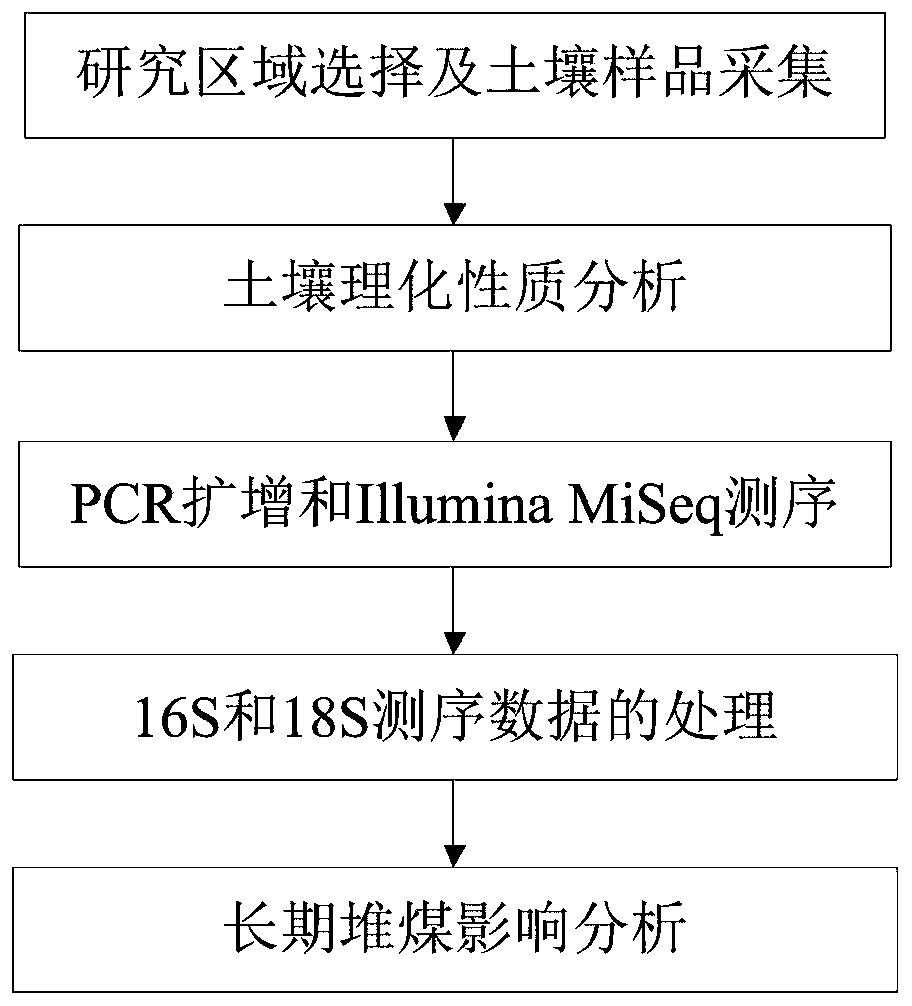

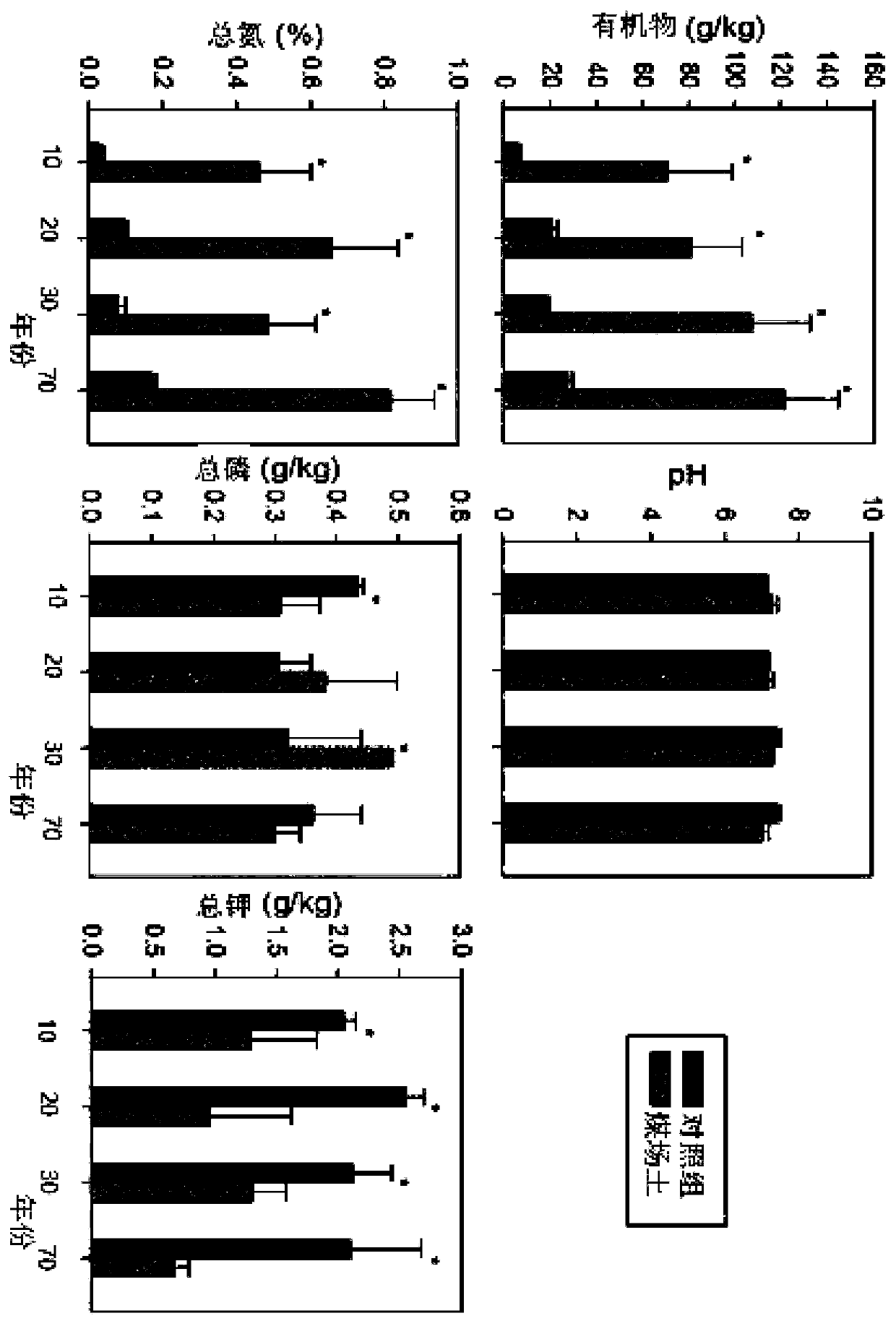

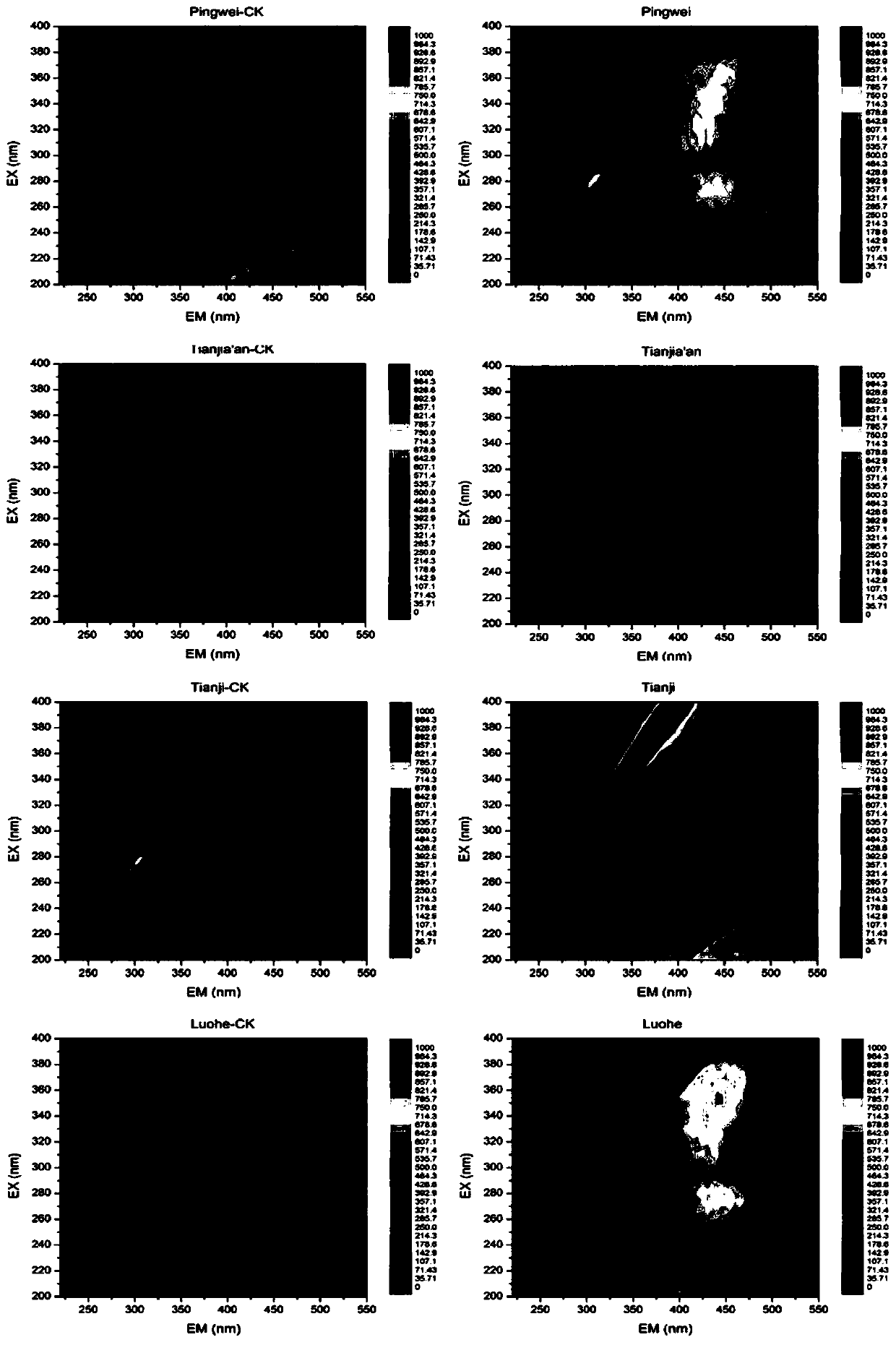

Operation method for influence of long-term coal pile on soil bacteria based on multi-dimensional indexes

PendingCN110714061AEasy to operateHigh feasibilityMicrobiological testing/measurementRevegetationSoil properties

The invention discloses an operation method for influence of long-term coal pile on soil bacteria based on multi-dimensional indexes, which comprises the following steps: (1) selecting research areasand collecting soil samples; (2) analysis of soil physical and chemical properties; (3) DNA extraction, PCR amplification and Illumina MiSeq sequencing; (4) processing of 16S and 18S sequencing data;(5) analysis of the influence of long-term coal piling on soil properties and microbial communities. Through the above steps, the influence of long-term coal piling in power plants on soil organic matter and soil bacterial diversity can be analyzed, which is of great significance for guiding environmental impact assessment and soil vegetation restoration of coal storage yards in coal-fired power plants.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

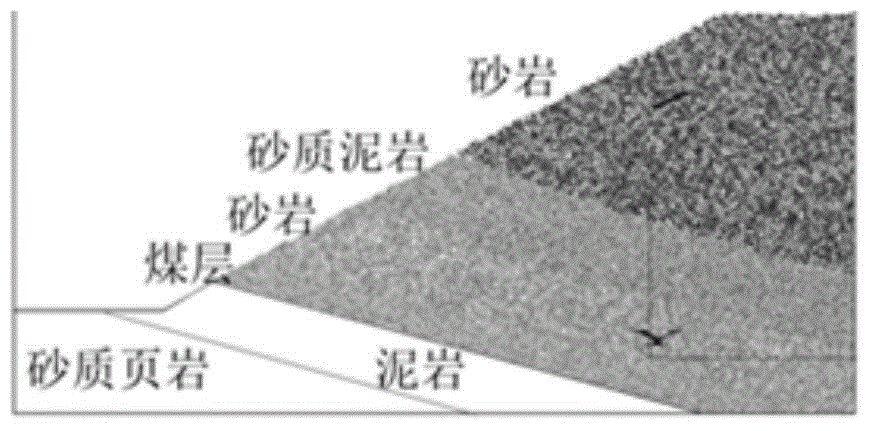

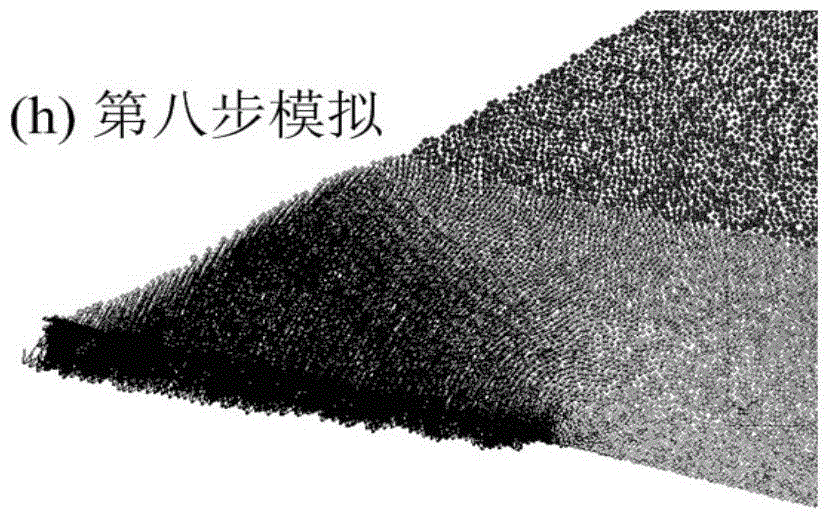

Method for determining spontaneous combustion temperature field and combustion depth of slope residual coal

The invention discloses a method for determining the spontaneous combustion temperature field and the combustion depth of slope residual coal. The method is characterized in that the movement of oxygen in cracks and the process of the reaction of the oxygen and a coal bed and the mutual development promoting of the oxygen and the coal bed are simulated based on PFC3D serving as a simulation platform with the help of a heating power coupling model of the PFC3D and the situation of cracks formed by slope damage caused by spontaneous combustion in earlier periods, and thus the slope internal temperature field and the combustion space area development depth are obtained; extremely small particles are used for simulating the flowing of oxygen and the reaction of the oxygen and the coal, and the process is achieved through FISH; the method comprises the following steps of structuring a slope model, forming an oxygen flow channel, structuring a residual coal spontaneous combustion microscopic model and simulating a temperature field result through heating power. The method can be used for analyzing the spontaneous combustion process of coal piles with certain scales.

Owner:HUOLINHE OPENCUT COAL IND CORP LTD OF INNER MOGOLIA

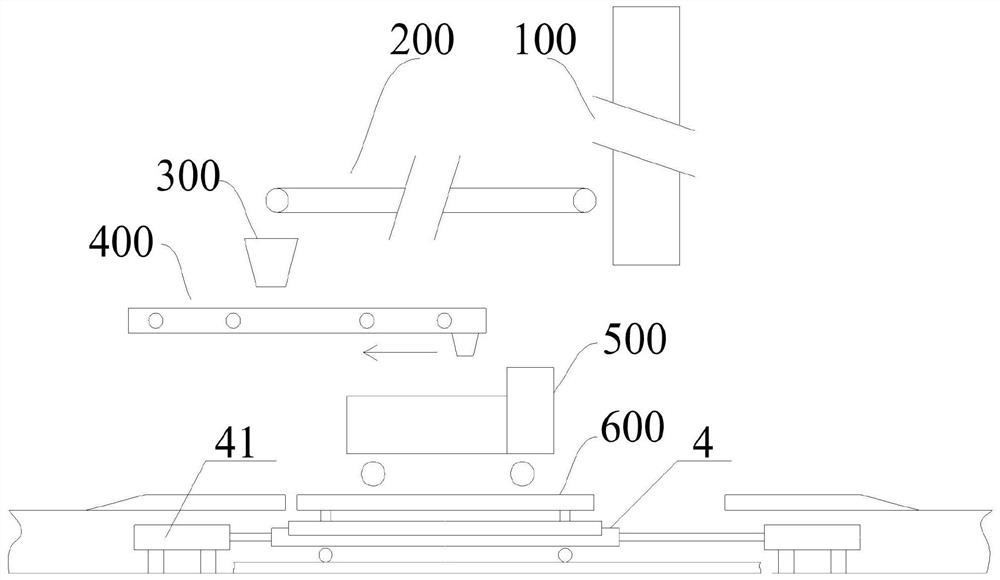

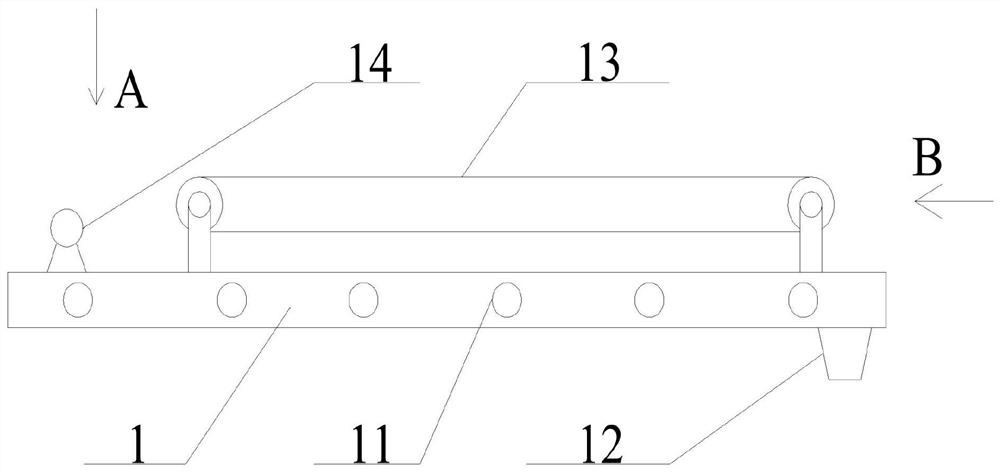

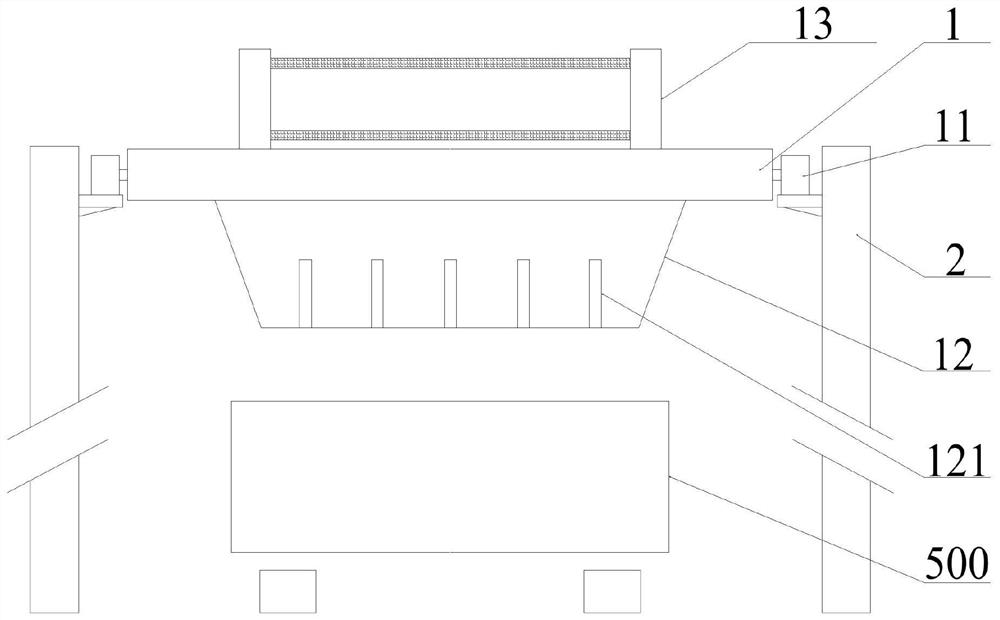

Wagon balance translation type automatic coal loading device

PendingCN111908181AGuaranteed stabilityHigh degree of automationConveyorsLoading/unloadingReciprocating motionAgricultural engineering

The invention relates to the technical field of coal mine equipment, and provides a wagon balance translation type automatic coal loading device. The wagon balance translation type automatic coal loading device comprises a stock bin, a transfer conveying belt and a wagon balance, wherein the wagon balance is arranged on a movable vehicle; a pressurizing cylinder is arranged at each of the two endsof the movable vehicle, and the pressurizing cylinders can drive the movable vehicle to reciprocate on a vehicle rail; specifically, when the pressurizing cylinder on one side is pushed out, the pressurizing cylinder on the other side retracts; and a movable coal loading mechanism is arranged above the wagon balance, and the movement direction of the movable coal loading mechanism is opposite tothe movement direction of the movable vehicle. According to the wagon balance translation type automatic coal loading device, a movable frame moving in the direction opposite to the movable vehicle isarranged for loading coal, the relative speed of the movable frame and the movable vehicle is large, the coal loading amount in unit time is increased, the coal loading time is shortened, and the coal loading efficiency is improved; meanwhile, the movable speed of the movable frame and the movable speed of the movable vehicle are not high, and the coal loading stability and the weighing accuracycan be effectively guaranteed; and the coal is fallen and loaded in a uniform motion mode, the top of a coal pile is flat, the later pile flattening operation is omitted, the operation efficiency is improved, and the labor is saved.

Owner:山东能源集团鲁西矿业有限公司

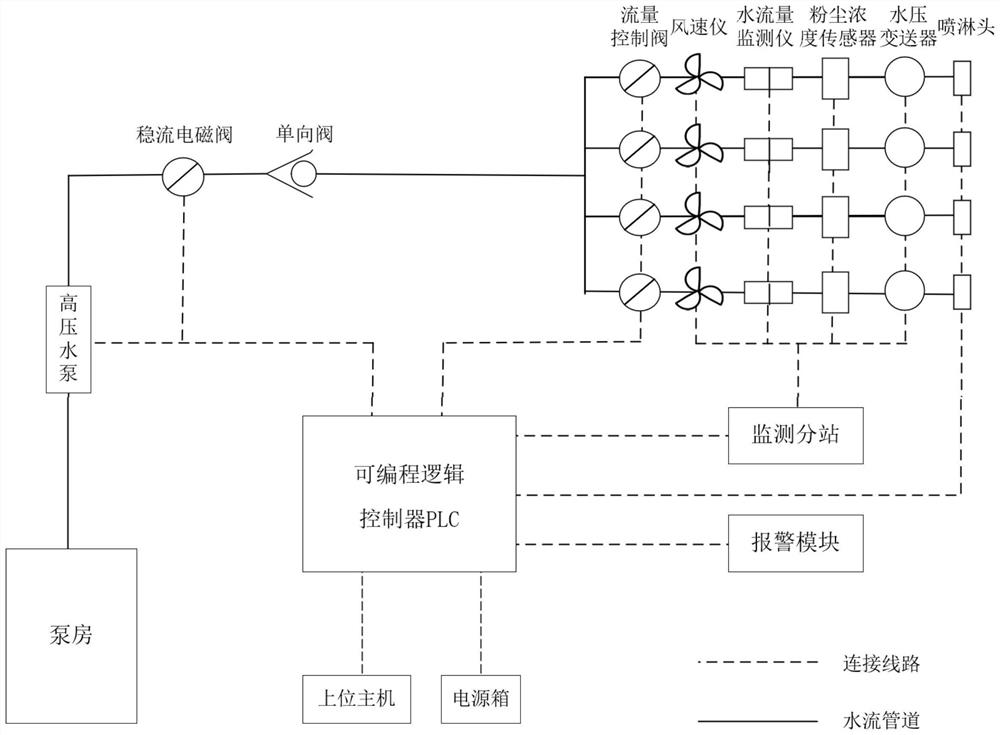

Intelligent control system for spray dust removal of storage yard

ActiveCN113341842AEconomical dust suppressionPrecise Dust ReductionProgramme controlComputer controlWind runDust control

The invention provides an intelligent control system for spray dust removal of a storage yard, and the system comprises a transportation track for transporting coal to a coal pile area; the coal pile area is arranged on one side or two sides of the transportation track, and a data monitoring module, a concentration over-limit alarm module, an intelligent control module and an automatic spraying module are arranged in the coal pile area; a data monitoring end of the data monitoring module is connected with a data monitoring end of the intelligent control module, a spraying control end of the intelligent control module is connected with a spraying control end of the automatic spraying module, and an alarm end of the intelligent control module is connected with an alarm end of the concentration over-limit alarm module; the intelligent control module controls the automatic spraying module to work according to monitoring data monitored by the data monitoring module, and gives an alarm through the concentration over-limit alarm module, so that large-range dust falling is realized, and the dust suppression effect is ensured. According to the invention, the influence of wind speed and wind direction on dust raising in the coal storage yard is considered, the spray header is controlled in a centralized manner according to factors such as wind speed and wind direction, dust concentration and the like, precise dust fall is realized, and economical dust fall is realized on the basis of improving dust suppression and dust fall effects.

Owner:SHANDONG UNIV OF SCI & TECH

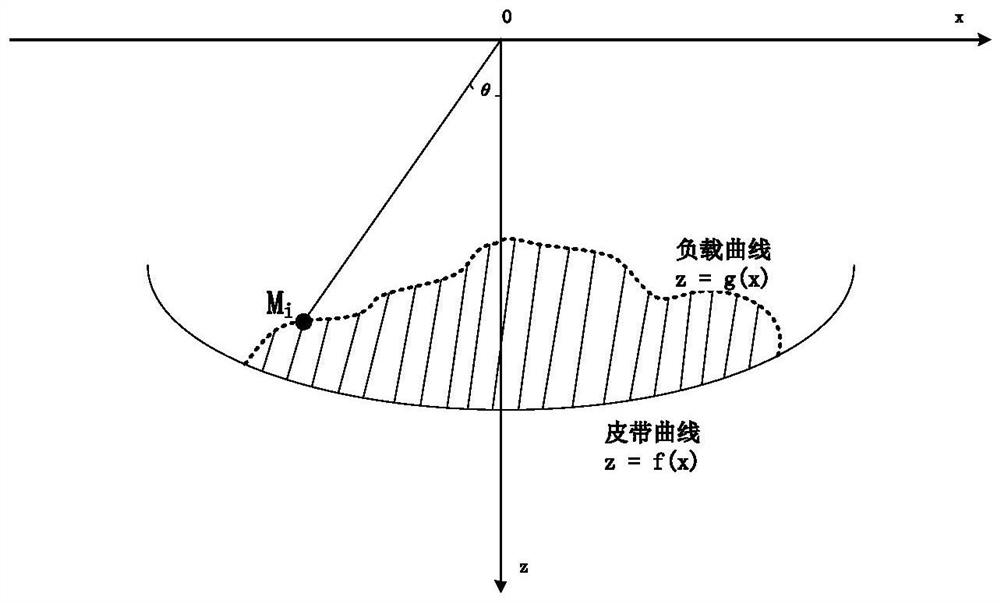

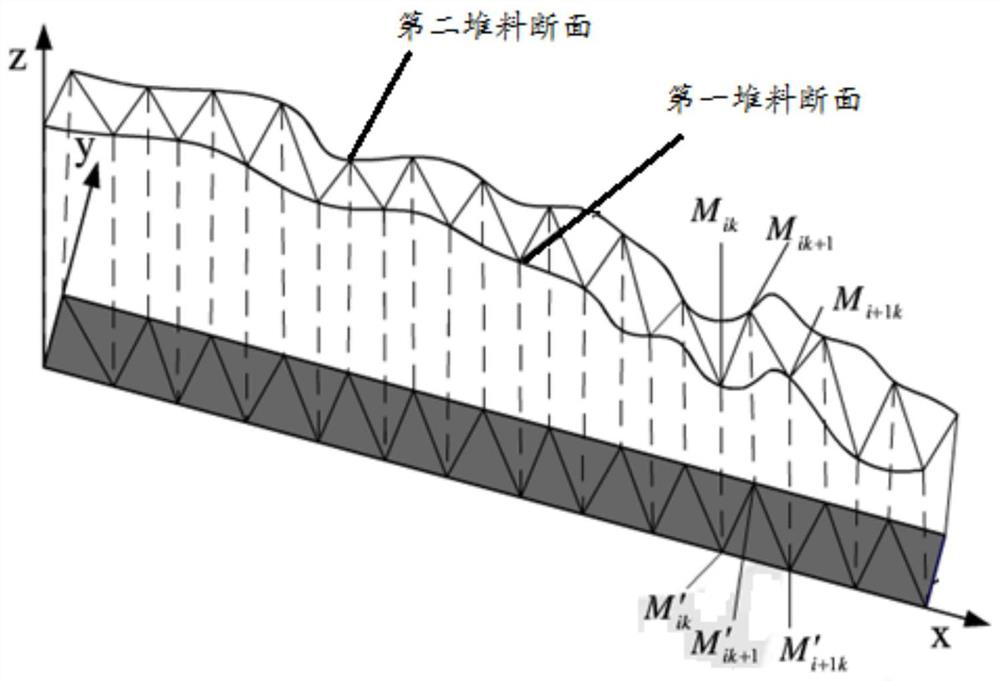

Belt material blockage detection method and system based on laser scanning

InactiveCN113135402AJudgment of blockingControl devices for conveyorsRectangular coordinatesLaser scanning

The invention discloses a belt material blockage detection method and system based on laser scanning. The method comprises the following steps of: S1, arranging a first laser scanning device and a second laser scanning device above a belt; S2, establishing a first rectangular plane coordinate system and a second rectangular plane coordinate system by taking the first laser scanning device and the second laser scanning device as original points respectively; S3, intercepting a first cross section and a second cross section of a material on the belt, calculating the volume Vin of the material passing through the first cross section within the time of delta t, and calculating the volume Vout of the material passing through the second cross section within the time of delta t; and S4, presetting an alarm threshold value Vc; and when Vin-Vout is larger than Vc, judging that material blockage occurs on the belt. The invention provides the belt material blockage detection method and system based on laser scanning, and aims to measure the volumes of coal piles entering and exiting from a chute in unit time and sample the distribution condition of the coal piles at the position of the belt so as to judge whether the chute is blocked or not.

Owner:国能长源汉川发电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com